Additional files:

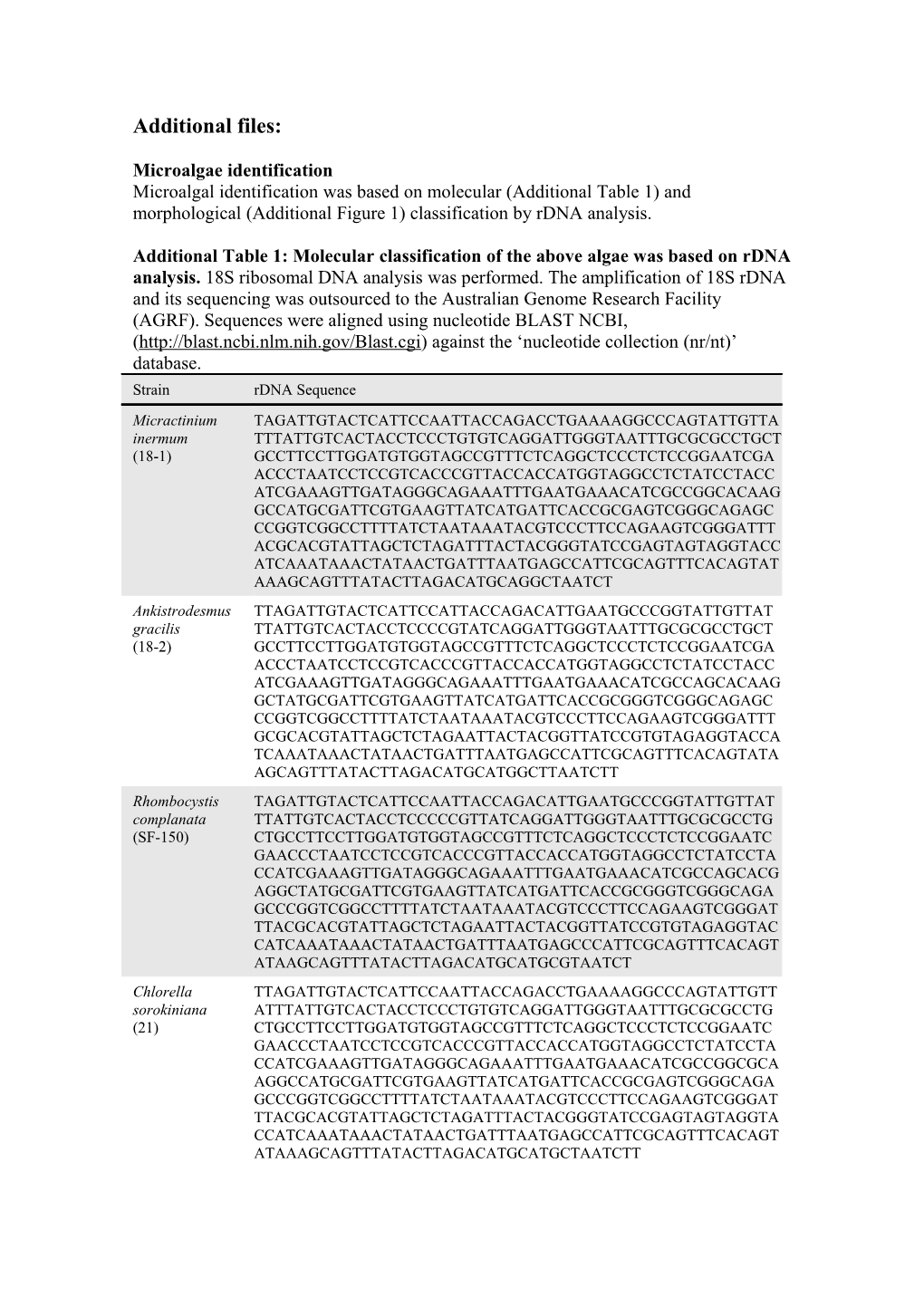

Microalgae identification Microalgal identification was based on molecular (Additional Table 1) and morphological (Additional Figure 1) classification by rDNA analysis.

Additional Table 1: Molecular classification of the above algae was based on rDNA analysis. 18S ribosomal DNA analysis was performed. The amplification of 18S rDNA and its sequencing was outsourced to the Australian Genome Research Facility (AGRF). Sequences were aligned using nucleotide BLAST NCBI, (http://blast.ncbi.nlm.nih.gov/Blast.cgi) against the ‘nucleotide collection (nr/nt)’ database. Strain rDNA Sequence Micractinium TAGATTGTACTCATTCCAATTACCAGACCTGAAAAGGCCCAGTATTGTTA inermum TTTATTGTCACTACCTCCCTGTGTCAGGATTGGGTAATTTGCGCGCCTGCT (18-1) GCCTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGAATCGA ACCCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATCCTACC ATCGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCGGCACAAG GCCATGCGATTCGTGAAGTTATCATGATTCACCGCGAGTCGGGCAGAGC CCGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGGGATTT ACGCACGTATTAGCTCTAGATTTACTACGGGTATCCGAGTAGTAGGTACC ATCAAATAAACTATAACTGATTTAATGAGCCATTCGCAGTTTCACAGTAT AAAGCAGTTTATACTTAGACATGCAGGCTAATCT Ankistrodesmus TTAGATTGTACTCATTCCATTACCAGACATTGAATGCCCGGTATTGTTAT gracilis TTATTGTCACTACCTCCCCGTATCAGGATTGGGTAATTTGCGCGCCTGCT (18-2) GCCTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGAATCGA ACCCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATCCTACC ATCGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCAGCACAAG GCTATGCGATTCGTGAAGTTATCATGATTCACCGCGGGTCGGGCAGAGC CCGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGGGATTT GCGCACGTATTAGCTCTAGAATTACTACGGTTATCCGTGTAGAGGTACCA TCAAATAAACTATAACTGATTTAATGAGCCATTCGCAGTTTCACAGTATA AGCAGTTTATACTTAGACATGCATGGCTTAATCTT Rhombocystis TAGATTGTACTCATTCCAATTACCAGACATTGAATGCCCGGTATTGTTAT complanata TTATTGTCACTACCTCCCCCGTTATCAGGATTGGGTAATTTGCGCGCCTG (SF-150) CTGCCTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGAATC GAACCCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATCCTA CCATCGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCAGCACG AGGCTATGCGATTCGTGAAGTTATCATGATTCACCGCGGGTCGGGCAGA GCCCGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGGGAT TTACGCACGTATTAGCTCTAGAATTACTACGGTTATCCGTGTAGAGGTAC CATCAAATAAACTATAACTGATTTAATGAGCCCATTCGCAGTTTCACAGT ATAAGCAGTTTATACTTAGACATGCATGCGTAATCT Chlorella TTAGATTGTACTCATTCCAATTACCAGACCTGAAAAGGCCCAGTATTGTT sorokiniana ATTTATTGTCACTACCTCCCTGTGTCAGGATTGGGTAATTTGCGCGCCTG (21) CTGCCTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGAATC GAACCCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATCCTA CCATCGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCGGCGCA AGGCCATGCGATTCGTGAAGTTATCATGATTCACCGCGAGTCGGGCAGA GCCCGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGGGAT TTACGCACGTATTAGCTCTAGATTTACTACGGGTATCCGAGTAGTAGGTA CCATCAAATAAACTATAACTGATTTAATGAGCCATTCGCAGTTTCACAGT ATAAAGCAGTTTATACTTAGACATGCATGCTAATCTT Monoraphidium TTAGATTGTACTCATTCCAATTACCAGACATTGAATGCCCGGTATTGTTA convolutum TTTATTGTCACTACCTCCCCGTATCAGGATTGGGTAATTTGCGCGCCTGC (9-FW) TGCCTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGAATCG AACCCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATCCTAC CATCGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCAGCACGA GGCTATGCGATTCGTGAAGTTATCATGATTCACCGCGGGTCGGGCAGAG CCCGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGGGATT TACGCACGTATTAGCTCTAGAATTACTACGGTTATCCGTGTAGAGGTACC ATCAAATAAACTATAACTGATTTAATGAGCCATTCGCAGTTTCACAGTAT AAGCAGTTTATACTTAGACATGCATGGCTTAATCT Chlorella GGTTTAGATTGTACTCATTCCAATTACCAGACCTGAAAAGGCCCAGTATT pyrenoidosa GTTATTTATTGTCACTACCTCCCTGTGTCAGGATTGGGTAATTTGCGCGC (22) CTGCTGCCTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGA ATCGAACCCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATC CTACCATCGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCGGC ACAAGGCCATGCGATTCGTGAAGTTATCATGATTCACCACGAGTCGGGC AGAGCCCGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGG GATTTACGCACGTATTAGCTCTAGATTTACTACGGGTATCCGAGTAGTAG GTACCATCAAATAAACTATAACTGATTTAATGAGCCATTCGCAGTTTCAC AGTATAAAGCAGTTTATACTTAGACATGCATGCTTAATCTT Micractinium TAGATTGTACTCATTCCAATTACCAGACCTGAAAAGGCCCAGTATTGTTA reisseri TTTATTGTCACTACCTCCCTGTGTCAGGATTGGGTAATTTGCGCGCCTGCT (13) GCCTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGAATCGA ACCCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATCCTACC ATCGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCGGCACAAG GCCATGCGATTCGTGAAGTTATCATGATTCACCGCGAGTCGGGCAGAGC CCGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGGGATTT ACGCACGTATTAGCTCTAGATTTACTACGGGTATCCGAGTAGTAGGTACC ATCAAATAAACTATAACTGATTTAATGAGCCATTCGCAGTTTCACAGTAT AAAGCAGTTTATACTTAGACATGCAGGCTAATCT Podohedriella AGATTGTACTCATTCCATTACCAGACACTAAGTGCCCGGTATTGTTATTT falcate ATTGTCACTACCTCCCCGTATCAGGATTGGGTAATTTGCGCGCCTGCTGC (4A-1) CTTCCTTGGATGTGGTAGCCGTTTCTCAGGCTCCCTCTCCGGAATCGAAC CCTAATCCTCCGTCACCCGTTACCACCATGGTAGGCCTCTATCCTACCAT CGAAAGTTGATAGGGCAGAAATTTGAATGAAACATCGCCGGCACTAGGC CATGCGATTCGTGAGAGTTATCATGATTCACCGCGGGTCGAGCAAAGCT CGGTCGGCCTTTTATCTAATAAATACGTCCCTTCCAGAAGTCGGGATTTA CGCATGTATTAGCTCTAGAATTACTACGGTTATCCATGTAGTAGGTACCA TCAAATAAACTATAACTGATTTAATGAGCCATTCGCAGTTTCACAGTATA TCAGTTTATACTTAGACATGCATGGCTTAATCT Additional Figure 1: Microscopic images of the microalgae strains screened. (a) M. inermum, (b) A. gracilis, (c) R. complanata, (d) C. sorokiniana, (e) M. convolutum, (f) C. pyrenoidosa, (g) M. reisseri and (h) P. falcate. Scale bar: 50 µm. Microalgal identification consisted of morphological investigation (Olympus BX42 and Nikon Ti-U, 200x and 400x magnification)

Additional Figure 2: Optimisation of gamma irradiation levels for nutrient media sterilisation. The gamma irradiation levels were tested in terms of their ability to sterilise LB medium inoculated with E.coli (inoculation density (OD600 = 0.002. The samples were treated with 0.1, 0.5 0.8, 1, 2, 3 and 4.5 kGy, with non-gamma treated samples providing the positive control and LB media the negative control. Post-gamma o irradiation, the flasks were incubated at 37 C for 8 days. The final OD600 were plotted and show that a dose of 2 kGy was sufficient to sterilise the inoculated medium. Additional Figure 3: Effect of gamma irradiation on vitamin B1 and B12 stability. The UV-visible spectra of vitamin B1 and vitamin B12 before (0kGy) and after (2kGy) gamma sterilization show significant spectral shifts indicative of radiation-induced damage. Consequently these vitamins could not be gamma sterilised effectively and so were filter sterilised prior to addition to gamma sterilised cultivation media (See materials and methods). Additional Table 2: t-test analysis shows that gamma sterilisation (2kGy) does not have a significant effect on the ability of nutrient screen 1 media to support Chlamydomonas reinhardtii growth.

Screen 1 media N Mean Standard Standard Error Treatment (OD750) Deviation Mean Gamma Sterilised 120 0.315 0.240 0.022

Non-gamma 120 0.324 0.270 0.025 Sterilised

Difference = µ (Gamma Sterilised) - μ (Non-Gamma Sterilised) Estimate for difference: -0.0091 95% CI for difference: (-0.0741, 0.0559) T-Test of difference = 0 (vs not =): T-Value = - 0.28, P-Value = 0.783 DF = 238 Both use Pooled StDev = 0.2557 Additional Table 3: Average macronutrient concentrations used in common media (see materials and methods).

)

1

- )

1 L ) - . 1

-

) ) g L

) 1 1 . ( L - -

) 1 )

. -

g 1 ) 1 ) - - ) L ( L 1 g 1 - 1 . . L - ( - . L m L

g g . . L L g ( m L ( . u . g g . ( i m

g ( u ( g

g

i ( d ( u (

i e

m

d t m m m m d e u m n u m u m i u m u e e

i i i i i u m u d u i r d d i i d m d N t e

d e e 1 e e d u d 3 s e 1 e m e N u M M M d M

m c G l a m m

l

1

c n o o n B í - o i

o o P t N l B M 1 s c

R d s 4 A u S 1 i ) o n e d l r l i r y T i / e e h H f G ) M i r i B p g o t f D B ( i d M S J

o o d e m B o ( u

l M e a M u l V a

V e

e g g a a r r e e v v A A l C 4 0.40 0.50 ------0.45 8.4 H N 3 O

N - - - 0.25 0.50 0.80 - 0.75 - 1.50 0.75 0.75 8.8 a N 4 O P 2 0.056 0.323 0.035 0.03 0.028 - 1.25 0.325 0.236 - - 0.285 2.1 H K O 2 H 2 .

2 0.05 0.02 - 0.025 0.034 0.04 - 0.025 0.034 0.036 0.036 0.033 0.22 l C a C O 2 H 7 · 4 0.1 0.02 0.25 0.03 0.06 0.05 0.004 0.075 0.04 0.04 0.075 0.078 0.316 O S g M Additional Table 4: Individual Screen 2 media conditions. Nutrient levels are coded as -1, 0 or 1, where 0 indicates the average value identified in Table 3, and -1 and +1 indicate the lower and higher concentrations tested for a given element (see materials and methods). CP indicates the centre point value (i.e. "0" settings for all ten nutrients varied in screen 2). 20 replicates of the centre point conditions were included in Screen 2 to provide a robust internal standard control. The centre point value corresponds to the basal nutrient concentration obtained from Screen 1).

Column1 1 2 3 4 5 6 7 8 9 10 Media No Ca Mg B Fe Cu Mn Zn Se V Si 1 0 0 1 0 1 0 -1 0 -1 0 2 0 -1 -1 0 0 0 1 1 0 0 3 -1 0 0 0 0 0 0 -1 -1 -1 4 0 0 1 -1 -1 0 0 0 0 -1 5 1 0 -1 0 0 -1 0 0 1 0 6 -1 0 0 -1 0 0 1 1 0 0 7 0 -1 0 -1 0 1 0 0 -1 0 8 0 -1 0 0 0 1 -1 0 0 1 9 0 -1 0 0 0 -1 1 0 0 -1 10 1 1 0 0 1 0 0 0 0 1 11 1 0 0 1 0 0 1 -1 0 0 12 0 0 0 -1 -1 -1 0 1 0 0 13 0 0 0 1 -1 -1 0 -1 0 0 14 0 0 0 1 1 -1 0 1 0 0 15 CP 0 0 0 0 0 0 0 0 0 0 16 -1 0 -1 0 0 -1 0 0 1 0 17 0 -1 1 0 0 0 -1 -1 0 0 18 0 1 1 0 0 0 1 1 0 0 19 0 0 0 1 1 -1 0 -1 0 0 20 -1 0 0 1 0 0 1 -1 0 0 21 0 0 -1 0 1 0 -1 0 -1 0 22 0 -1 0 0 0 1 -1 0 0 -1 23 0 0 -1 0 1 0 1 0 -1 0 24 -1 0 0 1 0 0 -1 -1 0 0 25 0 0 1 0 -1 0 -1 0 1 0 26 -1 0 0 0 0 0 0 -1 -1 1 27 0 0 1 0 1 0 1 0 1 0 28 0 0 -1 1 -1 0 0 0 0 -1 29 0 1 0 1 0 1 0 0 1 0 30 0 0 1 -1 -1 0 0 0 0 1 31 0 0 1 -1 1 0 0 0 0 -1 32 -1 -1 0 0 1 0 0 0 0 -1 33 -1 0 0 0 0 0 0 -1 1 1 34 0 -1 1 0 0 0 1 -1 0 0 35 0 -1 -1 0 0 0 -1 1 0 0 36 CP 0 0 0 0 0 0 0 0 0 0 37 0 -1 -1 0 0 0 -1 -1 0 0 38 -1 0 -1 0 0 1 0 0 1 0 39 1 0 0 -1 0 0 -1 -1 0 0 40 0 0 -1 0 -1 0 1 0 -1 0 41 -1 0 -1 0 0 1 0 0 -1 0 42 0 0 -1 1 1 0 0 0 0 -1 43 0 1 -1 0 0 0 1 1 0 0 44 1 0 1 0 0 1 0 0 1 0 45 1 0 0 0 0 0 0 -1 1 -1 46 -1 0 0 -1 0 0 1 -1 0 0 47 0 0 0 -1 1 1 0 1 0 0 48 0 -1 0 1 0 -1 0 0 1 0 49 0 0 1 0 1 0 1 0 -1 0 50 CP 0 0 0 0 0 0 0 0 0 0 51 CP 0 0 0 0 0 0 0 0 0 0 52 -1 1 0 0 -1 0 0 0 0 -1 53 CP 0 0 0 0 0 0 0 0 0 0 54 0 0 -1 0 -1 0 1 0 1 0 55 0 1 0 0 0 -1 1 0 0 1 56 0 1 0 0 0 -1 -1 0 0 1 Column1 1 2 3 4 5 6 7 8 9 10 Media No Ca Mg B Fe Cu Mn Zn Se V Si 57 0 0 -1 -1 1 0 0 0 0 -1 58 0 1 0 -1 0 -1 0 0 -1 0 59 0 1 0 1 0 -1 0 0 -1 0 60 -1 0 0 0 0 0 0 1 -1 1 61 -1 0 0 0 0 0 0 1 1 -1 62 0 -1 0 1 0 1 0 0 1 0 63 0 -1 0 -1 0 1 0 0 1 0 64 0 1 1 0 0 0 1 -1 0 0 65 CP 0 0 0 0 0 0 0 0 0 0 66 0 1 -1 0 0 0 -1 1 0 0 67 -1 1 0 0 1 0 0 0 0 1 68 CP 0 0 0 0 0 0 0 0 0 0 69 1 -1 0 0 -1 0 0 0 0 -1 70 0 0 0 -1 -1 1 0 1 0 0 71 CP 0 0 0 0 0 0 0 0 0 0 72 1 0 0 -1 0 0 -1 1 0 0 73 0 0 1 0 -1 0 1 0 -1 0 74 CP 0 0 0 0 0 0 0 0 0 0 75 1 0 0 0 0 0 0 -1 -1 -1 76 0 0 1 1 -1 0 0 0 0 -1 77 0 -1 0 0 0 -1 -1 0 0 -1 78 -1 0 0 1 0 0 1 1 0 0 79 1 0 0 1 0 0 1 1 0 0 80 0 0 0 1 -1 -1 0 1 0 0 81 1 1 0 0 -1 0 0 0 0 1 82 0 0 0 -1 -1 1 0 -1 0 0 83 0 1 0 1 0 1 0 0 -1 0 84 0 -1 1 0 0 0 1 1 0 0 85 CP 0 0 0 0 0 0 0 0 0 0 86 0 0 0 -1 1 -1 0 -1 0 0 87 -1 0 0 0 0 0 0 -1 1 -1 88 1 0 0 0 0 0 0 1 1 1 89 1 -1 0 0 1 0 0 0 0 -1 90 1 0 0 0 0 0 0 1 -1 1 91 0 0 0 1 -1 1 0 -1 0 0 92 0 1 0 0 0 -1 -1 0 0 -1 93 0 1 -1 0 0 0 -1 -1 0 0 94 -1 0 1 0 0 -1 0 0 -1 0 95 0 1 0 -1 0 1 0 0 -1 0 96 1 0 1 0 0 -1 0 0 -1 0 97 0 -1 0 0 0 1 1 0 0 -1 98 -1 -1 0 0 -1 0 0 0 0 1 99 0 0 1 1 1 0 0 0 0 -1 100 -1 0 -1 0 0 -1 0 0 -1 0 101 0 1 1 0 0 0 -1 1 0 0 102 1 0 0 -1 0 0 1 -1 0 0 103 0 1 0 0 0 1 -1 0 0 1 104 0 0 -1 0 -1 0 -1 0 1 0 105 1 0 0 0 0 0 0 -1 1 1 106 1 0 0 1 0 0 -1 1 0 0 107 CP 0 0 0 0 0 0 0 0 0 0 108 0 0 -1 0 -1 0 -1 0 -1 0 109 -1 -1 0 0 1 0 0 0 0 1 110 0 -1 -1 0 0 0 1 -1 0 0 111 1 0 -1 0 0 1 0 0 1 0 112 1 0 0 0 0 0 0 1 1 -1 Column1 1 2 3 4 5 6 7 8 9 10 Media No Ca Mg B Fe Cu Mn Zn Se V Si 113 1 1 0 0 -1 0 0 0 0 -1 114 1 0 0 1 0 0 -1 -1 0 0 115 -1 0 0 1 0 0 -1 1 0 0 116 -1 0 1 0 0 -1 0 0 1 0 117 -1 0 1 0 0 1 0 0 1 0 118 0 1 0 -1 0 1 0 0 1 0 119 0 0 -1 -1 1 0 0 0 0 1 120 0 1 0 0 0 1 1 0 0 -1 121 0 0 0 1 1 1 0 -1 0 0 122 0 0 0 -1 1 -1 0 1 0 0 123 CP 0 0 0 0 0 0 0 0 0 0 124 -1 0 1 0 0 1 0 0 -1 0 125 0 -1 1 0 0 0 -1 1 0 0 126 1 0 0 0 0 0 0 1 -1 -1 127 0 0 -1 0 1 0 -1 0 1 0 128 0 0 -1 0 1 0 1 0 1 0 129 CP 0 0 0 0 0 0 0 0 0 0 130 0 0 0 -1 1 1 0 -1 0 0 131 1 -1 0 0 -1 0 0 0 0 1 132 0 0 1 0 -1 0 1 0 1 0 133 0 0 0 1 1 1 0 1 0 0 134 1 0 1 0 0 -1 0 0 1 0 135 -1 0 0 0 0 0 0 1 -1 -1 136 -1 1 0 0 -1 0 0 0 0 1 137 CP 0 0 0 0 0 0 0 0 0 0 138 0 -1 0 0 0 1 1 0 0 1 139 CP 0 0 0 0 0 0 0 0 0 0 140 1 0 0 -1 0 0 1 1 0 0 141 0 -1 0 1 0 1 0 0 -1 0 142 1 0 1 0 0 1 0 0 -1 0 143 0 1 1 0 0 0 -1 -1 0 0 144 0 -1 0 0 0 -1 1 0 0 1 145 1 -1 0 0 1 0 0 0 0 1 146 -1 1 0 0 1 0 0 0 0 -1 147 0 0 1 0 1 0 -1 0 1 0 148 0 1 0 1 0 -1 0 0 1 0 149 CP 0 0 0 0 0 0 0 0 0 0 150 0 0 1 1 1 0 0 0 0 1 151 -1 -1 0 0 -1 0 0 0 0 -1 152 -1 0 0 -1 0 0 -1 1 0 0 153 0 0 0 1 -1 1 0 1 0 0 154 CP 0 0 0 0 0 0 0 0 0 0 155 1 1 0 0 1 0 0 0 0 -1 156 CP 0 0 0 0 0 0 0 0 0 0 157 0 1 0 0 0 1 -1 0 0 -1 158 0 0 1 -1 1 0 0 0 0 1 159 0 -1 0 1 0 -1 0 0 -1 0 160 0 0 -1 -1 -1 0 0 0 0 -1 161 0 0 0 -1 -1 -1 0 -1 0 0 162 0 -1 0 -1 0 -1 0 0 1 0 163 0 -1 0 -1 0 -1 0 0 -1 0 164 0 0 -1 -1 -1 0 0 0 0 1 165 0 0 -1 1 -1 0 0 0 0 1 166 -1 0 0 -1 0 0 -1 -1 0 0 167 0 1 0 0 0 -1 1 0 0 -1 168 0 1 0 0 0 1 1 0 0 1 Column1 1 2 3 4 5 6 7 8 9 10 Media No Ca Mg B Fe Cu Mn Zn Se V Si 169 0 0 1 0 -1 0 -1 0 -1 0 170 -1 0 0 0 0 0 0 1 1 1 171 0 -1 0 0 0 -1 -1 0 0 1 172 1 0 0 0 0 0 0 -1 -1 1 173 CP 0 0 0 0 0 0 0 0 0 0 174 0 1 0 -1 0 -1 0 0 1 0 175 0 0 1 1 -1 0 0 0 0 1 176 0 0 -1 1 1 0 0 0 0 1 177 1 0 -1 0 0 1 0 0 -1 0 178 1 0 -1 0 0 -1 0 0 -1 0 179 0 1 -1 0 0 0 1 -1 0 0 180 CP 0 0 0 0 0 0 0 0 0 0 Notes on statistical variability Maximising the breadth of the multidimensional screening space is central to the screen design. For routine analysis it is therefore designed to operate using single trial wells as opposed to duplicates or triplicates, with the 20 CP controls providing a robust internal control for inherent variability and the estimation of error ranges. Statistical reproducibility however requires evaluation of operational errors both in terms of well- to-well variability (repeatability test) and run-to-run variability (reproducibility test).

The statistical evaluation of these errors was conducted using eight microalgae strains for Screen 1 and three microalgae strains for Screen 2. Each species/trial combination was analysed in triplicate. Well-to-well repeatability was evaluated using the triplicate values of the highest growth rate values obtained for a given algae strain. Run-to-run reproducibility was evaluated using the highest growth rate values obtained for the triplicate TAP controls included in Screen 1.

The Multivariate Item Analysis Cronbach’s Alpha value was used to determine the degree of internal reliability and consistency of the triplicate data in these repeatability evaluations. The Cronbach’s Alpha value was calculated using Additional Equation 1

Additional Equation 1:

2 th 2 where Si = growth rate variance of the i item, ST = growth rate variance of the total scores, T = the total growth rate scores and k, the number of replicates or items in the analysis.

The Omitted Items Cronbach’s Alpha analysis is described in Additional Equation 2, and determines the level of correlation of the data between each of the three replicates by removing one of the replicate data points at a time. Replicate data with high correlativity will not show a significance difference in the Omitted Items Cronbach’s Alpha value.

Additional Equation 2

2 th 2 Si = growth rate variance of the i item, ST = growth rate variance of the total scores, 2 th STj = growth rate variance of the total scores calculated after omitting the j item, T = the total growth rate scores and k, the number of replicates or items in the analysis.

Cronbach’s Alpha values lie between 0 and 1 and the classification of the internal consistency of the data is as listed below: > 0.9: Excellent internal consistency 0.8-0.9: Good internal consistency 0.7-0.8: Acceptable internal consistency 0.6-0.7: Questionable internal consistency 0.5-0.6: Poor internal consistency < 0.5: Unacceptable internal consistency

The inter-replicate relationship trend and correlativity is graphically shown in the Matrix Plots in Additional Figure 5 (Screen 1) and Additional Figure 6 (Screen 2). Additional Figure 4 - Cronbach Alpha analysis of Screen 1.2. Each of the 8 strains were subjected to 60 Screen 1 nutrient conditions in triplicate (replicates = R1, R2 and R3). The individual highest growth rate in a specific cultivation media is represented by a red circle. The x- and y-axes display the highest growth rate, µ (h-1) of replicates 1, 2 and 3 and these are plotted in the following combinations: R1 vs. R2; R1 vs. R3; R2 vs. R3. In an ideal condition (i.e. all the replicates values are similar), the correlation line is a straight line with a slope value 1.0 (a perfect straight line). Data correlation line (blue line), showed positive correlation for all of the strains indicating high data consistency. Similar data trends between the replicates indicate excellent internal consistency (Cronbach alpha value >0.9). Additional Figure 5 - Cronbach analysis of Screen 2. Each of the 3 strains were subjected to 180 Screen 2 nutrient conditions in triplicate (replicates = R1, R2 and R3). The individual highest growth rate in a specific cultivation media is represented by a red circle. The x- and y-axes display the highest growth rate, µ (h-1) of replicates 1, 2 and 3 and these are plotted in the following combinations: R1 vs. R2; R1 vs. R3; R2 vs. R3. Data correlation line (blue line), showed positive correlation for all of the strains indicating high data consistency. In an ideal condition (all the replicates values are similar), the correlation line is a straight line with a slope value 1.0 (a perfect straight line). Similar data trends between the replicates indicate excellent internal consistency (Cronbach alpha value >0.9). Additional Figure 6: Analysis of the run-to-run reproducibility of the highest growth rate values obtained in screen 2. The average highest growth rate for each of the microalgae strains in the TAP control medium is represented as a bar chart (data from 9 internal replicates; triplicates of 3 samples). Exp1 and Exp2 refer to two independent Screen 1 trials. The average highest growth rate values obtained for each strain are shown above each corresponding bar chart. SD and Difference (%) denoted in the white boxes at the bottom of the bar charts represent the internal standard deviation and the inter-experiment percentage difference for each of the specific microalgae strains. The percentage differences ranged between 2.1 and 16.7%. Based on the average data of all of the strains, the inter-experiment percentage difference (reproducibility error was 8.1% ± 6.1 % (mean ± standard deviation). References: