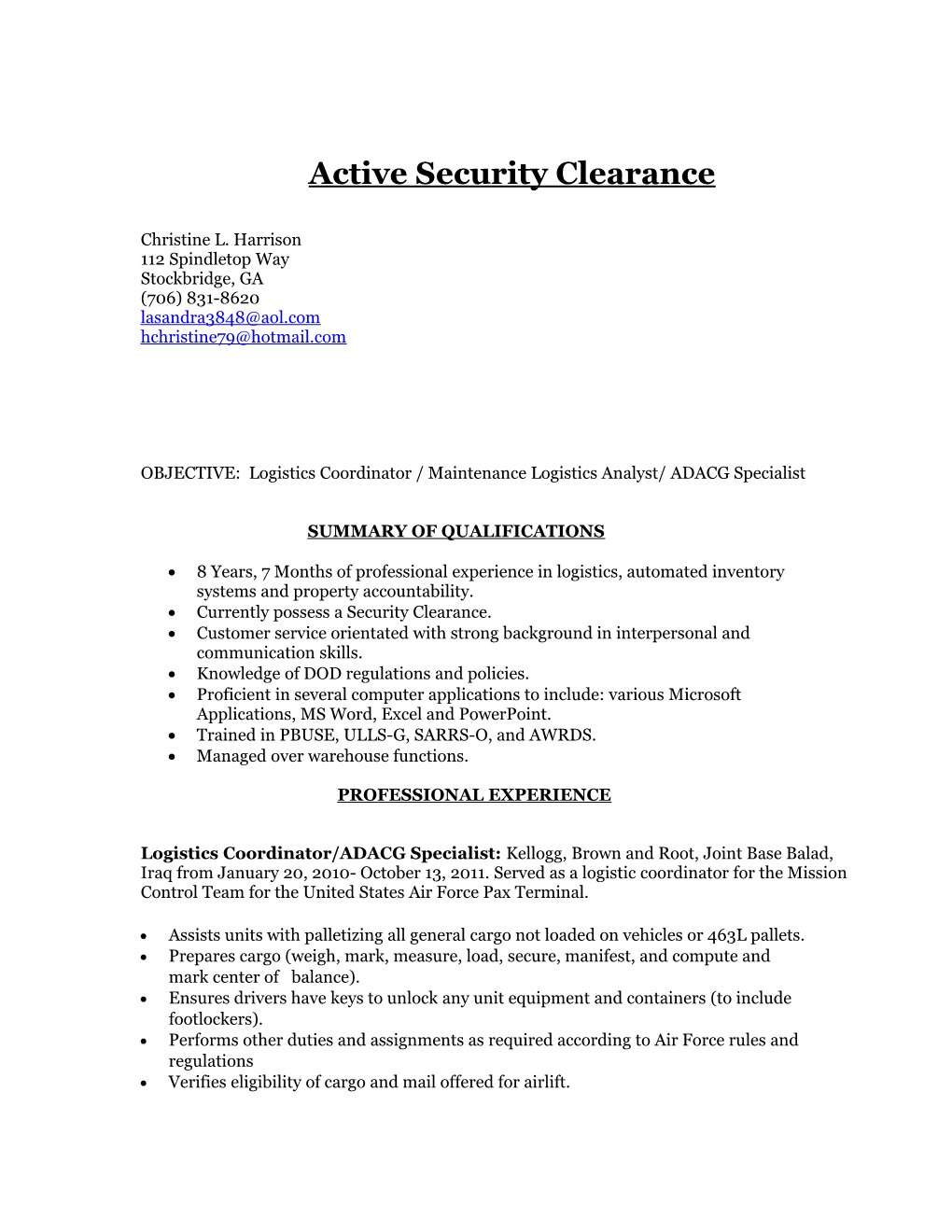

Active Security Clearance

Christine L. Harrison 112 Spindletop Way Stockbridge, GA (706) 831-8620 [email protected] [email protected]

OBJECTIVE: Logistics Coordinator / Maintenance Logistics Analyst/ ADACG Specialist

SUMMARY OF QUALIFICATIONS

8 Years, 7 Months of professional experience in logistics, automated inventory systems and property accountability. Currently possess a Security Clearance. Customer service orientated with strong background in interpersonal and communication skills. Knowledge of DOD regulations and policies. Proficient in several computer applications to include: various Microsoft Applications, MS Word, Excel and PowerPoint. Trained in PBUSE, ULLS-G, SARRS-O, and AWRDS. Managed over warehouse functions.

PROFESSIONAL EXPERIENCE

Logistics Coordinator/ADACG Specialist: Kellogg, Brown and Root, Joint Base Balad, Iraq from January 20, 2010- October 13, 2011. Served as a logistic coordinator for the Mission Control Team for the United States Air Force Pax Terminal.

Assists units with palletizing all general cargo not loaded on vehicles or 463L pallets. Prepares cargo (weigh, mark, measure, load, secure, manifest, and compute and mark center of balance). Ensures drivers have keys to unlock any unit equipment and containers (to include footlockers). Performs other duties and assignments as required according to Air Force rules and regulations Verifies eligibility of cargo and mail offered for airlift. Ensures all cargo documentation, packaging, RFID (Router Frequency Identifier Device), labeling and marking requirements, and all border clearance requirements have been met. Determines and implements necessary safety and security precautions for handling and storing dangerous materials, special cargoes, mail, and baggage. Prepares, completes, and maintains air movement’s records, documents, and reports. Working knowledge of USAF C-17, c-5, c-130, c-25, B-747, and B-737 aircraft , equipment, and systems.. Knowledge of ASP and SQL database. Proficient in U.S. Air Force programs: GATES, RFID-TV, GTN, and ITV. Validates transportation requirements and coordinates transportation support, and inbound clearance for moving units, personnel, and cargo Ensures all terminating cargo is distributed to SSA (Supply Support Activity) and MCY (Multi Class Yards). Knowledge of ALMSS (Automated Logistics Management Support System) and SBSS (Air Force Standard Base Supply System-Accounting.

Maintenance Logistics Analyst: U.S. Army, (92A) Automated Logistic Specialist, Fort Lewis, WA from April 10, 2007 – September 03, 2008. Served as an Item Manager for 202 BSB, 4th Brigade, and 2nd Infantry Division assisting the Corps. Researches, reviews and collects data pertinent to maintenance; communicates using web based programs to IMMC POCs, LIW and DOL reps. Attends weekly Major Subordinate Command maintenance meetings to directly resolve logistical issues with customer units. Assists customer units in ULLS-G, SAMS-1, SAMS-2 ensuring accurate information is provided to the Corps. Collects, compiles, processes and monitors Corps Army Materiel Status Systems AMSS report.

Lead Supply Technician: U.S. Army, (92A) Fort Lewis, WA from August 2004- April 2007. Served as the supervisor for the 202 BSB Stryker Brigade Central Receiving Point maintaining automated records of in-bound and out going equipment and supplies valued in excess of $30M annually. Received, stored, issued, shipped and tracked equipment by various means.

Maintained files for tracking and accountability purposes. Prepared supply documents and interacted with customers daily. Ensured accuracy of in-coming shipments to prevent loss by mishap, theft or damage Generated reports and updates to the chain of command. Input data into computer database for accountability. PBUSE trained. Supervised and trained others within the Central Receiving Point. Regarded by supervisors and colleagues as a subject matter expert who can be relied upon no matter how the complex challenge. Automated Logistical Supply Specialist (U.S. Army): Served at Fort Lewis, WA.

From July 27, 2004 – July 27, 2012. (92A) Served as a logistical specialist and supervisor ensuring proper ordering, receipt and issue of various items at the SSA (Supply Support Activity). Used ULLS-G, SARRS, and other computer applications to conduct business daily.

Manager over warehouse function, record keeping, Fed log CD-Rom Prescribed Load Lists (PLL), The Army Maintenance Management System (TAMMS), Unit Level Logistics System Ground (ULLS-G) Standard Army Retail Supply System-Objective (SARSS-O), Material Release Order Control (MROC), Care and Preservation of supplies and equipment Knowledge of the Federal Acquisition Regulation and FED LOG. Prepared documents Army Regulations 735-5(Property Accountability), Department of the Army Pamphlet 710-2-1(Unit Supply System), Department of the Army Pamphlet 710-2-2 (Supply Support Activity Supply System), and Army Regulations 190- 11(Ammunition and Explosives) Subsistence supply in support of the Army Field Feeding System Dispatch operations and track scheduled services using SAMS-E Transfer equipment maintenance data by diskette Issued, stored and received ammunition at ACP and AHA

EDUCATION AND TRAINING

Property Book Unit Supply – Enhanced (PBUSE)- Ft. Lewis, WA Ammunition Handlers course (AMMO 62)- Ft. Lewis, WA Hazardous Material Handlers Course- Ft. Lewis, WA ULLS-S4 Course- Ft. Lewis, WA SARRS-O Course- Ft. Lewis, WA Maintenance Management Systems Course- Ft. Lewis, WA Automated Logistical Supply Specialist Course-Ft. Lee, VA