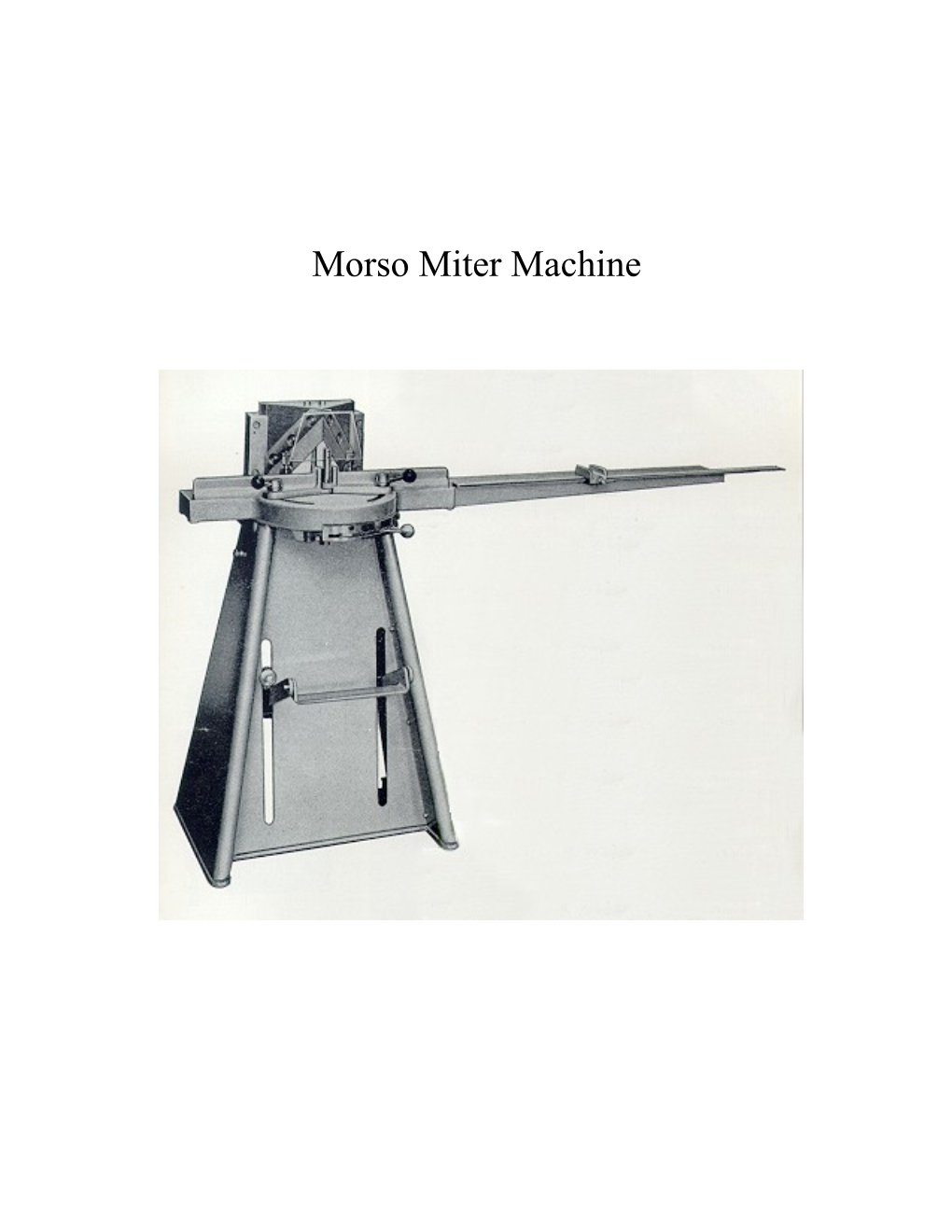

Morso Miter Machine

Morso Miter Machine

MORSØ-F Foot-operated mitering machine

The MORSØ F leaves the cut surface of the wood perfectly smooth and accurate– requiring no further preparation before joining. The horizontal movement of the knife block is stepwise adjustable. The sliding longitudinal stop and measuring scale ensure accurate repeat cuts. The special lever system of the machine makes it easy to operate. Twin return springs automatically bring the knives back to their starting position. This machine can cut tenon, mortise joints and a wide variety of angled cuts.

Features:

Sliding longitudinal stop Measuring scale Adjustable fences (45° - 90°) Adjustable rebate supports Double mitre cuts up to 45° Single mitre cuts up to 90°

Safety Rules

The miter machine is the only machine in our shop that doe not use electricity to power it. This tool is powered by good old fashioned "people power". Even though there is no electric motor attached to this machine it still has the potential of doing serious physical damage to the user. So, for your own safety follow the following rules and guidelines.

1. Always wear safety glasses or goggles. 2. Hold your material securely against the fence. 3. Make sure that your fingers are not under the knife blades before stepping on the foot pedal. 4. Insure all loose garments, jewellery, long hair are restrained and not in danger of getting caught in any moving parts. 5. Make sure your footing is secure when stepping on the foot pedal. 6. Keep the area around the tool clean and orderly. 7. Do not attempt to cut any metal with this machine. 8. Be sure that the cutting blades are properly sharpened. 9. Inform the technician if the tool seems to be malfunctioning or is damaged. 10. Learn the machine's applications and limitations, as well as the specific potential hazards peculiar to this machine. Follow available operating instructions and safety rules carefully. Operation: Wood Framing Moulding

The knife block (fig. 1) is drawn backwards in proportion to the width of the moulding to be cut. The moulding is placed in the machine. When cutting moulding with a rabbet, the rabbet holders (fig.1) are pushed into the rabbet, so that they just touch the moulding without raising it from the bottom knives. The knives (fig. 1) are now pressed home by means of the foot pedal (fig. 2). When the knives have been brought back to their starting position by springs, the knife block is drawn a little forward using the knife block adjuster (fig.1), the moulding is given another cut, and this procedure is continued until the moulding has been cut in two.

knife block

rabbet holders

knives

knife block adjuster

Fig.1 The last cut should always be a small one. Even in the case of small framing moulding, which might cut through in one cut, the moulding should be given a small final cut in order to obtain a fine result.

Vertical stop device

Foot pedal

Fig. 2 The vertical stop device (fig. 2) at the left-hand slit of the front plate of the stand is used to stop the vertical movement of the knives at the height suitable for the size of the moulding to be cut. The vertical stop should also be used to lock the knives in the lower position, when the machine is not used. The measuring scale engraved in the table is used in the following way: If for instance, a moulding 35 inches long is desired, the point of intersection between the end of the moulding and the front edge of the moulding must hit the oblique line marked 35. The stop rail (fig. 3) is drawn towards the end of the moulding and locked (fig. 3) in position.

(1) knife block

(1) knife block

Fig. 3

Operation: Stretcher Material

The operation is the same for stretcher material as it is for wooden frame moulding. The only difference being is that the 1" x 2" pine, which is what we use, is place against the fence securely with the long leg in a vertical position. This means that the width that we are actually cutting is 3/4" and the depth is 1-3/4". If we are not too concerned with the finish on the cut we can move the cutting head forward all the way and cut through the material in one stroke. The edge will be left slightly ragged but the canvas we stretch over the frame will hide a multitude of sin.

This manual has been extracted in part from the Morso Miter Frame leaflet.