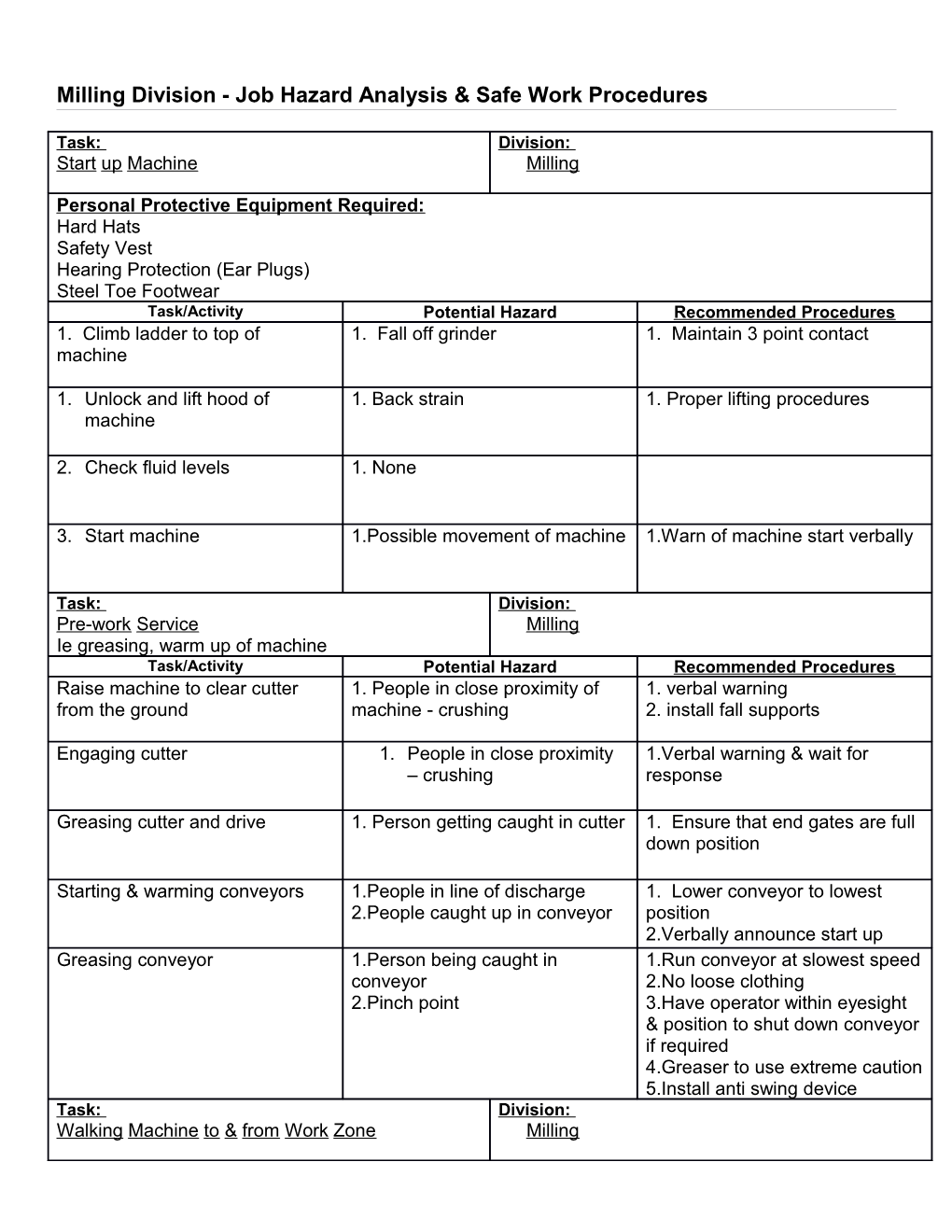

Milling Division - Job Hazard Analysis & Safe Work Procedures

Task: Division: Start up Machine Milling

Personal Protective Equipment Required: Hard Hats Safety Vest Hearing Protection (Ear Plugs) Steel Toe Footwear Task/Activity Potential Hazard Recommended Procedures 1. Climb ladder to top of 1. Fall off grinder 1. Maintain 3 point contact machine

1. Unlock and lift hood of 1. Back strain 1. Proper lifting procedures machine

2. Check fluid levels 1. None

3. Start machine 1.Possible movement of machine 1.Warn of machine start verbally

Task: Division: Pre-work Service Milling Ie greasing, warm up of machine Task/Activity Potential Hazard Recommended Procedures Raise machine to clear cutter 1. People in close proximity of 1. verbal warning from the ground machine - crushing 2. install fall supports

Engaging cutter 1. People in close proximity 1.Verbal warning & wait for – crushing response

Greasing cutter and drive 1. Person getting caught in cutter 1. Ensure that end gates are full down position

Starting & warming conveyors 1.People in line of discharge 1. Lower conveyor to lowest 2.People caught up in conveyor position 2.Verbally announce start up Greasing conveyor 1.Person being caught in 1.Run conveyor at slowest speed conveyor 2.No loose clothing 2.Pinch point 3.Have operator within eyesight & position to shut down conveyor if required 4.Greaser to use extreme caution 5.Install anti swing device Task: Division: Walking Machine to & from Work Zone Milling Task/Activity Potential Hazard Recommended Procedures 1. Start moving machine 1. Machine coming into contact 1. Operator does visual with objects or people inspection from both sides of operator station. 2. Ground man positions himself with clear view of front & rear of machine 3.Operator makes visual contact with ground man

4.Ground man gives operator OK to move

2. Walking machine 1. Machine running over objects 1. Visual inspection of area or people in blind spots of operator a) forward 1.Ground man position front of machine in eye sight of operator 2.Have TCPs’ where appropriate b) backward 1.Ground man position rear of machine in eye sight of operator 2.Have TCPs’ where appropriate Task: Division: Putting Machine into Operation Milling

Task/Activity Potential Hazard Recommended Procedures 1. Positioning machine for work 1. Possible interference with 1. Operator & ground man make other personnel and equipment visual contact with all personnel in work zone in proximity of machine and physically indicate intention 2. Lowering machine into cut 1. Possibility of machine lurching 1. Operator to apply brake and backward without control have hand ready on emergency stop shut down switch. 2. Ground man to ensure no one is immediately in the back of machine 2.Dust 1.Operator to ensure water system is on 2. Consult the ECP1 3.Backing in trucks 1.Running over property or 1.Operator and ground man to personnel ensure immediate area behind truck is clear of people & objects 2.Back up alarm must be working

4.Turning on conveyors 1. Flying debris from conveyor 1.Operator to make sure no one is standing under or close to the conveyor

1 Added point Task: Division: Working in Traffic Milling

Task/Activity Potential Hazard Recommended Procedures 1. Setting up work zone 1. Possible traffic confusion 1. Always have proper signage, delineation & controls 2.Milling in close proximity of 1.Restricted space for ground 1.Have TCP monitor traffic traffic man setting depth of machine 2.Do adjustments facing traffic 2.Contact of cars with machine 1.Ensure delineators are set sensors clear of sensors

2.Position TCP at rear corner of machine

3.Checking cut 1.Possible contact with traffic 1.Check cut back of machine standing inside cut

4.Bringing trucks to and from 1.Traffic following trucks into 1.Trucks to have 4 ways on when machine closure entering work zone

2.Traffic unaware of truck 2.TCPs’ to accommodate enter & entering travel lane exit of trucks

Task: Division: Backing up Machine Milling

Task/Activity Potential Hazard Recommended Procedures 1. Back up procedure 1. Large blind spot for operator 1. Ground man to cover blind immediately behind machine. spot for operator 2.Possible contact with objects or 2. Both operator and ground personnel during back up man to follow strict back up procedure 2. Back up alarms must be functioning

Task: Division: Backing up Trucks Milling

Task/Activity Potential Hazard Recommended Procedures 1. Backing up trucks 1. Running over property or 1. Truck driver to have eye personnel contact with all personnel working around work area 2. Trucks not to move until piles are shovelled and personnel signals trucker to move 3. have conversation with trucker to make sure rules are understood 4. make sure that back up alarms and lights are in working order Task: Division: Watering machine - Stationary Milling

Task/Activity Potential Hazard Recommended Procedures 1. Truck pulling into closure 1. Traffic following water truck 1. Water truck stop & sound beside the stationary machine into the closure. horn to alert TCP before proceeding into closure. Ensure warning lights are on 2.Workers unaware of water 1.Sound horn again once in truck closure to alert crew & equipment 2. Watering machine 1. Restricted space between 1. Water truck driver to stay back machine & water truck of machine until operator has stopped machine, applied brake and indicates for driver to pull forward 3.Transferring water - stationary 1.Improper connection procedure 1.Both machine & truck in park resulting in uncontrolled water position before operation to begin spray 2.All crew to visually give OK of connections made and valves open before water pump is started 3.Water truck driver monitor water levels

Task: Division: Watering machine on the Move Milling

Task/Activity Potential Hazard Recommended Procedures 1. Stop milling machine 1. None

2. Pull water truck next to 1. Running over property or 1. Truck driver to have eye machine personnel contact with all personnel working around work area 3. Attach hose to machine from 1. None truck

4. Turn pump on 1. None

5. Truck and machine both move 1. Crushing between truck and 1. Do not go between machine ahead machine and truck while in motion.

6. Disconnect hose 1. None 7. Pull truck away from machine 1. Running over property or 1. Truck driver to have eye personnel contact with all personnel working around work area Task: Division: Grease Machine Milling

Task/Activity Potential Hazard Recommended Procedures 1. Put in leg stands 1. Crushing due to hydraulic 1. Put in leg stands failure 2.Turn on conveyors 1.Materials coming out of 1.Visually check below conveyor conveyor 2.Vocally warn of start up 2.Person getting caught in 1.Vocally warn of start up conveyor

3.Pinch points 1.No one on deck while greasing

3.Turn on drum 1.Person being caught in drum 1.Vacally warn of start up

4.Put grease in grease nipples as 1.None directed by greasing schedule

Task: Division: Changing Teeth Milling

Task/Activity Potential Hazard Recommended Procedures 1. Raise machine 1. Crushing due to hydraulic 1. Put in leg stands failure

2. Raise door to cutter housing 1. Crushing due to Hydraulic 1. Make sure door is proper Failure height and above safety catch

3. Remove and replace teeth 1. Flying debris 1. Wear safety goggles with air gun or hand tool

2. Hitting hand with air tool or 1. Wear gloves hammer.

4. Lower cutter housing door 1. Crushing 1. Visual inspection and Verbal warning.

Task: Division: Securing Machine after Work Milling

Task/Activity Potential Hazard Recommended Procedures 1. Parking machine 1. property damage sinking in 1. Scout suitable parking area soft ground poses possible risk to before proceeding to area public & traffic 2. Lower machine to lowest possible position and position conveyors appropriately 1.Securing machine 1. Possible starting and operating 1. Delineate and lock out power by unqualified people source.

2.Lock all control panels

2.Possible contamination of area 1.Visually inspect machine for due to oil or fuel leaks & mechanical failures

Task: Division: Fire Hydrant Use - Opening Milling

Task/Activity Potential Hazard Recommended Procedures

1. Pre - opening of a hydrant If you stand in front of the 1. Secure proper permits & hydrant and the cap is not documentation secure, it will come off with 2. Visually & physically significant pressure behind it. inspect hydrant for This could cause serious damage/defects injury/death. 3. If damage is noted, notify your supervisor informing him of location & hydrant If these procedures are not done I.D.# He will make the call in the proper order, water will be to the city propelled with such a great force 4. Stand behind hydrant that could violently project 5. Ensure that hydrant valve items/people. is shut off 6. Ensure all caps are secure 7. Install back flow preventer and hydrant hook up 8. Slightly open back flow valves before opening service valve. This allows the valve to seat properly

2. Slowly open valve on Prevents water hammer & hydrant noting number of damage to the mains. The turns required to fully open counting is used as a double check system to ensure when closing the hydrant you have made the correct amount of turns.

3. Purge valve This reduces potential contamination to water tank on machine 4. Close service valve before Avoids potential trapping water connecting to machine pressure in plastic service hose 5. Re-open service valve after connection to machine is made Task: Division: Fire Hydrant Use – Shut down Milling

Task/Activity Potential Hazard Recommended Procedures 1. Close hydrant hook up valves approximately 9/10th 2. Slowly shut down hydrant Must be done slow to prevent water hammer & damage to the mains 3. Ensure same number of If the numbers don’t match, the 1. Listen for a sucking noise turns are used to close as hydrant isn’t fully closed when opening 4. Fully open all valves on hydrant hook up 5. Allow a drain down time of This ensures the stem of the 15 minutes hydrant will be void of water, preventing freeze up and damage to the hydrant Task: Division: Milling adjacent to or in close Milling proximity to a drop off or unstable ground Task/Activity Potential Hazard Recommended Procedures Before moving machine into If the crew feel that the ground is area, milling crew do a unstable and cannot withstand walkthrough of area to evaluate the weight of the machine, it can conditions and potential hazards. exercise its right to refuse. Contact their immediate supervisor right away. Position machine a safe distance Unstable ground gives away; Do NOT drive or back machine from potential hazard, lower legs may cause machine to tip or roll into position close to edge of and set depth BEFORE over pavement with legs fully proceeding forward with the extended. milling function Where appropriate, operator should crab machine to be able to run the front track farther away from edge of pavement Ground man must monitor any Ground man should avoid changes in ground conditions so positioning themselves on the as to be able to warn operator of side of the potential hazard within any such changes the length of the machine Vehicle Breakdowns and Accidents

1. If a vehicle breaks down, operators must get the vehicle off and away from the travelled portion of the road if possible (this particularly applies to emergency vehicle routes on the project site). If they can't, then they must: Activate vehicle emergency flashers If visibility is poor because of fog, rain, hill, curve, dusk, etc., set out flares or flashers supplied with the vehicle Set flares or flashers 32 m (100 ft) behind and 32 m (100 ft) in front of the vehicle. (Do not set out flares if you are well off the road.)

2. Immediately report all Company vehicles breakdowns to head office.

3. Report accidents involving Company vehicles as described in Section 8 - Incidents. Give all the details possible, such as width of roads, length of skids, presence of traffic signs, vision obstructions, names and addresses of persons involved and witnesses. In case of an accident the operator must: Pull off the road, if possible, to avoid obstructing traffic Place warning reflectors on the road as necessary Render first aid to any person who may be injured Report the accident to his supervisor as soon as possible Refrain from entering into any argument or dispute with the driver of the other vehicle, pedestrians or bystanders Make no admission of liability or offer any settlement of claim Record license plate numbers and driver's license numbers of any other involved persons (including witnesses) Make arrangements with your supervisor to report the accident to the necessary authorities Boosting a Battery Always wear safety goggles to protect yourself from acid and fragments in case of an explosion. It’s a good idea to store safety goggles with your jumper cables.

Check to see if the battery is really dead, or if the terminals and clamps might just be corroded.

Restore correct fluid levels to the battery. If you are dealing with the more recent sealed type batteries, it is not always possible to restore these fluid levels. If this is the case, the battery should be replaced.

Make sure the battery is not frozen. Trying to jump a frozen battery could result in an explosion.

The electrical systems of both vehicles must be the same voltage and both must have a negative ground. Mismatched batteries are less likely than they were 20 years ago but six-volt batteries are still in use today. Using a 12 volt battery to boost a six volt battery could cause the six volt battery to explode.

Part the vehicles close together, but not touching. Put both vehicles in “park” or in “neutral”, with parking brakes set.

Turn off the engine, and any electrical accessories including interior lights on both vehicles.

Remove the battery vent caps to allow any previously built up gas to escape. Then cover the holes with a damp rag or replace the caps.

Do not lean over the battery at any time.

Connect the red clamps to the positive “+” posts of each battery. Reverse connection causes a battery explosion hazard.

Connect one black clamp to the negative “-“ terminal of the good battery.

Connect the other black clamp to a good ground; a clean, unpainted spot on the engine, frame or body of the disabled vehicle, placing it as far away as possible from the battery. This will prevent sparks from occurring in the vicinity of any explosive gases.

When connecting the clamps, do not allow them to touch any other metal. This would not only cause a spark which could trigger an explosion, but it could destroy parts of the vehicle’s electrical and computer system.

Start the vehicle with the good battery.

Start the disabled vehicle.

Remove the cables in reverse order.

Detach the “-“cable first from the disabled car’s frame.

Then take the “-“of the good car’s negative terminal.

Remove the disabled cars “+” cable. Then remove the live car’s “-“connection.

Other Tips Avoid any sparks or flames. NO SMOKING.