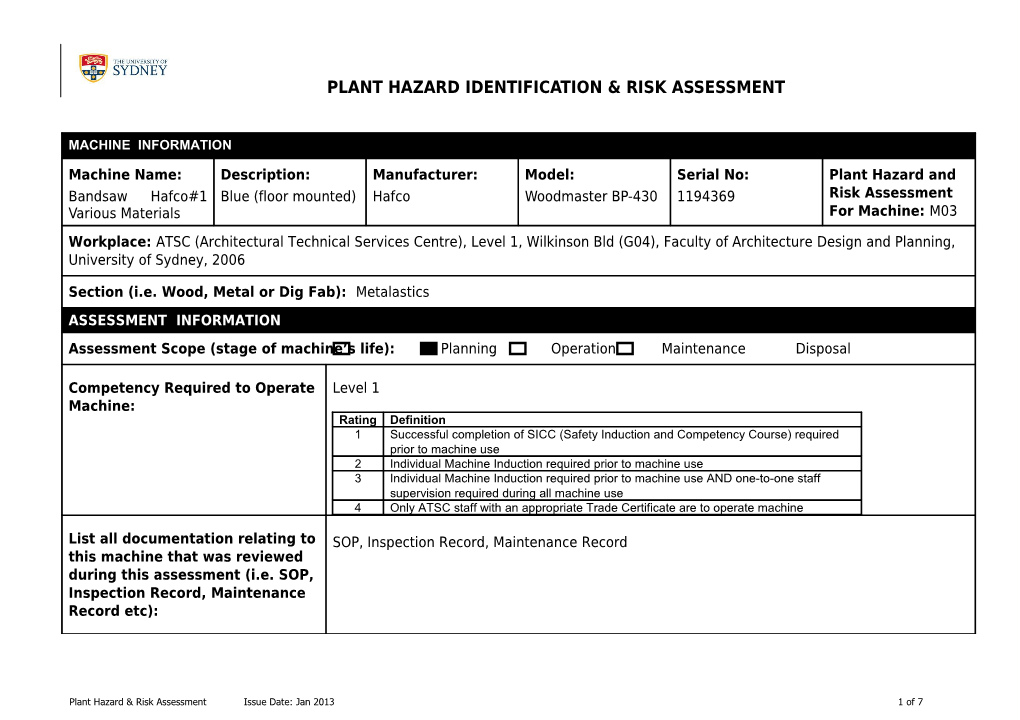

PLANT HAZARD IDENTIFICATION & RISK ASSESSMENT

MACHINE INFORMATION

Machine Name: Description: Manufacturer: Model: Serial No: Plant Hazard and Bandsaw Hafco#1 Blue (floor mounted) Hafco Woodmaster BP-430 1194369 Risk Assessment Various Materials For Machine: M03 Workplace: ATSC (Architectural Technical Services Centre), Level 1, Wilkinson Bld (G04), Faculty of Architecture Design and Planning, University of Sydney, 2006

Section (i.e. Wood, Metal or Dig Fab): Metalastics ASSESSMENT INFORMATION Assessment Scope (stage of machine’s life): Planning Operation Maintenance Disposal

Competency Required to Operate Level 1 Machine: Rating Definition 1 Successful completion of SICC (Safety Induction and Competency Course) required prior to machine use 2 Individual Machine Induction required prior to machine use 3 Individual Machine Induction required prior to machine use AND one-to-one staff supervision required during all machine use 4 Only ATSC staff with an appropriate Trade Certificate are to operate machine

List all documentation relating to SOP, Inspection Record, Maintenance Record this machine that was reviewed during this assessment (i.e. SOP, Inspection Record, Maintenance Record etc):

Plant Hazard & Risk Assessment Issue Date: Jan 2013 1 of 7 PLANT HAZARD IDENTIFICATION & RISK ASSESSMENT

MACHINE INFORMATION Hazard Identification Risk Assessment Inherent Risk Control Residu Person Implemen Revie (If Yes, then risk assessment is Risk (Consider Hierarchy of Controls al Responsib ted w required) rating for each hazard) Risk le Date Date rating Entanglement Medium Elimination Not possible Low SOP May 2012. 14/03/ Can anyone’s hair, clothing Potential for entanglement Substitution Not possible already Reviewed 14 gloves, necktie, jewellery, rags exists with the following: Isolation Not possible completed March and other materials become 1. When contact with the Engineering Not possible and 2013 machine parts wearing lose Administrative Staff to be trained in present. entangled with moving parts of clothing and/or long hair SOP. Meeting plant, or materials in motion? uncontained Students must be properly inducted in Marjo held on the safe operation and the Niemela 27/3/13 to Yes No characteristics of the machine and train all materials involved. new ATSC PPE Appropriate wear and eye staff in protection must be worn machine protocol Crushing Elimination Can anyone be crushed due to Substitution falling, uncontrolled or unexpected Isolation movement of plant or its load, Engineering lack of capacity to slow, stop or Administrative PPE immobilise the plant, tipping or rolling over, parts of plant collapsing, contact with moving parts during testing, inspection, maintenance, cleaning or repair, thrown off, under or trapped between plant and materials or fixed structures?

Yes No Cutting, Stabbing and Potential for cuts, abrasions Medium Elimination Not possible Low SOP May 2012. 14/03/ Puncturing and bodily injury to hands Substitution Not possible already Reviewed 14 Can anyone be cut, stabbed or and arms due to fast moving Isolation Not possible completed March sharp blade. Engineering Not possible and 2013 punctured by coming in contact Administrative Staff to be trained in present.

Plant Hazard & Risk Assessment Issue Date: Jan 2013 2 of 7 PLANT HAZARD IDENTIFICATION & RISK ASSESSMENT

MACHINE INFORMATION with moving plant or parts, sharp SOP. Meeting or flying objects, work pieces Students must be properly inducted in Marjo held on ejected, work pieces the safe operation and the Niemela 27/3/13 to disintegrated or other factors not characteristics of the machine and train all mentioned? materials involved. new ATSC PPE Appropriate footwear and eye staff in protection must be worn machine Yes No protocol

Shearing Elimination Can anyone’s body parts be cut Substitution off between two parts of the Isolation plant, or between a part of the Engineering Administrative plant and a work piece or PPE structure?

Yes No Electrical Potential for electrical risks Medium Elimination Not possible Low SOP May 2012. 14/03/ Can anyone be injured by exists with the following: Substitution Not possible already Reviewed 14 electrical shock or burnt due to 1. Electrical leads are not Isolation Not possible completed March damaged or poorly maintained test and tag Engineering Not possible and 2013 Administrative Staff to be trained in present. leads or switches, water near SOP. Meeting electrical equipment, working Students must be properly inducted in Marjo held on near or contact with live the safe operation and the Niemela 27/3/13 to electrical conductors, lack of characteristics of the machine and train all isolation procedures or the materials involved. new ATSC factors not mentioned? For Ensure electrical lead are tested and staff in example, are any switches tagged before use machine broken; is there a red emergency PPE Appropriate footwear and eye protocol stop? Can each machine be protection must be worn 20/3/13 locked off for repairs?

Yes No

Plant Hazard & Risk Assessment Issue Date: Jan 2013 3 of 7 PLANT HAZARD IDENTIFICATION & RISK ASSESSMENT

MACHINE INFORMATION

Explosion Elimination Can anyone be injured by an Substitution explosion of gas, vapours, Isolation liquids, dusts or other Engineering Administrative substances, triggered by plant operation? PPE

Yes No Friction Elimination Can anyone be burnt due to Substitution contact with moving parts or Isolation surfaces of the plant, or material Engineering Administrative handled by the plant? PPE Yes No Striking Potential for eye and bodily Medium Elimination Not possible Low SOP May 2012. 14/03/ Can anyone be struck by moving injuries due to fragments Substitution Not possible already Reviewed 14 objects due to plant or work and projectiles, which may Isolation Not possible completed March pieces being ejected or fly from the high speed Engineering Not possible and 2013 blades. Administrative Staff to be trained in present. disintegrated, mobility, SOP. Meeting uncontrolled or unexpected Students must be properly inducted in Marjo held on movement of the plant or other the safe operation and the Niemela 27/3/13 to factors? characteristics of the machine and train all materials involved. new ATSC Yes No PPE Appropriate footwear and eye staff in protection must be worn machine protocol 20/3/13

Plant Hazard & Risk Assessment Issue Date: Jan 2013 4 of 7 PLANT HAZARD IDENTIFICATION & RISK ASSESSMENT

MACHINE INFORMATION Slipping, Tripping and Elimination Not possible Low SOP May 2012. 14/03/ Potential for slips, trips and Medium Substitution Not possible already Reviewed 14 Falling falls exists with the Isolation Not possible completed March Can anyone using the plant or in following: Engineering Not possible and 2013 the vicinity of the plant, slip, trip 1. Poor housekeeping Administrative Staff to be trained in present. or fall due to the working 2.Where obstacles are SOP. Meeting environment or other factors?, placed around the plant Students must be properly inducted in Marjo held on poor housekeeping, dust on the whilst it is in operation the safe operation and the Niemela 27/3/13 to characteristics of the machine and train all floor around machines, slippery materials involved. new ATSC or uneven work surfaces or lack Ensure good housekeeping and staff in of guardrails. surrounding areas are safe machine PPE Appropriate wear and eye protocol Yes No protection must be worn 20/3/13 Suffocation Elimination Can anyone be suffocated due to Substitution lack of oxygen, or atmospheric Isolation contamination? Engineering Administrative PPE Yes No High Temperature or Fire Elimination Can anyone come into contact Substitution with objects at high temperature Isolation or injured by fire? Engineering Administrative PPE Yes No Temperature (Thermal Elimination Comfort) Substitution Can anyone suffer ill health due Isolation Engineering to exposure to high or low Administrative temperatures? PPE Yes No

Plant Hazard & Risk Assessment Issue Date: Jan 2013 5 of 7 PLANT HAZARD IDENTIFICATION & RISK ASSESSMENT

MACHINE INFORMATION

Ergonomic Elimination Can anyone be injured due to Substitution seating design, repetitive body Isolation movement or posture, excessive Engineering Administrative effort, poor workplace or plant design causing mental or PPE physical stress, lack of consideration for human behaviour, poor lighting or other factors not mentioned?

Yes No High Pressure Fluid Elimination Can anyone come into contact with Substitution fluids under high pressure, due to Isolation plant failure or misuse of the plant? Engineering Administrative Yes No PPE Other Hazards Potential for mild hearing Medium Elimination Not possible Low SOP May 2012. 14/03/ damage when cutting dense Substitution Not possible already Reviewed 14 Can anyone be injured or suffer ill materials for long periods of Isolation Not possible completed March health from exposure to: work. Engineering A stand alone and 2013 Chemicals extraction system eliminates the present. Toxic Gases Or Vapours Potential Risk of inhalation inhalation risk Meeting Fumes of dust particles when Administrative Staff to be aware to Marjo held on Dusts cutting wood / plastics enforce earmuffs be worn if students Niemela 27/3/13 to Noise are using machine for 30minutes or train all Vibration more at a time new ATSC Radiation Or PPE Noise protection must be worn staff in Other Factors Not Mentioned? for periods of extended use machine protocol 20/3/13 Yes No

Plant Hazard & Risk Assessment Issue Date: Jan 2013 6 of 7 PLANT HAZARD IDENTIFICATION & RISK ASSESSMENT

Sign Off (This risk assessment was carried out in consultation with the Risk Assessment Information Sheet following persons): Likelihood Names Signature Very Likely Unlike Very likely ly Unlikely Marjo Niemela (ATSC) ______Date: Death or serious High High High Medium ______injury Melinda Wimbourne (ATSC) ______Date: Several days off High High Mediu Medium Consequen ______work m ces Colin Chua (WHS ADVISOR) ______Date: First aid required High Mediu Mediu Low ______m m

______Date: Property damage Mediu Mediu Low Low ______m m

Risk Ratings (Priority): High – Institute controls in the short term (e.g. one month) Medium – Institute controls in the medium term (e.g. 3 months) Low – Institute controls in the long term (e.g. 6- 12 months)

Plant Hazard & Risk Assessment Issue Date: Jan 2013 7 of 7