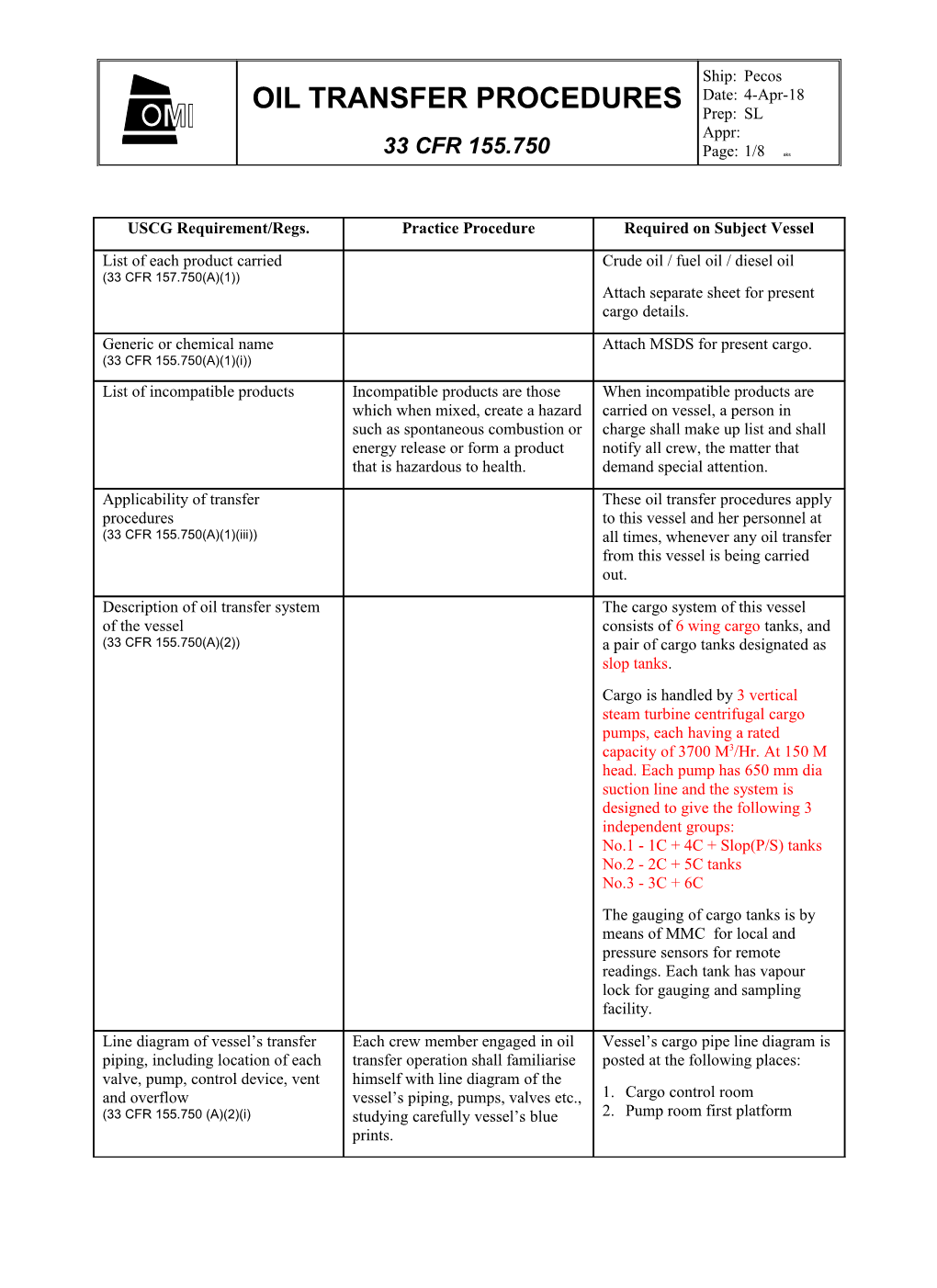

Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 1/8 aks

USCG Requirement/Regs. Practice Procedure Required on Subject Vessel List of each product carried Crude oil / fuel oil / diesel oil (33 CFR 157.750(A)(1)) Attach separate sheet for present cargo details.

Generic or chemical name Attach MSDS for present cargo. (33 CFR 155.750(A)(1)(i)) List of incompatible products Incompatible products are those When incompatible products are which when mixed, create a hazard carried on vessel, a person in such as spontaneous combustion or charge shall make up list and shall energy release or form a product notify all crew, the matter that that is hazardous to health. demand special attention.

Applicability of transfer These oil transfer procedures apply procedures to this vessel and her personnel at (33 CFR 155.750(A)(1)(iii)) all times, whenever any oil transfer from this vessel is being carried out. Description of oil transfer system The cargo system of this vessel of the vessel consists of 6 wing cargo tanks, and (33 CFR 155.750(A)(2)) a pair of cargo tanks designated as slop tanks. Cargo is handled by 3 vertical steam turbine centrifugal cargo pumps, each having a rated capacity of 3700 M3/Hr. At 150 M head. Each pump has 650 mm dia suction line and the system is designed to give the following 3 independent groups: No.1 - 1C + 4C + Slop(P/S) tanks No.2 - 2C + 5C tanks No.3 - 3C + 6C The gauging of cargo tanks is by means of MMC for local and pressure sensors for remote readings. Each tank has vapour lock for gauging and sampling facility.

Line diagram of vessel’s transfer Each crew member engaged in oil Vessel’s cargo pipe line diagram is piping, including location of each transfer operation shall familiarise posted at the following places: valve, pump, control device, vent himself with line diagram of the and overflow vessel’s piping, pumps, valves etc., 1. Cargo control room (33 CFR 155.750 (A)(2)(i) studying carefully vessel’s blue 2. Pump room first platform prints. Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 2/8 aks

USCG Requirement/Regs. Practice Procedure Required on Subject Vessel

Bunker line / vents diagram put up in engine control room, and in alleyway along with Oil Transfer Procedures.

Location of shut off valves or other 1. Person in charge shall also 1. Vessel is an SBT tanker, at isolation devices that separate any familiarise himself with present ballast and cargo system bilge or ballast system from the important valves which on vessel are completely transfer system separate any bilge or ballast segregated. One spool piece is (33 CFR (A)(2)(ii)) system from the oil transfer provided in pump room for system. connection of cargo and ballast line on suction side. 2. Persons engaged in cargo operations shall handle all 2. For preventing oil spillage, all valves only after confirmation important valves, such as, sea of valve numbers which are valves, overboard valves etc. discriminately marked on all have been marked specially in valves. order to discriminate them from other valves. Overboard discharges have been blanked, all sea and overboard valves have been highlighted and locked in close position. USCG placard – DISCHARGE OF OIL PROHIBITED has been placed adjacent to it. 3. The distinguishing numbers shall be marked on all valves. 4. Emergency shut off switches for cargo pumps are located at: (A) Cargo control room, individual pumps (B) Pump room entrance (C) Pump room bottom, individual pumps (D) Manifold port & stbd A description of and procedure for 1. Vessel is provided with emptying the discharge discharge containment under containment system required by cargo / bunker manifolds, port 33 CFR 155.310 and 155.320 and stbd, capacity 12.60 M3. (33 CFR 155.750(A)(2)(iii)) 2. These containments are connected by drain lines and valves to cargo oil tank 4(P/S). 3. The chicksons / cargo lines Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 3/8 aks

USCG Requirement/Regs. Practice Procedure Required on Subject Vessel

should be drained into 4(P/S) tank, prior disconnection. 4. For draining drip trays in tank, this tank must be depressurised first. 5. The containments should be kept clean and dry at all times. Bunker connections for lubes are provided aft, with drip tray. Capacity 0.6 M3. This is manually emptied in to bunker tanks or waste oil tank.

The number of persons required to 1. Minimum number of persons 1. Chief Officer shall be person in be on duty, during oil transfer required to be on duty during charge of cargo operations. He operations cargo loading, shall be as will be suitably relieved by (33 CFR 155.750(A)(3)) follows: Master or Duty Officer. Duty Officer 1 Control station 1 2. During initial start of On deck 3 operations, or topping off Total 5 operations, COW operations, number of hands shall be 2. Minimum number of persons increased as follows: required to be on duty during Person in charge (CO) 1 cargo discharge operations, Duty Officer 2 shall be as follows: Deck crew 4 Duty Officer 1 Control station 1 3. For all bunker transfer On deck 2 operations, Chief Engineer shall Pump room 1 be the person in charge. Total 5 Minimum 4 persons shall be on watch during bunkering; Chief Engineer 1 Duty Engineer 1 At bunker manifold 1 In area of fuel tank 1 The duties by title of each Officer, All duties of each person are At the start and finishing of cargo person in charge, tanker man, deck specified in respect of; operations: hand, and any other person required for each transfer operation I. The start of operations; Chief Officer, directs entire cargo (33 CFR 155.750(A)(4)) transfer operation, in charge of II. Finishing of cargo operations, cargo control room, makes contact including topping off with loading master of the terminal, procedures. ensures that the vessel complies For all cargo transfer operations, with terminal safety requirements. the person in charge is to be 2nd Officer, attends hose Chief Officer; connection and disconnection, make contact with terminal for Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 4/8 aks

USCG Requirement/Regs. Practice Procedure Required on Subject Vessel

Person engaged in oil transfer above, supervise draining of operations, shall under take his manifold drip tray and main lines duties in accordance with under into cargo tank. mentioned assignments rd respectively: 3 Officer, assistant to Chief Officer, confirm compliance of The person in charge shall have to ship / shore check list, calculate oil ensure that all crew know the quantities. contents of oil transfer operation. He shall make Cadets and Pumpman, assistant to loading / discharging plans. Chief Officer, line up all valves as per loading plan under instructions Instruct all crew thoroughly, the of Chief Officer, take rounds of plan of oil transfer procedure. deck, ensure no leakages, keep oil spill clean up material ready at Tests and inspections of oil transfer manifold, ullaging and sampling. equipment shall be practised and these records shall be Bosun + 3 AB, prepare cranes for kept on board. connection / disconnection, take local ullages of tanks, attend to Before oil transfer operation, the moorings, watch surroundings, vessel shall test and inspect assist in ullaging and sampling. the equipment listed in Declaration of Inspection. During cargo operation: For bunker transfer procedures, Chief Officer or Duty Officer, in Chief Engineer shall complete cargo control room, command and comply with bunkering cargo transfer operations, calculate check list. rate of transfer, trim, heal, stability, ensure operations are conducted as planned and agreed with the terminal. Chief Officer is in charge of all COW operations. Cadet on duty, take rounds on deck, take local tank readings with MMC. Bosun / Pumpman / and 2 AB, keep watch at manifold and gangway, make note of all shore personnel on board, inform cargo control room, watch for any sea or air pollution, assist cadet in opening / closing valves. Procedure and duty assignments Vessel’s moorings shall be Attach following on separate sheet; for tending the vessel’s moorings, carefully tended to and quick during the transfer of oil or action in emergency shall be taken 1. Vessel is made fast at the hazardous material as follows: terminal by following moorings: Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 5/8 aks

USCG Requirement/Regs. Practice Procedure Required on Subject Vessel

(33 CFR 155.750(A)(5)) Moorings shall be strong enough to Head lines, fwd aft hold vessel in all expected Breast lines, fwd aft conditions of surge, current and Springs, fwd aft weather and be long enough to allow adjustments in draft, trim 2. Vessel head at terminal ____ and tide during transfer; degrees. Moorings shall be tended with 3. Tide / tidal current condition: proper tension at all times; Time HT Time HT High High When other vessels are passing, Low Low mooring lines shall be watched carefully; 4. Current Maximum rate When transfer hoses are connected Direction by chickson arm, movement of the ship in direction fore and aft 5. Expected wind while alongside shall be watched for, in the terminal: particular. Force Direction

Emergency shut down procedure 1. The location of emergency shut Before commencing oil transfer and communication means downs shall be highlighted and operations, means, times to activate required by 33 CFR 155.780 and known to all persons engaged and means of communication of 155.785 in oil transfer operations. emergency shut down procedures (33 CFR 155.750(A)(6)) shall be agreed and exchanged in 2. Emergency shut downs shall be writing. tried out and recorded. On this vessel, emergency shut 3. When emergency shut down is down switches for cargo pumps are required during oil discharge located at: operation, shore receiving facility and the engine control (A) Cargo control room, room shall be informed at the individual pumps same time of shut down. (B) Pump room entrance When it is required to stop flow of oil during cargo loading (C) Pump room bottom, operation, vessel shall inform individual pumps shore facility in accordance (D) Manifold port & stbd with agreed system, no person on vessel shall shut down any ship’s valves without permission of oil supplier.

Procedure for topping off tanks (A) The topping off (33 CFR 155.750(A)(7)) operations of tanks should be carried out by the person in charge of transfer operations. (B) Ensure that topping off levels and quantity to be Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 6/8 aks

USCG Requirement/Regs. Practice Procedure Required on Subject Vessel

loaded are verified to ensure safe balance space. (C) Ensure topping off rates are agreed with terminal in pre-loading conference. (D) Ensure manual and fixed gauging systems are compared. (E) Prior coming to topping levels, valves of tanks in question are slightly operated to confirm that they are having the desired effect. (F) List and trim conditions should be taken into account when topping off tanks.

Procedure for ensuring valves shut On completion of oil transfer after oil transfer operation operation, all valves should be (33 CFR 155.750(A)(8)) shut. Person in charge shall make crew shut and confirm that valves are shut, while following line diagram. For important valves, such as, sea valves, overboard valves etc., person in charge shall confirm their closed position, himself. Watch to be kept overside for any leakage.

Procedure for closing and opening 1. No person may open any cargo This vessel has following cargo vessel’s openings tank openings, unless tank openings: (33 CFR 155.750(A)(9)) authorised. 1. Expansion trunk hatches; 2. If any openings are open with 2. Ullage openings; permission, person in charge 3. Sounding ports / plugs; should ensure the closure of the 4. Tank cleaning openings. openings. Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 7/8 aks

USCG Requirement/Regs. Practice Procedure Required on Subject Vessel

Procedure for reporting discharge When oil is discharged in to water, Activate oil pollution contingency of oil or hazardous material into oil transfer operation shall be plan. water stopped as soon as possible. Report (33 CFR 155.750(A)(10)) pollution to onshore facility and to all other parties as follows: 1. USCG; 2. Captain of the port; 3. Agents; 4. Owners; 5. Managers; 6. Qualified individual Report as per Emergency Response Plan. 1. Chemicals shall not be used unless USCG permits same. 2. All efforts should be made to prevent oil from spreading by using oil boom.

Exemptions or alternatives granted None (33 CFR 155.750(B)) Amendments to Oil Transfer Nil Procedures (33 CFR 155.750(C)) Designation of person in charge Chief Officer is qualified person (33 CFR 155.700) and is designated as person in charge of the transfer operations.

Compliance with transfer These transfer procedures are to be procedures complied at all times, whenever (33 CFR 155.710) carrying out any oil transfer. Availability of transfer procedures These transfer procedures are to be (33 CFR 155.730) posted in cargo control room, accommodation alleyway, and engine control room. Declaration of inspection These should be filled out by (33 CFR 156.150) person in charge.

Copy to be placed in separate attached sheet. Record of equipment tests and Record of all cargo equipment tests inspection to be kept in a separate folder. (33 CFR 156.170) Ship: Pecos Date: 4-Apr-18 OIL TRANSFER PROCEDURES Prep: SL Appr:

33 CFR 155.750 Page: 8/8 aks