OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 1 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title:Material Handling Equipment

1.0 Purpose: To provide guidelines for safe handling of materials manually or by using moving machinery like Fork Lifts Trucks, Trailer EOT, Jib Cranes and Hoists, Passenger Lifts. Transfer Trolly, Hand Trolly etc.

2.0 Reference:

3.0 Associated Hazards : Poor site layout; falls from vehicles; height restrictions; over turning; collision; striking people and equipment. falling, tripping etc.

4.0 Applicability: TRF WORKS

5.0 Responsibility :Contractors, Drivers of the equipment, shift Supervisor/Officers.

6.0 Procedure:

S.No Requirements

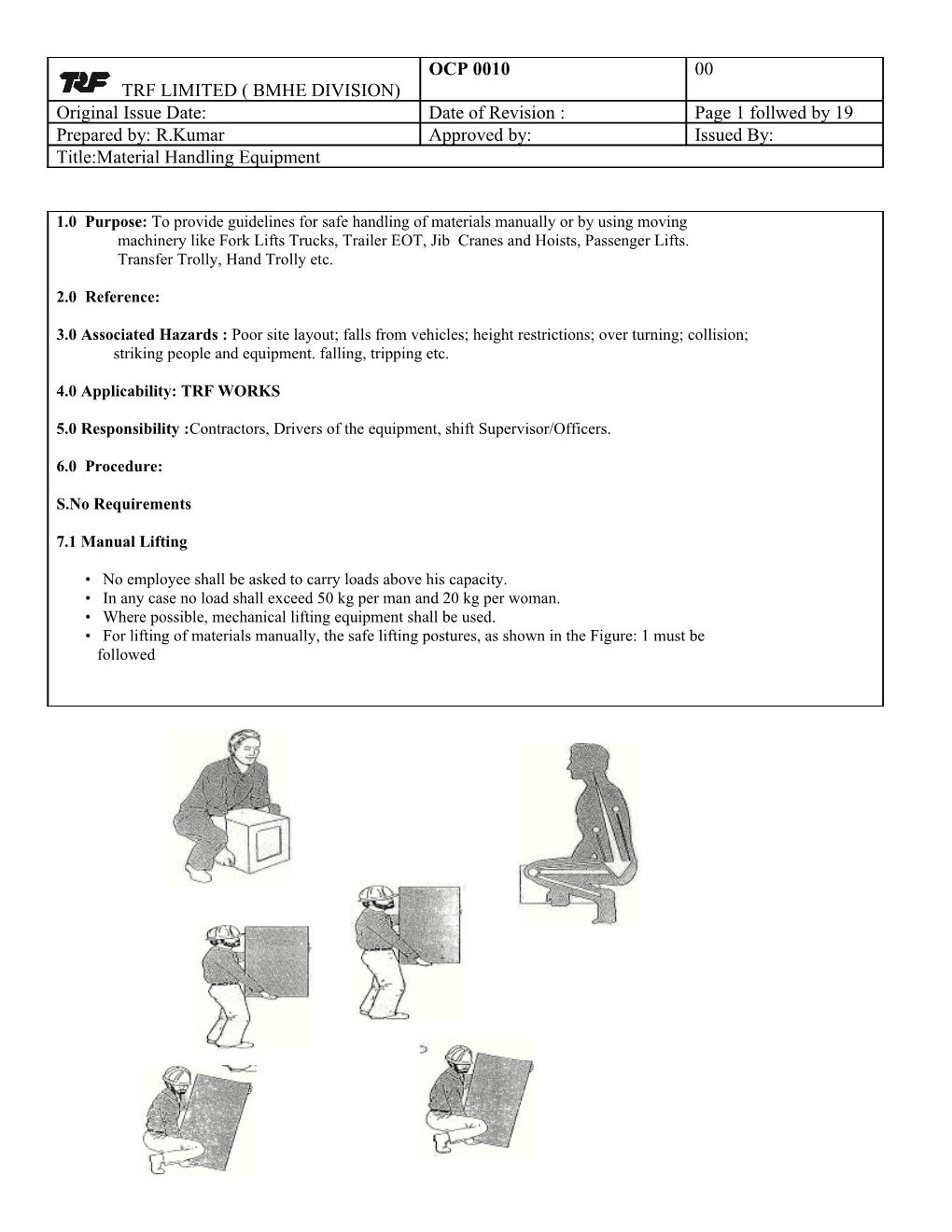

7.1 Manual Lifting

• No employee shall be asked to carry loads above his capacity. • In any case no load shall exceed 50 kg per man and 20 kg per woman. • Where possible, mechanical lifting equipment shall be used. • For lifting of materials manually, the safe lifting postures, as shown in the Figure: 1 must be followed

OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 2 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

7.2 Mechanical Lifting

General • Every driver / Operator of material moving machinery shall possess adequate skill and documented training in the operation of the particular lifting appliance. Suitable sticker is to be pasted on the helmet of successful employees, as an easy way for supervisors to know if the person operating the equipment has been formally trained.

• No person under 18 years of age shall be employed for operations of these machines or for giving signals to operator.

• All lifting machines and lifting tackles shall bear :

° Identification Mark Number (as mentioned in the Test Certificate) ° Safe Working Load ° Date of Last Test, and Next due date of test.

• Operator shall leave no machinery unattended, while power is on or load is suspended to above machinery.

• No person shall ride on suspended load or any lifting machine

• All lifting machinery shall be tested by competent person yearly and the test record shall be maintained by the owner department.

• While material handling, following precautions to be taken :

° The load is safe and secured while lifting ° Slinging method is proper for the load ° Lifted load shall not exceed the safe working load of the slinging gear ° The load is so slung that it will not collapse and does not damage the sling in gear.

• All persons at the site shall strictly use helmet with chin belt and shoes.

• Two-crane lift is always considered to be critical and hence care should be taken to ensure a) proper planning for the lift, b) no lateral load on the boom and c) to use lifting tackles as far as possible.

7.2.1 Fork Lift Trucks

• The forklift truck shall –

OCP 0010 00 TRF LIMITED ( BMHE DIVISION)

Original Issue Date: Date of Revision : Page 3 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

° Be provided with overhead protection for the driver.

° Be provided with an automatic reverse activated horn or buzzer and light.

• No person other than the trained operator shall operate forklift trucks. • No attachment shall be incorporated on the forklift unless the necessary precautions are taken against the possible changes in the design specifications such as load centre, maximum safe capacity, etc. • All persons, drivers and banks men shall be thoroughly conversant with the factors which affect the stability of the forklift in operation. • Before driving fill out a daily forklift safety inspection checklist, including conditions and operability of seat belt. • When driving without load, fork must be kept 15-20 cm above floor. • Drive at a safe speed as per the work area. • Wheel, tyres must always be adequately inflated.(WHEREVER REQD.) • Switch off engine when machine is unattended. • Keep hand dry and clean when driving. • Avoid driving over any object lying on the path. This may topple the load and the vehicle. • Avoid sudden stops and sudden turns. • If load is obstructing a clear view, operate in reverse gear. • Use pallets for carrying small / or loose materials. • Pick up the load at its proper centre. • Tilt the load against back-rest, before moving on. • Return the tilt to vertical before lowering or picking up load. • When stocking / unloading materials, ensure employees / personnel stand clear of the load and machine. OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 4 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

.

7.2.2 Cranes & Dericks

7.2.3 General requirements.

a) The employer shall comply with the manufacturer's specifications and limitations applicable to the operation of any and all cranes and derricks. Where manufacturer's specifications are not available the limitations assigned to the equipment shall be based on the determinations of a qualified engineer, competent in this field and such determinations will be appropriately documented and recorded. Attachments used with cranes shall not exceed the capacity, rating, or scope recommended by the manufacturer.

b) Rated load capacities, and recommended operating speeds, and special hazard warnings, or Instruction shall be conspicuously posted on all equipment. Instructions or warnings shall be visible to the operator while at the control station. A chart indicating safe working load (SWL) at various inclinations or radii of jib shall be displayed in the driver’s cabin. This is needed only in cases where automatic SWL indicator is not provided on the crane.

c) Standard Hand signals, as given in Fig.-2, 3a and 3b, shall be used to crane and derrick operators OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 5 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

d) Every lifting appliance or machine and every part thereof including all working gear and all other plant or equipment used for anchoring or fixing such appliances or machines shall be of good mechanical construction, sound material, adequate strength and free from defect. The employer shall designate a competent person who shall inspect all machinery and equipment prior to each use, and periodically during use to make sure it is in safe operating condition. Any deficiencies shall be repaired, or defective parts replaced, before further use.

e) A thorough, annual inspection of the hoisting machinery shall be made by a competent person or competent private agency recognized by the department. The employer shall maintain a permanent record of the dates and results of all inspections for each hoisting machine and piece of equipment.

f) A tag line or guide rope shall be used on all loads that swing freely. Guide ropes or tag lines shall be held by experienced persons.

g) Care shall be taken to guard against injury to workers, or damage to scaffolds or buildings, from swinging loads.

h) The operator shall avoid carrying loads over people. No one must walk below a suspended load or the boom.

i) When work is stopped or when the derrick is not in operation, the boom shall be lowered to a horizontal position or tied in place to prevent it whipping with the wind or other external force.

j) Only authorized personnel shall make sling hitches on loads.

k) Workers shall not be allowed to ride on loads handled by derricks.

l) Operators shall observe signals only from duly authorized persons. Under no circumstances shall a load be moved until the signal is received from authorized personnel. The Crane operator shall respond to signals only from appointed signaler but shall obey stop signal given by anyone at anytime.

m) Belts, gears, shafts, pulleys, sprockets, spindles, drums, fly wheels, chains, or other reciprocating, rotating, or other moving parts or equipment shall be guarded if such parts are exposed to contact by employees, or otherwise create a hazard. Any anchoring or fixing arrangement provided in connection with the lifting appliances or machines shall be adequate and secured. Do not operate a crane, which does not have the facility of automatic braking (in case of power failure). OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 6 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

n) A minimum distance of one meter clearance shall be maintained between the swing radius of the greatest extension of the crane superstructure or counterweights and a stationary object, including the crane itself, while the crane is in operation. When this clearance cannot be maintained, suitable barricades or safeguards shall be used to isolate the pinch point hazard area. No person should approach nearer than six meter of the crane truck, when crane is in motion or loaded.

o) All exhaust pipes shall be guarded or insulated where contact by employees, in the performance of normal duties, is possible.

p) Crane shall be stationed: on a firm ground when operating.

q) When leaving crane, operator must : ° Lower any suspended load to the ground. ° Disengage the clutch. ° Engage all safety locks. ° Secure boom against high winds.

r) When parking overnight, in addition to the above: ° Release the load ° Lower the boom to ground ° Provide wheel locks and wheel blocks

s) Cranes must not be operated between sunset and sunrise without adequate lighting provision.

t) When traveling up a gradient, the load shall be derricked out and when traveling down a gradient, the load shall be derricked into the minimum radius, and this position shall be corrected on reaching level ground. Otherwise, constant watch on the radius should maintained while traveling on uneven surfaces.

u) The mobile crane shall be fitted with suitable horn, head lights, side lamps, and flashing reverse direction indicator.

v) Cranes with cantilever type jib, when traveling without load, the jib should be lowered to a horizontal position.

w) The pneumatic tyres shall be maintained at the correct pressure at all times.

x) Do not block emergency egresses, electrical panel or fire equipment with a truck or load.

y) Lock out the malfunctioning equipment and schedule for repair by maintenance OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 7 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

7.2.3.1Additional requirements.

a) Whenever internal combustion engine powered equipment exhausts in enclosed spaces, tests shall be made and recorded to see that employees are not exposed to unsafe concentrations of toxic gases or oxygen deficient atmospheres.

b) All cab glazing shall be safety glazing material. Windows shall be provided in the front and on both sides of the cab or operator's compartment with visibility forward and to either side. Visibility forward shall include a vertical range adequate to cover the boom point at all times.

c) Where necessary for rigging or service requirements, a ladder or steps shall be provided to give access to a cab roof.

d) On cranes, guardrails, handholds and steps shall be provided for easy access to the car.

e) Cab Platforms and walkways shall have anti-skid surfaces.

f) Fuel tank filler pipe shall be located in such a position, or protected in such manner, as to not allow spill or overflow to run onto the engine, exhaust, or electrical equipment of any machine being fueled. An accessible fire extinguisher shall be available at all operator stations or cabs of equipment.

g) Except where electrical distribution and transmission lines have been de-energized and visibly grounded at point of work or where insulating barriers, not a part of or an attachment to the equipment or machinery, have been erected to prevent physical contact with the lines, equipment or machines shall be operated proximate to power lines only in accordance with the following:

h) For lines rated 50 kV or below, minimum clearance between the lines and any part of the crane or load shall be the meters.

i) For lines rated over 50 kV, minimum clearance between the lines and any part of the crane or load shall be three meters plus one centimeter for each 1 kV over 50 kV., or twice the length of the line insulator, but never less than three meters.

j) In transit with no load and boom lowered, the equipment clearance shall be a minimum of 1.2 m for voltages less than 50 kV., and 3 m for voltages over 50 kV. up to and including 345 kV., and 4.8 m for voltages up to and including 750 kV; OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 8 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

k) A person shall be designated to observe clearance of the equipment and give timely warning to insure that the required separation is maintained for all operations where it is difficult for the operator to maintain the desired clearance by visual means; While working under HT cables. Electrical department Representative and the job Supervisor must be present throughout the entire duration of the jib. A written clearance MUST be signed by the Electrical Department, the Mechanical Department and Safety Officer, when Cranes operate near or below H.T. electrical cables.

l) Any overhead wire shall be considered to be an energized line unless and until the person owning such line or the electrical utility authorities indicate that it is not an energized line and it has been visibly grounded;

m) Combustible and flammable materials shall be removed from the immediate area prior to operations.

n) No modifications or additions which affect the capacity or safe operation of the equipment shall be made by the employer without the manufacturer's or a qualified engineer's written approval. If such modifications or changes are made, the capacity, operation, and maintenance instruction plates, ,tags, shall be changed or decals accordingly. In no case shall the original safety factor of the equipment be reduced.

OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 9 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

7.2.3.2 Overhead and gantry cranes.

a) The rated load of the crane shall be plainly marked on each side of the crane. If the crane has more than one hoisting unit, each hoist shall have its rated load marked on it or its load block, and this marking shall be clearly legible from the ground or floor.

.

b) Except for floor-operated cranes, a gong or other effective audible warning signal shall be provided for each crane equipped with a power traveling mechanism.

d) All overhead and gantry cranes in use, shall meet the applicable requirements for design, construction, installation, testing, maintenance, inspection, and operation.

e) On every stage gantry or other place where a lifting appliance having a traveling or stewing motion is in use, an unobstructed passageway not less than 600 mm wide shall be maintained between any part of the appliance liable so to move and any guard-rails, fencing or other nearby fixture.

OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 10 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

.

7.2.4 Mobile cranes. a) In all power driven shovel operations the person in charge shall issue instructions necessary to prevent accidents, to detect and correct unsafe acts and dangerous conditions, and to enforce all safety rules and regulations. The person in charge shall also issue instructions on the proper method of using tools and handling material. b) Where the ground is soft or uneven, timbering and planking shall be used to provide firm foundation and distribute the load. c) In case of a breakdown, the shovel shall be moved away from the foot of the slope before repairs are made. d) All persons shall keep away from the range of the shovel's swing and shall not be permitted to stand back of the shovel or in line with the swing of the dipper during operation or moving of shovel. e) Unauthorized persons shall not be allowed on the shovel during operations, and the operator shall not converse with other persons while operating machine OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 11 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment f) The shovel dipper shall rest on the ground or on blocking during shut down periods. g) Shovels shall be inspected daily and all defects promptly repaired. h) All rubber tired mobile cranes shall be equipped with outriggers and sufficient blocking to properly stabilize crane while operating. i) Rubber tired mobile cranes shall be equipped with rear view mirrors. j) Positive boom stops shall be provided on all mobile cranes of the wheel and crawler type. k) Length of a crane boom and amount of counterweight shall not exceed manufacturer's rated capacity for equipment involved; except on isolated cases where permission is granted by the department. l) On all cranes where wedge brackets are used as terminal connections, the proper size wedge shall be used. m) On all mobile cranes, the hoist and boom drums shall be provided with a positive operated pawl or dog which shall be used in addition to the brake to hold the load and boom when they are suspended. Counterweight operated dogs are prohibited. n) Oiling and greasing shall be done under safe conditions with machine at rest, except when motion of machine is necessary. o) All steps, running boards, and boom ladder shall be of substantial construction and in good repair at all times. p) Operators shall not leave the cab while master clutch is engaged. q) Fire extinguishers shall be readily accessible and within reach of operator at all times. r) All shovel and crane cabs shall be kept clean and free of excess oil and grease on floor and machinery. Oily and greasy rags shall be disposed of immediately after use and not allowed to accumulate. s) Tools shall not be left on the cab floor. Spare cans of oil or fuel, and spare parts, shall not be stored in cabs, except in approved racks provided for that purpose. t) Mats or planking shall be used in moving shovels or cranes over soft or uneven ground OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 12 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment u) Cranes or shovels setting on steep grades shall be securely blocked or secured with a tail hold. v) Smoking shall be prohibited while fueling or oiling machines.

. w) Where cables cross roads they shall be elevated or placed in a trench. x) On all power shovels and on all drag-line cranes or all-purpose cranes of the crawler or wheel type, two persons shall constitute the minimum working crew. It is mandatory that one be a qualified operator of the equipment in use. The job title of the other crewmember may be oiler, rigger, signal person, or a laborer. The primary purpose of the second crewmember is to signal the operator when the operator's vision is impaired or obscured and to be on-hand in case of emergency. ° Second-crew persons shall be properly trained in “second-person required skills”. ° The second crewmember shall be close enough to the machine in operation to be aware of any emergency, if one arises, and to assure the machine is operated with necessary and appropriate signals to the operator.

7.2.5 Cabins for Drivers The driver of every power driven lifting appliance shall be provided with a suitable cabin and the cabin shall • provide an unrestricted view for proper operation OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 13 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

7.2.6 Drums and Pulleys

• Every drum or pulley round which the chain or wire rope of any lifting appliance is carried shall be of suitable diameter and construction for the chain or rope used.

• Every chain or rope shall be properly anchored and secured to the drum of a lifting appliance and at least two turns shall remain on the drum in every operation position of the appliance.

• All cranes, crabs and winches shall be fitted with brakes capable of holding and controlling their maximum loads.

• Control handles, levers, switches shall be designed so that they cannot be operated accidentally and shall be marked to show what they are for and how they should be operated.

7.2.7 Safe means of Access

Where any person engaged on the examination, repair or lubrication of any lifting appliance! Machine is liable to fall a distance of more than 2 m. there shall be provided and maintained safe means of access to and egress from the place at which the person has to work with adequate hand holds and foot holds.

7.2.8 .Stability of Lifting Appliance a) Appropriate precautions shall be taken to ensure the stability of lifting appliances used on a soft or uneven surface or on a slope. b) Cranes shall be

• Anchored to the ground or other foundations. Rail tracks shall not be used as anchorage.

• Securely counter weighted or ballasted to prevent overturning when working. OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 14 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

. c) Whenever a crane is erected before the crane is put to work, by applying a load 25% higher than the maximum rated load. A report of these tests shall be maintained at the construction site by the contractor.

Some important points for loading on trailors.

• Examine the trailor for tyre condition, general health, road worthiness and conformance to all safety requirements.

• Examine the underframe of the trailor to ensure that it can take the load at the edges. For transporting the loading will be mostly on the edges of the trailor.

• Width of the trailor bed should be such that when the center line of the track chain is parallel to the length of the trailor, most of the track chain will be within the width of the trailor.

• The trailor should be parked on the level ground at the time of the loading. Necessary wedges should be put on the wheel to prevent movement during loading.

• No one should be on the trailor bed while loading the crane on the trailor.

• The loading and lifting arrangement should be checked as per safety standards.

• All fastening between the trailor and the crane like D –shackles, chains, hooks etc. should be checked before hand.

. • Necessary lashing, chain etc. shall be used to hold the load in desired condition. These should be of adequate strength to prevent toppling on transit.

• All other jobs related to this shall be done as per the requirement of relevant safety standards OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 15 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

. 7.2.9 Passenger Lifts a) Trained and designated operated shall operate passenger lift. b) The lift shall indicate the safe carrying capacity. For hoist, load carrying capacity shall be displayed at conspicuous locations. c) No over loading must be allowed. d) Routine checks should be carried out Quarterly. The records of such checking must be maintained in standard formats provided by the manufacturers. e) Drop test and other load / Empty test should be carried out as prescribed. f) Authorized personnel must do all repairs. g) A limit switch should be provided at the extreme operating points. h) All hoists and lifts must have proper and adequate enclosure on the ground. i) Entrance / Exit and loading access must be free from obstructions. j) All landings must have :

° Proper closing and operating gates

° Gates must remain automatically closed when not in use

° All gates / doors must have interlock switch. OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 16 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

7.2.10 Monitoring & Reviewing

Frequency Mechanism Record Responsibility Quartely Inspection / Maintenance Inspection / Contractors, Maintenance Record Annual Test Contractors, Record Once in ayear Annual Test by competent person for Cranes and Hoists, Passenger Lifts. OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 17 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

Figure – 2 : Hand Signals for Overhead Cranes OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 18 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

Fig. : 3a : Hand Signal for Mobile Cranes OCP 0010 00 TRF LIMITED ( BMHE DIVISION) Original Issue Date: Date of Revision : Page 19 follwed by 19 Prepared by: R.Kumar Approved by: Issued By: Title: Material Handling Equipment

Fig. 3b : Hand Signals for Mobile Crane