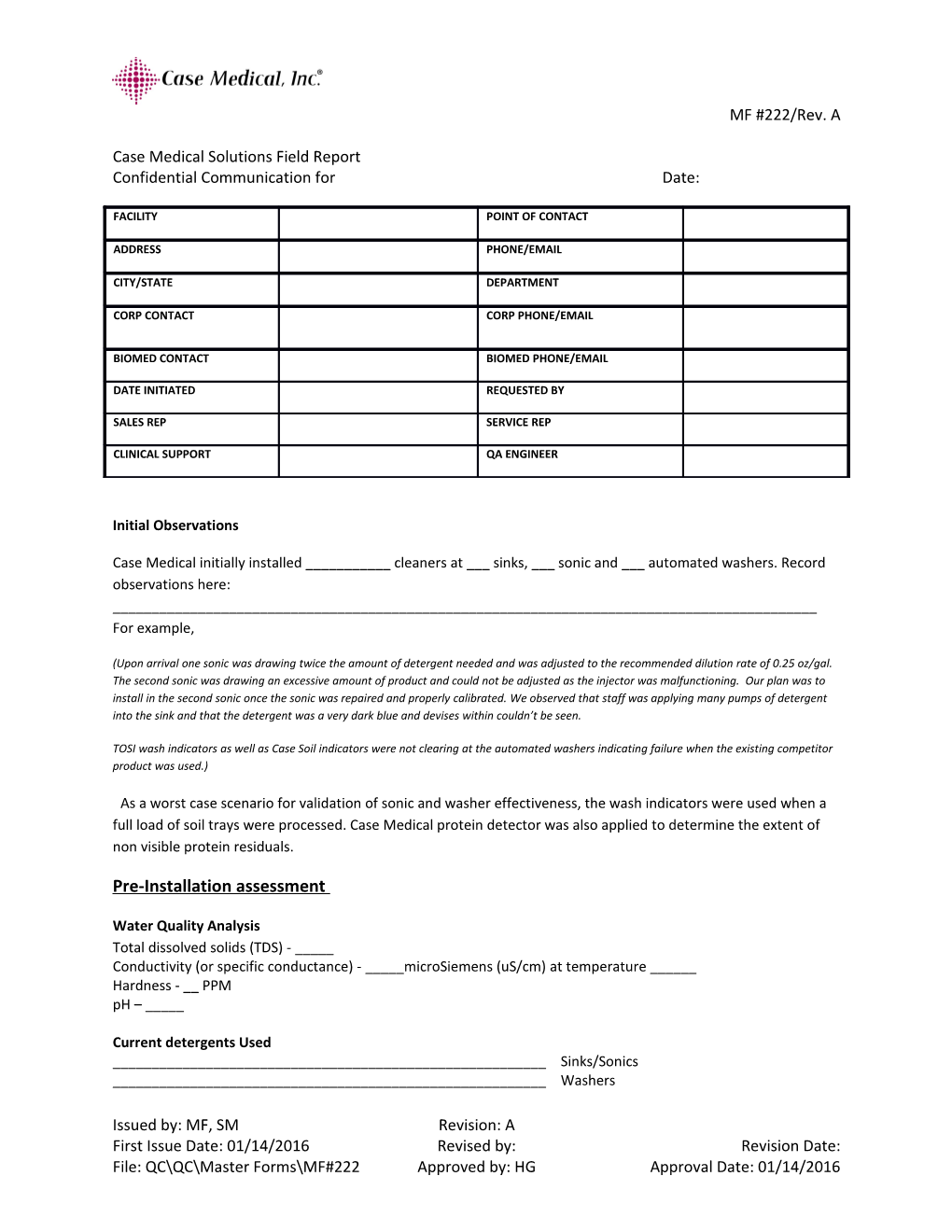

MF #222/Rev. A

Case Medical Solutions Field Report Confidential Communication for Date:

FACILITY POINT OF CONTACT

ADDRESS PHONE/EMAIL

CITY/STATE DEPARTMENT

CORP CONTACT CORP PHONE/EMAIL

BIOMED CONTACT BIOMED PHONE/EMAIL

DATE INITIATED REQUESTED BY

SALES REP SERVICE REP

CLINICAL SUPPORT QA ENGINEER

Initial Observations

Case Medical initially installed ______cleaners at ___ sinks, ___ sonic and ___ automated washers. Record observations here: ______For example,

(Upon arrival one sonic was drawing twice the amount of detergent needed and was adjusted to the recommended dilution rate of 0.25 oz/gal. The second sonic was drawing an excessive amount of product and could not be adjusted as the injector was malfunctioning. Our plan was to install in the second sonic once the sonic was repaired and properly calibrated. We observed that staff was applying many pumps of detergent into the sink and that the detergent was a very dark blue and devises within couldn’t be seen.

TOSI wash indicators as well as Case Soil indicators were not clearing at the automated washers indicating failure when the existing competitor product was used.)

As a worst case scenario for validation of sonic and washer effectiveness, the wash indicators were used when a full load of soil trays were processed. Case Medical protein detector was also applied to determine the extent of non visible protein residuals.

Pre-Installation assessment

Water Quality Analysis Total dissolved solids (TDS) - _____ Conductivity (or specific conductance) - _____microSiemens (uS/cm) at temperature ______Hardness - __ PPM pH – _____

Current detergents Used ______Sinks/Sonics ______Washers

Issued by: MF, SM Revision: A First Issue Date: 01/14/2016 Revised by: Revision Date: File: QC\QC\Master Forms\MF#222 Approved by: HG Approval Date: 01/14/2016 MF #222/Rev. A

SINK Total amount of gallons of water at the sink per cycle: __ gallons Was proportioner, hand pump or other used at the sink? Identify ______Staff is dispensing ___ oz/gal or ___ applications at least.

SONIC A Water used per cycle: ____ gallons Detergent used per cycle: ____ ml (____ US fluid oz) ____ oz / _____ gal = _____ oz/gal

SONIC B Water used per cycle: ____ gallons

Washer #1 – UNIT # ______Washer settings: 1. MOTOR SPEED = ______2. PRE-WASH1 a. RECIRCULATION TIME = _____ min b. WATER TEMP = _____ 3. ENZYME WASH a. SOAKING TIME = _____ min b. WATER TEMP = _____ 4. PUMP 1 – WASH 1 (DETERGENT WASH) a. RECIRCULATION TIME = _____ min b. HEATED AT = _____ F 5. RINSE 1 a. RECIRCULATION TIME = _____ min b. WATER TEMP = _____ 6. THERMAL a. RECIRCULATION TIME = _____ min b. HEATED AT = _____ F 7. DRYING a. TIME = _____ min b. HEATED AT = _____ F

Note: Washers dilution rate might be measured in minutes, seconds, ml/L depending on the machine

Washer #2 – UNIT # ______Washer settings: 1. MOTOR SPEED = ______2. PRE-WASH1 a. RECIRCULATION TIME = _____ min b. WATER TEMP = _____ 3. ENZYME WASH a. SOAKING TIME = _____ min b. WATER TEMP = _____ 4. PUMP 1 – WASH 1 (DETERGENT WASH) a. RECIRCULATION TIME = _____ min Issued by: MF, SM Revision: A First Issue Date: 01/14/2016 Revised by: Revision Date: File: QC\QC\Master Forms\MF#222 Approved by: HG Approval Date: 01/14/2016 MF #222/Rev. A

b. HEATED AT = _____ F 5. RINSE 1 a. RECIRCULATION TIME = _____ min b. WATER TEMP = _____ 6. THERMAL a. RECIRCULATION TIME = _____ min b. HEATED AT = _____ F 7. DRYING a. TIME = _____ min b. HEATED AT = _____ F

Note: Washers dilution rate might be measured in minutes, seconds, ml/L depending on the machine

Post-Installation assessment

Observations

For example:

(Adjustments were made to reduce the amount of product drawn. Temperature was adjusted for the detergent wash cycle in the automated washer. Cycle times were increased to attain a successful outcome. All TOSI and Case Soil wash indicators cleared. The amount of product dispensed at the sink was reduced by a factor of 4 (from 1 oz/gal to 0.25 oz/gal). The product used at the SONIC A was reduced by a factor of 4 (from 1 oz/gal to 0.25 oz/gal).

Note: SONIC B was not installed as it was drawing an uncontrolled amount of product. Once the injector is repaired and calibrated we will install.)

Case Solutions/ SuperNova products used PentaPrep Multi-Enzyme Pre-Soak Spray ___ OR/Decomtam (Ready to use pre-cleaner) SuperNova .___ Multi-Enzymatic Cleaner ___ Sinks/Sonics/Washers SuperNova .___ NpHD Neutral Detergent ___ Washers Lubricant ___ Washers/manual Wipes ___ Manual Ink and adhesive remover ___ Manual SchmutzOff ___ Descaler and reconditioner Case Dry ___ CaseCarts Case Soil Indicator ___ Wash monitor Case Soil Detector ___ Protein residual indicator Brushes ___ Manual cleaning

For NovaPlus Products, identify below: Precleaner______Enzymatic Cleaner ______Detergent______Lubricant______Wipe______Other______

SINK Total amount of gallons of water at the sink per cycle: ___ gallons Staff using hand pump and dispensing ____ oz/gal or ____ applications. Issued by: MF, SM Revision: A First Issue Date: 01/14/2016 Revised by: Revision Date: File: QC\QC\Master Forms\MF#222 Approved by: HG Approval Date: 01/14/2016 MF #222/Rev. A

Issued by: MF, SM Revision: A First Issue Date: 01/14/2016 Revised by: Revision Date: File: QC\QC\Master Forms\MF#222 Approved by: HG Approval Date: 01/14/2016 MF #222/Rev. A

SONIC A Water used per cycle: ____ gallons Detergent used per cycle: ___ ml (____ US fluid oz) ____ oz / ____ gal = ____ oz/gal

SONIC B Water used per cycle: ____ gallons On hold until repaired

AUTOMATED WASHERS (NEW SETTINGS) Note: Temperature and time were adjusted to clear wash indicators.

For Example: (In total, ______additional minutes were required or reduced to achieve a successful outcome.)

New settings are notated below:

Washer #1 – UNIT # ______Washer settings: 1. MOTOR SPEED = ______2. PRE-WASH1 a. RECIRCULATION TIME = _____ min b. WATER TEMP = _____ 3. ENZYME WASH a. SOAKING TIME = _____ min b. WATER TEMP = _____ 4. PUMP 1 – WASH 1 (DETERGENT WASH) a. RECIRCULATION TIME = _____ min b. HEATED AT = _____ F 5. RINSE 1 a. RECIRCULATION TIME = _____ min b. WATER TEMP = _____ 6. THERMAL a. RECIRCULATION TIME = _____ min b. HEATED AT = _____ F 7. DRYING a. TIME = _____ min b. HEATED AT = _____ F

In summary:

A significant amount of product was reduced for the sink and sonic at a significant cost savings. Where automated washers were not passing the wash indicators at all, after installation all coupons cleared and no detectable protein residue was found.

Issued by: MF, SM Revision: A First Issue Date: 01/14/2016 Revised by: Revision Date: File: QC\QC\Master Forms\MF#222 Approved by: HG Approval Date: 01/14/2016 MF #222/Rev. A

Issued by: MF, SM Revision: A First Issue Date: 01/14/2016 Revised by: Revision Date: File: QC\QC\Master Forms\MF#222 Approved by: HG Approval Date: 01/14/2016 MF #222/Rev. A

No changes were made to existing settings. If adjustment is needed, identify. For example: (Temperature was increased for the detergent wash cycle. Seven minutes were added in total to the automated washer to pass replicate cycles. All coupons tested after processing with protein detector showed no blue coloration, the marker for retained protein residuals.)

All product and equipment were adjusted for maximum effectiveness and cost savings. A projected savings of $______per year over existing product was calculated based on current spend, dosing and volume of product required.

Presented to:______Date:______Presented by:______Date:______

Issued by: MF, SM Revision: A First Issue Date: 01/14/2016 Revised by: Revision Date: File: QC\QC\Master Forms\MF#222 Approved by: HG Approval Date: 01/14/2016