Those #*#$%*&#*# Headlights!

By Wayne Torman ([email protected])

“My lights are stuck in the ‘on’ position and they won’t turn over! HELP!”

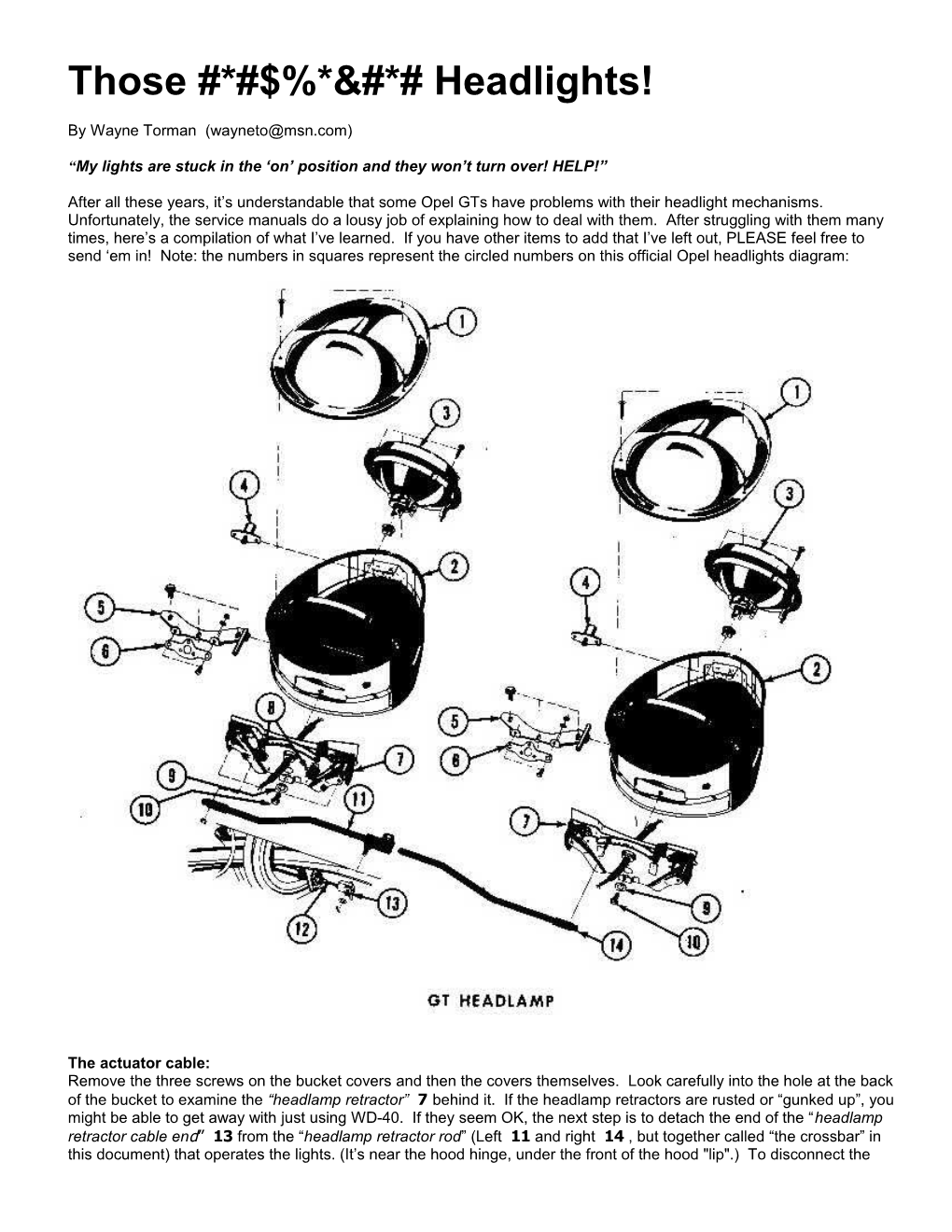

After all these years, it’s understandable that some Opel GTs have problems with their headlight mechanisms. Unfortunately, the service manuals do a lousy job of explaining how to deal with them. After struggling with them many times, here’s a compilation of what I’ve learned. If you have other items to add that I’ve left out, PLEASE feel free to send ‘em in! Note: the numbers in squares represent the circled numbers on this official Opel headlights diagram:

The actuator cable: Remove the three screws on the bucket covers and then the covers themselves. Look carefully into the hole at the back of the bucket to examine the “headlamp retractor” 7 behind it. If the headlamp retractors are rusted or “gunked up”, you might be able to get away with just using WD-40. If they seem OK, the next step is to detach the end of the “headlamp retractor cable end” 13 from the “headlamp retractor rod” (Left 11 and right 14 , but together called “the crossbar” in this document) that operates the lights. (It’s near the hood hinge, under the front of the hood "lip".) To disconnect the cable, remove the cotter pin and washer, and pull the fitting on the end of the cable off of the post that it fits onto. At that point, you might be able to move the headlight buckets manually. If the headlights move but the cable doesn’t, then probably your control cable is frozen or possibly the ball at the base of the operating lever (in the tranny hump) has snapped off. If you think it’s frozen, spray WD-40 into the end of the cable and then work it back and forth (without the lights attached, it’s MUCH easier!). Once it moves freely, oil it up and continue to work the cable until the oil penetrates throughout. If the WD-40 and/or oil don’t do the trick, it might be because it can’t get through to the rest of the cable from the end. You might want to consider either poking a pin-oiler through, or installing a grease fitting on, the outer sheath of the actuator cable. If you do decide to inject oil or grease into the cable, you must do it, at it’s highest point for maximum effectiveness. If you attach the fitting be sure to close it when you are done; if you chose to inject oil into a hole, then be sure to tape over the hole carefully so that no dirt gets in there. Next, reattach the fitting to the post on the crossbar and you might be done if that solved your problem!

Disconnecting the two headlight mechanisms from each other: If the cable *does* move freely after being detached, but the headlights won’t, then it is time to narrow down which of the two buckets is frozen. To do this, you should locate the attachment point of the two halves of the crossbar (the “junction bracket” on the end of 11 with the 6MM Allen head bolt). Mark the bar on the passenger side of the bracket, either by scratching it (preferred method) or by wrapping tape around it, so that you'll know how much to push back in when you reassemble them. Once you’ve marked it, remove the Allen bolt and pull the two halves apart. This *should* result in one of the buckets rolling over a little, since probably only one of them is frozen. Move both halves back and forth to see if either of the buckets will roll. If either one rolls, but the other doesn't, you'll know which one is causing your problem!

Broken, twisted, gnarly evil little special 8mm bolts: For the one (or both... but I sure hope not!) that seems stuck, look through the whole at the back of the bucket to where the wires come through the swivel assembly, and closely inspect the three (8mm I think) bolts around the center circle. If they appear loose or bent or twisted they could be causing the problem. They may just need to be tightened, but they may need to be removed and replaced, or they may even need to be drilled out and replaced. Remove them *very carefully* …if these bolts are AT ALL "too tight" to move, then you MUST use Liquid Wrench or whatever to get them free. DO NOT PUT SO MUCH PRESSURE ON THESE BOLTS THAT YOU RISK SNAPPING THEM OR YOU'LL BE *VERY* SORRY BECAUSE DRILLING THEM OUT SUCKS! If you must drill them out, it might be possible without removing the buckets from the car, but I don’t believe that I’ve ever actually done that. Unfortunately, these bolts are unique and quite hard to find, at least at hardware and auto parts stores. The Opel vendors probably have them, if you don’t have access to a stash of them yourself. Of course, it’s great to salvage them from junked Opel GTs if you can!

“Swivel strips”: If you have faith in Opel, then you’ll believe that they used such thin metal on purpose, as a… failsafe… yeah… that’s it… a failsafe… or maybe a cushion… sure. Sometimes, the two or three (I think it varies from car to car) thin metal plates (“headlamp retractor connector shackles” 6 – but I prefer to call them “swivel strips”) between the “headlamp retractor connector” 5 (“swivel plates”) and the “headlamp retractor” 7 can break or rip and might need to be replaced. If so, you can either buy one from one of the Opel vendors (I imagine – I haven’t asked) or make it yourself. If the plate just ripped in half, you can hold the two pieces together to make a pattern on light cardboard to transfer to sheet metal. But if the thing is fairly destroyed, you may then have to open up and get the ones from the other bucket out just to make the pattern. You really want to just buy these somewhere. Really.

Before you can remove the buckets: The next step might be to remove the entire bucket(s) (officially known as “headlamp housings” 2 ) from the car (

Removing the buckets: Removing the bucket (see next page) Very important: Once you've got all the bolts out, so that the bucket has dropped down into the oval-shaped hole in the body, you MUST use masking tape to protect the entire opening that the bucket fits into. PLEASE, DO NOT remove the buckets without the tape in place!!! To actually remove a bucket, "roll" it (down in the hole) so that the side of the bucket is at its highest point, then slowly tilt the front down and carefully roll the back of the bucket up and out as you sort of “twist-roll” it out of the hole. (Aren’t you glad you used the masking tape now?)

Removing the headlamp retractor assemblies: Once the buckets are out, you've got a somewhat better view of the headlamp retractor so either you'll see the problem immediately, or you'll have to remove the headlamp retractor assembly just to find out. I have seen many that were broken, so apparently it's not that unusual... but the moving parts are all behind it, so unfortunately, you have to remove it to get a clear picture, or get to and replace the microswitches if they are your problem. Another unfortunate thing is that if you do have to remove the assembly, you can't really mark the positions of two of the three 10mm bolts that hold it in place. Those two bolts are behind a little plate at the front of the inside of the wheel well, so just remove the four screws and the plate and then the two bolts behind that. (It is possible to mark the lower of the two bolts in there, but very hard to see while you are reinstalling, so it’s sort of pointless.) The third bolt is up in the engine compartment just under the hood lip, near the master cylinder and behind a hole in the sheet metal. That one should be marked before removing. For that top one on the driver's side, by the way, I strongly recommend that you go to Sears or find a Snap- On truck and get a ¼” drive 10MM socket with a swivel built in, so that you can get to it more easily. It is not a fun bolt to remove OR reinstall at all, and this tool really helps!

The microswitches:

Headlight Headlight Indicator Relay Switch Switches

Figure 2. Wiring for the microswitches (assemblies shown in detached and lowered position)

Once you’ve “dropped” the swivel assemblies, you can examine the mechanics and the switches (along with their wiring). Usually, the only way to know if the microswitches themselves need to be replaced is to remove the wires from them and then use an ohmmeter or some other continuity tester on the leads (prongs) from the switch. The various prongs on the switches are NO (normally open), NC (normally closed) and COM (common) as marked in Figure 2, above. To test them, make sure that NO connects to COM, but only when the lever is pressed, and NC connects to COM only when the lever isn’t pressed! If you do need to replace the microswitches, be sure to follow the diagram above. By the way, if you are in here looking at the wiring and you haven’t yet replaced the last foot and a half or so of the headlight power and ground wires leading through the hole to the headlights, this is a SUPERB time to do it…

Replacing the headlight power and ground wires: Be sure to use #12 Marine quality (it’s better than the original!) wiring of the proper colors - white, yellow and brown. Cut the old wires off just short of the headlight plug. Tape the three wires together, with a sturdy piece of string taped in (leading away from the wires) as well. (This string will be used later to easily pull the new wires back out through the hole.) With wires and string securely taped, pull the three-wire bundle through the assemblies and out through the sheet metal under the hood lip. Carefully cut and unravel some of the tape on the old wires BEFORE cutting them. Examine the plastic coating on the wires. Unfortunately, the original headlight wire, though extremely flexible when it was new, has a tendency to get brittle when it gets old, which is what usually causes headlight-shorting problems in the first place! Make sure you unravel the tape far enough back to splice the new leads into wire that still has soft, flexible plastic coating.

Putting it all back together: When you are ready to put the retractor assemblies back in, just put them in there approximately, paying attention to where you marked the top hole, but not necessarily too closely, since you’ll be loosening and adjusting it again shortly. Do the rest of the reassembly of the buckets in the reverse of the order above, carefully following the marks that you made before disassembly. Reconnect the crossbar by pushing the two halves together to the mark you made earlier and tightening the 6MM Allen bolt. Reconnect the retractor cable to the fitting on the crossbar; put the washer and cotter pin in place. When all of the pieces are back together, loosen and re-adjust the three retractor assembly bolts (in the wheel well and the engine compartment) until the headlight(s) can roll over while clearing the body hole without touching any edges. Roll the headlights to the “closed” position.

Adjusting the position of the buckets in the body: This is where the PERFECT adjustment has to be made… you are not done reinstalling your headlights until they fit flush and even with the body holes in the closed position! The unfortunate thing is that you can’t support the bucket in the closed position, so you have to actually make the adjustments in the open position and then proceed by trial-and- error. Plan which way you are going to adjust them next, open the lights, loosen the bolts slightly, adjust to the planned new position, and then re-tighten the bolts, then check it in the closed position, and repeat this cycle until they fit just right! Go very slowly in rolling the buckets over after each new adjustment, to make sure that they don’t bang against any edges! Once you are sure that the bucket will clear, use full force on the lever to lock the lights in place so that you can make an accurate next adjustment of the swivel bracket.

Possible adjustments: If you need to move the bucket forward in the car, you should loosen the large bolt at the center of the front support plate, and if necessary, slightly loosen the three bolts on the horizontal support plate and slide the whole bucket forward. To move the bucket rearwards, tighten the front center bolt and, if necessary, loosen the horizontal support plate and slide the whole bucket rearwards. To move the front from side to side or up and down, loosen the two bolts of the front support plate and adjust the bucket relative to the plate as necessary. To move the rear from side to side, or up and down it might be easiest to move the whole swivel assembly or to loosen the bolts that attach to the “swivel strips” and allow you to move the swivel plate around, depending on the circumstances. To make sure that the lights operate in parallel (i.e. are both fully open or closed at the same time), loosen the 6MM Allen bolt and adjust the length of the crossbar by pushing or pulling on the passenger side bar and then re-tightening the bolt until they operate together.

What’s left?: Once the buckets have been rewired or replaced or reinstalled or just adjusted, you should be sure to keep them well- lubricated and clear of debris, because you’ll never want to have to do this again!

PLEASE let me know if any of this is inaccurate or unclear or if you know other things about the headlights that I haven’t covered. I’d love to extend this article with a “Part 2” containing such additional information. You can either e-mail it to me at [email protected] or you can “snail mail” it to Charles Goin at the club’s address and he’ll get it to me!