Document Number: ECP 11-0218

Version: 3.0

Date: 30/01/2017

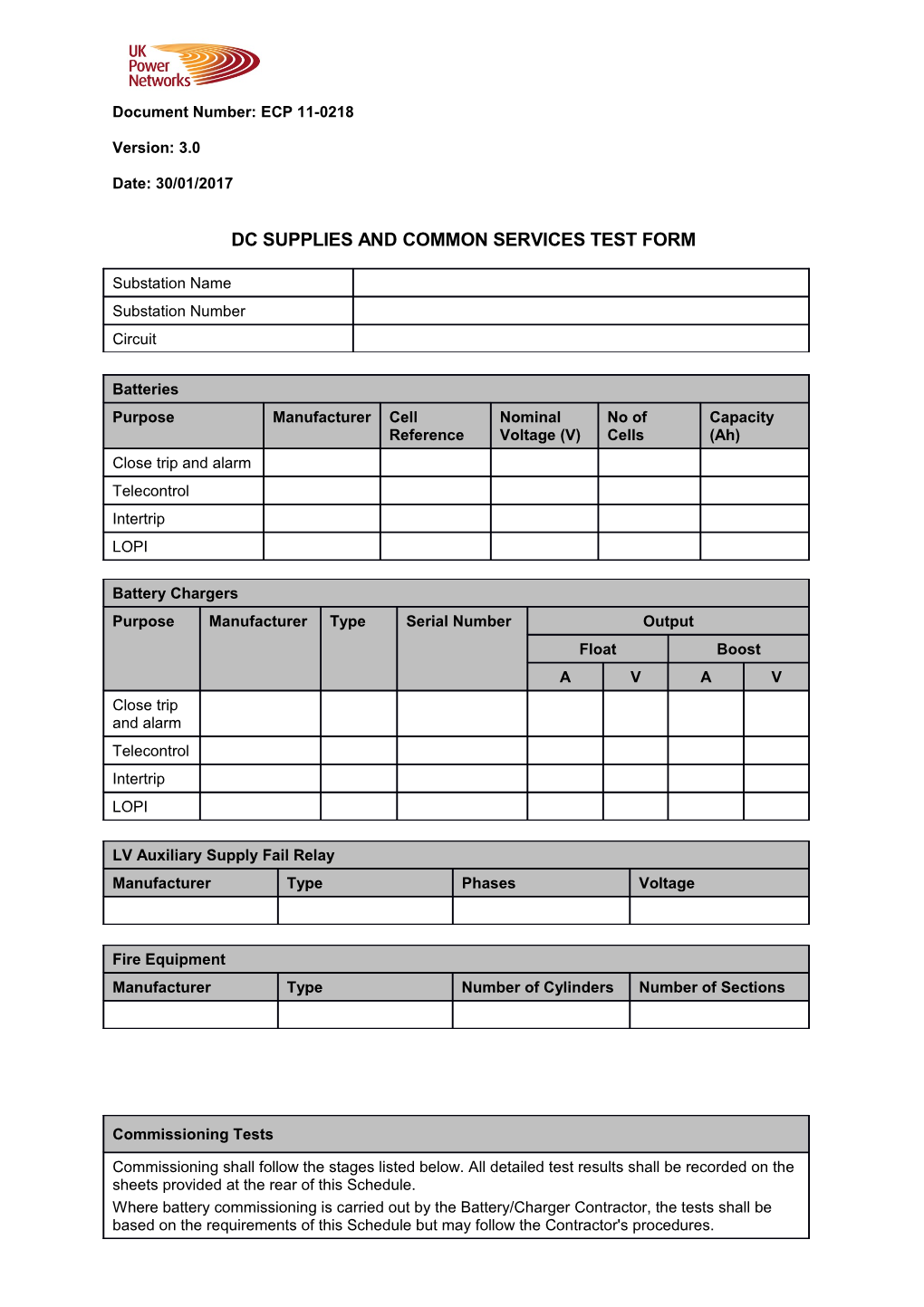

DC SUPPLIES AND COMMON SERVICES TEST FORM

Substation Name Substation Number Circuit

Batteries Purpose Manufacturer Cell Nominal No of Capacity Reference Voltage (V) Cells (Ah) Close trip and alarm Telecontrol Intertrip LOPI

Battery Chargers Purpose Manufacturer Type Serial Number Output Float Boost A V A V Close trip and alarm Telecontrol Intertrip LOPI

LV Auxiliary Supply Fail Relay Manufacturer Type Phases Voltage

Fire Equipment Manufacturer Type Number of Cylinders Number of Sections

Commissioning Tests

Commissioning shall follow the stages listed below. All detailed test results shall be recorded on the sheets provided at the rear of this Schedule. Where battery commissioning is carried out by the Battery/Charger Contractor, the tests shall be based on the requirements of this Schedule but may follow the Contractor's procedures. Stage 1 – After Erection of Battery, Charger and Switchboard and Connection of AC Supply to Charger, but Before Equipment is Required for Use

Objective - to ensure erection is carried out satisfactorily and that working equipment is available for Stage 2 tests; also to maintain the battery charge level until required for service.

()

Check erection of battery, charger and switchboard and interconnection of same Measure and record individual cell terminal voltages and specific gravities (where appropriate) of battery 'as received', before charger is connected and switched on Check presence and value of all fuses Check insulation to earth of battery connections, using 1000V megger Check insulation to earth of charger and switchboard, using 1000V megger. Advise Commissioning Engineer if any drying out required Check AC supply fuse and connections to Charger, and that correct supply is available Check that Charger operates normally in both 'float' and 'boost' outputs. Record 'float' and 'boost' charger voltages and currents. (This does not necessitate carrying out the functional tests required in stage 2.) At the end of these tests the charger is to be left in the 'Float' position with an AC supply on Note: If it is not practicable to maintain the Battery on continuous float charge between stages 1 and 2, agreement shall be reached with the Battery Manufacturer on the procedure to be adopted. No discharge shall be taken from the battery prior to Stage 2. DC Supplies and Common Services Test Form Document Number: ECP 11-0218

Version: 3.0

Date: 30/01/2017

Stage 2 - When DC Supply System is Complete and Immediately Prior to Placing into Service

() Ensure that the battery is in a charged condition prior to commencement of tests. This can be checked by reading the specific gravity of electrolyte in one cell, or for sealed cells, by reading the terminal voltage with charger 'off' and no load Repeat Stage 1 test (5), unless Stages 1 and 2 are carried out concurrently when there will be no necessity to repeat (For Plante cells only) Top up battery, if necessary, with distilled water. De- mineralised water may be used subject to approval by the battery manufacturer Connect load equivalent to approximately 50% of charger rating and, with charger switched off, check that battery discharges correctly into it (instrument polarities correct, etc.) also that low voltage alarm relay operates. Discharge need not exceed 10-15 minutes Switch charger on and to 'float'. Check charger attains full rated output (this rate may last for a short time only if Battery is in a fully charged condition) and that current-limit feature operates Switch charger to 'boost' and, with load still connected, check that full rated output is obtainable. Note that maximum charger output may only persist for a short time before tapering down Note, for sealed gas recombination cells, 'boost' charging must be kept to the minimum period Switch charger back to 'float' position and, with load still connected, check that DC standing voltage is within limits required by the specification. Remove load, and check that voltage remains within limit The correct 'float' voltage is carefully set-up and locked during test at the charger manufacturer's works, and should not normally require adjustment on-site Check operating voltage of low voltage, charger fail (abnormal) and high voltage alarm relays. Record values on forms attached. Check operation of earth fault detector by connecting each pole of the system to earth in turn, via a 47k resistor (For Plante cells only) Disconnect load, switch charger to 'boost', and continue until battery is fully charged. Then record specific gravity and voltage of each cell (with charging current still flowing) (For all cell designs) Switch charger to 'float' and leave. It is important that an AC supply to the charger shall be maintained continuously from this point onwards, and the charger left in the 'float' position in order to keep the battery fully charged. Record all cell or monoblock terminal voltages on the form attached Note, on some chargers the 'float' output may be labelled 'normal', whilst the 'boost' output may be selected on some by means of change over links inside, and on others by means of a switch either on the front or inside Test operation of substation auxiliary supply fail relay, by reducing each phase input voltage in turn, and record operating voltages. Check operation of telecontrol Alarm Test operation of fire Protection equipment telecontrol alarm (where fitted)

© UK Power Networks 2017 All rights reserved 3 of 12 Type Purpose Date Cell Temperature C Cell Temperature C SG Correction Factor SG Correction Factor BATTERY AS-RECEIVED BATTERY AS-RECEIVED Cell SG V Cell SG V Cell SG V Cell SG V 1 31 1 31 2 32 2 32 3 33 3 33 4 34 4 34 5 35 5 35 6 36 6 36 7 37 7 37 8 38 8 38 9 39 9 39 10 40 10 40 11 41 11 41 12 42 12 42 13 43 13 43 14 44 14 44 15 45 15 45 16 46 16 46 17 47 17 47 18 48 18 48 19 49 19 49 20 50 20 50 21 51 21 51 22 52 22 52 23 53 23 53 24 54 24 54 25 55 25 55 26 56 26 56 27 57 27 57 28 58 28 58 29 59 29 59 30 60 30 60 Check battery polarity () Initial charger checks Switch charger to float, check output A V Switch charger to boost, check output A V DC Supplies and Common Services Test Form Document Number: ECP 11-0218

Version: 3.0

Date: 30/01/2017

Type Purpose Date Cell Temperature C Cell Temperature C SG Correction Factor SG Correction Factor BATTERY AS-RECEIVED BATTERY AS-RECEIVED Cell SG V Cell SG V Cell SG V Cell SG V 1 31 1 31 2 32 2 32 3 33 3 33 4 34 4 34 5 35 5 35 6 36 6 36 7 37 7 37 8 38 8 38 9 39 9 39 10 40 10 40 11 41 11 41 12 42 12 42 13 43 13 43 14 44 14 44 15 45 15 45 16 46 16 46 17 47 17 47 18 48 18 48 19 49 19 49 20 50 20 50 21 51 21 51 22 52 22 52 23 53 23 53 24 54 24 54 25 55 25 55 26 56 26 56 27 57 27 57 28 58 28 58 29 59 29 59 30 60 30 60 Check battery polarity () Initial charger checks Switch charger to float, check output A V Switch charger to boost, check output A V

© UK Power Networks 2017 All rights reserved 5 of 12 Type Purpose Date Cell Temperature C Cell Temperature C SG Correction Factor SG Correction Factor BATTERY AS-RECEIVED BATTERY AS-RECEIVED Cell SG V Cell SG V Cell SG V Cell SG V 1 31 1 31 2 32 2 32 3 33 3 33 4 34 4 34 5 35 5 35 6 36 6 36 7 37 7 37 8 38 8 38 9 39 9 39 10 40 10 40 11 41 11 41 12 42 12 42 13 43 13 43 14 44 14 44 15 45 15 45 16 46 16 46 17 47 17 47 18 48 18 48 19 49 19 49 20 50 20 50 21 51 21 51 22 52 22 52 23 53 23 53 24 54 24 54 25 55 25 55 26 56 26 56 27 57 27 57 28 58 28 58 29 59 29 59 30 60 30 60 Check battery polarity () Initial charger checks Switch charger to float, check output A V Switch charger to boost, check output A V DC Supplies and Common Services Test Form Document Number: ECP 11-0218

Version: 3.0

Date: 30/01/2017

DC Circuits

Insulation Tests 1000V Megger Disconnect Circuits from battery and charger.

Battery Supply to Charger DC Board or Remote DC Board

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Closing (Solenoid) Supplies – Section 1

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Closing (Solenoid) Supplies – Section 2

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Trip and Close Alarm Supplies – Section 1 (Transformers)

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

© UK Power Networks 2017 All rights reserved 7 of 12 Trip and Close Alarm Supplies – Section 2 (Transformers)

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Trip and Close Alarm Supplies – Section 1 (Feeders)

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Trip and Close Alarm Supplies – Section 2 (Feeders)

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Other Supplies (e.g. Auto Switching or Tap Change Control Common DC Supply)

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Number 1 Number 2 Cable Low Oil Pressure Circuits – Battery Supplies Circuit Circuit

DC polarity check () () Fuse rating and link proved for correct function () () Insulation resistance between cores MΩ MΩ Insulation resistance positive to earth MΩ MΩ Insulation resistance negative to earth MΩ MΩ

Number 1 Number 2 Intertrip Circuits – Battery Supplies Circuit Circuit

DC polarity check () () Fuse rating and link proved for correct function () () Insulation resistance between cores MΩ MΩ DC Supplies and Common Services Test Form Document Number: ECP 11-0218

Version: 3.0

Date: 30/01/2017

Insulation resistance positive to earth MΩ MΩ Insulation resistance negative to earth MΩ MΩ

Charger Circuits It is recommended that tests to detect possible earth faults on the charger be carried out in such a way as to include as much of the dc circuitry as practicable. For batteries that are 'unearthed' and not fitted with a Battery Earth Fault Alarm detection circuit, under healthy conditions a Voltmeter connected from battery terminals to earth should indicate either no, or a very low value, of standing voltage. If significant readings are obtained, then the lower voltage indicates the leaky or faulty pole. Where a Battery Earth Fault Alarm is installed, this will effectively place a high-impedance earth connection on the centre-point of the battery, so that under healthy conditions each battery pole will be at approximately half battery voltage to Earth. If the readings are greatly different, then the lower voltage indicates the leaky or faulty pole. Battery Purpose DC voltages measured from: Positive terminal to earth V V V Negative terminal to earth V V V

Telecontrol 48V Battery Supplies

Ensure terminal equipment e.g. outstation is disconnected at remote end before carrying out insulation tests.

Switchgear Marshalling Cabinet Supplies

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Tap Change Marshalling Cabinet Supplies

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Channelling Equipment Supplies

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ

© UK Power Networks 2017 All rights reserved 9 of 12 Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

Data Concentrator and/or Outstation Supplies

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

PAX Supplies

DC polarity check () Fuse rating and link proved for correct function () Insulation resistance between cores MΩ Insulation resistance positive to earth MΩ Insulation resistance negative to earth MΩ

110V Battery High volt alarm Setting 128V Operates at V High volt alarm time delay (1-5s nominal) () Low volt alarm (switchgear to BS 116) Setting 94V Operates at V Low volt alarm (switchgear to BS 5311/IEC 56) Setting 100V Operates at V Low volt alarm time delay 20-50ms () Charger fail alarm Setting 118V Operates at V Charger fail alarm time delay (1-5s nominal) ()

48V Battery High volt alarm Setting 56V Operates at V High volt alarm time delay (1-5s nominal) () Low volt alarm Setting 47V Operates at V Charger fail alarm Setting 51V Operates at V Charger fail alarm time delay (1-5s nominal) ()

Battery Alarm Circuits (with marshalling cabinet links open)

Insulation Resistance 110V Battery 48V Battery High volt alarm between cores X37-X2 M M to earth X37-E M M Low volt alarm between cores X45-X2 M M to earth X45-E M M Charger fail alarm between cores X51-X2 M M to earth X51-E M M DC Supplies and Common Services Test Form Document Number: ECP 11-0218

Version: 3.0

Date: 30/01/2017

Battery Alarm Circuits (with marshalling cabinet links open)

Insulation Resistance 110V Battery 48V Battery Common to earth X2-E M M Common to earth W2-E M M

Alarm Checks 110V Battery 48V Battery

Low volt alarm () () Check receipt of alarm signal at marshalling High volt alarm () () cabinet links Charger fail alarm () ()

Substation LV Supply Monitoring (Auxiliary Supply Fail)

Phase Voltage Auxiliary Supply Fail Relay Reduced Setting Operating With normal voltages supplied check output Red relay energised. Next reduce voltage of each Yellow phase in turn and note voltage at which output relay de-energises Blue

Supply Fail Alarm Circuit

Ensure marshalling cabinet links are open Insulation resistance between cores X57-X2 M Insulation resistance to earth X57-E M Check alarm received at marshalling cabinet link ()

Fire Protection Alarm

Ensure marshalling cabinet links are open Insulation resistance between cores X35-X2 M Insulation resistance to earth X35-E M Check alarm received at marshalling cabinet link ()

© UK Power Networks 2017 All rights reserved 11 of 12 Comments

Test Equipment

Purpose Make/Type Serial Number

Certification ()

Attach manufacturer’s specific tests (if applicable) All tests have been completed satisfactorily

Contractor Commissioning Engineer (if applicable)

Organisation Name

Date Signature

UK Power Networks Commissioning Engineer

Name Signature Date