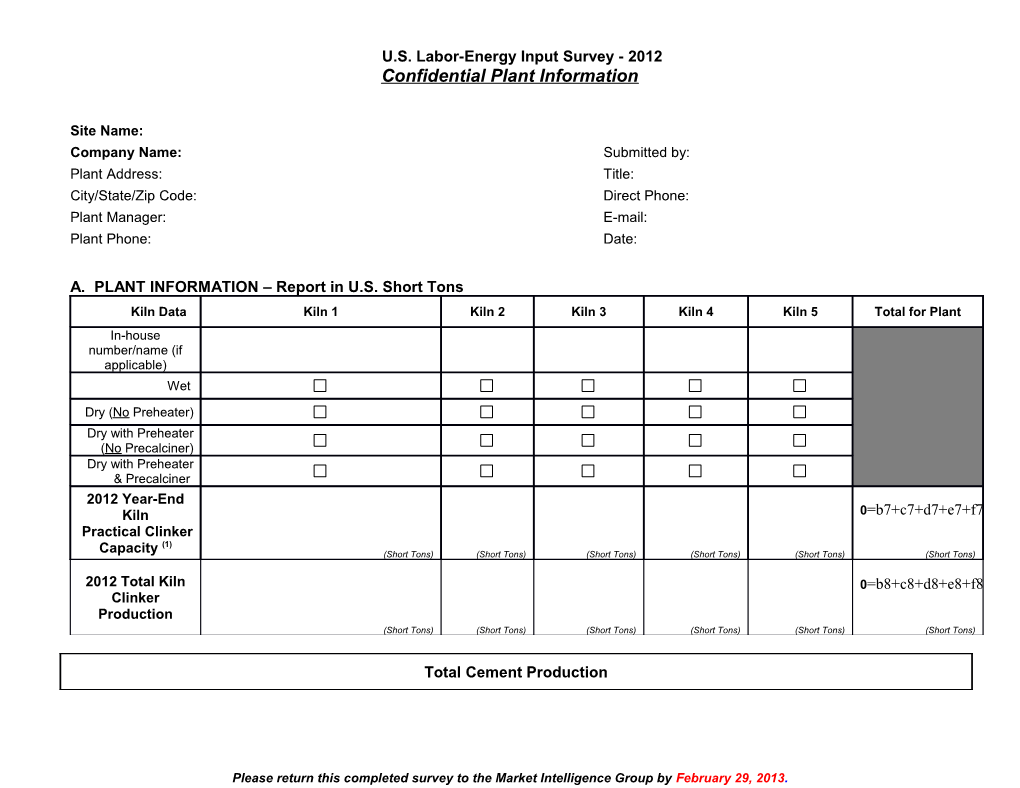

U.S. Labor-Energy Input Survey - 2012 Confidential Plant Information

Site Name: Company Name: Submitted by: Plant Address: Title: City/State/Zip Code: Direct Phone: Plant Manager: E-mail: Plant Phone: Date:

A. PLANT INFORMATION – Report in U.S. Short Tons Kiln Data Kiln 1 Kiln 2 Kiln 3 Kiln 4 Kiln 5 Total for Plant In-house number/name (if applicable) Wet

Dry (No Preheater) Dry with Preheater (No Precalciner) Dry with Preheater & Precalciner 2012 Year-End Kiln 0=b7+c7+d7+e7+f7 Practical Clinker (1) Capacity (Short Tons) (Short Tons) (Short Tons) (Short Tons) (Short Tons) (Short Tons)

2012 Total Kiln 0=b8+c8+d8+e8+f8 Clinker Production (Short Tons) (Short Tons) (Short Tons) (Short Tons) (Short Tons) (Short Tons)

Total Cement Production

Please return this completed survey to the Market Intelligence Group by February 29, 2013. 2 Portland Masonry Blended Hydraulic Other Total 2012 Total Plant Finished Cement Production 0=b2+c2+d2+e2+f2

(Short Tons) (Short Tons) (Short Tons) (Short Tons) (Short Tons) (Short Tons)

(1) Practical Clinker Capacity = 365 days less normal down days x daily practical capacity

B. LABOR DATA

Plant Function Number of Employees Employee Hours

Salaried Hourly Contracted Total Salaried Hourly Contracted Total

0=b3+c3+d3 0=f3+g3+h3

Direct Labor

0=b4+c4+d4 0=f4+g4+h4 Indirect Labor

TOTAL LABOR 0=b3+b4 0=c3+c4 0=d3+d4 0=e3+e4 0=f3+f4 0=g3+g4 0=h3+h4 0=i3+i4 3

LABOR DATA DEFINITIONS

Report the number of employees and total annual hours worked for direct and indirect labor. If the number of employees fluctuated during the year, report the number that would be considered to be typical under normal operations. Part-time employees and hours should be reported as fractional and combined to equal full time employee count (e.g. two ½ time employees = 1 full time). Exclude vacation time, sick leave, holidays, and any other time that the employee was paid but did not work. Some plants contract with outside firms to have work done, such as general plant maintenance, refractory work and quarrying. Please report these workers as contracted workers by their plant function.

Report employee and employee hours for the entire plant payroll by function for hourly, salaried, and contracted labor. If time records are not kept for certain employees, an estimate of their time should be made using 2080 hours plus overtime but minus time not worked. Report all employee hours, including contracted employee hours, related specifically to the production of cement.

Exclude from this survey any labor such as personnel, purchasing, accounting, secretarial, sales, traffic and engineering workers, laboratory research workers, and corporate office workers who might be at the facility but are not directly related to the production process.

Direct labor hours for salaried, hourly, and contracted labor should include labor involved in raw material handling, production, distribution and maintenance.

Indirect labor should encompass the following:

(1) general labor and mill indirect, meaning production personnel not allocated to a specific department, e.g., the plant manager, superintendent, foremen, computer control personnel, clerks, timekeepers, watchmen, storekeepers, and other miscellaneous personnel related to the production of cement (2) laboratory, including both salaried and hourly employee hours used at the plant by chemists and assistants involved in quality control (exclude laboratory time allotted for research)

If employee hours are not separable by type of compensation, please indicate totals only.

Company & City: C. PLANT FUEL AND POWER SUMMARY (1) Fuel Consumption (2) Conversion factor (Btu per Unit) PRIMARY FUELS (Sum should equal total for each fuel type) (High Heat Content)

R a w

M a t e r i a l H a n d Raw l Material i Drying Fuel Handling, n and Drying and Clinkering and Finish Non- Specified by Default value Type Units Amount g Grinding Grinding Cooling Grinding Distribution Process respondent if not specified

Gasoline gallons = + + + + + + 125,071 Btu/gal

Diesel gallons = + + + + + + 129,500 Btu/gal

Fuel Oil gallons = + + + + + + 138,690 Btu/gal

22,565,000 Coal tons = + + + + + + Btu/ton

Residual Oil gallons = + + + + + + 149,690 Btu/gal

million 1,030,000,000 Natural Gas cubic feet = + + + + + + Btu/MMCF per mm ft3 Petroleum 30,120,000 Coke tons = + + + + + + Btu/ton

LPG gallons = + + + + + + 85,857 Btu/gal

1,000 kilowatt 3,412,000 Btu/ Electricity hr = + + + + + + 1000 kWh

ALTERNATIVE FUELS (Specify alternative fuel type, units (i.e. tons, gallons, pounds), and Btu conversion factor per unit) Units Amount

Renewable* = + + + + + + Btu /

Type:

Waste Oil = + + + + + + Btu / Solvents = + + + + + + Btu /

Tire Derived = + + + + + + Btu /

Other Solid = + + + + + + Btu /

Type: Other:

= + + + + + + Btu / (1) Fuels used for electricity co-generation should not be reported. (2) See Appendix for Descriptions Biomass, Biofuels, Wind, etc. Company & City: D. Kiln Fuel and Power Summary (1) (Skip if only 1 kiln operation.) (Sum of kilns should equal total amount for each fuel type provided in Section C) Amount Type Units (Total) Kiln 1 Kiln 2 Kiln 4 Kiln 5

In-house kiln number/na me (if applicable)

Gasoline Gallons = + + + +

Diesel Gallons = + + + +

Fuel Oil Gallons = + + + +

Coal Tons = + + + +

Residual Oil Gallons = + + + +

Million Natural Gas cubic feet = + + + +

Petroleum Tons Coke = + + + +

LPG Gallons = + + + +

1,000 Electricity kilowatt hr = + + + + Alternative Specify alternative fuel type and units (i.e., short tons, gallons, pounds, etc.) Fuels

Renewable* = + + + +

Type: Waste Oil = + + + +

Solvents = + + + +

Tire Derived = + + + +

Other Solid = + + + +

Type: Other: = + + + +

(1) Fuels used for electricity co-generation should not be reported. Biomass, Biofuels, Wind, etc. Company & City:

APPENDIX

Raw Material Handling - Raw material handling should encompass all energy used at the plant to quarry, crush, preblend, and store all raw materials including limestone, shale, clay, gypsum, etc.

Raw Material Drying and Grinding - This begins at the discharge from raw material storage and ends at the kiln feed inlets. Dry-process plants should report all energy used to operate drying equipment, conveyors, grinding mills, classifiers, dust collectors, homogenizers, blending silos, and kiln feed storage equipment. Wet- process plants should report energy used to operate proportioning equipment, grinding mills, pumps, classifiers, mixers, and agitators.

Fuel Handling, Drying and Grinding - Fuel handling, drying and grinding category encompasses the energy required to process the fuel from storage location to injection into the kiln.

Clinkering and Cooling - Clinkering and cooling starts at the kiln-feed inlet and ends at the inlets to finish grinding mills. Plants should report all energy used to operate the kilns, clinker coolers, dust collectors, conveyors, and coal mills.

Finish Grinding - Finish grinding should include all energy required to operate finish grinding mills, classifiers, dust collectors, conveyors, cement coolers, and pumps.

Distribution - Distribution includes the energy required to operate the plant's cement storage facilities, pack houses, bagging, and palletizing equipment and bulk loading equipment. Include only the fuels consumed at the plant site for distribution. The energy used to operate company-owned trucks, boats, barges, or train engines should be excluded.

Non-Process - The energy required for facility heating, ventilation, and air conditioning; also lighting and facility support.