Last Name ______First Name ______ID ______

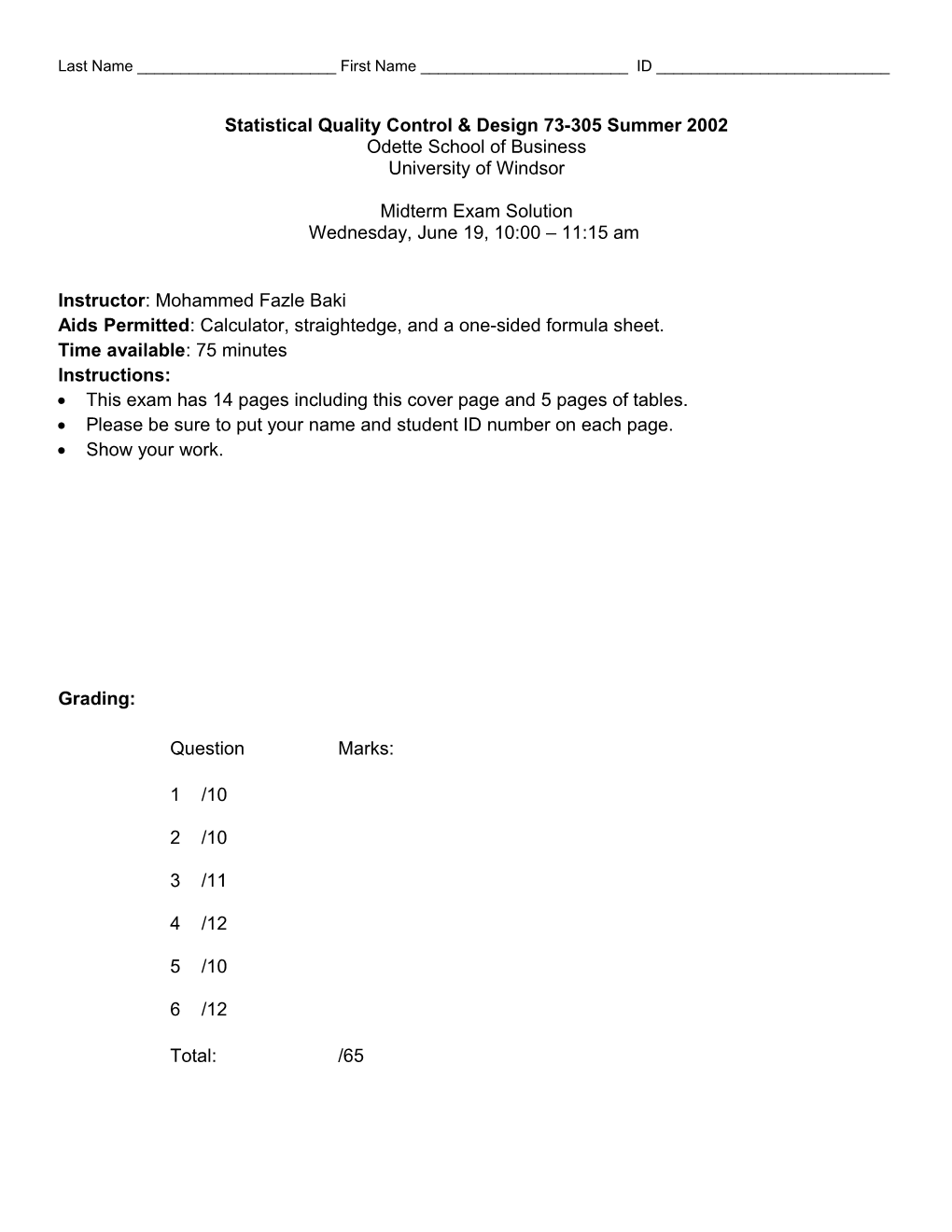

Statistical Quality Control & Design 73-305 Summer 2002 Odette School of Business University of Windsor

Midterm Exam Solution Wednesday, June 19, 10:00 – 11:15 am

Instructor: Mohammed Fazle Baki Aids Permitted: Calculator, straightedge, and a one-sided formula sheet. Time available: 75 minutes Instructions: This exam has 14 pages including this cover page and 5 pages of tables. Please be sure to put your name and student ID number on each page. Show your work.

Grading:

Question Marks:

1 /10

2 /10

3 /11

4 /12

5 /10

6 /12

Total: /65 Name:______ID:______

Question 1: (10 points)

1.1 ______illustrate a chain of symptoms leading to the true cause of a problem. a. Cause and effect diagrams b. Why-why diagrams

1.2 A ______ranks causes of problems a. cause and effect diagram b. Pareto chart

1.3 A ______is a graphical summary of the frequency distribution of the data a. Pareto chart b. histogram

1.4 A ______is a data-recording device. a. check sheet b. histogram

1.5 A ______is used to analyze the relationship between two different variables. a. Run chart b. Scatter diagram

1.6 In a flowchart, a circle represents a. operation b. inspection

1.7 Force-field analysis is used during a. plan b. do c. study d. act

1.8 ______state product or service characteristics in terms of desired dimension a. Specification limits b. Control limits

1.9 ______emphasizes prevention of defects a. Statistical quality control b. Statistical process control

1.10 If measurement of an item does not meet specification a. the item is defective b. the process is out-of-control c. both d. none

2 Name:______ID:______

Question 2: (10 points) a. (5 points) A large bank establishes X and R charts for the time required to process applications for its charge cards. A sample of 5 applications is taken each day. The six weeks (30 days) of data give X 20 min and R 10 min. Calculate the centerline and trial control limits for the X and R charts.

n 5, A2 0.577 (See Appendix 2) UCL X A R 20 0.577 10 25.77 min X 2 LCL min X X A2 R 20 0.57710 14.23

D3 0, D4 2.114 (See Appendix 2)

UCLR D4 R 2.11410 21.14 min

LCLR D3 R 010 0 min b. (5 points) The bank decides to take a sample of 15 applications each day and establish X and s charts. Another six weeks (30 days) of data give X 20.5 min and s 4 min. Calculate the centerline and trial control limits for the X and s charts.

n 15, A3 0.789 (See Appendix 2) UCL X A s 20.50 0.789 4 23.656 mm X 3 UCL mm X X A3 s 20.50 0.7894 17.344

B3 0.428, B4 1.574 (See Appendix 2)

UCLs B4 s 1.5744 6.288 mm

LCL s B3 s 0.4284 1.712 mm

Question 3: (11 points)

A certain manufacturing process has been operating in control at a mean of 70 mm and a standard deviation 0.10 mm. Assume a normal distribution of this dimension. a. (3 points) If the specifications are 700.25 mm, what proportion of products are defective?

Proportion of defective = Pa randomly selected item is defective PX USL or X LSL PX USL PX LSL PX 70.25 | 70, 0.10 PX 69.75 | 70, 0.10 70.25 70 69.75 70 P z P z Pz 2.5 Pz 2.5 0.10 0.10 1 0.9938 0.0062 (See Appendix 1) 0.0124

3 Name:______ID:______b. (1 point) If a control chart is used with a subgroup size of four, what is the standard deviation of subgroup means?

0.10 0.05 X n 4 c. (3 points) Type I error probability: Suppose that the control limits on X chart are 700.14 mm. If the subgroup size is four, what is the probability of a subgroup mean falling outside the control limit when the process mean is not changed?

n 4, 70 mm, 0.05 mm, UCL 70.14 mm, LCL 69.86 mm X X X Probability Type I error, UCL or LCL UCL LCL PX X X X PX X PX X P X 70.14 | 70, 0.05 P X 69.86 | 70, 0.05 X X 70.14 70 69.86 70 P z P z Pz 2.8 Pz 2.8 0.05 0.05 1 0.9974 0.0026 (See Appendix 1) 0.0052 d. (4 points) Type II error probability: If the control limits and the subgroup size are as stated in parts b and c, what is the probability of not detecting a shift in the mean to 70.05 mm on the first subgroup sampled after the shift occurs?

ProbabilityType II error, P LCL X UCL | ' 70.05, 0.05 X X X P 69.86 X 70.14 | ' 70.05, 0.05 X 69.86 70.05 70.14 70.05 P z 0.05 0.05 P 3.8 z 1.8 Pz 1.8 Pz 3.8 0.9641 0.0001 (See Appendix 1) 0.9640

4 Name:______ID:______Question 4: (12 points)

A quality analyst is checking the process capability associated with the production of struts, specifically the amount of torque used to tighten a fastener. A total of 30 subgroups each of size 5 have been taken. The upper and lower control limits for the X chart are 79.5 Nm and 77.5 Nm, respectively. X is 78.5 Nm. R is 1.733 Nm. The specification limits are 79 Nm 4. Calculate ^ a. (2 points) 6

n 5,d 2 2.326 (See Appendix 2) ^ R 1.733 0.7451 d 2 2.326 ^ 6 6 0.7451 4.4703

b. (4 points)C p

USL - LSL 83 75 C p ^ 1.7896 6 4.4703

c. (4 points)C pk

USL - X 83 - 78.5 zUSL ^ 6.0395 0.7451 X LSL 78.5 - 75 zLSL ^ 4.6974 0.7451 zmin min6.0395,4.6974 4.6974 zmin 4.6974 C 1.5658 pk 3 3

d. (2 points) Interpret the values of C p and C pk

C p 1.7896 1, so the variation is small

C pk 1.5658 1, so the process is capable of meeting the specification

Note: zUSL 6.0395 4.6974 zLSL, so the process is not centered.

5 Name:______ID:______Question 5: (10 points)

Using the information shown below, compute per period total cost of sampling, searching, and operating in out-of-control condition when n 5 and k 2.5 . Economic design of X-bar control chart Sampling cost, a 1 $2 per item Search cost, a 2 $100 per search Cost of operating out of control, a 3 $600 per period Prob(out-of-control in one period), 0.03 Number of by which mean shift, 1.5 (when the process is in out-of-control condition)

n 5 k 2.5

k 0.0124 k sqrt(n)-k sqrt(n) 0.1965 E(T)=()/ 32.3333 E(S)=1/(1- 1.2446 E(C)=E(T)+E(S) 33.5779 Sampling cost per cycle= a 1* n* E(C) 335.7793 Search cost per cycle = a 2*[1+E(T)] 140.1559 Operating cost per cycle = a 3*E(S) 746.7555 Total cost per cycle, S 1 1222.6907 Total cost per period, S 2 = S 1/E(C) 36.4135 The above table shows the result obtained by Excel. The result obtained by hand computation may be different due to rounding. Results obtained by hand computation are shown below:

2 2.5 20.0062 0.0124 (See Appendix 1) 2.5 1.5 5 2.5 1.5 5 0.8541 5.8541 0.1963 0 0.1963 1 0.03 ET 32.3333 0.03 1 ES 1.2442 1 0.1963 EC 32.3333 1.2442 33.5775 Sampling cost per cycle = (2)(5)(33.5775)=$335.7758 Search cost per cycle = 100[1+(0.0124)(32.33)]=$140.0933 Operating cost per cycle = 600(1.2442)=$746.5472 Total cost per cycle = 335.7758+140.0933+746.5472 = $1222.4163 Total cost per period = 1222.4163/33.5775 = $36.4057

6 Name:______ID:______Question 6: (12 points)

RM Manufacturing makes thermometer for use in the medical field. These thermometers, which read in degrees Celsius, are able to measure temperatures to a level of precision of two decimal places. Each hour, RM manufacturing tests a subgroup of 8 randomly selected thermometers in a solution that is known to be at a temperature of 30C. RM manufacturing conducts a test for a total of 200 hours and records average temperature of each of 200 subgroups. The sample data is used to estimate the mean and standard deviation of the subgroup average temperature. The sample data shows that the subgroup average temperature has a mean, X = 30C and a standard deviation, s = 0.020C. The frequency distribution of the subgroup average temperature is shown below: Lower limit 0 2.96 2.98 3.00 3.02 3.04 Upper limit 2.96 2.98 3.00 3.02 3.04 Frequency 5 22 72 76 18 7 Can we conclude at the 5% level of significance that the subgroup average temperature is normally distributed with a mean, = 30C and a standard deviation, = 0.020C. Use chi-square test. a. (2 points) State the null and alternate hypotheses 0 H0: The average temperatures of subgroups with size 8 are normally distributed with 3 C and 0.020 X C 0 HA: The average temperatures of subgroups with size 8 are not normally distributed with 3 C 0.020 and X C b. (7 points) Compute the chi-square test value.

Class Observed u Px u Pl x u Expected Chi-Square z Interval frequency 2 z frequency, f e statistic, f 0 l u 200P l x u 2 f o f e

f e

0-2.96 5 -2 0.0228 0.0228 4.56 0.042

2.96-2.98 22 -1 0.1587 0.1359 27.18 0.987

2.98-3.00 72 0 0.5000 0.3413 68.26 0.205

3.00-3.02 76 1 0.8413 0.3413 68.26 0.878

3.02-3.04 18 2 0.9772 0.1359 27.18 3.100

3.04- 7 ---- 1.000 0.0228 4.56 1.306

Total 200 6.518

(Continued…)

7 Name:______ID:______c. (3 points) State the conclusion of the test and interpret the conclusion.

Degrees of freedom, k 1 p 6 1 2 3 2 2 2 2 critical = , 3,0.05 7.81473 (See the table) 2 2 test = 6.518 < 7.81473 = critical

Conclusion: Do not reject H0 Interpretation: There is not enough statistical evidence to conclude at a level of significance 0.05 that the average temperatures of subgroups with size 8 are not normally distributed with 0 0.020 3 C and X C. The test passes.

8