MEMPHIS REFINERY STANDARD PROCEDURES

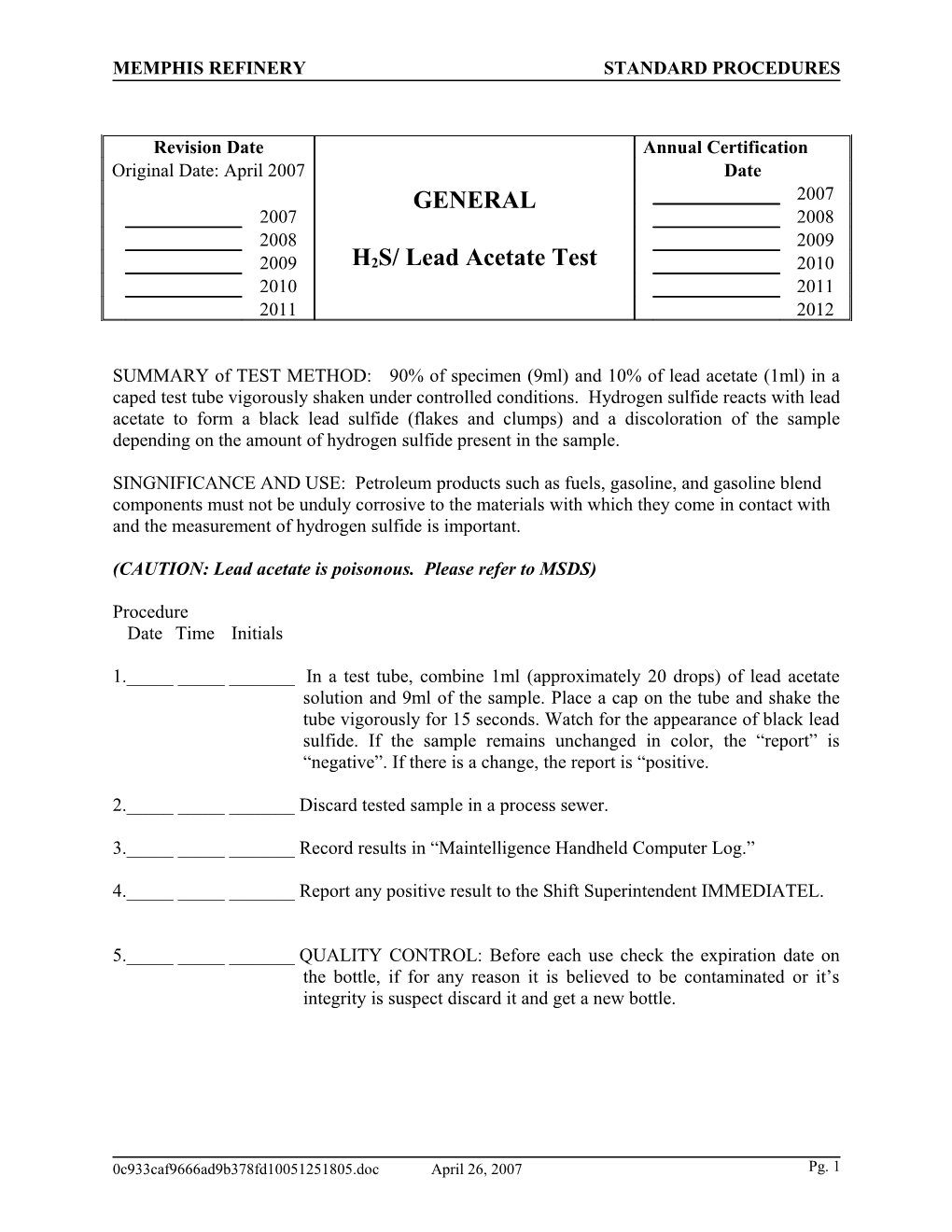

Revision Date Annual Certification Original Date: April 2007 Date GENERAL 2007 2007 2008 2008 2009 2009 H2S/ Lead Acetate Test 2010 2010 2011 2011 2012

SUMMARY of TEST METHOD: 90% of specimen (9ml) and 10% of lead acetate (1ml) in a caped test tube vigorously shaken under controlled conditions. Hydrogen sulfide reacts with lead acetate to form a black lead sulfide (flakes and clumps) and a discoloration of the sample depending on the amount of hydrogen sulfide present in the sample.

SINGNIFICANCE AND USE: Petroleum products such as fuels, gasoline, and gasoline blend components must not be unduly corrosive to the materials with which they come in contact with and the measurement of hydrogen sulfide is important.

(CAUTION: Lead acetate is poisonous. Please refer to MSDS)

Procedure Date Time Initials

1.______In a test tube, combine 1ml (approximately 20 drops) of lead acetate solution and 9ml of the sample. Place a cap on the tube and shake the tube vigorously for 15 seconds. Watch for the appearance of black lead sulfide. If the sample remains unchanged in color, the “report” is “negative”. If there is a change, the report is “positive.

2.______Discard tested sample in a process sewer.

3.______Record results in “Maintelligence Handheld Computer Log.”

4.______Report any positive result to the Shift Superintendent IMMEDIATEL.

5.______QUALITY CONTROL: Before each use check the expiration date on the bottle, if for any reason it is believed to be contaminated or it’s integrity is suspect discard it and get a new bottle.

0c933caf9666ad9b378fd10051251805.doc April 26, 2007 Pg. 1 MEMPHIS REFINERY STANDARD PROCEDURES

PROCEDURE INFORMATION

PURPOSE: This test method indicates the presence of hydrogen sulfide in diesel fuel..

PREREQUISITES:

RESPONSIBILITY: MATERIALS AND EQUIPMENT: REAGENTS and MATERIALS: Purchased Lead Acetate solution: 10% (W/V), AQUEOUS (to be supplied by the Refinery Lab) 20mm test-tube with plastic cap

SAFETY: CAUTION: Lead acetate is poisonous. Please refer to MSDS. Special or Unique Hazards: Safety gloves, safety glasses or goggles, and any other personal protective equipment needed to conduct this test in a safe manner.

Engineering Controls: .

Administrative Controls:

Personal Protective Equipment (PPE):

SAFETY SYSTEMS Shutdowns: N/A

Relief: N/A

Other Safety: N/A

QUALITY AND INVENTORY Inventory: Quality:

0c933caf9666ad9b378fd10051251805.doc April 26, 2007 Pg. 2 MEMPHIS REFINERY STANDARD PROCEDURES

Operating Limits: Description Limits Consequences of Deviation Corrective and Avoidance Steps N / A

Chemical Safety: General information is provided here. Additional information is available from the MSDS sheet for the specific material in question. Chemical Name Properties Hazards Actions if Exposed

0c933caf9666ad9b378fd10051251805.doc April 26, 2007 Pg. 3 MEMPHIS REFINERY STANDARD PROCEDURES

0c933caf9666ad9b378fd10051251805.doc April 26, 2007 Pg. 4