Panel Raising Cutterhead with Turnblade Knives

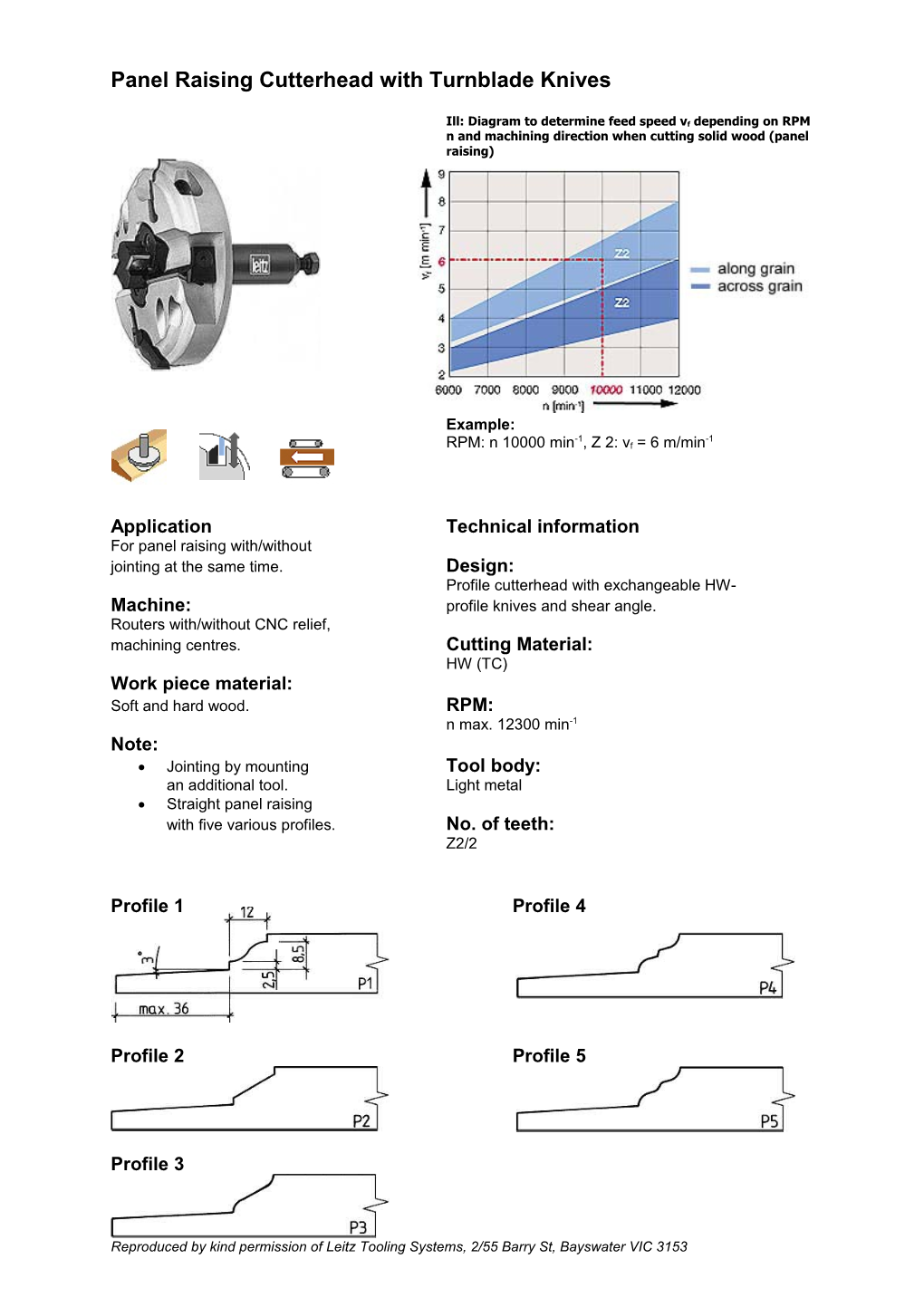

Ill: Diagram to determine feed speed vf depending on RPM n and machining direction when cutting solid wood (panel raising)

Example: -1 -1 RPM: n 10000 min , Z 2: vf = 6 m/min

Application Technical information For panel raising with/without jointing at the same time. Design: Profile cutterhead with exchangeable HW- Machine: profile knives and shear angle. Routers with/without CNC relief, machining centres. Cutting Material: HW (TC) Work piece material: Soft and hard wood. RPM: n max. 12300 min-1 Note: Jointing by mounting Tool body: an additional tool. Light metal Straight panel raising with five various profiles. No. of teeth: Z2/2

Profile 1 Profile 4

Profile 2 Profile 5

Profile 3

Reproduced by kind permission of Leitz Tooling Systems, 2/55 Barry St, Bayswater VIC 3153 Diamaster Pro Z2+2, Router Cutter

Ill.: Diagram to determine feed speed vf depending on grooving depth ap 1 = Jointing cut 2 = Sizing cut

Router cutter, Diamaster PRO, Z 2+2 Work piece material: plastic coated chipboards Operation: Jointing, sizing RPM: n 18000 min-1 Factor of correction vf: MDF = 0,6; Veneer across grain = 0,7

Application Technical information For pre-cutting and sizing abrasive materials, especially Design: suitable for small and medium Router cutter with alterative shear angle batch productions. and plunging tip.

Machine: Cutting Material: Routers with/without CNC relief. DP (DIA)

Work piece material: RPM: Soft and hard wood, laminated materials n 16000 - 30000 min-1 chipboards and fibre materials (chipboards, MDF, HF, etc.) No. of teeth: Z2/2 Note: Quiet running by irregular Note: pitch and large gullet areas. Diamaster PRO-tipping for regrinding twice. Cutting edges with shear angle and polished face increase the edge quality of coated workpieces. Z2+2 design for feed speeds up to 22 m/min. Regrindable tool with Diamaster PRO-tipping.

Router cutter, cylindrical shank, NL 43/48 mm

Tool position when machining Axial plunging Ramp plunging Boring/cutting panels - thickness 16 mm. Reproduced by kind permission of Leitz Tooling Systems, 2/55 Barry St, Bayswater VIC 3153 Roughing Spiral Router Cutter

Ill.: Diagram to determine feed speed vf depending on grooving

depth ap, D 16 - 20 mm

Spiral roughing router cutters: Solid HW design, Z3 Workpiece material: Soft wood Operation: Sizing RPM: n 18000 min-1

Factor of correction vf Hard wood = 0,8; chipboards raw = 1,2; laminated materials = 0,9

Application Technical information For pre-cutting with fast hogging in roughing quality. Design: Router cutter, spiral cutting edges in roughing design, Machine: grinded on face for plunging. Routers with/without CNC relief. Cutting Material: Work piece material: HW (TC) Plastic coated and veneered (plywood, etc.), glulams (HPL, CPL, RPM: Trespa), duromers, plastomers, polymer- n 16000 - 36000 min-1 plastics (Corian, Varicor, etc.), composite materials (veneered solid wood, HF Note: coated). ● Solid HW design with large regrinding area.

Note: Positive twist (see below) for optimum chip flow; negative twist for better clamping, when machining small work pieces. Short design for higher stability and reduced vibration at high feed speeds, especially for Spiral roughing router cutter machining HPL and CPL.

RL – RD positive twist RL – LD negative twist

Ill.: Diagram to determine feed speed vf depending on grooving

depth ap, D 12 - 14 mm

Spiral roughing router cutters: Solid HW design, Z3 Workpiece material: Soft wood Operation: Sizing RPM: n 18000 min-1

Factor of correction vf Hard wood = 0,8; chipboards 1,3; laminated materials = 0,9

LL – LD positive twist Reproduced by kind permission of Leitz Tooling Systems, 2/55 Barry St, Bayswater VIC 3153 © Commonwealth of Australia 2005