EET 220 - Lab #1 Programmable Logic Controllers K. Dudeck

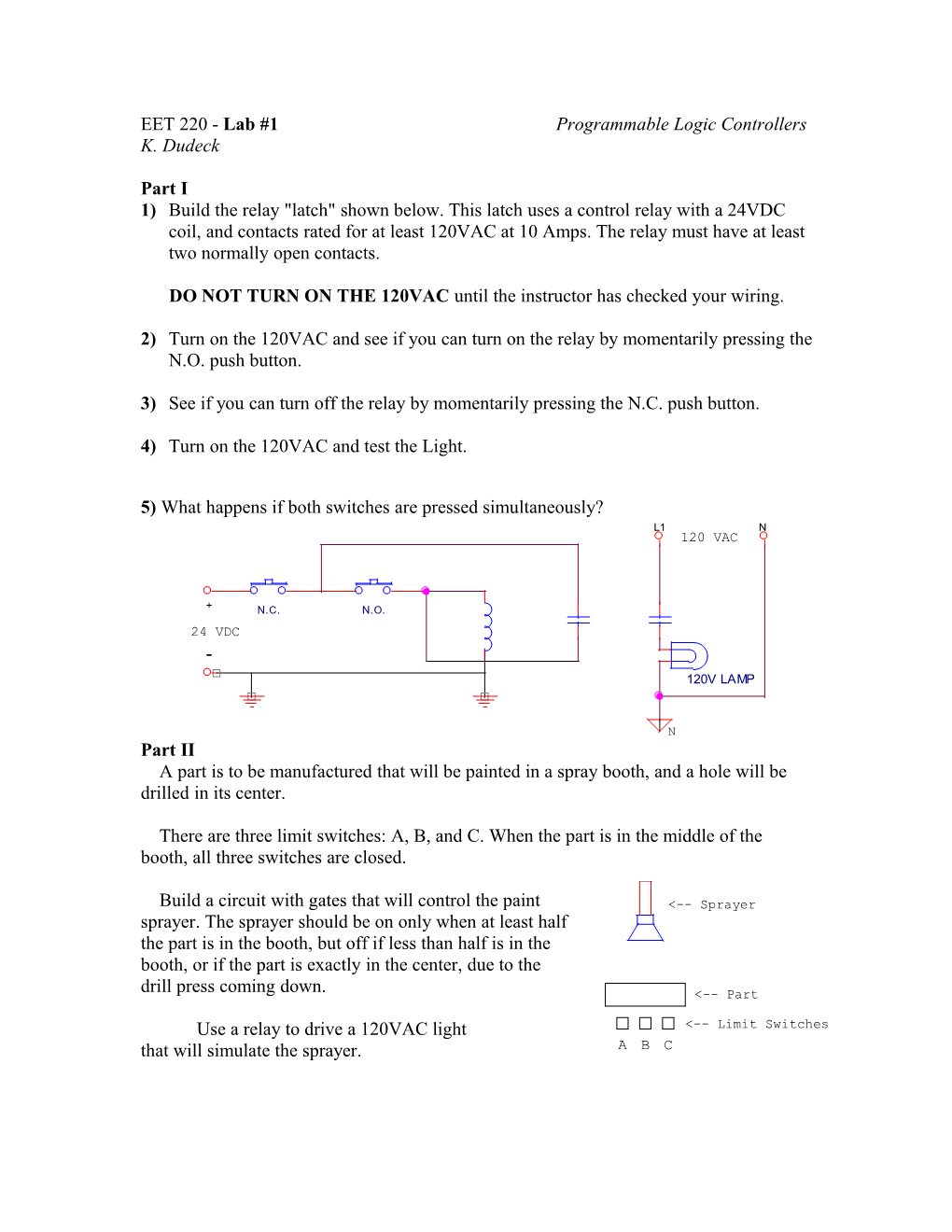

Part I 1) Build the relay "latch" shown below. This latch uses a control relay with a 24VDC coil, and contacts rated for at least 120VAC at 10 Amps. The relay must have at least two normally open contacts.

DO NOT TURN ON THE 120VAC until the instructor has checked your wiring.

2) Turn on the 120VAC and see if you can turn on the relay by momentarily pressing the N.O. push button.

3) See if you can turn off the relay by momentarily pressing the N.C. push button.

4) Turn on the 120VAC and test the Light.

5) What happens if both switches are pressed simultaneously? L1 N 120 VAC

+ N.C. N.O. 24 VDC - 120V LAMP

N Part II A part is to be manufactured that will be painted in a spray booth, and a hole will be drilled in its center.

There are three limit switches: A, B, and C. When the part is in the middle of the booth, all three switches are closed.

Build a circuit with gates that will control the paint <-- Sprayer sprayer. The sprayer should be on only when at least half the part is in the booth, but off if less than half is in the booth, or if the part is exactly in the center, due to the drill press coming down. <-- Part

Use a relay to drive a 120VAC light <-- Limit Switches that will simulate the sprayer. A B C EET 220 - Lab #2 Programmable Logic Controllers K. Dudeck

Part I - Software Configuration and ON LINE Monitoring

In this part you will configure the Programming Software appropriate to the PSU Hazleton Hardware options, then load a test program onto the SLC 5/01 PLC.

In this PLC Laboratory, we have three pieces of software that are used to program, communicate, and monitor the PLC system. The PLC system consists of three hardware components that communicate via Allen Bradley’s DH488 communication protocol. Each of the system components are assigned a DH488 Node Address. The three hardware components are :

1) The Personal Computer (PC) – Used to program and monitor the PLC. Also used to program the Panel View Operator Panel. (DH488 Node 0)

2) The Programmable Logic Controller (PLC) – A SLC5/01 processor with three I/O racks. (DH488 Node 1)

3) Panel View Operator Terminal – A Panel View 300 Operator Terminal. This terminal is used to send and receive operators input to, or receive data from the PLC while it is running its program. OpPanels are used in industrial applications to replace discrete switches and lights with a single panel that can be easily programmed to provide the operator interface need to run the process. (DH488 Node 2)

The three software packages used will be:

1) RS Linx – This is the communications package that provides the Dynamic Data Exchange (DDE) between the PC and its windows-based applications, the PLC, and the Panel View Terminal.

2) RS Logix 500 – This is the software package that is used to write and later download the Ladder Logic program to the PLC. The software also provides for live “on-line” monitoring of the PLC process currently running.

3) Panel Builder 32 – This software package is used to write the program for the Panel View Terminal and then to download it. Then functions keys on the terminal can be assigned to elements in the PLC processor file.

The software should be properly configured on the lab computers, but to illustrate the concepts of setting up a functional Allen Badley PLC communication system, follow the steps for initializing the Rockwell Software shown on the next page. Procedure for Initializing the Rockwell Software for PLC Data Communications

RS Linx - Start Up Procedure

1) Make sure the Rockwell Master Disk is in the A: drive.

2) Open the “RS Linx” software located in the Rockwell Software folder.

3) Configure the “RS Linx” software. a) From the menu, Select >Communications, >Configure Drivers b) Select the 1747 PIC / AIC + Driver and then >Add New… c) Accept the Default name “AB-PIC-1” and Com1, Station #0.

4) Check the DH488 interface by clicking on the “AB-PIC-1” icon and verify that the computer (node 0) and the PLC (node 1) are recognized. If a Panel View 300 terminal is connected on the bus, it too should be seen.

5) Minimize the RS Linx software.

RS Logix 500 - Start Up Procedure

1) Make sure the the Rockwell Master Disk is in the A: drive.

2) Open the “RS Logix 500” software located in the Rockwell Software folder.

3) Select new file, give the processor a project a name that you can identify later. (i.e “test1”, “proj1”). Then select the processor as: SLC 5/01 – 1K MEM

4) Configure the I/O rack to tell the software what I/O cards are in the PLC. Select > IO Configuration . Make sure that the Rack #1 is defined as a 4-slot rack, and that Rack 2 and 3 are not installed.

For the slots shown, assign the I/O cards by selecting the following:

Slot 1 – 1746-IA16 16-input 120VAC Slot 2 - 1746-OW16 16-output (Relay) Slot 3 – 1746- NIO4V Analog 2 Ch in/ 2 Ch voltage out

These assignments match the hardware installed in the PLC. Close the I/O configuration window.

5) At this point, you can write the Ladder Logic for your application, download it to the PLC, and run it. Panel Builder - Start Up Procedure

1) If you are using a Panel View in your project, open the “Panel Builder 32” software located in the Panel Builder folder.

2) Create a new application, and give it a unique name. This name should correspond to the processor name so that you can remember which PLC program it is associated with. Make sure that the Panel type is PV300 and the protocol is DH485. A display of a PV300 panel should appear on the computer screen.

3) Select > Application Settings, > Communications Make sure that the Node Address is 2.

4) Right Click on the “..End of Node List..” field under the Node Name column. Then select > Insert Node

5) Then fill in the node name as “PLC” and the node address as 1.

6) At this point, you can enter your panel program for your application and download it to the PV300.

We will download a PLC program called “test1”, that is saved on the computer hard drive, to the SLC 5/01 processor.

Procedure

1) Make sure the PIC interface is plugged into the computer’s COM1 port and into the 5/01 processor DH488 port.

2) Make sure that Linx is running and that the Computer (node 0) and the PLC (node 1) are both recognized.

3) Start the RSLogix software. Select >file >open “test1” This is a simple program that we will download to the PLC. The software will be in the offline mode, which means ladder programs can be written without a PLC actually being present.

4) Now select > comms >download and the “test1 program will be sent to the PLC.

5) We will go ONLINE to see this program running. Select >comms >go online

The ladder program comes on the screen. Notice the MOV instruction. This takes the analog input at I: 3.0 and sends it to the analog output at O: 3.0 . As you press the thumb switches, notice how the values change. 6) We will look at elements in the data table which is shown under the data files folder.

Click on the input file. Notice how the bits change as you turn the switches on.

Click on the output file. Notice how O:2 0/0 changes when the light comes on.

7) Change the PLC to program.

Set output bits O:2/6, O:2/7, and O:2/8 ON by changing them in the data file.

8) Change PLC mode back to RUN, what happens? Pressing the switch 0 will still operate light 0, as done by the first line of the ladder program. Note: you can change data in the data file ONLINE, but the SLC 5/01 ladder program cannot be changed ONLINE.

9) Outputs and inputs can be FORCED on or off in the data table, and these bits are not altered by the ladder program running. Try forcing some input and output.

10) If you have a Panel View available, connect the Panel View to the DH488 bus and notice how the F1 key operates Light 15. This is done via B3/0. The Panel View sets this bit in the PLC data table via the DH488. The second rung of the program makes the light turn on.

Part II - Offline Programming In order to write a new or edit an existing PLC ladder program, you must work offline. We will write a very simple program that turns on the light directly above each corresponding switch, and we will call this program "LIGHTS."

1) From the main menu, we must first select the program. Choose >file >new, and give the name "LIGHTS," and the station address of 1.

2) Now go OFFLINE

3) Since "LIGHTS" is a new processor file, the program does not know the configuration of the PLC, namely what SLC 500 and what I/O cards are plugged into the rack. Configure the program file as follows:

a: Select the processor 5/01, 1K Memory

b: Rack #1 , 4-slot

c: Slot 1 - 1746-IA16 Slot 2 - 1746-OW16 Slot 3 - 1746-NIO4V

Always make these selections for any future ladder program you are writing. 4) *Write the LIGHTS program* Right Click on the left side of the End Rung. It will be the red area. The select > Insert Rung.

5) Enter the first line of the ladder program as shown below. Have your instructor assist you in the edit commands. I :1 O:2 ------| |------( )------0 0

When this rung is complete Right click on the left side of the rung and select >Verify rung.

This rung has the first switch turn on the first light. Enter 15 more rungs like this that operate the other lights in a similar fashion. When the program is finished, exit and save, then DOWNLOAD to the PLC. Test the new running PLC program.

6) *Modify the LIGHTS program* to provide a Lamp Test feature. If both the first and the last are on, light all the lights regardless of the other switch positions.

7) Save, download, and test this version of the PLC program.

8) Can you think of a way to implement this last program with using only two rungs? What happens when you MOV the 16-bit word I:1 to the 16-bit word O:2 ?

EET 220 - Lab #3 Programmable Logic Controllers *ACME Boiler Company* K. Dudeck In this lab you will write a PLC program that controls a gas fired boiler steam furnace. The boiler has the following inputs and outputs assigned to it: 120 VAC Inputs 120 VAC Outputs* Word I:1 Word O:2 /00 - /00 - Water Level HIGH /01 - Water Tank Fill Valve /01 - Gas Level LOW Main Valve /02 - Over Pressure Sensor /03 /02 - Pilot Light Valve /03 - - Room Therm wants heat /04 - Hot Water Valve Pilot Light O.K. / 05 - Light Pilot Switch *120VAC OPENS the valves

Analog Input

I:3.0 - Tank water temperature 0 - +10VDC (0 -400F)

-The Control Philosophy-

1) The Tank Fill Valve should remain unchanged when the water level is between the two water level sensors. The Valve should be opened when they level falls below the low sensor, and closed when the level rises above the high sensor.

2) The Gas Main Valve should be opened to cause the boiler to heat up the water whenever the water temperature falls below 280F, and the valve should be closed when the water temperature rises about 320F. If the temperature is between these two temperatures, the valve should remain unchanged (Furnace Idle).

The Gas Main Valve should be opened regardless of water temperature, if the Hot Water Valve is opened, because the temperature must be brought to a boil (Furnace Running).

WARNING: Regardless of the water temperature, or Hot Water Valve, the Gas Main Valve should be closed if the boiler Over-Pressure Sensor is true, or if the Pilot Light is not O.K.

3) The Pilot Light Valve should be opened when the Light Pilot Switch is closed (momentary switch), but closed if the pilot is not O.K after 10 seconds. Once the pilot is O.K., if it ever goes out, the valve should be closed immediately.

4) The Hot Water Valve should be opened whenever the Room Thermostat calls for heat. This allows hot water to flow into the radiators around the house. This valve should stay open for an additional 30 seconds after the desired room temperature is achieved, to relieve the steam pressure in the boiler.

I : 1/03 PRESSURE SWITCH N.O.

BOILER I : 1/00 HIGH LEVEL SWITCH N.O.

I : 1/01 LOW LEVEL SWITCH N.O.

O : 2/03 O : 2/00 < <

HOT WATER VALVE TANK FILL VALVE > O : 2/01 O : 2/02 MAIN GAS VALVE PILOT LIGHT VALVE

GAS SUPPLY >

PILOT LIGHT O.K. I : 1/04 LIGHT PILOT SWITCH I : 1/05 THERMOSTAT WANTS HEAT I : 1/03 EET 220 – Final Project Programmable Logic Controllers K. Dudeck

You are required to complete a final project for this course. The project must be presented in class on the last day of the course. Each lab group will do one project and presentation. The presentation should be in made using power point.

The project topic should be a PLC program and interface to real world control process. For example, an elevator control system for a four floor building, as demonstrated in class. Switches and lights can be used to simulate the real world inputs and outputs, however it is encouraged that at some I/O be physically interfaced for the project.

The student will be graded on three elements for the project.

1) Once the students have agreed on a project, they must submit a proposal to the instructor. The proposal should describe the process and how the solution may be accomplished.

2) A printed report at the time of the presentation is required for each lab group. The report should include a copy of the PLC ladder logic along with the I/O assignments.

3) Each lab group will be graded on the actual presentation. Each member of the lab group should print out a copy of the evaluation sheet that follows on the next page. Please come to class with the title of the project and names of each member in your group filled in. These sheets will be used by the judges as your project is presented.

EET 220 – PLC FINAL DESIGN PROJECT JUDGES SCORE SHEET

Project Title: ______

Project Participants: ______

Presentation Date: ______

Please evaluate each item on a 5 point system ( 5 –Highest 1 – Lowest )

1. Project Vision : 5 4 3 2 1

2. Project Difficulty: 5 4 3 2 1

3. Design Approach: 5 4 3 2 1

4. Presentation : 5 4 3 2 1

5. Overall: 5 4 3 2 1

Total points : ______X 2 =

Final Score

Comments: