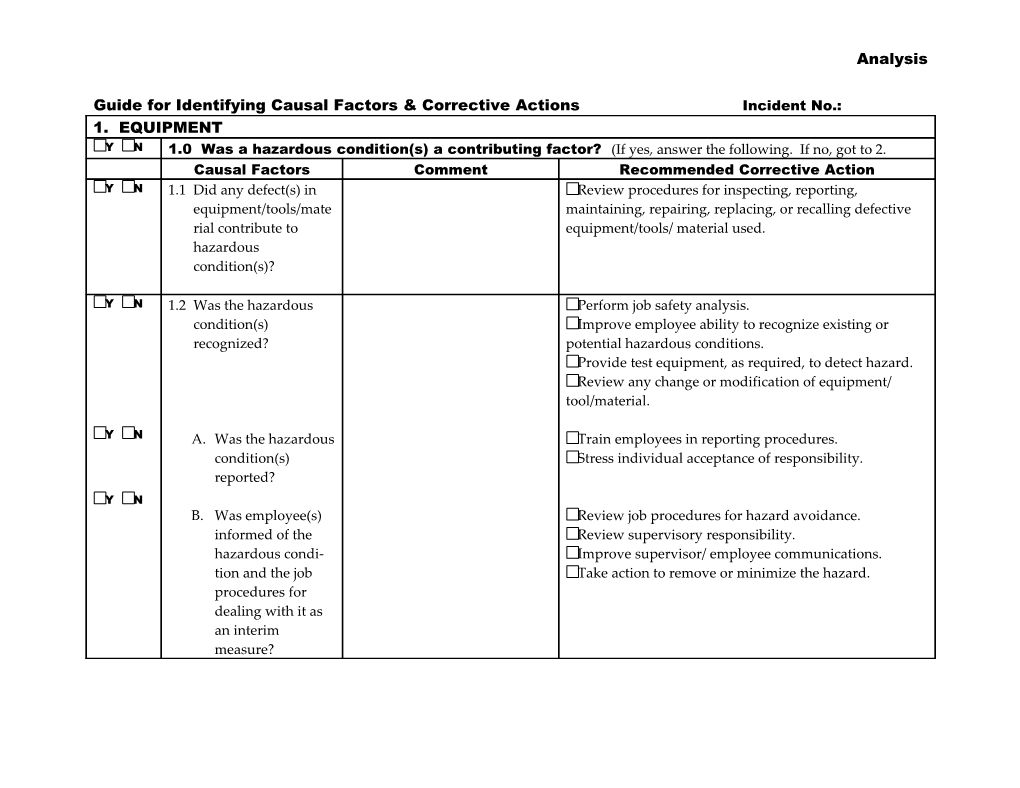

Analysis

Guide for Identifying Causal Factors & Corrective Actions Incident No.: 1. EQUIPMENT Y N 1.0 Was a hazardous condition(s) a contributing factor? (If yes, answer the following. If no, got to 2. Causal Factors Comment Recommended Corrective Action Y N 1.1 Did any defect(s) in Review procedures for inspecting, reporting, equipment/tools/mate maintaining, repairing, replacing, or recalling defective rial contribute to equipment/tools/ material used. hazardous condition(s)?

Y N 1.2 Was the hazardous Perform job safety analysis. condition(s) Improve employee ability to recognize existing or recognized? potential hazardous conditions. Provide test equipment, as required, to detect hazard. Review any change or modification of equipment/ tool/material.

Y N A. Was the hazardous Train employees in reporting procedures. condition(s) Stress individual acceptance of responsibility. reported? Y N B. Was employee(s) Review job procedures for hazard avoidance. informed of the Review supervisory responsibility. hazardous condi- Improve supervisor/ employee communications. tion and the job Take action to remove or minimize the hazard. procedures for dealing with it as an interim measure? Analysis

1. EQUIPMENT Causal Factors Comment Recommended Corrective Action Y N 1.3 Was there an equip- Develop and adopt procedures (ex. an inspection ment inspection system) to detect hazardous conditions. procedure to detect Conduct test. the hazardous condi- tion(s)? Y N 1.4 Did the existing Review procedures. equipment inspection Change frequency or comprehensiveness. procedure detect the Provide test equipment as required. hazardous condition? Improve employee ability to detect defects and hazardous conditions. Change job procedures as required. Y N 1.5 Was the correct Specify correct equipment/ tool/material in job equipment/tool/ procedure. material used? Y N 1.6 Was the correct Provide correct equipment/ tool/material. equipment/tool/ Review purchasing specifications and procedures. material readily Anticipate future requirements. available? Y N 1.7 Did employee know Review procedures for storage, access, delivery, or where to obtain distribution. equipment/tool/ Review job procedures for obtaining equipment/ material required for tool/material. the job? Y N 1.8 Was substitute equip- Provide correct equipment/tool/material. ment/tool/material Warn against use of substitutes in job procedures and used in place of in job instruction. correct one? Analysis

1. EQUIPMENT Causal Factors Comment Recommended Corrective Action Y N 1.9 Did the design of the Review human factors engineering principles. equipment/tool/ Alter equipment/tool/material to make it more material create compatible with human capability and limitations. operator stress or Review purchasing procedures and specs. encourage operator Check out new equipment and job procedures error? involving new equipment before putting into service. Encourage employees to report potential hazardous conditions created by equipment design. Y N 1.10Did the general design Review criteria in codes, standards, specifications, and or quality of the regulations. equipment/tool Establish new criteria as required. contribute to a hazar- dous condition? Y N 1.11List other causal factors in “Comment” column.

2. ENVIRONMENT Y N 2.0 Was the location of equipment/materials/employee(s) a contributing factor? (If yes, answer the following. If no, got to 3. Causal Factors Comment Recommended Corrective Action Y N 2.1 Did the location/ Perform job safety analysis. position of equipment/ Review job procedures. material/employee(s) Change the location, position, or layout of the Analysis

contribute to the equipment. hazardous condition? Change position of employee(s). Provide guard-rails, barricades, barriers, warning lights, signs, or signals.

2. ENVIRONMENT Causal Factors Comment Recommended Corrective Action Y N 2.2 Was the hazardous Perform job safety analysis. condition Improve employee ability to recognize existing or recognized? potential hazardous conditions. Provide test equipment, as required, to detect hazard. Review any change or modification of equipment/ tool/material.

Y N A. Was the Train employees in reporting procedures. hazardous condition Stress individual acceptance of responsibility. reported? Y N B. Was employee(s) Review job procedures for hazard avoidance. informed of the Review supervisory responsibility. hazardous condition Improve supervisor/ employee communications. and the job procedures Take action to remove or minimize the hazard. for dealing with it as an interim measure? Y N 2.3 Was employee(s) Review job procedures and instruction. supposed to be in the Provide guard-rails, barricades, barriers, warning lights, vicinity of the signs, or signals. equipment/material? Y N 2.4 Was the hazardous Change lighting or layout to increase visibility of condition created by equipment. Analysis

the location/ position Provide guardrails, barricades, barriers, warning lights, of equipment/ signs or signals, floor stripes, etc. material visible to employee(s)? Y N 2.5 Was there sufficient Review workspace requirements and modify as workspace? required.

2. ENVIRONMENT Causal Factors Comment Recommended Corrective Action Y N 2.6 Were environmental Monitor, or periodically check, environmental conditions a contrib- conditions as required. uting factor (ex. Check results against acceptable levels. illumination, noise Initiate action for those found unacceptable. levels, air contami- nants, temperature extremes, ventilation, vibration, radiation)? Y N 2.7 List other causal factors in “Comments” column.

3. PEOPLE Y N 3.0 Was a hazardous condition(s) a contributing factor? (If yes, answer the following. If no, got to 4. Causal Factors Comment Recommended Corrective Action Y N 3.1 Was there a written Perform job safety analysis and develop procedure. or known procedure (rule) for this job?

Y N Analysis

A. Did job Perform job safety analysis and change job procedure. procedures anticipate the factors that contributed to the accident?

3. PEOPLE Causal Factors Comment Recommended Corrective Action Y N B. Did employee(s) Improve job instruction. know the job Train employees in correct job procedures. procedure?

Y N C. Did employee(s) Determine why. deviate from the Encourage all employees to report problems with an know job established procedure to supervisor. procedure? Review job procedure and modify if necessary. Counsel or discipline employee. Provide closer supervision. Y N 3.2 Was employee(s) Review employee requirements for the job. mentally and Improve employee selection. physically capable of Remove or transfer employees who are temporarily, performing the job? either mentally or physically, incapable of performing the job. Y N 3.3 Were any tasks in the Change job design and procedures. job procedure too difficult to perform (ex. excessive concen- Analysis

trations or physical demands)? Y N 3.4 Is the job structured Change job design and procedures. to encourage or require deviation from job procedures (ex. incentive, piece- work, work pace)? Y N 3.5 List other causal factors in “Comment” column.

3. PEOPLE Causal Factors Comment Recommended Corrective Action Y N 3.6 Was lack of personal protective equip- ment or emergency equipment a contrib.- uting factor in the injury?

Y N A. Was appropriate Review methods to specify PPE requirements (e.g. personal completing a Hazard Assessment Form). protective equipment (PPE) specified for the Y N task or job? i. Was appropriate Provide appropriate PPE. Y N PPE available? ii. Did employee Review job procedures. know that Improve job instruction. Analysis

wearing specified PPE was Y N required? iii. Did employee Improve job instruction. know how to use and maintain the PPE? Y N 3.7 Was the PPE used Determine why and take appropriate action. properly when the Implement procedures to monitor and enforce use of injury occurred? PPE. Y N 3.8 Was the PPE Review PPE requirements. adequate? Check standards, specs, and certification of the PPE.

3. PEOPLE Causal Factors Comment Recommended Corrective Action Y N 3.9 Was emergency Provide emergency equipment as required. equipment specified for this job (ex. emergency showers, Y N eyewash fountains)? A. Was emergency Install emergency equipment at appropriate locations. equipment readily available?

Y N B. Was emergency Incorporate use of emergency equipment in job equipment procedures. properly used? Y N C. Did emergency Establish inspection/monitor-ing system for emergency equipment equipment. Provide for im-mediate repair of defects. Analysis

function properly? Y N 3.10 List other causal factors in “Comments” column.

4. MANAGEMENT Y N 4.0 Was a management system defect a contributing factor? (If yes, answer the following. If no, stop. Causal Factors Comment Recommended Corrective Action Y N 4.1 Was there a failure Improve supervisor capability in hazard recognition by supervision to and reporting procedures. detect, anticipate, or report a hazardous condition? 4. MANAGEMENT Causal Factors Comment Recommended Corrective Action Y N 4.2 Was there a failure Review job safety analysis and job procedures. by supervision to Increase supervisor monitoring. detect or correct Correct deviations. deviations from job procedure? Y N 4.3 Was there a super- Establish a procedure that requires a review of hazards visor/employee and job procedures (preventative actions) for tasks review of hazards performed infrequently. and job procedures for tasks performed infrequently? Y N 4.4 Was supervisor Define and communicate supervisor responsibility and responsibility and accountability. Analysis

accountability Test for understandability and acceptance. adequately defined and understood? Y N 4.5 Was supervisor Train supervisors in accident prevention fundamentals. adequately trained to fulfill assigned responsibility in accident prevention? Y N 4.6 Was there a failure to Review management safety policies and level of risk initiate corrective acceptance. action for a known Establish priorities based on potential severity and hazardous condition probability of recurrence. that contributed to Review procedure and responsibility to initiate and this accident? carry out corrective actions. Monitor progress. Y N 4.7 List other causal factors in “Comment” column.