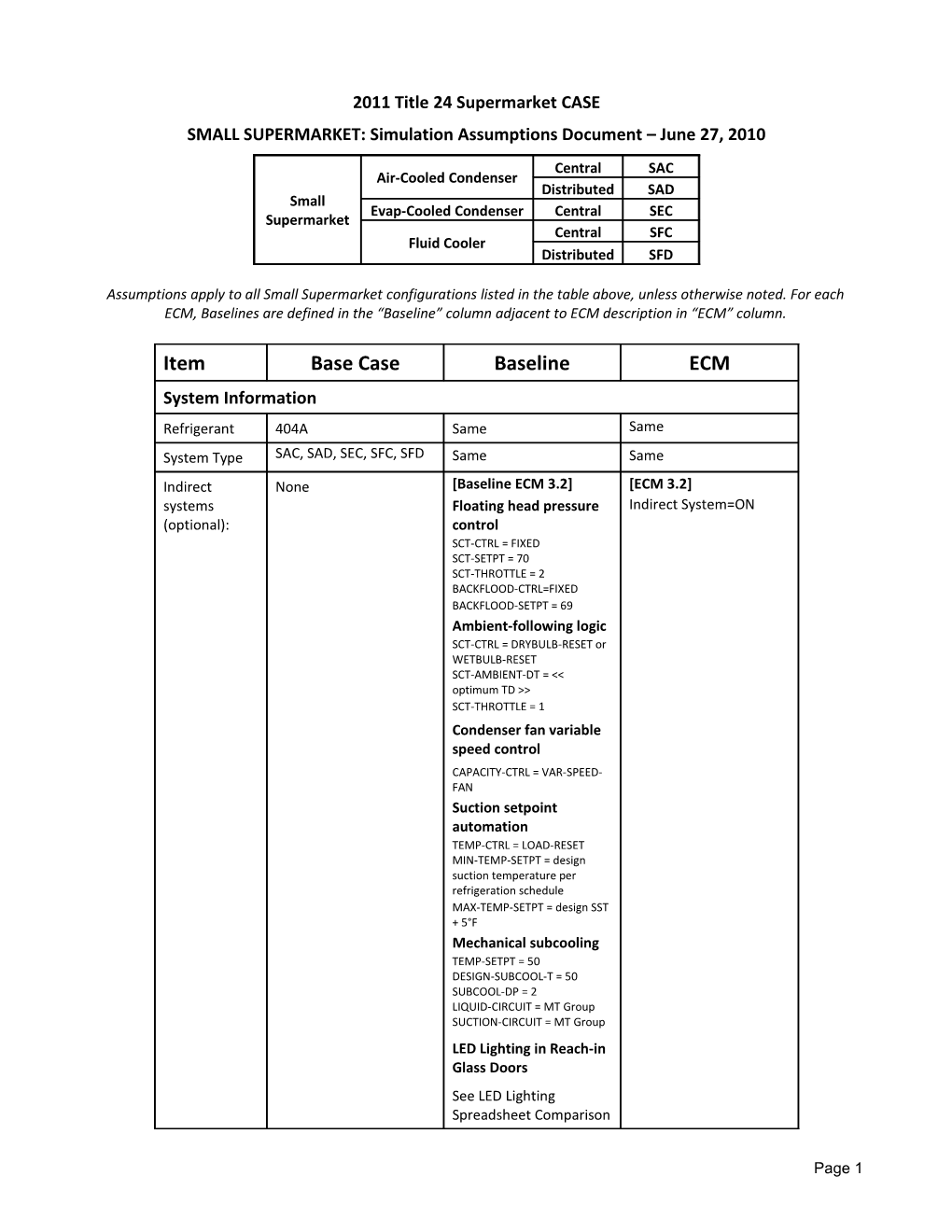

2011 Title 24 Supermarket CASE SMALL SUPERMARKET: Simulation Assumptions Document – June 27, 2010

Central SAC Air-Cooled Condenser Distributed SAD Small Evap-Cooled Condenser Central SEC Supermarket Central SFC Fluid Cooler Distributed SFD

Assumptions apply to all Small Supermarket configurations listed in the table above, unless otherwise noted. For each ECM, Baselines are defined in the “Baseline” column adjacent to ECM description in “ECM” column.

Item Base Case Baseline ECM System Information Refrigerant 404A Same Same System Type SAC, SAD, SEC, SFC, SFD Same Same Indirect None [Baseline ECM 3.2] [ECM 3.2] systems Floating head pressure Indirect System=ON (optional): control SCT-CTRL = FIXED SCT-SETPT = 70 SCT-THROTTLE = 2 BACKFLOOD-CTRL=FIXED BACKFLOOD-SETPT = 69 Ambient-following logic SCT-CTRL = DRYBULB-RESET or WETBULB-RESET SCT-AMBIENT-DT = << optimum TD >> SCT-THROTTLE = 1 Condenser fan variable speed control CAPACITY-CTRL = VAR-SPEED- FAN Suction setpoint automation TEMP-CTRL = LOAD-RESET MIN-TEMP-SETPT = design suction temperature per refrigeration schedule MAX-TEMP-SETPT = design SST + 5°F Mechanical subcooling TEMP-SETPT = 50 DESIGN-SUBCOOL-T = 50 SUBCOOL-DP = 2 LIQUID-CIRCUIT = MT Group SUCTION-CIRCUIT = MT Group LED Lighting in Reach-in Glass Doors See LED Lighting Spreadsheet Comparison

Page 1 LED Lighting in Open Cases See LED Lighting Spreadsheet Comparison

Compressor Compressor SAC, SEC, SFC: Semi- Same Same Type hermetic compressors SAD, SFD: Scroll compressors Compressor SAC, SEC, SFC: Same Same Selection LT Semi-Hermetic: 06DR316 MT Semi-Hermetic: 06DR725 SAD, SFD: LT Scroll: ZF40KVE MT Scroll: ZB92KCE Suction (2) Two SST Levels Same Same Groups (1) LT Suction Group (1) MT Suction Group No AC Rack Pressure Drop 2°F Same Same between SET and SST Compressor See representative Same Same RGT compressor Adjustment spreadsheets (RGT = Return Gas Temperature)

Means of Fixed setpoint electronic Same [ECM 2.3] Suction compressor sequencing control with setpoint automation control on/off cycling TEMP-CTRL = LOAD-RESET MIN-TEMP-SETPT = design DESIGN-SST = design suction temperature per suction temperature per refrigeration schedule MAX-TEMP-SETPT = design SST refrigeration schedule + 5°F Subcooling None None [ECM 2.4] Mechanical subcooling TEMP-SETPT = 50 DESIGN-SUBCOOL-T = 50 SUBCOOL-DP = 2 LIQUID-CIRCUIT = MT Group SUCTION-CIRCUIT = MT Group Condenser

Condenser SAC, SAD: Air cooled Same Same Type

Page 2 SEC: Evaporative cooled SFC, SFD: Fluid cooler Ambient Title 24 Joint Appendix Same Same Temperature JA2 & Condenser 0.1% for design Wet Bulb Approach TD Temperature 0.1% for design Dry Bulb Temperature TBD Condenser 10°F TD for LT air-cooled Same Same condensers Selection TD Note: Condenser 15°F TD for MT air- Air Cooled approach not included in cooled condensers Condenser high priority ECMs to be modeled for 9/15 Webinar. Condenser Between 20°F and 25°F Same Same TD, based on WBT: Selection TD Note: Condenser Evaporative 78°F WBT: 98°F SCT approach not included in Cooled 72°F WBT: 95°F SCT high priority ECMs to be Condenser 68°F WBT: 93°F SCT modeled for 9/15 Pick the closest TD for Webinar. the ambient temperature Condenser Condenser approach: Same Same 20F and Fluid Note: Condenser Cooler Fluid cooler approach: approach not included in Selection TD Same method as evap high priority ECMs to be Water condenser selection modeled for 9/15 Cooled above, less 5 F. Webinar. Condenser Condenser 140 BTU/Watt for Same [ECM 1.5] Condenser Specific evaporative @ 100ºF SCT specific efficiency Efficiency & 70ºF WBT Air Cooled and 53 BTU/Watt for air- Evaporative cooled @ 10ºF TD Cooled Condensers Water Cooled 105 BTU/Watt Same [ECM 1.5] Condenser Condensers Fluid cooler pump is specific efficiency and Fluid controlled at a fixed Cooler speed. Base case pump power is TBD, but not exceeding that required for the base case GPM at 30 PSID. Condenser Fan Motor power is inherent Same [ECM 1.5] Condenser Motor Power in the base case specific specific efficiency

Page 3 and Efficiency efficiency calculation.

Means of Fixed setpoint strategy [Baseline ECM 1.2] [ECM 1.2] Ambient- Condenser SCT-CTRL = FIXED Ambient-following logic following logic Control SCT-THROTTLE = 2 BACKFLOOD-CTRL=FIXED SCT-CTRL = DRYBULB-RESET or BACKFLOOD-SETPT = 69 WETBULB-RESET OVERRIDE-MIN-SCT = 70 SCT-AMBIENT-DT = << optimum TD >> SCT-THROTTLE = 1 Means of Air cooled: fan cycling [Baseline ECM 1.3] [ECM 1.3] Condenser fan Condenser Fan (based on pressure) Condenser fan variable variable speed control speed control Control CAPACITY-CTRL = CYCLE-FAN CAPACITY-CTRL = VAR-SPEED- BACKFLOOD-CTRL=FIXED Evap cooled: two-speed FAN BACKFLOOD-SETPT = 69 fan control OVERRIDE-MIN-SCT = 70 CAPACITY-CTRL = TWO-SPEED- SCT-CTRL = DRYBULB-RESET or FAN WETBULB-RESET SCT-AMBIENT-DT = << optimum TD >> SCT-THROTTLE = 1 Condensing 85°F SCT Same [ECM 1.1] Floating head Temperature SCT-SETPT = 85 pressure control Setpoint BACKFLOOD-CTRL = FIXED SCT-CTRL = FIXED BACKFLOOD-SETPT = 84 SCT-SETPT = 70 SCT-THROTTLE = 2 BACKFLOOD-CTRL=FIXED BACKFLOOD-SETPT = 69 Pressure Drop 3°F Same Same at SDT and SCT Heat Recovery None Same Same (air) Note: Heat recovery (air) not included in high priority ECMs to be modeled for 9/15 Webinar. Heat Recovery None Same Same (domestic hot Note: Heat recovery water heating) (DHW) not included in high priority ECMs to be modeled for 9/15 Webinar. Walk-ins and unit coolers

Unit Cooler See Walk-in box See Walk-in box Same Sizing definitions below definitions below Note: Unit cooler approach not included in high priority ECMs to be modeled for 9/15 Webinar. Unit Cooler See Walk-in Box Same [ECM 5.2] Unit cooler CFM and Definitions below specific efficiency wattage Fan Motor ECM in walk-in Same Same

Page 4 Type evaporator coils for all fan motors < 460V and < 1 hp. Otherwise, PSC fan motors. Walk-in R-25 for cooler walls, Same Same insulation ceiling and doors level R-32 for freezer walls, ceiling and doors R-28 for freezer floors Walk-ins LT Suction Group: Same Same served by (1) Freezer, (18 x 8 x 9) ft3 System A Evaporator Temp: -20°F Discharge Temp: -10°F (Walk-in Box Coil Capacity @ 10°F TD: Loads per

Supermarket 13,600 Btuh Tables, as Coil Air Flow: 2,760 cfm noted) Fan Power: 59 W/motor Defrost Type: Electric Walk-in Box Load: 12,100 Btuh MT Suction Group: (1) Dairy Cooler, (43 x 8 x 9) ft3 Evaporator Temp: +24°F Coil Capacity @ 10°F TD: 13,000 Btuh Coil Air Flow: 1,300 cfm Fan Power: 59 W/motor Defrost Type: Off Cycle Walk-in Box Load: 21,400 Btuh (1) Produce Cooler, (11 x 8 x 9) ft3 Evaporator Temp: +50°F Discharge Temp: +60°F Coil Capacity @ 10°F TD: 9,000 Btuh Coil Air Flow: 1,400 cfm Fan Power: 59 W/motor Defrost Type: Off Cycle Walk-in Box Load: 5,600 Btuh Walk-ins None Same Same served by System B Walk-ins None Same Same served by System C

Page 5 Walk-ins None Same Same served by System D Fan Motor Fan motor input Same Same Power wattage. See walk-in box definitions above. Fan Control Continuous operation Same [ECM 5.3] Variable with no VFD speed fan control FAN-CONTROL = FAN-EIR-FPLR MIN-FLOW-SCH = 0.7 for 22 hrs FAN-EIR-FPLR = no_unload_fplr & 1.0 for 2 hrs FAN-CONTROL = FAN-EIR-FPLR FAN-EIR-FPLR = New-EIR-fPLR New-EIR-fPLR = CURVE-FIT TYPE= RATIO-FRATIO ORDER-OF-FIT= CUBIC INPUT-TYPE= COEFFICIENTS MIN-INPUT-1 = 0 MAX-INPUT-1 = 1.01 COEFFICIENTS= (0.001,- 0.0444,0.3634,0.6808) Liquid-suction None [Baseline ECM 5.4] [ECM 5.4] Liquid-suction heat Liquid-suction heat heat exchangers exchangers exchangers Superheat Gain in LSHX: (direct BACKFLOOD-CTRL=FIXED XX°F (also XX°F RGT) BACKFLOOD-SETPT = 69 refrigerant) OVERRIDE-MIN-SCT = 70 Subcooling Gain in LSHX: SCT-CTRL = DRYBULB-RESET or XX°F WETBULB-RESET SCT-AMBIENT-DT = << TBD optimum TD >> SCT-THROTTLE = 1 Leaving Gas LT: 30°F Same Same Temperature MT: 20°F Defrost Defrost Load: 70% of Same Same Assumptions design load Defrost Effectiveness: 15% Quantity of Defrosts per Day: 4 Defrost Duration: 15 minutes Display Case

Case fan See display case Same Same motor type definitions below Case light Fixture efficiency – Same [ECM 4.2] LED Lighting in wattage standard offer published Reach-in Glass Doors by manufacturer. See LED Lighting Spreadsheet Comparison [ECM 4.3] LED Lighting in Open Cases See LED Lighting

Page 6 Spreadsheet Comparison

Case lighting For multi-deck meat and Same Same configuration deli cases: 2 row canopy assumptions lights + all shelves lighted (if available) For multi-deck dairy, beverage and produce cases: 2 row canopy lights + no lighted shelves Display Case Low wattage doors Same Same Reach-in Glass Door anti- sweat heater type & wattage Display Case None Same Same Reach-in Glass Note: Reach-in door anti- Door anti- sweat heater control not sweat heater included in high priority control on ECMs to be modeled for glass door 9/15 Webinar. cases Night curtains None Same [ECM 4.5] Night (applicable INF-SCH = SCHEDULE curtains/covers only to open TYPE = FRACTION 55% reduction in INF- cases) THRU DEC 31 (ALL) (1,24) (0.80,0.80,0.80,0.80,0.80,0.80, LOAD. 0.80,0.80,0.80,0.80,0.80,0.85, INF-SCH = SCHEDULE 0.85,0.90,0.90,0.95,0.95,0.95, TYPE = FRACTION 0.90,0.90,0.80,0.80,0.80,0.80) THRU DEC 31 (ALL) (1,24) (0.25,0.25,0.25,0.25,0.25,0.25, 0.25,0.80,0.80,0.80,0.80,0.85, 0.85,0.90,0.90,0.95,0.95,0.95, 0.90,0.90,0.80,0.80,0.80,0.25) Indirect None Same Same Cooling for Note: Display Case Display Cases Indirect Cooling not included in high priority ECMs to be modeled for 9/15 Webinar. Defrost Type Electric, Off Cycle or Hot Same Same Gas – See refrigeration Note: Defrost method schedule not included in high priority ECMs to be modeled for 9/15 Webinar. Defrost Time initiated, per Same Same Control manufacturers Note: Demand Defrost frequency. not included in high

Page 7 Temperature terminated priority ECMs to be on LT electric defrost modeled for 9/15 only Webinar. Demand Defrost established as a REACH CODE? Liquid-suction None [Baseline ECM 4.8] [ECM 4.8] Liquid-suction heat Liquid-suction heat heat exchangers exchangers exchangers Superheat Gain in LSHX: (direct BACKFLOOD-CTRL=FIXED XX°F (also XX°F RGT) BACKFLOOD-SETPT = 69 refrigerant) OVERRIDE-MIN-SCT = 70 Subcooling Gain in LSHX: SCT-CTRL = DRYBULB-RESET or XX°F WETBULB-RESET SCT-AMBIENT-DT = << TBD optimum TD >> SCT-THROTTLE = 1 Electronic None Same Same expansion Note: Electronic valves/case expansion valves/case controllers controllers not included in high priority ECMs to be modeled for 9/15 Webinar. Leaving Gas LT: 30°F Same Same Temperature MT: 20°F Display Case MT Suction Group: Same [ECM 4.2] LED Lighting in served by Reach-in Glass Doors System A Case Length: 16 ft See LED Lighting Evaporator Temp: +30°F Spreadsheet Comparison Discharge Temp: +35°F Fan Power: 8.63 W/ft [ECM 4.3] LED Lighting in (ECM) Open Cases No. Fans: 3 fans/12 ft See LED Lighting Canopy Light W/ft: 7.2 Spreadsheet Comparison Shelf Light W/ft: None No. Canopy Lights: 2 No. Shelves w/ Lights: 0 Defrost Type: Off Cycle Defrost Freq x Duration: 3 x 40 mins.

Case Length: 24 ft Evaporator Temp: +23°F Discharge Temp: +33°F Fan Power: 14.9 W/ft (STD) No. Fans: 5 fans/12 ft Canopy Light W/ft: 7.1 Shelf Light Watts: None No. Canopy Lights: 2 No. Shelves w/ Lights: 0 Defrost Type: Off Cycle

Page 8 Defrost Freq x Duration: 4 x 30 mins.

Case Length: 24 ft Evaporator Temp: +23°F Discharge Temp: +33°F Fan Power: 14.9 W/ft (STD) No. Fans: 5 fans/12 ft Canopy Light W/ft: 7.1 Shelf Light W/ft: 2.4 No. Canopy Lights: 2 No. Shelves w/ Lights: 5 Defrost Type: Off Cycle Defrost Freq x Duration: 4 x 30 mins.

Case Length: 8 ft Evaporator Temp: +23°F Discharge Temp: +33°F Fan Power: 8.63 W/ft (ECM) No. Fans: 3 fans/12 ft Canopy Light W/ft: 7.2 Shelf Light W/ft: 2.4 No. Canopy Lights: 2 No. Shelves w/ Lights: 5 Defrost Type: Off Cycle Defrost Freq x Duration: 3 x 40 mins.

Case Length: 24 ft Evaporator Temp: +30°F Discharge Temp: +35°F Fan Power: 8.63 Watts/ft (ECM) No. Fans: 3 fans/12 ft Canopy Light W/ft: 7.2 Shelf Light W/ft: 2.4 No. Canopy Lights: 2 No. Shelves w/ Lights: 5 Defrost Type: Off Cycle Defrost Freq x Duration: 3 x 40 mins.

Case Length: 8 ft Evaporator Temp: +30°F Discharge Temp: +35°F Fan Power: 8.63 Watts/ft (ECM)

Page 9 No. Fans: 3 fans/12 ft Canopy Light W/ft: 7.2 Shelf Light W/ft: 2.4 No. Canopy Lights: 2 No. Shelves w/ Lights: 5 Defrost Type: Off Cycle Defrost Freq x Duration: 3 x 40 mins.

Case Length: 8 ft Evaporator Temp: +30°F Discharge Temp: +35°F Fan Power: 15.2 Watts/ft (STD) No. Fans: 5 fans/12 ft Canopy Light W/ft: 8.8 Shelf Light Watts: None No. Canopy Lights: 2 No. Shelves w/ Lights: 0 Defrost Type: Off Cycle Defrost Freq x Duration: 4 x 40 mins.

Case Length: 12 ft Evaporator Temp: +23°F Discharge Temp: +33°F Fan Power: 8.63 Watts/ft (ECM) No. Fans: 3 fans/12 ft Canopy Light W/ft: 7.2 Shelf Light Watts: None No. Canopy Lights: 2 No. Shelves w/ Lights: 0 Defrost Type: Off Cycle Defrost Freq x Duration: 3 x 40 mins.

Number of Doors: 7 drs Evaporator Temp: +30°F Discharge Temp: +35°F Fan Power: 23.0 Watts/ft (ECM) No. Fans: 5 fans/5 drs Lighting W/dr: 64 Anti-swt htr cntrl: Fixed Anti-swt htr W/dr: 38 Defrost Type: Off Cycle Defrost Freq x Duration: 1 x 30 mins.

Page 10 Display Case None Same Same served by System B Display Case None Same Same served by System C Display Case None Same Same served by System D Point of Sale None Same Same (POS) Boxes with Reach-in (RI) Glass Doors POS Box N/A, since no POS Boxes Same Same Reach-in Glass in Base Case Door anti- sweat heater type & wattage Operation, Occupancy and Schedules

Facility size 10,000 ft2 (gross area) Same Same

Main Sales 15 ft Same Same Interior Spaces Height People Heat 600 Btu/hr/person Same Same Gain (Sensible/Late nt) 2 People 200 ft /person Same Same Occupancy (Main Sales Area) 2 People 100 ft /person Same Same Occupancy (Employee Areas) Schedules See schedules Same Same spreadsheet Equipment ? W/sf Same Same Plug Load Building HVAC

Packaged Packaged Rooftop Units Same Same rooftop units with EER per Title 24 (RTU) standards Number of Packaged

Page 11 Rooftop Units: 3

Main Air None Same Same Handling Unit Fan Operation Always On Same Same

Temperature Two fixed setpoints Same Same Control No night setpoint adjustment Main Sales 74°F Same Same HVAC Cooling Setpoint Main Sales 70°F Same Same HVAC Heating Setpoint Ventilation Always On Same Same Control Infiltration CFM = ? Same Same Load SBD: Engineering evaluation from exhaust quantity, store size, orientation, etc. Envelope & Lighting

Exterior Roof U-factor based on Title Same Same Construction 24 – Table 143-A Prescriptive Envelope Criteria for Roofs For Sacramento (CZ12), U-factor = 0.039 Exterior Wall U-factor based on Title Same Same Construction 24 – Table 143-A Prescriptive Envelope Criteria for Walls For Sacramento (CZ12), U-factor = ? Roof AGED Reflectance = 0.55 Same Same Absorptivity (Title 24 – Table 143-A) Skylights No Skylights Same Same

Skylight No Skylights Same Same Characteristics Daylighting Not applicable, since no Same Same Controls skylights Lighting Power 1.5 Watts/ ft2 (Complete Same Same Density Building Method)

Page 12 (except for Walk-in Coolers & Freezers) Lighting Power 0.7 Watts/ ft2 Same Same Density (Walk- in Coolers & Freezers) Lighting Non-24 hour store: 50% Same Same Control (Main reduction during non- Sales) operating hours Lighting Manual Same Same Control Lights ON 100% from (Offices) 8am – 5pm Lights ON 50% from 5pm – 8am Lighting Manual Same Same Control Lights ON 100% 24 (Stockroom) hours/day Lighting Manual Same [ECM X.X] Display Case Control Lights ON 100% 24 Lighting Control (Display Cases) hours/day Lights OFF during non- operating hours Lighting Manual Same Same Control (Walk- Lights ON 80% 24 in Boxes) hours/day Occupancy None Same Same Sensors in Walk-in Coolers & Freezers Occupancy ? Same Same Sensors in Individual Rooms

Page 13