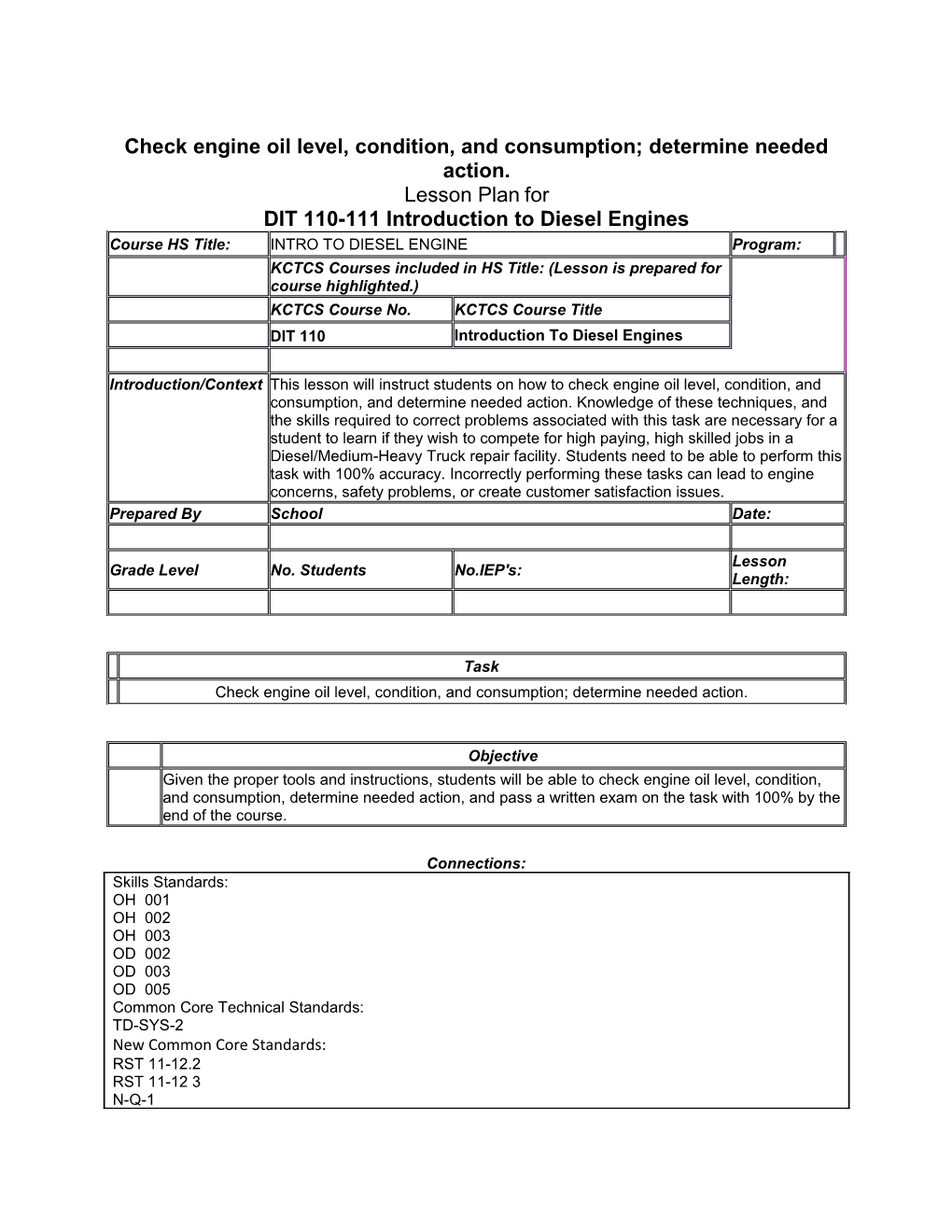

Check engine oil level, condition, and consumption; determine needed action. Lesson Plan for DIT 110-111 Introduction to Diesel Engines Course HS Title: INTRO TO DIESEL ENGINE Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 110 Introduction To Diesel Engines

Introduction/Context This lesson will instruct students on how to check engine oil level, condition, and consumption, and determine needed action. Knowledge of these techniques, and the skills required to correct problems associated with this task are necessary for a student to learn if they wish to compete for high paying, high skilled jobs in a Diesel/Medium-Heavy Truck repair facility. Students need to be able to perform this task with 100% accuracy. Incorrectly performing these tasks can lead to engine concerns, safety problems, or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Check engine oil level, condition, and consumption; determine needed action.

Objective Given the proper tools and instructions, students will be able to check engine oil level, condition, and consumption, determine needed action, and pass a written exam on the task with 100% by the end of the course.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 N-Q-1 INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts Instructor may use the content section of this plan to create a handout for the students.

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Kershaw/Bennett Medium/Heavy Duty Truck Diesel Engines Shop Manual 2001 Delmar 174-178 Alice Adams Tractor-Trailer Driver Handbook/Workbook Third Delmar 184

Content/Presentation/Demonstration Outline Instruct students that to check the oil level, they should follow these steps: Tell students to park the vehicle on level ground, and then shut off the engine. Instruct students to wait a few minutes for the oil to drain down. They should then find the dipstick and remove it. Tell them to wipe it clean and replace it, then pull it out again and check the oil level. Inform students that the oil level should be between the “full” and the “add” marks. Let them know to not overfill or drive when the oil level is below the “add” mark, and to be careful not to overfill when they need to add oil. Teach students to check the condition of the oil. Explain that when oil becomes contaminated, it can lead to complete engine failure. Let them know that contaminated oil has some characteristic telltale signs. Tell them that visual and odor testing can identify contaminated oil, and when required, the oil can be analyzed. Instruct students that the following are some common contaminants. *FUEL Teach students that when fuel contaminates engine oil, the oil loses its lubricity and it appears thinner and blacker in color. Let them know that this condition is usually easy to detect because small amounts of fuel in oil can he recognized by odor. Explain that when fuel is found in significant quantities in engine oil, the cylinder heads are the likely source. COOLANT Instruct students that coolant in the engine lubricant gives it a milky, cloudy appearance when churned into the oil. After settling, explain that the coolant will usually collect at the bottom of the oil sump. Let them know that when the drain plug is removed, the heavier coolant will exit first, as long as sufficient time has passed since running the engine. Inform students that when coolant is found in the engine oil, the cylinder head injector tubes and cylinder head gasket are the most likely source. OIL AERATION Teach students that aeration of engine oil, also known as foaming, can severely affect its ability to properly lubricate the engine. Explain that aerated engine oil can be caused either by the chemical characteristics of the oil itself (such as detergent additives) or by contaminants such as water. Also, surface tension is a factor. Let them know that oil in the crankcase is aerated from the rotary action of the crankshaft, the sucking of air into the oil pump inlet, and the free fall of oil into the crankcase from the oil pump relief valve and cylinder walls. Inform students that antifoaming additives inhibit oil aeration, and that silicone polymers are used to prevent foaming in diesel engine lubricants. COLD SLUDGE Instruct students that cold sludge is caused by oil degeneration that occurs during prolonged engine low-load operation at low temperatures. It settles in the engine crankcase and can accelerate engine wear. Let them know that when a diesel engine is operated with its coolant thermostat(s) removed, cold sludge can form. Instruct students about Oil Consumption: Tell students to verify the concern by monitoring oil consumption and analyzing exhaust smoke. Inform them about some possible causes and suggested solutions. Tell them to check for the following: *Excess cylinder wall lubrication. Let students know that it may be caused by a high oil sump level, excessive connecting rod and big end bearing oil throw-off, plugged oil control or wiper rings, oil pressure that is too high, or oil diluted with fuel. Explain that this type of problem usually requires an engine disassembly to diagnose and repair. *External oil leaks: Instruct students to steam or pressure wash the engine, then load it on a chassis dynamometer or road. This will help to determine the source. *High oil temperatures: Explain that this may be caused by a malfunctioning boost air heat exchanger, lug down engine loading, overfueling, incorrect fuel injection timing, or a problem with the oil cooler or engine cooling system. *Piston ring fit abnormality: Teach students that this is usually caused by wear. Tell them they would replace the rings. *Piston ring failure: Instruct students to determine the cause. Have them check for other damage, and then replace the rings. *Turbocharger seal failure: Tell students they would recondition the turbocharger. *High oil sump level: Remind students that this causes aeration. Tell them to determine the cause of high oil level, and check for the presence of fuel and engine coolant in the oil. *Glazed cylinder liners or sleeves: Explain that this is caused by using improper break-in procedure or prolonged engine idling. Tell students that they would replace the cylinder liners/sleeves or use a glaze- buster to machine crosshatch. *Worn cylinder head valve guides or seals: Instruct students to measure to specification and recondition the cylinder head, if required.

Applications/Practice 1 Refer to Content

Evaluation and feedback Prior to Testing or Lab Work Objective 1/ Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist should be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1/ Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)