CASTER

Objective: The student will construct a complete set of working drawings for the Caster including, detail drawings, assembly drawing(s), Parts List and tolerance calculations.

Assignment:

Part I: Preliminary Sketches Make a sketch on Graph Paper of each of the parts of the Caster. Show the necessary views and add the required dimensions.

Part #1: Top Plate Part #2: Wheel ¨ Sketch of the necessary views ¨ Sketch of the necessary views ¨ Sketch showing required dimensions ¨ Sketch showing required dimensions

Part #3: Axle Support Part #4: Axle ¨ Sketch of the necessary views ¨ Sketch of the necessary views ¨ Sketch showing required dimensions ¨ Sketch showing required dimensions

Part #5: Bushing Assembly Drawing ¨ Sketch of the necessary views ¨ Sketch of the necessary views ¨ Sketch showing required dimensions ¨ Parts List

Part #6: M10 x 50 Hex Head Bolt Part #7: M10 Nut ¨ Sketch of the necessary views ¨ Sketch of the necessary views ¨ Sketch showing required dimensions ¨ Sketch showing required dimensions

Part #8: M10 Lock Washer Steel Plate ¨ Sketch of the necessary views ¨ Sketch of the necessary views ¨ Sketch showing required dimensions ¨ Sketch showing required dimensions

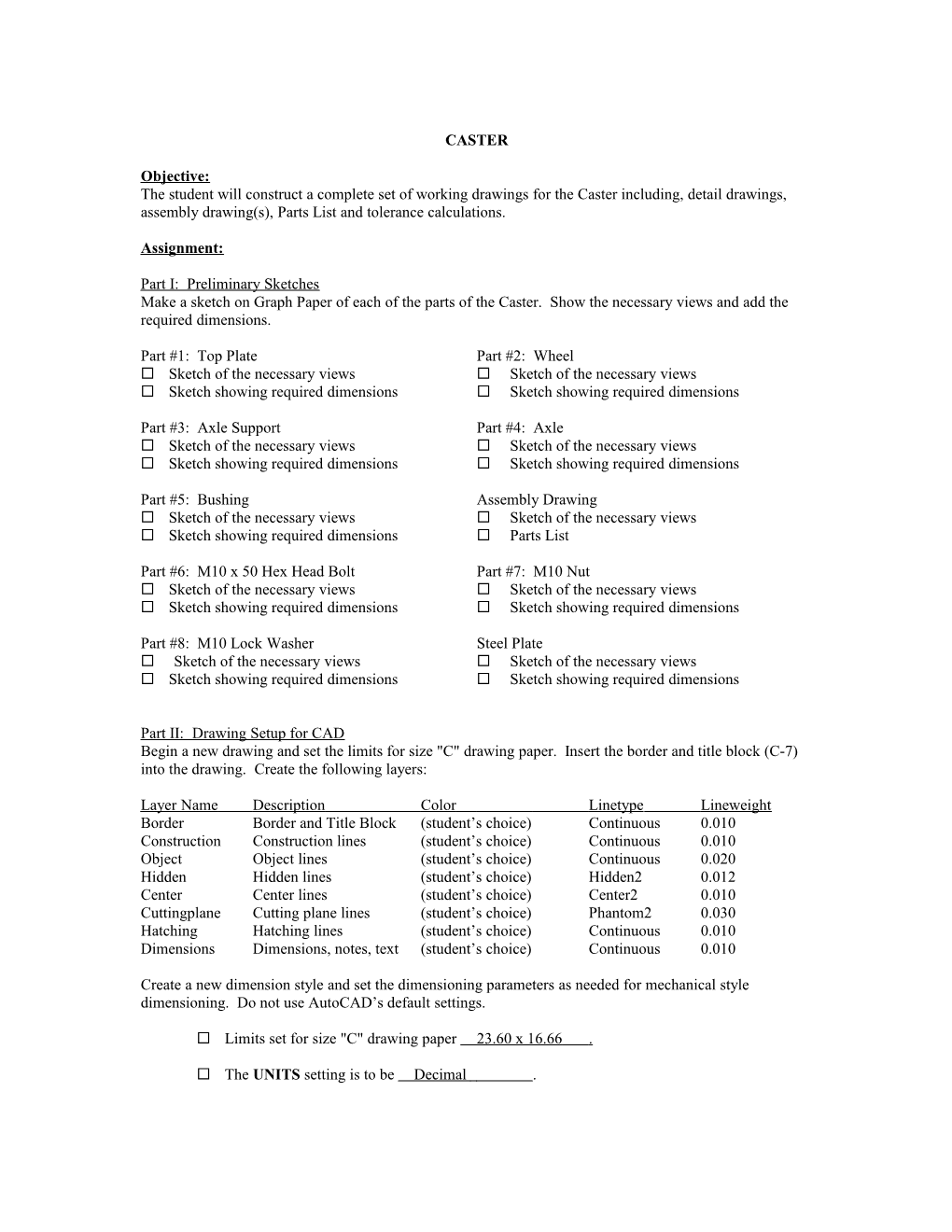

Part II: Drawing Setup for CAD Begin a new drawing and set the limits for size "C" drawing paper. Insert the border and title block (C-7) into the drawing. Create the following layers:

Layer Name Description Color Linetype Lineweight Border Border and Title Block (student’s choice) Continuous 0.010 Construction Construction lines (student’s choice) Continuous 0.010 Object Object lines (student’s choice) Continuous 0.020 Hidden Hidden lines (student’s choice) Hidden2 0.012 Center Center lines (student’s choice) Center2 0.010 Cuttingplane Cutting plane lines (student’s choice) Phantom2 0.030 Hatching Hatching lines (student’s choice) Continuous 0.010 Dimensions Dimensions, notes, text (student’s choice) Continuous 0.010

Create a new dimension style and set the dimensioning parameters as needed for mechanical style dimensioning. Do not use AutoCAD’s default settings.

¨ Limits set for size "C" drawing paper 23.60 x 16.66 .

¨ The UNITS setting is to be Decimal . ¨ The precision setting for dimensioning is to be 0.00 .

2 CASTER

Part III: Tolerance Calculations Calculate the tolerance dimensions for the following parts:

Fit between Part 4 and Part 5: H8/f7 Fit between Part 3 and 5: H7/p6 Fit between Part 2 and Part 4: H8/f7

Use the Preferred Metric Hole Basis Clearance Fits-American National Standard tables in your textbook To find the limit dimension values.

The precision setting for tolerance dimensions is to be 0.000 .

Part IV: Complete the required drawings Complete all of the required drawings following ANSI and ISO drafting standards. Drawings will include detail drawings, assembly drawing(s), Parts List, revisions block, and general notes. Add identification circles to the assembly drawing. Consult your drafting textbook for correct sizes. Be sure to add the titles of each part below each detailed drawing.

3