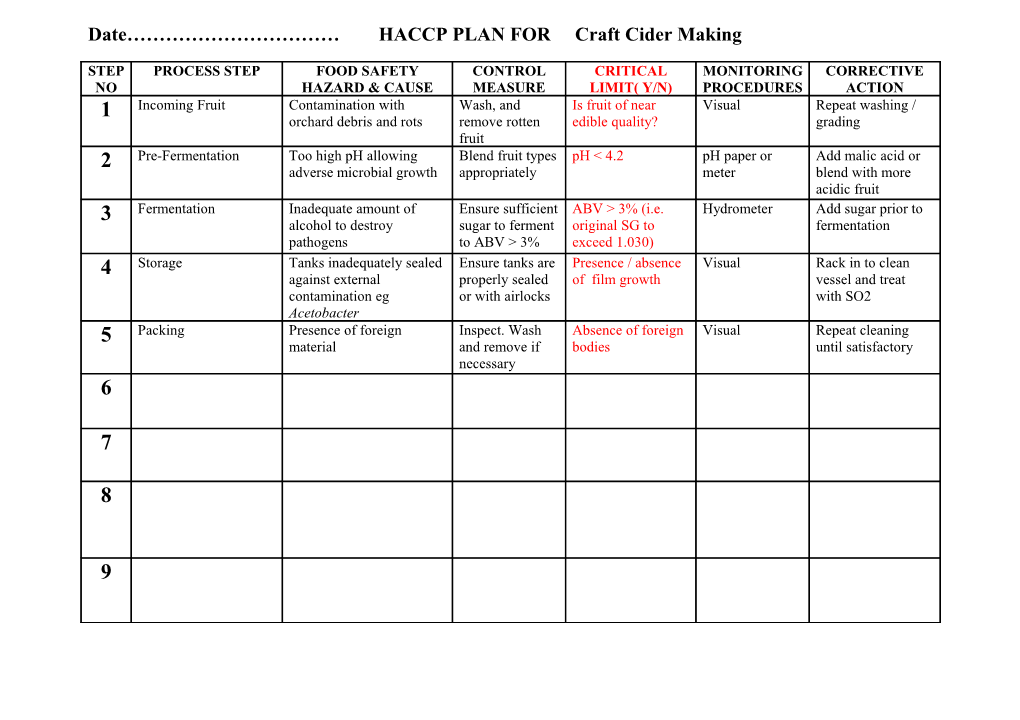

Date…………………………… HACCP PLAN FOR Craft Cider Making

STEP PROCESS STEP FOOD SAFETY CONTROL CRITICAL MONITORING CORRECTIVE NO HAZARD & CAUSE MEASURE LIMIT( Y/N) PROCEDURES ACTION 1 Incoming Fruit Contamination with Wash, and Is fruit of near Visual Repeat washing / orchard debris and rots remove rotten edible quality? grading fruit 2 Pre-Fermentation Too high pH allowing Blend fruit types pH < 4.2 pH paper or Add malic acid or adverse microbial growth appropriately meter blend with more acidic fruit 3 Fermentation Inadequate amount of Ensure sufficient ABV > 3% (i.e. Hydrometer Add sugar prior to alcohol to destroy sugar to ferment original SG to fermentation pathogens to ABV > 3% exceed 1.030) 4 Storage Tanks inadequately sealed Ensure tanks are Presence / absence Visual Rack in to clean against external properly sealed of film growth vessel and treat contamination eg or with airlocks with SO2 Acetobacter 5 Packing Presence of foreign Inspect. Wash Absence of foreign Visual Repeat cleaning material and remove if bodies until satisfactory necessary 6

7

8

9 10

1) This Hazard Analysis and Critical Control Point (HACCP) Plan was completed on ………………………………………..

2) The plan was completed by ………………………………………………………..

3) The HACCP plan(s) covers 1) Biological contaminants 2) Chemical contaminants, and 3) Physical contaminants which may present food safety hazards during:

4) The Scope of this HACCP Plan covers the manufacture of ……………………………………………………………….

RECIPE DETAILS/INGREDIENTS LIST