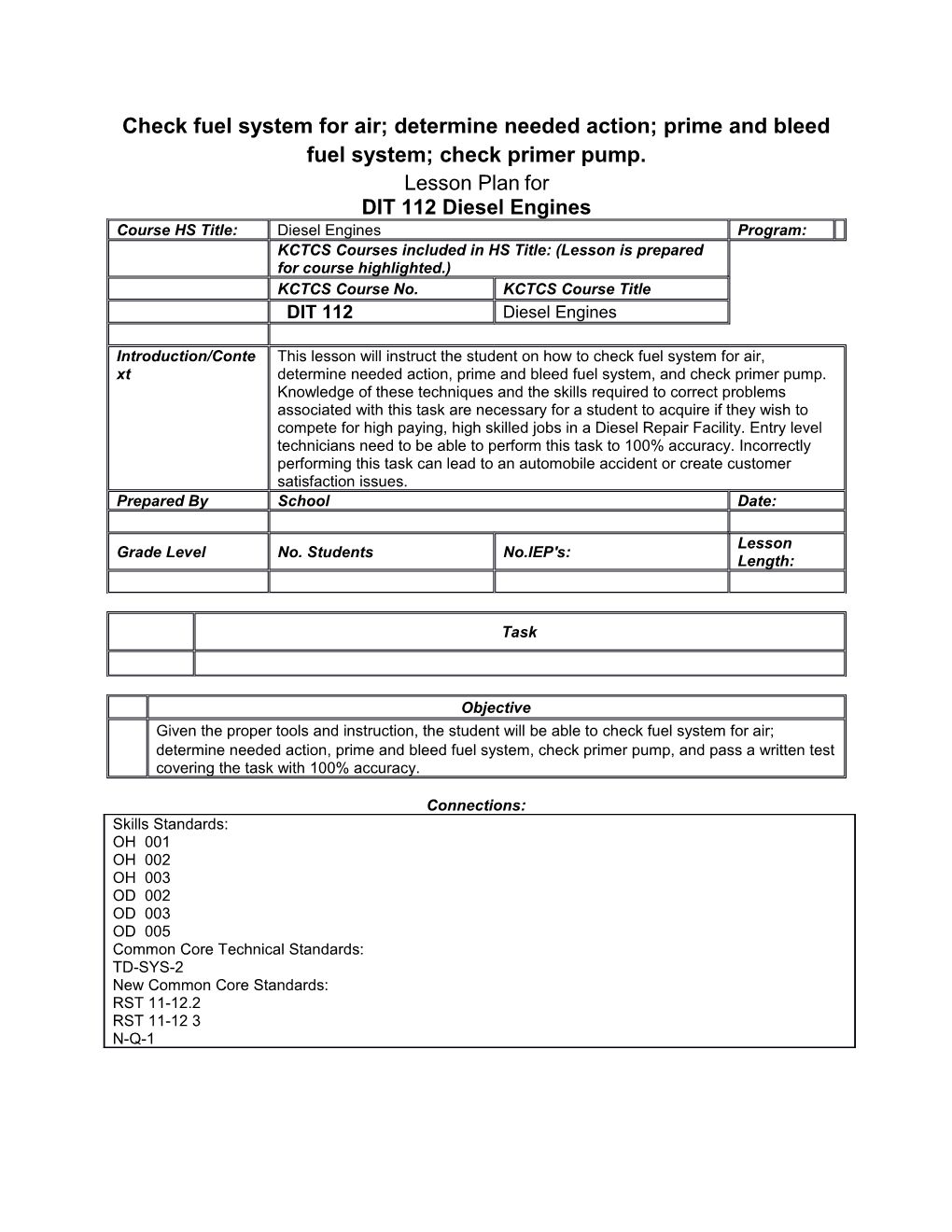

Check fuel system for air; determine needed action; prime and bleed fuel system; check primer pump. Lesson Plan for DIT 112 Diesel Engines Course HS Title: Diesel Engines Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 112 Diesel Engines

Introduction/Conte This lesson will instruct the student on how to check fuel system for air, xt determine needed action, prime and bleed fuel system, and check primer pump. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Diesel Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task

Objective Given the proper tools and instruction, the student will be able to check fuel system for air; determine needed action, prime and bleed fuel system, check primer pump, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 N-Q-1 INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Editio Publishe Page Author Title/ISBN No. n r s Don Knowles Medium/Heavy Duty Truck Technician Certification 2008 Delmar 145

Equipment Quantity Item Source

Content/Presentation/Demonstration Outline Instruct students that they can check for air in the fuel system by installing a clear plastic hose in the return line and look for consistent large bubbles. To troubleshoot the source of air leaks, tell them a diagnostic sight glass can be used. It consists of a clear section of tubing with hydraulic hose couplers at either end and it is fitted in series with the fuel flow. However, let them know the process of uncoupling the fuel hoses always admits some air into the fuel system, so the engine should be run for a while before reading the sight glass. Inform students that a fuel system must be sealed to operate properly. Any introduction of air may cause air locks, which prevent fuel from reaching the injectors. Tell students that to bleed air from the fuel system, manufacturers install primer pumps to pressurize the system. Once pressurized, opening the end of the lines forces trapped air out of the line. Let them know that some injectors incorporate a return line that allows excess fuel to return to the tank. This type of system is self-priming, but some manufacturers strongly recommend against priming this way. Explain that the excess fuel is used to cool and lubricate fuel system components. Most manufacturers will install a hand primer to make priming systems easier. Instruct students that when a vehicle runs out of fuel and the fuel system requires priming, remove the filters and fill them with filtered fuel. Tell students to follow these steps to prime the fuel system: * Have them locate a bleed point in the system, and open the bleed valve. On an in-line injection pump system, this will be at the exit of the charging gallery. * Next, tell them that if the system is equipped with a hand primer pump, actuate it until air bubbles cease to exit from the open valve. If the system is not equipped with a hand primer pump, have them fit one upstream from the secondary filter and actuate it until air bubbles cease to exit from the open valve. * Have them close the bleed valve. Tell them to crank engine for 30-second segments with at least 2- minute intervals between crankings until it starts. Inform them that this procedure allows for starter motor cool-down. Let them know that in most diesel fuel systems, the high-pressure circuits will self-prime once the subsystem is primed. Some engine manufacturers recommend priming the fuel system by supplying air pressure to the fuel tank. Tell students that when using this procedure air pressure above 55 psi (8 kPa) may cause fuel tank damage.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)