A Fuzzy Multi-Objective Mixed Integer Programming Model for Multi Echelon Supply Chain Network Design and Optimization

Turan PAKSOY*, Nimet YAPICI PEHLİVAN** Eren ÖZCEYLAN***

*Selçuk University, Department of Industrial Engineering, Campus, 42031, Konya, Turkey (Tel: +90 332 223 20 40; e-mail: [email protected]) **Selçuk University, Department of Statistics, Campus, 42031, Konya, Turkey (Tel: +90 332 223 13 48; e-mail: [email protected]) ***Selçuk University, Department of Industrial Engineering, Campus, 42031, Konya, Turkey (Tel: +90 332 223 20 75; e-mail: [email protected])

Abstract: This paper applies a fuzzy multi-objective nonlinear programming model with piecewise linear membership function to design a multi echelon supply chain network (SCN) by considering total transportation costs and capacities of all echelons with fuzzy objectives. The model attempts to aim three different fuzzy objective functions. The first one is minimizing the total transportation costs between all echelons (suppliers, plants, distribution centers (DCs) and customers). Second one is minimizing of holding and ordering costs in DCs and the last objective function is minimizing the unnecessary and unused capacity of plants and DCs via decreasing variance of transported amounts between echelons. A numerical example is solved to demonstrate the feasibility of applying the proposed model to given problem, and also its advantages are discussed.

Keywords: Fuzzy modeling, optimization, network design, supply chain, nonlinear programming, triangular fuzzy numbers.

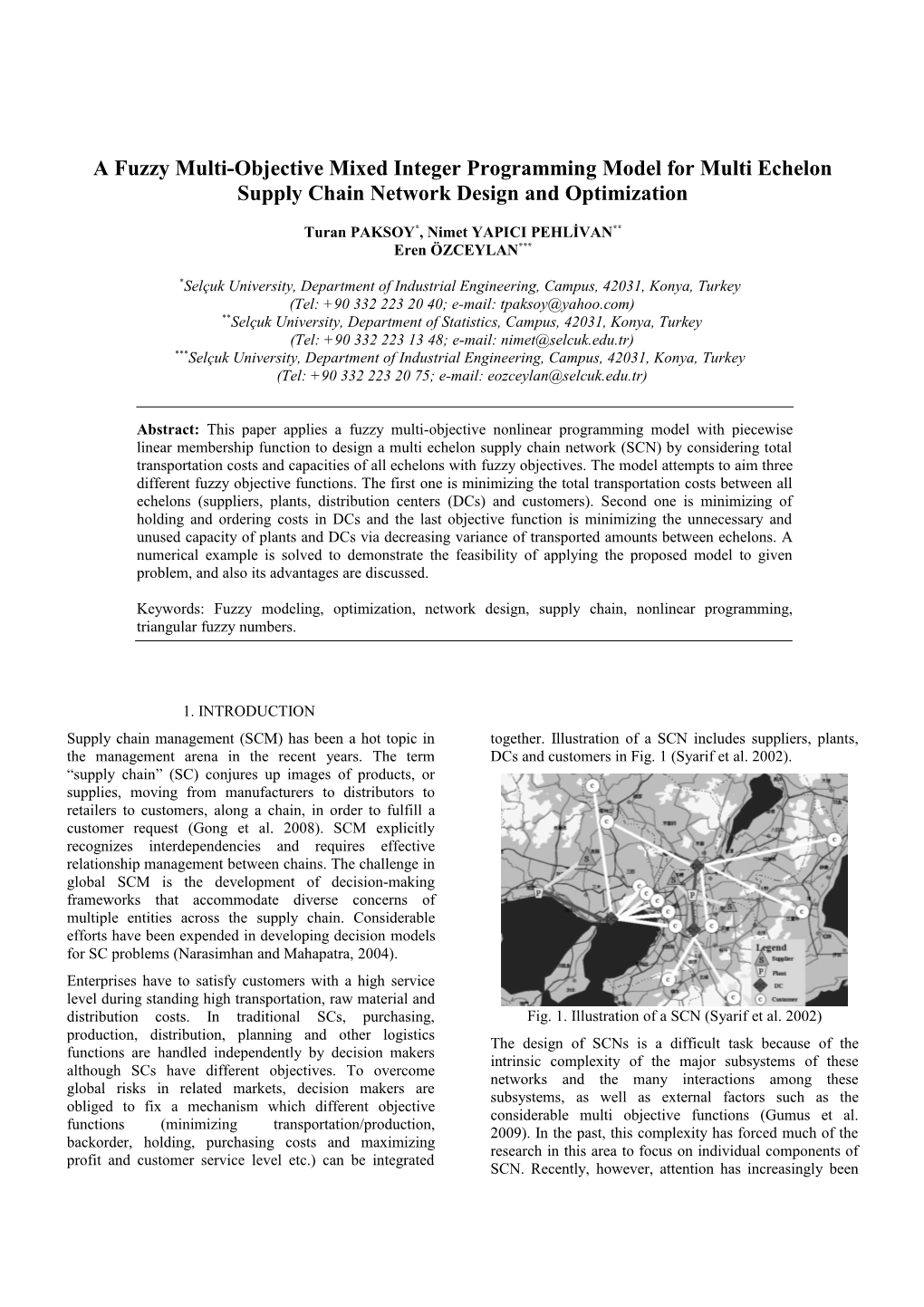

1. INTRODUCTION Supply chain management (SCM) has been a hot topic in together. Illustration of a SCN includes suppliers, plants, the management arena in the recent years. The term DCs and customers in Fig. 1 (Syarif et al. 2002). “supply chain” (SC) conjures up images of products, or supplies, moving from manufacturers to distributors to retailers to customers, along a chain, in order to fulfill a customer request (Gong et al. 2008). SCM explicitly recognizes interdependencies and requires effective relationship management between chains. The challenge in global SCM is the development of decision-making frameworks that accommodate diverse concerns of multiple entities across the supply chain. Considerable efforts have been expended in developing decision models for SC problems (Narasimhan and Mahapatra, 2004). Enterprises have to satisfy customers with a high service level during standing high transportation, raw material and distribution costs. In traditional SCs, purchasing, Fig. 1. Illustration of a SCN (Syarif et al. 2002) production, distribution, planning and other logistics The design of SCNs is a difficult task because of the functions are handled independently by decision makers intrinsic complexity of the major subsystems of these although SCs have different objectives. To overcome networks and the many interactions among these global risks in related markets, decision makers are subsystems, as well as external factors such as the obliged to fix a mechanism which different objective considerable multi objective functions (Gumus et al. functions (minimizing transportation/production, 2009). In the past, this complexity has forced much of the backorder, holding, purchasing costs and maximizing research in this area to focus on individual components of profit and customer service level etc.) can be integrated SCN. Recently, however, attention has increasingly been placed on the performance, design, and analysis of the SC production/distribution planning decisions, but using these as a whole. decisions prevent possible improvement in decision effectiveness. Hence, the issues of how to simultaneously SCs performance measures are categorized as qualitative integrate manufacturing and distribution systems in a and quantitative. Customer satisfaction, flexibility, and supply chain with multi objectives have attracted effective risk management belong to qualitative considerable interest from both practitioners and performance measures. Quantitative performance academics (Liang and Cheng, 2009). Literature review measures are also categorized by: (1) objectives that are presents a review about supply chain modeling and fuzzy based directly on cost or profit such as cost minimization, applications in SC planning, respectively. sales maximization, profit maximization, etc. and (2) objectives that are based on some measure of customer Cohen and Lee (1989) present a deterministic, mixed responsiveness such as fill rate maximization, customer integer, non-linear programming with economic order response time minimization, lead time minimization, etc quantity technique to develop a global supply chain plan. (Altiparmak et al., 2006). However, the SCM design and Output of the model provides global resource deployment planning is usually involving trade-offs among different policy for the plants, distribution centers and customer goals. zones. Pyke and Cohen (1993) develop a mathematical programming model by using stochastic sub-models to In this study, we developed a mixed integer linear design an integrated supply chain that involves programming model to design and optimize a supply chain manufacturers, warehouses and retailers. Due to not network via providing multi objective functions mentioned considering multiple products and having only one plant, above together. We considered three objectives for SCM one warehouse and one retailer, the model fails to problem: (1) minimization of total transportation costs represent the complicated supply chain networks of the between suppliers-plants-distribution centers and real world. Ozdamar and Yazgac (1997) develop a distribution costs between distribution centers and distribution/production system that involves a customers, (2) minimization of holding and ordering costs manufacturer center and its warehouses. The paper tries to in DCs based EOQ (economic order quantity) and (3) minimize total costs such as inventory; transportation costs providing equity of the capacity utilization ratio of plants etc. under production capacity and inventory equilibrium and DCs. Much of the decision making in the real world constraints. Syarif et al. (2002) propose new algorithm takes place in an environment in which the goals, the based genetic algorithm to design a multi stage supply constraints, and the consequences of the possible actions chain distribution network under capacity constraints for are not known precisely. As in the same manner, SCs each echelon. Although experimental results show that the operate in a somehow uncertain environment. Uncertainty proposed algorithm can give better heuristic solutions than may be associated with target values of objectives, traditional genetic algorithm, the comparison with the external supply and customer demand etc. Supply chain performances of other meta-heuristic techniques (tabu distribution network design models developed so far either search, simulated annealing etc.) are remained ignored uncertainty or consider it approximately through unanswered. Yan et al. (2003) try to contrive a network the use of probability concepts (Selim and Ozkarahan, which involves suppliers, manufacturers, distribution 2008). Because of the uncertain parameters, considering centers and customers via a mixed integer programming this need, fuzzy set theory is applied to the model. under logic and material requirements constraints. Chen Additionally, to provide the DMs with a decision making, and Lee (2004) develop a multi-product, multi-stage, and we propose a novel fuzzy multi objective mixed integer multi-period scheduling model to deal with multiple mathematical model. Through the solution approach, DMs incommensurable goals for a multi-echelon supply chain determine the preferred compromise solution. network with uncertain market demands and product The paper is further organized as follows: After the prices. The supply chain scheduling model is constructed introduction section, in Section 2, we described the as a mixed-integer nonlinear programming problem to relevant literature about supply chain modeling and fuzzy satisfy several conflict objectives, such as fair profit applications. In Section 3, the proposed model which is distribution among all participants, safe inventory levels, fuzzy multi objective mixed integer linear programming maximum customer service levels, and robustness of model and the model development are presented. We decision to uncertain product demands, therein the tested the novel model with a numerical example and compromised preference levels on product prices from the discussed the results obtained by LINGO 12.0 (industrial sellers and buyers point of view are simultaneously taken version) package programmer in Section 4. After into account. Gen and Syarif (2005) deal with a presenting the computational experiments, the paper is production/distribution problem to determine an efficient finalized with conclusion section. integration of production, distribution and inventory system in order to minimize system wide costs while 2. LITERATURE REVIEW satisfying all demand required. The study proposes a new In real-world situations, most enterprises have only paid technique called spanning tree-based genetic algorithm. In attention on separately optimizing their order to improve its efficiency, the proposed method is hybridized with the fuzzy logic controller concept for auto- In most real-world SCM problems, environment tuning the genetic algorithm parameters. The proposed coefficients and model parameters are frequently imprecise method is compared with traditional spanning tree-based / fuzzy because some information is incomplete and/or genetic algorithm approach. This comparison shows that unavailable over the planning. Conventional LP and the proposed method gives better results. Lin et al. (2007) special solution algorithms can not solve all fuzzy SCM compare flexible supply chains and traditional supply problems. Fuzzy set theory was developed by Zadeh in chains with a hybrid genetic algorithm and mention 1965, since then fuzzy set theory has been applied to the advantages of flexible ones. Azaron et al. (2008) develop a fields of operations research (linear programming, non- multi-objective stochastic programming approach for linear programming, multiple criteria decision making and supply chain design under uncertainty. Demands, supplies, so on), management science, artificial intelligence/expert processing, transportation, shortage and capacity system, statistics and many other fields. To formulate the expansion costs are all considered as the uncertain fuzzy/imprecise numbers, membership functions can be parameters. Their multi-objective model includes (i) the used. Traditional mathematical programming techniques, minimization of the sum of current investment costs and obviously, can not solve all fuzzy programming problems. the expected future processing, transportation, shortage In practice, input data are usually fuzzy / imprecise and capacity expansion costs, (ii) the minimization of the because of incomplete or non-obtainable information and variance of the total cost and (iii) the minimization of the knowledge. Because of this, precise mathematics is not financial risk or the probability of not meeting a certain sufficient to model a complex system. For solving decision budget. You and Grossmann (2008) address the making problem and fuzzy linear programming problem, optimization of supply chain design and planning under various models are developed. In the last two decades, responsive criterion and economic criterion with the multiple objective decision making techniques have been presence of demand uncertainty. By using a probabilistic applied to solve practical problems, such as academic model for stock-out, the expected lead time is proposed as planning, production and manufacturing planning, the quantitative measure of supply chain responsiveness. location, logistics, financial planning, portfolio selection, Farahani and Elahipanah (2008) develop a mixed integer and so on (Lai and Hwang, 1992). linear programming model with two objective functions: Hu and Fang (1999) solve the problem of fuzzy minimizing costs, and minimizing the sum of backorders inequalities linear membership function by employing the and surpluses of products in all periods. They also consider concepts of constraint surrogating and maximum entropy. delivery lead times and capacity constraints in a multi- Vasant et al. (2005) propose a new fuzzy linear period, multi-product and multi-channel network. Tuzkaya programming based methodology using modified S-curve and Önüt (2009) develop a model to minimize holding membership function. Liang (2006) develops an inventory and penalty cost for suppliers, warehouse and interactive fuzzy multi-objective linear programming manufacturers based a holonic approach. The model is method for solving the fuzzy multi objective transportation restricted to only two-echelon and does not involve problems with piecewise linear membership function. determining location strategy of the supply chain. Peidro et al. (2007) propose a new mathematical Sourirajan et al. (2009) consider a two-stage supply chain programming model for supply chain planning under with a production facility that replenishes a single product supply, process and demand uncertainty. Chang (2007) at retailers. The objective is to locate distribution centers in proposes a new idea of how to formulate the binary the network such that the sum of facility location, pipeline piecewise linear membership function. Alves and Climaco inventory, and safety stock costs is minimized. They use (2007) review interactive methods for multi objective genetic algorithms to solve the model and compare their integer and mixed integer programming. Liang (2008) performance to that of a Lagrangian heuristic developed in develops a fuzzy multi-objective linear programming earlier work. Xu and Nozick (2009) formulate a two-stage model with piecewise linear membership function to solve stochastic program and a solution procedure to optimize integrated multi-product and multi-time period supplier selection to hedge against disruptions. Their production/distribution planning decisions problems with model allow for the effective quantitative exploration of fuzzy objectives. Liang and Cheng (2009) apply fuzzy sets the trade-off between cost and risks to support improved to multi-objective manufacturing/distribution planning decision-making in global supply chain design. Shin et al. decision problems with multi-product and multi-time (2009) provide buying firms with a useful sourcing policy period in supply chains by considering time value of decision tool to help them determine an optimum set of money for each of the operating categories. Peidro et al. suppliers when a number of sourcing alternatives exist. (2009) propose a new mathematical programming model They propose a probabilistic cost model in which for supply chain planning under supply, process and suppliers’ quality performance is measured by demand uncertainty. The model has been formulated as a inconformity of the end product measurements and fuzzy mixed integer linear programming model where data delivery performance is estimated based on the suppliers’ are ill-known and modeled by triangular fuzzy numbers. expected delivery earliness and tardiness. Cao et al. (2010) develop stochastic chance constrained mixed-integer nonlinear programming models to solve the bsk is the quantity of raw material shipped from refinery short-term crude oil scheduling problem. supplier s to plant k f is the quantity of the product shipped from plant k 3. PROBLEM FORMULATION kj to DC j In this section, a fuzzy multi-objective mixed integer qji is the quantity of the product shipped from DC j to nonlinear programming model for multi echelon supply customer i chain network here can be described as follows. 3.1. Problem description, assumptions, and notations Here, the constituted model represents three echelons, 1, if DC j is serves customer i multi supplier, multi manufacturer, multi DC, and multi yji customer problem. Decision maker wishes to design of SC 0, otherwise. network for the end product, select suppliers, determine the manufacturers and DCs and design the distribution Model parameters; ~ network strategy that will satisfy all capacities and demand Dk is the fuzzy capacity of plant k requirement for the product imposed via customers. The ~ Sups is the fuzzy capacity of supplier s for raw material problem is a single-product, multi-stage SCN design ~ problem. Considering company managers’ objectives, we W j is fuzzy distribution capacity of DC j formulated the SCN design problem as a fuzzy multi- di is the demand for the product at customer i objective mixed-integer non-linear programming model. Cji is the unit transportation cost for the product from The objectives are minimization of the total cost of supply DC j to customer i chain, minimization holding and ordering costs in DCs, and maximization of capacity utilization balance for DCs akj is the unit transportation cost for the product from (i.e. equity on utilization ratios). plant k to DC j tsk is the unit transportation and purchasing cost for the The assumptions used in this problem are: raw material from supplier s to plant k (1) The number of customers and suppliers and their demand and capacities are known, Ch is the holding cost per year at DC j (2) The number of plants and DCs and their maximum S is ordering cost to plant k from each of DCs capacities are known, (3) Customers are supplied product from a single DC. Objectives;

Fig. 2 presents a simple network of three-stages in supply f1 is the total cost of SCN. It includes the variable chain network. costs of transportation raw material from suppliers to manufacturers and the transportation the product The mathematical notation and formulation are as follows: from plants to customers through DCs. Indices; f2 is annual holding and ordering cost of products in i is an index for customers, for all i = 1,2…I DCs according to the economic order quantity j is an index for DCs, for all j = 1,2…J (EOQ) model. k is an index for plants, for all k = 1,2…K s is an index for suppliers, for all s = 1,2…S f3 is the equity of the capacity utilization ratio for manufacturers and DCs, and it is measured by mean square error (MSE) of capacity utilization ratios. The smaller value is, the closer the capacity utilization ratio for every manufacturer and DC is, thus ensuring the demand are fairly distributed among the DCs and manufacturers, and so it maximizes the capacity utilization balance.

Min f1 . . . t sk bsk akj f kj c ji q ji s k k j j i (1)

Fig 2. SCN of the proposed model

Model variables; constraint. Finally, constraints (11) and (12) are integrality 2.S.f kj constraints. s. . k f kj ch k Min f ch For convenience, in numerical example section, according 2 j 2 to Analytic Hierarchical Process (AHP) methodology, 2.S.f kj k fuzzy multi objective mixed integer nonlinear ch programming problem is converted to a single objective (2) problem by calculating priorities of objectives as 2 following, ( / ) ( / ) [ f kj Dk f kj Dk ] k j k j k Min g0 (x) w1 f1 w2 f2 w3 f3 Min f3 k w . . . 2 1 t sk bsk akj f kj c ji q ji ( / ) ( / ) s k k j j i [ q ji W j q ji W i ] j i j i i 2.S.f j kj s. f . k (3) kj ch k ch w 2 j 2.S.f 2 kj Subject To; k y 1 ch ji i (4) 2 j ( / ) ( / ) ~ [ f kj Dk f kj Dk ] k j k j k d i.y ji W j j w i 3 k (5) . q ji d i y ji i, j 2 ( / ) ( / ) [ q ji W j q ji W i ] (6) j i j i i j f kj q ji j k i (7) 3.2. Model Development ~ Sup Fuzzy nonlinear programming (FNLP) problem should be bsk s s k transferred into an equivalent crisp nonlinear programming (8) (NLP) problem as follows; f kj bsk ~ j s k Min g0 (x) (9) ~ ~ (Ax) b , i 1,2,..., m f i kj Dk k j x 0 (10) (13) 0,1 y i, j (11) ji Then it can be solved by conventional solution techniques , , 0 bsk f kj q ji i, j,k,s (12) or packages of NLP. Considering the Zimmermann’s method with fuzzy constraints and fuzzy objective, the problem is equivalent to; The model is composed of three objective functions (1-3). Max The first objective function (1) defines minimizing (x) shipment costs between suppliers, manufacturers, DCs and g0 customers. The second objective function is minimizing (x) holding and ordering costs in DCs using economic order i quantity model (2). Equation 3 (third objective) minimizes [0,1] equity of the capacity utilization ratio of manufacturers x 0 and DCs. (14) Constraint (4) represents the unique assignment of a DC to In the (14), S-curve membership function is used for fuzzy a customer, (5) is the fuzzy capacity constraint for DCs, nonlinear objective function and non-increasing linear (6) and (7) gives the satisfaction of customer and DCs membership function is used for fuzzy constraints. demands for the product, (8) gives the fuzzy supplier capacity constraint, (9) describes the raw material supply The S-curve membership function is a particular case of restriction, (10) is fuzzy manufacturer production capacity logistic function with specific values of B, C and . The modified S-curve membership function proposed by 4. COMPUTER EXPERIMENT Vasant (2005) is given in (15) and depicted in Fig. 3. In this section we present a numerical example to illustrate the proposed model mentioned in previous section. The 1, x x a application of the model is performed for a logical data 0.999, x x a which was inspired from related cases in the real world. The considered supply chain network includes five B (x) , x a x xb suppliers which are located in different places, three x 1 Ce manufacturer plants, three distribution centers and four 0.001, x xb customers (Fig. 2). The network is structured to supply raw materials and transport products from suppliers to end- b 0, x x users is constituted from multi echelon and capacitated (15) elements of network considering minimizing the total transportation costs between all echelons (suppliers, is the degree of membership function. The values of B, manufacturers, distribution centers (DCs) and customers, C and are found as B=1, C=0.001001001 and holding and ordering costs in DCs and unnecessary and =13.81350956 (Vasant, 2005). unused capacity of plants and DCs via decreasing variance of transported amounts between echelons. Numerical data used in example are given below, respectively. Table 1 and (x) 2 gives the priorities of objectives obtained by Expert 1 Choice 11.5 program to find rate of purposes according to 0.999 AHP methodology. Table 1. Relatives of Objective Functions (AHP) 0.5 f1 f2 f3 f 1 2 3 0.001 1 f2 1/2 1 3/2 0 x f3 1/3 2/3 1 a Sum 1.83 3.67 5.5 x x0 xb Fig. 3. The modified S-curve membership function Table 2. Normalized AHP Matrix The non-increasing linear membership function proposed f1 f2 f3 by Verdegay is given by (16) and depicted in Fig. 4 (Lai f1 0.545 0.545 0.545 and Hwang, 1992). f2 0.273 0.273 0.273 f3 0.182 0.182 0.182 1, (Ax)i bi According to Table 2, weight of each objective function is [(Ax)i bi ] w 0.542 , w 0.273 and w 0.182 , respectively. i (x) 1 , bi (Ax)i bi pi 1 2 3 pi Because of matrix consistency < 0.1, this matrix will be 0, (Ax)i bi pi accepted. (16) Number of Total Suppliers: 5 Number of Total Customers: 4 where; bi is right hand side of and pi is the tolerance of Number of Total Manufacturers: 3 the ith constraint. Number of Total Distribution Centers: 3 S: 20tl; Ch: 1.5tl (tl: Turkish liras) i (x) Table 3. Unit transportation costs values between suppliers and manufacturers (TL) Suppliers 1 Manufacturers 1 2 3 4 5 1 0.5 0.3 0.4 0.4 0.5 2 0.6 0.4 0.5 0.6 0.6 3 0.5 0.5 0.6 0.6 0.4 b b p (Ax) i i i i Table 4. Unit transportation costs values between manufacturers and DCs (TL) Fig. 4. The membership functions for the fuzzy constraints ~ Manufacturers (Ax)i bi DCs 1 2 3 Nonincreasing linear membership function of 1st DC’s 1 1.4 1.1 1.1 fuzzy capacity constraint in (5) is given as, 2 1.1 1.2 0.8 3 1.3 1.4 0.9 i (x) Table 5. Unit transportation costs values between DCs and Customers (TL) 1 DCs 1, d y 6300 Customers 1 2 3 i ji i 1 0.9 0.9 0.7 2 0.7 0.6 0.6 [ di y ji 6300] d y 6300 6930 i ji i 3 0.8 0.5 0.7 (x) 1 , 6300 d y 6930 i 630 i ji 4 0.6 0.9 0.8 i i Table 6. Fuzzy capacities of suppliers, manufacturers, DCs 0, di y ji 6930 (b , b p ) i and demands of customers (unit) i i i Suppliers Manufacturers DCs Customers 1 (5000, 5500) (7000,7700) (6300,6930) 3100 In the equation (8), nonincreasing linear membership 2 (5500,6050) (6500,7150) (6700,7370) 3100 function for fuzzy capacity constraint of 1st supplier is 3 (5250,5775) (6500,7150) (6000,6600) 3100 given as, 4 (4750,5225) ------3100 5 (4500,4950) ------1, 5000 bsk k 4.1 Computational analysis [ 5000] bsk k For the proposed model, S-curve membership function of (x) 1 , 5000 5500 i 500 bsk the fuzzy objective g0 (x) is given as follows, k 0, 5500 bsk k a 1, g 0 (x) g 0 (x ) a 0.999, g 0 (x) g 0 (x ) 1 a b (x) (x) , g0 (x ) g0 (x) g 0 (x ) g (x)g (xa ) i 13.81 0 0 g (xb )g (xa ) 1 0.001e 0 0 1 b 0.001, g 0 (x) g0 (x ) b 0, g0 (x) g0 (x ) bsk a b k where: g0 (x ) 13678.3 and g0 (x ) 18648.7 are obtained as the value of minimizing and maximizing 5000 5500 g0 (x) . In the equation (10), nonincreasing linear membership function of 1st manufacturer’s fuzzy capacity constraint is (x) given as, i (x) g0 1 1, 7000 f kj j 0.999 1 [ 7000] f kj j 0.5 i (x) 1 , 7000 7700 700 f kj j 0.001 0, 7700 f kj j 7000 7700 f 0 kj x j 13678.3 16163.518648.7 i (x) Fig. 5. The S-curve membership function

1

7000 7700 f kj j come and go from 2800 units to 3400 units considering balancing distribution. When applying the fuzzy model to the computational problem, the output is given in Table 7. According to the fuzzy approach, the distribution follows like; 2225 units from first supplier, 5225 units from fourth supplier, 4800 units of fifth suppliers are transported to the manufacturer According to output obtained by LINGO 12.0 package plants. program, results are given in Table 7. Table 7. The results obtained by LINGO package program Fuzzy Problem Crisp Problem Decision Value Decision Value variable variable

b1,1 2225 b1,3 2000 b4,3 5225 b2,1 2428 b5,1 3975 b2,2 3072 b5,3 975 b3,2 28 f1,1 6200 b4,1 372 f3,3 6200 b5,3 4500 q1,2 3100 f1,2 2800 q1,3 3100 f2,1 3100 q3,1 3100 f3,2 3400 q3,4 3100 f3,3 3100 y1,2 1 q1,4 3100 y1,3 1 q2,2 3100 y3,1 1 q2,3 3100 y3,4 1 q3,1 3100 Fig. 6. Optimal distribution network y1,4 1 y2,2 1 6200 units which come from first and fifth supplier are y2,3 1 shipped to first DC from first manufacturer plant. Also y3,1 1 6200 units of product are transported from third Total 16783.83 TL Total 13678.27 TL manufacturer plant to third DC. Ensuring equation 4 Objective Objective constraint, each customer provided their demand only one 30185 30185 TL f1 TL f1 DC via providing a better balanced distribution. All customers’ demand is supplied from DCs as 6200 units f2 1219.83 TL f2 1472.5 TL from first and 6200 units from third DCs (Fig. 6). At three f3 0.6542 f3 0.4655 echelons, all transportation costs and holding/ordering According to solving the crisp problem, decision maker costs in DCs (first and second objective functions) purchased raw materials from all suppliers. 2000 units calculated about 16783.83 TL. Supporting the third from first suppliers, 5500 units from second supplier, 28 objective, as crisp model, the unnecessary and unused units from third supplier, 372 units from fourth and 4500 capacity of plants and DCs are minimized. When we units from fifth supplier, are transported to manufacturers. examined the second and third echelons’ distribution, it’s 2800 units which come from second and fourth supplier seen that the transportation between manufacturers-DCs- are shipped to second DC from first manufacturer. Also customers steadied 6200 units. It is better than the crisp 3100 units of product are transported from second model. As a result, although increased cost, fuzzy model manufacturer to first DC. 3400 units to second DC and provides a better balanced distribution flows between 3100 units to third DC totally 4500 units of product facilities. shipped from third manufacturer. Supporting equation 4 constraint, each customer provided their demand only one 5. CONCLUSION DC via providing a better balanced distribution. All In this study, a fuzzy mixed integer non-linear customers’ demand is supplied from DCs as 3100, 6200 programming model is developed to design a supply chain and 3100 units respectively (Fig. 6). At three echelons, all network by combining three different objectives. We have transportation costs and holding/ordering costs in DCs considered three objectives: (1) minimization of total (first and second objective functions) calculated about transportation cost of plants and distribution centers (DCs), 13678.27 TL. Providing the third objective, the inbound and outbound distribution costs, (2) minimization unnecessary and unused capacity of plants and DCs are of holding and ordering costs via EOQ method (3) minimized via decreasing variance of transported amounts maximization of capacity utilization balance for DCs (i.e. between second and third echelons. When we examined equity on utilization ratios). We used the developed model the second and third echelons’ distribution, it’s seen that to determine from which suppliers, manufacturers, DCs the transportation between manufacturers-DCs-customers and how much amounts will be transported to answer customers demand. We developed binary variables to Farahani, R.Z. and M. Elahipanah (2008). A genetic provide a DC for a customer. So we have prevented algorithm to optimize the total cost and service level for unbalanced distributions between DCs and customers. For just-in-time distribution in a supply chain. Int. J. the fuzzy nonlinear objective function, S-curve Production Economics 111, pp. 229–243. membership function and non-increasing linear Gen M. and A. Syarif (2005). Hybrid genetic algorithm for membership function are used for the fuzzy nonlinear multi-time period production distribution planning. objective function and fuzzy constraints, respectively. The Computers and Industrial Engineering 48, pp. 799-809. proposed model shows that fuzzy logic application could increase the cost but it provides better balanced Gong, Q., K.K. Lai and S. Wang (2008). Supply chain distribution to satisfy customers. networks: Closed Jackson network models and properties. International Journal of Production Economics 113, pp. As a future work, uncertainty of costs and demands can be 567-574. considered in the model and new solution methodologies including uncertainty can be developed via fuzzy models Gumus, A.T., A.F. Guneri and S. Keles (2009). Supply with piecewise membership function and various s-shaped chain network design using an integrated neuro-fuzzy and membership functions. Additionally, new solution MILP approach: A comparative design study. Expert methodology based on tabu search or heuristic methods Systems with Applications 36 (10), pp. 12570-12577. can be developed to obtain new optimal solutions for the Hu, C.F. and S.C. Fang (1999). Solving fuzzy inequalities multi-objective SCN design problem, and the effectiveness with piecewise linear membership functions, IEEE of the solution methodology can be investigated. Transactions on Fuzzy Systems, 7 (2), pp. 230-235. 6. REFERENCES Lai, Y.J. and C.L. Hwang (1992). Fuzzy mathematical Altiparmak, F., M. Gen, L. Lin and T. Paksoy (2006). A programming: Method and applications. Springer-Verlag. genetic algorithm approach for multi-objective Liang, T.F. (2006). Distribution planning decisions using optimization of supply chain networks. Computers and interactive fuzzy multi-objective linear programming. Industrial Engineering 51, pp. 197-216. Fuzzy Sets and Systems, 157, pp. 1303-1316. Alves, M.J. and J. Climaco (2007). A review of interactive Liang, T.F. (2008). Fuzzy multi-objective methods for multiobjective integer and mixed-integer production/distribution planning decisions with multi- programming approach. European Journal of Operational product and multi-time period in supply chain. Computers Research 180, pp. 99-115. and Industrial Engineering, 55, pp. 676-694. Azaron, A., Brown, K.N., Tarim, S.A. and M. Modarres Liang, T.F. and H.W. Cheng (2009). Application of fuzzy (2008). A multi objective stochastic programming sets to manufacturing/distribution planning decisions with approach for supply chain design considering risk. multi-product and multi-time period in supply chains. International Journal of Production Economics 116 (1), pp. Expert Systems with Applications 36, pp.3367-3377. 129-138. Lin, L., M. Gen and X. Wang (2007). A hybrid genetic Cao, C., X. Gu and Z. Xin (2010). Stochastic chance algorithm for logistics network design with flexible constrained mixed-integer nonlinear programming models multistage model. International Journal of Information and the solution approaches for refinery short-term crude Systems for Logistics and Management 3 (1), pp. 1-12. oil scheduling problem. Applied Mathematical Modelling, doi:10.1016/j.apm.2010.02.015. Narasimhan, R. and S. Mahapatra (2004). Decision models in global supply chain management. Industrial Marketing Chang, C.T. (2007). Binary behavior of fuzzy Management 33, pp. 21-27. programming with piecewise linear membership functions. IEEE Transactions on Fuzzy Systems, 15 (3), pp. 342-349. Ozdamar, L. and T. Yazgac (1997). Capacity driven due date settings in make-to-order production systems. Chen, L. and W. Lee (2004). Multi objective optimization International Journal of Production Economics 49 (1), pp. of multi echelon supply chain networks with uncertain 29-44. product demands and prices. Computers and Chemical Engineering 28, pp. 1131-1144. Peidro, D., J. Mula and R. Poler (2007). Supply chain planning under uncertainty: a fuzzy linear programming Cohen, M.A. and H.L. Lee (1989). Resource deployment approach. In: Fuzzy Systems Conference, 2007 FUZZ- analysis of global manufacturing and distribution IEEE, 2007 IEEE International, pp. 1-6. networks. Journal of Manufacturing and Operations Management 2, pp. 81-104. Peidro, D., J. Mula, R. Poler and J.L.Verdegay (2009). Fuzzy optimization for supply chain planning under supply, demand and process uncertainities. Fuzzy Sets and Systems 160 (18), pp. 2640-2657. Pyke, D.F. and M.A. Cohen (1993). Performance characteristics of stochastic integrated production- distribution systems. European Journal of Operational Research 68 (1), pp. 23-48. Selim, H. and I. Ozkarahan (2008). A supply chain distribution network design model: An interactive fuzzy goal programming-based solution approach. International Journal of Advanced Manufacturing Technologies 31, pp. 401-418. Shin H., W.C. Benton and M. Jun (2009). Quantifying suppliers’ product quality and delivery performance: A sourcing policy decision model. Computers & Operations Research 36, pp. 2462-2471. Sourirajan K., L. Ozsen and R. Uzsoy (2009) A genetic algorithm for a single product network design model with lead time and safety stock considerations. European Journal of Operational Research 197 (2), pp. 599-608. Syarif, A., Y. Yun and M. Gen (2002). Study on multi- stage logistics chain network: a spanning tree-based genetic algorithm approach. Computers and Industrial Engineering 43 (1), pp. 299-314. Tuzkaya U. and S. Önüt (2009). A holonic approach based integration methodology for transportation and warehousing functions of the supply network. Computers and Industrial Engineering 56, pp. 708-723. Vasant, P., R. Nagarajan and S. Yacoob (2005). Fuzzy linear programming with vague objective coefficients in an uncertain environment. Journal of the Operational Research Society, 56, pp. 597-603. Xu, N. And L. Nozick (2009). Modeling supplier selection and the use of option contracts for global supply chain design. Computers & Operations Research 36, pp. 2786- 2800. Yan H., Z. Yu and T.C.E. Cheng (2003). A strategic model for supply chain design with logical constraints: formulation and solution. Computers & Operations Research 30 (14), pp. 2135-2155. You, F. and E. Grossmann (2008). Design of responsive supply chain under demand uncertainty. Computers & Chemical Engineering 32 (12), pp.3090-3111. Zadeh, L.A. (1965). Fuzzy sets. Information and Control 8, pp. 338-353.