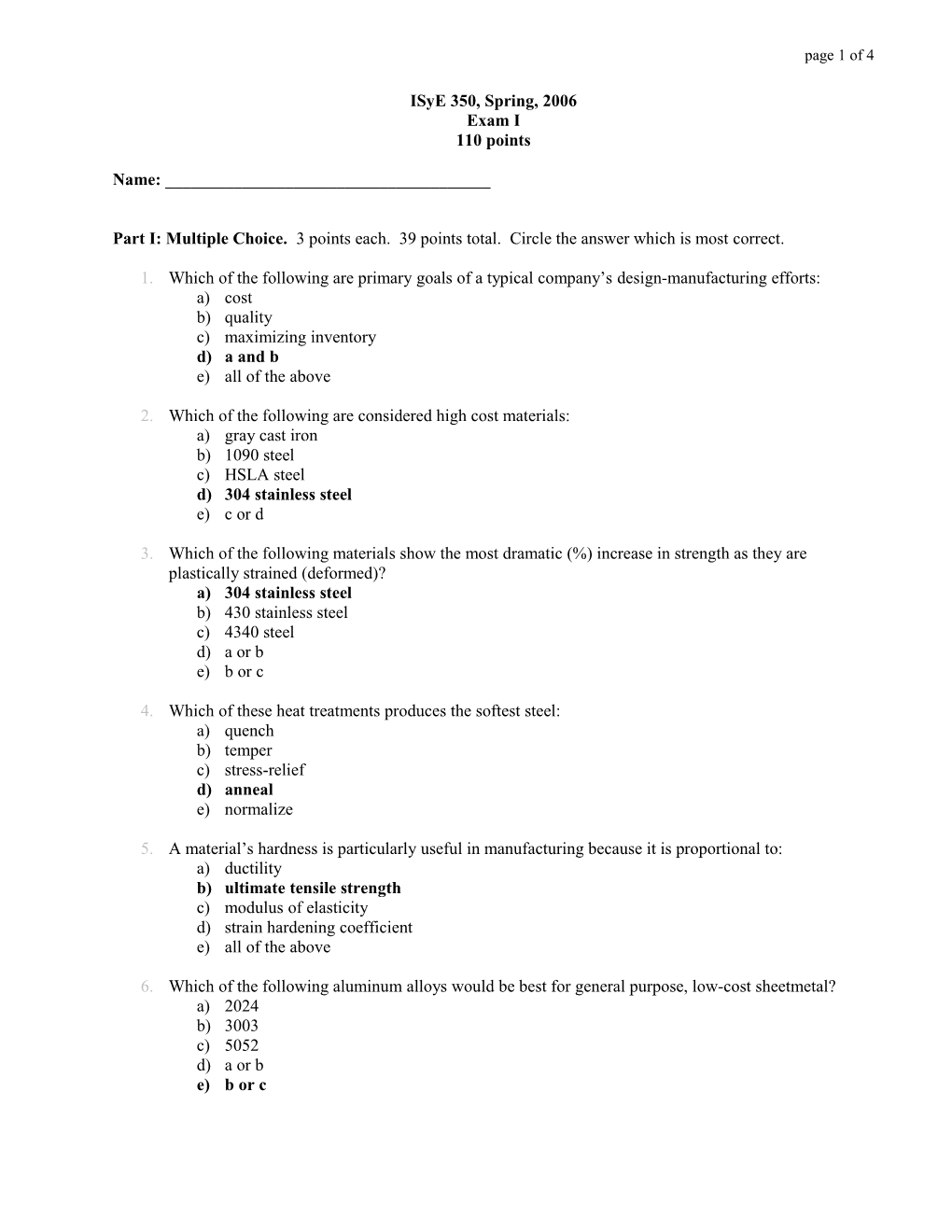

page 1 of 4

ISyE 350, Spring, 2006 Exam I 110 points

Name: ______

Part I: Multiple Choice. 3 points each. 39 points total. Circle the answer which is most correct.

1. Which of the following are primary goals of a typical company’s design-manufacturing efforts: a) cost b) quality c) maximizing inventory d) a and b e) all of the above

2. Which of the following are considered high cost materials: a) gray cast iron b) 1090 steel c) HSLA steel d) 304 stainless steel e) c or d

3. Which of the following materials show the most dramatic (%) increase in strength as they are plastically strained (deformed)? a) 304 stainless steel b) 430 stainless steel c) 4340 steel d) a or b e) b or c

4. Which of these heat treatments produces the softest steel: a) quench b) temper c) stress-relief d) anneal e) normalize

5. A material’s hardness is particularly useful in manufacturing because it is proportional to: a) ductility b) ultimate tensile strength c) modulus of elasticity d) strain hardening coefficient e) all of the above

6. Which of the following aluminum alloys would be best for general purpose, low-cost sheetmetal? a) 2024 b) 3003 c) 5052 d) a or b e) b or c page 2 of 4

7. Recyclable plastics generally include a) thermoplastics b) thermosets c) heavily cross-linked polymers d) a and b e) a and c

8. Which of these plastics is most commonly used for low-cost translucent containers? a) PS / Polystyrene b) PVC / Polyvinyl-chloride c) Nylon / Polyamide d) HDPE / High density polyethylene e) PP / Polypropylene

9. Which of the following is considered an “engineering thermoplastic” (high strength)? a) PS / Polystyrene b) PVC / Polyvinyl-chloride c) Nylon / Polyamide d) HDPE / High density polyethylene e) PP / Polypropylene

10. The Widget company has setup a new production line to make Widgets. A key dimension is specified as 8.500” +/- 0.050”. The first 1000 parts off their assembly line show these statistics for that dimension: mean value = 8.520” and standard deviation = 0.007”. What is the value of Cpk for these data? a) 1.19 b) 2.38 c) 0.71 d) 1.43 e) 3.33 f) none of the above

11. Which of the following process capability data shows the best current capability? a) Cp = 2.0, Cpk = 0.8 b) Cp = 1.8, Cpk = 1.1 c) Cp = 1.6, Cpk = 1.4 d) Cp = 1.2 and Cpk = 1.2 e) Either a or b

12. Which of the following process capability data shows the best potential capability? (options are the same as previous question): a) Cp = 2.0, Cpk = 0.8 b) Cp = 1.8, Cpk = 1.1 c) Cp = 1.6, Cpk = 1.4 d) Cp = 1.2 and Cpk = 1.2 e) Either a or b

13. Which of these product design procedures is most likely to result in an optimum product? a) Select the material and then design to suit this material. b) Select the material at the same time as making design decisions. c) Design the product, then choose the material to suit the design. d) Either a or c. page 3 of 4

Part II: Short Answer. 4 points each. 60 points total. Succinctly answer these questions. (A few words in some cases, a few sentences in others).

1. Name four types of machining operations. milling, turning, drilling, broaching, shaping...

2. Name eight general design/manufacturing factors that influence the cost of a product. materials, components, labor, engineering, inventory, depreciation, fabrication, scrap/rework, inspection, regulatory, taxes.

3. The ACME company is heat treating (long) 5” diameter 1040 steel bars with a heat-quench operation. The surface of the bars hardens to Rc=45, but the center of the bars only hardens to Rc=20. They want to achieve Rc of between 40 and 45 throughout the bar’s cross-section. What alternative steel alloy(s) would you recommend? 4140 or 4340 (higher hardenability than 1040 but same max hardness)

4. Now the ACME Company is wearing out their High Speed Steel (HSS) toolbits very quickly. Name two alternative cutting materials that would wear less quickly. tungsten carbide (“carbide”), cermet, TiN coated carbide, TiN coated HSS.

5. In process capability studies, what is the difference between assignable cause and common cause?

6. Give two examples of assignable cause factors.

7. In comparison to other manufacturing processes, name the main advantage and the main disadvantage of machining. Advantage: it is adaptable. It can make almost anything with little product-specific investment. Disadvantage: it is generally inefficient. Time consuming to make each part.

8. What is the key defining difference between “hot working” and “cold working”? Hot working is above the recrystallization temperature. Cold working is below the recrystallization temperature.

9. The Bent Bar Company is attempting to bend 1090 steel bars 90 degrees, but the bars develop cracks about halfway through the operation. What process recommendations would you make to increase ductility, so that the bars smoothly bend through the full 90 degrees instead of breaking? The dimensions of the bar and the 1090 material must not be changed. Employ hot working: raise the temperature of the bar during the bending operation. Ductility increases with increasing temperature. NOT the same as “heat treating”. page 4 of 4

10. In a typical company that designs and manufactures products, describe and/or draw an optimal relationship between the Product Design group, the Production/Process Design group, and the Cost/Budget/Accounting group. All are inter-related and work concurrently. Organization structure is flat -- not hierarchical. Drawing would be a triangle with each group at a corner, arrows between each.

11. Name 3 advantages and 1 disadvantage of gray cast iron. Advantages: inexpensive, easy to manufacture, very common, wear resistant, self-lubricating, self- damping, machines easily, slightly lower density than steel, suitable for parts of any size. Disadvantages: brittle, weak, heavy, not weldable, lower modulus than steel.

12. For ductile cast iron, a) What is unique about the graphite that forms in it? b) What is one disadvantage of this material? a) graphite is in the shape of round nodules. b) it is difficult / costly to manufacture compared to grey cast iron.

13. The We-Weld-It company was making bicycle frames from 1020 steel, then recently switched to 4340 steel using the same manufacturing procedures. After the switch, customers report that cracks are occurring at the frame joints. What is the most likely metallurgical explanation for this, and what process change would you recommend to solve it (keeping the 4340 steel)? Martensite is probably forming at the welds due to the high-hardenability of 4340 (makes martensite easily). Martensite is brittle so cracks easily. Temper the joints after welding to restore ductility. Or, switch to a brazing technique so that the 4340 does not transform to austenite (and then martensite).

14. Give two examples of how materials selection and manufacturing process selection are inter-related. If you want to use cast iron, you can’t later bend or weld it. If you want to cast something, you are limited to the materials/alloys that can be cast—cast iron, A380 aluminum. If you want to weld something, you are limited to weldable metals such as steel, 6061 aluminum. If you grind high carbon steel, you will need to temper it after (or grind with coolant to keep it cool). Etc.

15. Rank these instruments in order of typical accuracy (from best to worst): dial caliper, micrometer caliper, CMM, machinist’s rule. CMM, micrometer, dial caliper, machinist’s rule.

Part III: Matching. 1 points for each match. 11 points total. Write the item number from the left column in the matching space in the right column.

Ferrous alloys: 1. “18-8” _5__ 4130 steel 2. low-carbon _4__ 1045 steel 3. tool steel _2__ 1020 steel 4. strong and ductile _1__ 304 stainless steel 5. “cromoly” _3__ W1 6. high-carbon _6__ 1095 steel

Tolerances: 1. minimum clearance _2__ LMC 2. smallest shaft _1__ allowance 3. smallest hole _5__ interference 4. a little greater than LSL _3__ MMC 5. a tight press-fit _4__ LCL