5th International DAAAM Conference "INDUSTRIAL ENGINEERING - ADDING INNOVATION CAPACITY OF LABOUR FORCE AND ENTREPRENEURS" 20 – 22nd April 2006, Tallinn, Estonia

RECYCLING AND APPLICATION OF PERFORATED STEEL BAND AND PROFILES

Mironov, V., Boyko, I. & Serdjuks, D.

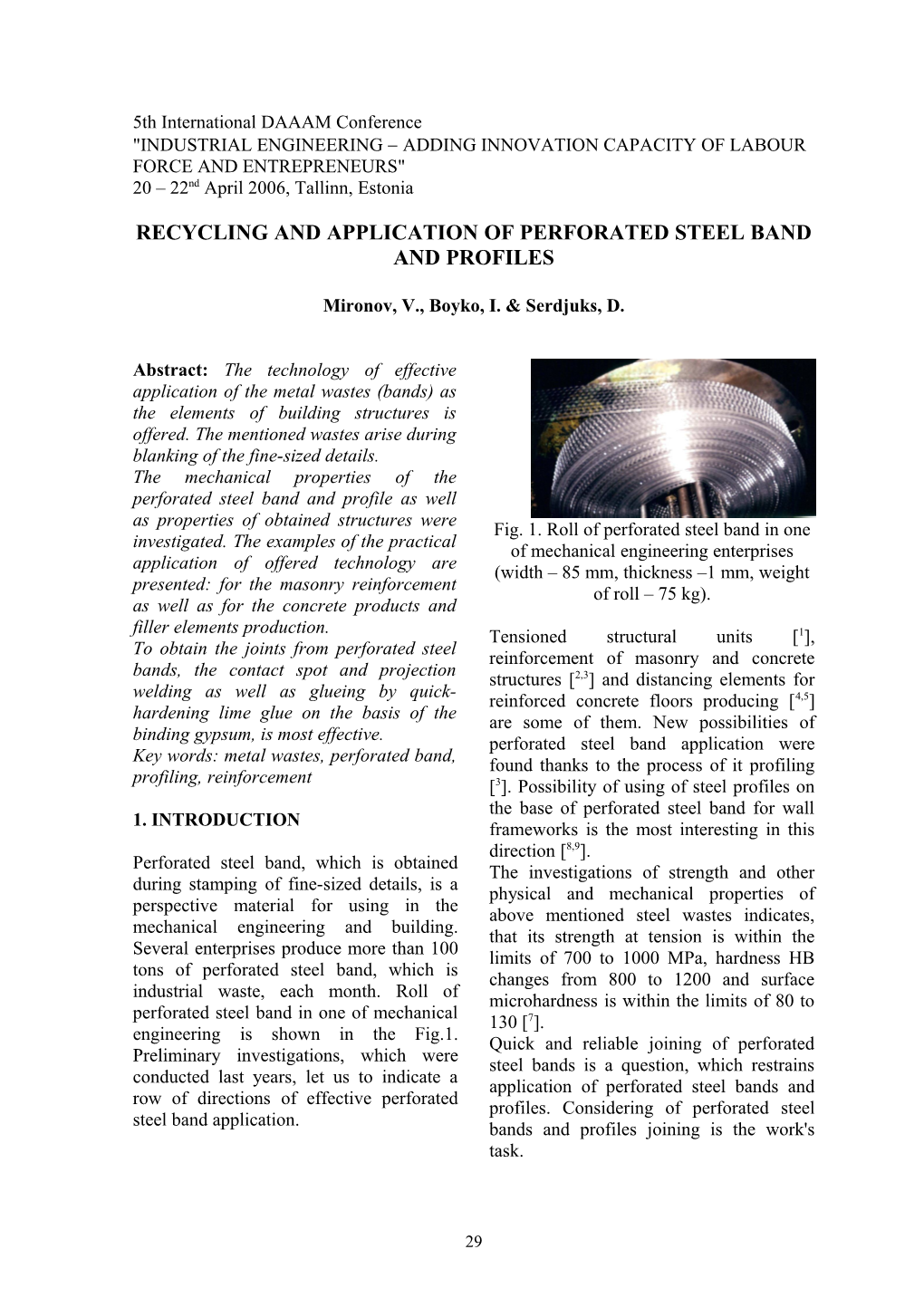

Abstract: The technology of effective application of the metal wastes (bands) as the elements of building structures is offered. The mentioned wastes arise during blanking of the fine-sized details. The mechanical properties of the perforated steel band and profile as well as properties of obtained structures were Fig. 1. Roll of perforated steel band in one investigated. The examples of the practical of mechanical engineering enterprises application of offered technology are (width – 85 mm, thickness –1 mm, weight presented: for the masonry reinforcement of roll – 75 kg). as well as for the concrete products and filler elements production. Tensioned structural units [1], To obtain the joints from perforated steel reinforcement of masonry and concrete bands, the contact spot and projection structures [2,3] and distancing elements for welding as well as glueing by quick- reinforced concrete floors producing [4,5] hardening lime glue on the basis of the are some of them. New possibilities of binding gypsum, is most effective. perforated steel band application were Key words: metal wastes, perforated band, found thanks to the process of it profiling profiling, reinforcement [3]. Possibility of using of steel profiles on the base of perforated steel band for wall 1. INTRODUCTION frameworks is the most interesting in this direction [8,9]. Perforated steel band, which is obtained The investigations of strength and other during stamping of fine-sized details, is a physical and mechanical properties of perspective material for using in the above mentioned steel wastes indicates, mechanical engineering and building. that its strength at tension is within the Several enterprises produce more than 100 limits of 700 to 1000 MPa, hardness HB tons of perforated steel band, which is changes from 800 to 1200 and surface industrial waste, each month. Roll of microhardness is within the limits of 80 to perforated steel band in one of mechanical 130 [7]. engineering is shown in the Fig.1. Quick and reliable joining of perforated Preliminary investigations, which were steel bands is a question, which restrains conducted last years, let us to indicate a application of perforated steel bands and row of directions of effective perforated profiles. Considering of perforated steel steel band application. bands and profiles joining is the work's task.

29 2. WELDING OF PERFORATED STEEL BANDS AND PROFILES Several methods of perforated steel bands welding were considered to determine the optimum method for structures producing. Resistance spot welding, hand-made electric arc welding by the electrode and wire and tungsten arc welding in the protective gas medium should be mentioned among them. Butt and lap weldings are necessary to produce flat frameworks, which are used as Fig. 3. Contact welding machine reinforcement of masonry and concrete DPM60CV (Oerlicon) for spot welding of elements (Fig.2). perforated steel band. a)

b) Fig. 4. Macrostructure of lap joint of perforated steel bands.

Projection welding should be used for butt joint receiving of perforated steel bands. The method shows good results for the protective guards’ production. But hand made electric welding has low productivity and presence of faced material’ bulges (Fig.2 b)). Fig. 2. Lap a) and butt b) weldings of perforated steel bands. 3. BINDING OF PERFORATED STEEL BANDS Lap joints are worth while to produce by Binding is an effective method of the contact spot welding. Experimental perforated bands joining in the conditions investigations were conducted by the butt of the construction site. Metal clamps also welding machine DPM60CV (Oerlicon) can be used for the producing of load with the vertical placement of electrode bearing elements. Metal wire or quick- (Fig.3). Welding current and compression action clamps are used for the joining of force were equal to 24 kA and 650 kPa, the distancing elements and reinforcement. respectively. Reliable welding joints with Investigations were carried out by the small deformations were obtained in the plastic clamps with thickness 0.1 mm results. However, the method has low (Fig.5) and metal wire. Binding gun was productivity. Using of semi-automatic arc used in the case when joining was welding machine is more effective method conducted by the metal wire. in the case.

30 5. PRACTICAL EXAMPLE OF PERFORATED STEEL BAND AND PROFILES APPLICATION Profiles on the base of perforated steel bands, which are wastes of stamping pro- duction, can be used for the distancing elements [9]. The purpose of distancing elements is to provide correct placement of reinforcement of reinforced concrete floors. Fig. 5. Plastic clamps for perforated steel Using of distancing elements on the base of bands joining. perforated steel bands enables to improve some disadvantages of just existing ones, Obtained results indicate, that binding is an such as complexity of production, small effective method of perforated steel bands strength, big cost and limitation of sizes. and profiles joining. Using of binding guns Examples of distancing elements are given enables to increase the effectiveness of the in Fig.7. method.

4. JOINING BY THE GLUEING Perforated steel profiles are used for the wall frameworks. Double-T and U-shape a) b) profiles are the most effective because heat insulating materials can be placed between the flanges (Fig.6).

c) d) e) Fig. 7. Examples of distancing elements on the base of perforated steel band: a), b) T- shape distancing elements; c), d) double-T- shaped distancing elements; e) U-shaped distancing element; a, b, c, h, h1, h2, m, n – dimensions of cross-sections. Distancing elements, which are shown in the Fig.4 a) –d), consist from the two parts – angles and U-profiles, joined together by Fig. 6. Joint of finishing panel and binding or welding. Heights of these perforated steel band. distancing elements are within the limits of 20 to 100 mm. The distancing elements can Finishing panel, which is made from the have the length from 80 to 2500 mm. regypsum, is joined with the steel profile Distancing elements should possess by the quick-hardening glue on the basis of enough strength to take up concentrated the binding gypsum. The joint has enough force in 1.2 kN. The value of force is dead strength at shear (0.73 – 1.5 MPa) [9], to weight of a worker, multiplied by safety take up the stresses acting in it due to the factor. dead weight of finishing panel. Load-bearing capacities of distancing elements were evaluated experimentally.

31 Three distancing elements of type d) and the binding gypsum can be recommended three of type e) were tested at the action of for a wide application in the constructional axial force. The elements of type d) were practice. produced by the resistance spot welding. Dimensions of cross-section for distancing 7. REFERENCES element of type d) h, m and n were equal to 53, 40 and 25 mm, respectively. 1. Serdjuks, D. Mironov, V. Perforated steel Dimensions of cross-section for distancing band in the composite saddle shape cable element of type e) h and c were equal to 55 roof. Proceedings of the 2nd International and 15 mm, respectively. All specimens DAAAM Conference, Tallinn, 2002, 212- have length, equal to 110 mm. Scheme of 215. specimens loading is shown in Fig.8. 2. Mironovs V., Lapsa V.A. Mūra stieg- rojuma karkass. Latvijas patenta pietei- kums nr. P-04-126, 18.10.2004. 3. Mironov, V, Serdjuk, D. Composite materials on the base of perforated steel band., Proc of 12th Int. Conf. “Eng. Materials and Tribology. Baltmattrib- 2003”, Tallinn, 2003, 54-55. 4. Mironov, V. Working armature for the reinforcement of the building material ware. High Tech in Latvia, 2001, Latv. TP, a) b) c) 21. Fig.8. Scheme of specimens loading: a), b) 5. Mironov, V. Lapsa, V.A. Dzelzsbetona double-T-shaped distancing elements, c) konstrukciju stiegrojuma distanceri. U-shaped distancing element. Latvijas patenta pieteikums nr. P-04-98, 16.06.2004. Results of experiment illustrate, that load- 6. Mironov, V., Serdjuk, D., Muktupavela, bearing capacity of all distancing elements F. Steel Profile from the perforated bands. is significantly larger, than 1.2 kN. So, Proc of 4th Int. DAAAM Conf., Tallinn, double-T-shaped distancing elements can 2004, 138-140. carry 2 KN in the case, when the load is 7. Lapsa V-A., Mironovs V. Sienas applied in the longitudinal direction konstrukcija. Latvijas patents nr. 13363B, (Fig.8.a)), and 1.35 kN in the case, when Cl. E04C5/03, iesn. 31.03.2004, iesn. nr. P- the load is applied in the transversal 04-38, publ. 01.12.2005. direction (Fig.8.b)). U–shaped distancing 8. Lapsa, V.A., Mironovs, V. Sienas elements can take up load of 5 kN. But the konstrukcija. Atbalstsienas elements nr. ribs of U–shape distancing elements must 13291B, Cl. E04135/16, iesn. 08.10.2003, be vertical. iesn. nr. P-03-108, publ. 20.08.2005. 9. Mironov, V., Serdjuk, D., Muktupavela, 6. CONCLUSIONS F. Profiles from the wastes of stamping production., Proc of 13th Int. Conf. “Eng. Methods of perforated steel bands joining Materials and Tribology. Baltmattrib- by welding, binding and glueing are 2004”, Tallinn, 2003, 46–50. suggested. Contact spot welding and projection 7. CORRESPONDING AUTHOR welding are preferable for welding of perforated steel bands and profiles. V. Mironov. Riga Tehnical University, Joining of perforated steel bands and LV-1048, Azenes 20-331, Riga, Latvia, profiles by steel wire binding and glueing Phone 371-7089270, Fax. 371-7419153, by the quick–hardening glue on the basis of E-mail: [email protected].

32