1

Problem Analysis on PVC-u Clamp on Saddle (Clamp Saddle) 1. Definition of Clamp Saddle: The Clamp on Saddle is a device which is used as adaptor for connecting service line to supply pipe line (main line) by means of solvent cement socket, threaded joint or compression fit. The saddle is in two halves and is entrapped around the supply pipe and is tightened with help of “V” grooved clamps or bolts.

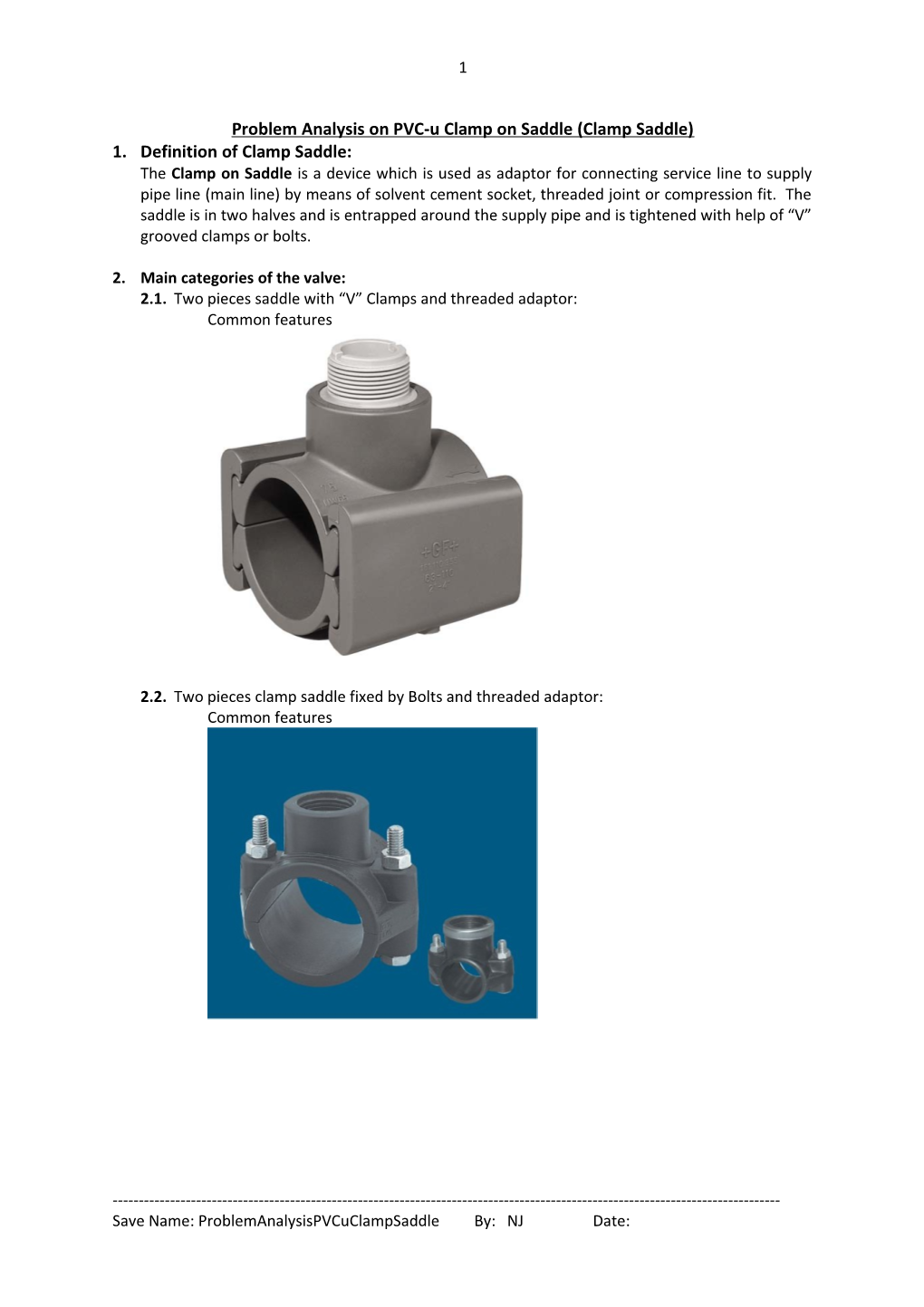

2. Main categories of the valve: 2.1. Two pieces saddle with “V” Clamps and threaded adaptor: Common features

2.2. Two pieces clamp saddle fixed by Bolts and threaded adaptor: Common features

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 2

2.3. Two pieces clamp saddle fixed by Bolts and service connection by compression fit: ------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 3

Common features of the valve with Plastic Body are shown in diagram

3. Common failure modes in PVC clamp saddle in potable water supply: The following table summarizes most common types of field failure modes in water supply mains. The table has been developed on the observations of field officers.

3.1. Problems associated with Clamp on saddles and their causes

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 4

Problem causes 1 Splitting (Cracking) or Due to unbearable external load breaking of Boss (protruded Over tightening the service connector neck) of the saddle (See Mismatching thread of service connector with photograph below) thread of saddle-boss (Photograph 1, shown below) Too much of entangling thread seal around the service connector Non standard product and their material 2 Leakage through interface of Connection made by mismatched mating service connector and clamp- threads boss (protrude portion) Improper /inadequate sealing material on thread Non standard product and their material 3 Leakage through clamp Under size “O” ring Inadequate tightening of clamp saddle Non standard material Non standard product and their material 4 Breakage of saddle (See Due to unbearable external load photograph below) Mismatching pipe size with dimensions of saddle due to wrong selection of products Insertion of debris in interface between saddles and main pipe Over tightening the clamps Fatigue failures due to pressure fluctuation in the pipe Non standard product and their material

Photograph 1: Splitting (Cracking) of Boss:

Longitudinal splits

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 5

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 6

4. Analysis of failures and causes: 4.1. Dimensions mismatching: 4.1.1. Thread type of ferrule inlet connection: Example referring to specific of product Pipe Dimensions Clamp Dimensions Ferrule Dimension BS EN 1452-1 & 2 - Imperial BS EN 1452-1 & 3 - Imperial Nominal size – 4” PVC clamp –Imperial 4” X Outer diameter- 114.1 mm Inner diameter of the saddle 114.4 mm -114 mm

BS EN 1452-1 & 2 - Din 8061 – Metric pipe Din 8061 – Metric pipe PVC clamp – metric 110 X Nominal size – 110 mm Inner diameter of the saddle - Outer diameter- 110.0 mm 110 mm 110.3 mm Threads: Threads: BS EN 10226-1:2004 (Parallel BS EN 10226-1:2004 (Taper thread) thread) Thread per inch for 1” BSP – 11 Thread per inch for 1” BSP – 11 Pitch - 2.309 mm Pitch - 2.309 mm Threads: Threads: NPT (ANSI standard B1.20.1) – NPT (ANSI standard B1.20.1) – Thread per inch for 1” - 11½; Taper Thread per inch for 1” - Pitch - 2.208 mm 11½; Pitch - 2.208 mm

If the boss of the saddle having female parallel thread (G –thread) of standard BS EN 0228-1:2003 (Parallel thread) is over tighten with ferrule having tapered thread (R-thread) of EN 10226 or NPT (ANSI standard B1.20.1) the saddle boss could be split as seen in photograph above. It is also

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 7 possible to split the boss even with the ferrule having parallel thread of BS EN 0228-1:2003 (Parallel thread) if it is tightened with excessive layers of thread seal tape wrapped around the ferrule shank.

4.1.2. Mismatching of shank length with depth of boss of saddle:

dxR d1 L E H Z 110x3/4 22.0 19 176 105 72.0 110x1 28.0 22 176 105 72.0 110x1 1/2 40.0 25 176 105 72.0

160x1 28.0 22 238 120 98.0 160x1 1/2 40.0 25 238 120 98.0

Gun metal Ferrule:

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 8

If the length of shank of the ferrule (L1) / valve socket (L1) is greater than that of the boss of the saddle there is a tendency to split the boss in case of over tightening the ferrule. The above example of saddle and valve socket shows that the correct length of threaded parts of both parts.

4.1.1. Mismatching of Inner Diameter of saddle straps with outer diameter of the pipe: The saddle straps manufactured on metric dimension can’t be fixed on the PVC pipes of the standard BS EN 1452-2 ; Annex B –imperial size pipes, because inner diameter of the saddle is usually smaller than the outer diameter of the pipe (e. g. saddle straps of nominal size 110 mm of which inner dia. 110 mm with the pipe of nominal size 4” of which outer dia. -114 mm). In this case if the saddle- halves wrapped around the pipe and are tightened together it is possible to break the saddle along the corner between the collar and the circular body. This type of breakage sample is shown in the photograph above.

4.2. Pipe deflection due to excessive load: The PVC pipes are flexible to certain degree without breaking the pipe so that buried pipes are progressively deflected with soil weight until the point where soil stiffness become equal to lateral forces experienced due to deflection of the pipe (Fig 1). When the pipe is loaded externally from soil weight or soil weight together with other external forces such as vehicular traffic to exceed the limit of soil stiffness the diametric deflection of the pipe will be progressed further resulting in the breakage of pipe longitudinally. Maximum recommended diametric deflections are as follows. PVC pressure pipes - 5% PVC sewer / Drain pipe - 7½% PVC electrical conduits - 5%

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 9

The effect of soil weight together with external loads such as vehicular traffic against soil type and buried depth is expressed by following equation named as Lowa equation.

Where PS is pipe stiffness in psi P is soil density in lb/ft3 w’ live load factor in lb/ft3 E’ is degree of compaction of pipe zone on soil type in lb/ft3

Clamp deflection: Flexibility of PVC or PP clamp is lower than PVC pipe due to its shape and material so that lateral soil resistance on the clamp gained due to soil stiffness is less. It is therefore tendency to exceed the limit of diametric deflection of the saddle resulting longitudinal breakages as shown in photograph of failure samples. Forces acting on the clamp saddle are shown in Fig. 2 when it mounted on the pipe.

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 10

Forces acting on one piece of the saddle are shown in Fig. 3 as follows.

4.3. Fatigue failures There is a tendency to break the clamps on fatigue due to prolong cyclic load experienced on it. But identification of pattern of cyclic load experienced on the clamp saddle is not easy. Some research

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 11 finding has suggested that the safety factors to be incorporated in pipe laying design approximately according to the table below on the shape of the pressure variation as shown in Fig 4.

Recommended fatigue cycle factors for PVC-U, PVC –M and PVC –O are included in following table. Total cycle Approx No. Cycles/day for 100y life Fatigue Cycle Factors, f PVC -U PVC -M PVC - O 26,400 1 1 1 1 100,000 3 1 0.67 0.75 200,000 5.5 0.81 0.54 0.66 500,000 14 0.62 0.41 0.56 1,000,000 27 0.50 0.33 0.49 2,500,000 82 0.38 0.25 0.41 5,000,000 137 0.38 0.25 0.41 10,000,000 274 0.38 0.25 0.41

This analysis can’t be applied to the assembled unit of clamp on saddle fixed on the water pipe as their geometrical shape and material properties differ from the pressure pipe alone. The fatigue failures of the clamp unit could be occurred in two possibilities as follows. According to the different variable soil load or vehicular traffic exerted on the clamp saddle vertically There is very less possibility of repeating variable external load due to vehicular traffic and soil load over the working clamp saddle buried in soil by the side of road. The assumption of expecting this type of fatigue failure is therefore, not reasonable. According to the different magnitude of soil resistance experienced on the clamp saddle vertically and horizontally on variation of internal pressure of the pipe

The soil resistance generated vertically against the pressure variation inside the pipe is greater than the resistance generated horizontally. The clamp assembled unit is therefore deflected diametrically outward in horizontal direction and the magnitude will be varied according to pressure variation inside the pipe. Accepting this phenomena in the working clamp unit, the limitation of fatigue failure in number of cycles deflecting within the accepting magnitude of diametrical deflection of the clamp saddle can be find out by experimentally in the laboratory.

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 12

5. Leakage into pipe system: There is high possibility of sucking external dirty water into the mains during the negative pressure generated in pipe line which is common phenomena experienced in potable water pipe line.

6. Conclusion: It is necessary to conduct further surveys to analyze the problem in details and identify the cause and effects clearly.

[BS EN ISO 228-1:2003 Pipe threads where pressure-tight joints are not made on the threads. Dimensions, tolerances and designation

BS EN 10226-1:2004 Pipe threads where pressure tight joints are made on the threads. Taper external threads and parallel internal threads. Dimensions, tolerances and designation Status : Current Published : July 2004 ------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 13

BS EN 10226-2:2005 Pipe threads where pressure tight joints are made on the threads. Taper external threads and taper internal threads. Dimensions, tolerances and designation Status : Current Published : January 2006

ISO 7-1:1994 Pipe threads where pressure-tight joints are made on the threads -- Part 1: Dimensions, tolerances and designation

BS EN 10226-3:2005 Pipe threads where pressure-tight joints are made on the threads. Verification by means of limit gauges Status : Current Published : September 2005

ISO 7-2:2000 Pipe threads where pressure-tight joints are made on the threads -- Part 2: Verification by means of limit gauges]

ISO 13460:1998 Agricultural irrigation equipment -- Plastics saddles for polyethylene pressure pipes

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 14

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 15

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 16

Pipes and fittings made of polypropylene “Random copolymer” are used for inner hot water and cold water supply conduits and for industrial pipe-lines. Pipe-line made of PPRC is a remarkable decision for internal wiring of cold and hot water supply. Polypropylene pipes from the Borisov Plastic Products Plant are produced from high-quality propylene of modern generation – random copolymer BOREALIS RA 130E.

Random copolymer (type3) is a modification of polypropylene, which supplies with better characteristics and, first of all, continuous firmness to high temperature and pressure. Pressure conduits made of this material gave an excellent account of themselves during 1980s and 90s in many developed and developing countries. They can be considered to be an optimal industrial solution in our conditions: modern, ecologically neutral, long-lasting supply and heating systems, which allow to replace traditional steel wiring – by parts as well as entirely – with minimum expenses.

The reason for PPRC pipes success primarily is in material properties. First of all, polypropylene is absolutely non- toxic: even if to bring it to fire, only carbonic acid and water will escape. Secondly, this material is not sensitive to high temperature and pressure. With good safety margin it withstands common for water supply loads.

Polypropylene pipes, in comparison with steel pipes, have much plainer inner surface and possesses minor thermal conduction. Owing to these properties, PPRC pipes are notable for lesser pressure and heat loss. Condensate is not generated so abundantly on cold water pipes, and it is required less insulating material for lagging arrangement. When fluid in PPRC pipes is congealed, they don’t destroy, but enlarge in diameter and reacquire the previous size when defrosted.

One more attractive characteristic of PPRC pipes is the bounding technique. Fittings and stop valve are produced not from expensive non-ferrous metals, but from the same polypropylene. Sleeve welding used for assembling is highly a simple technology, and anyone who wishes is able to master it. Pipes are bounded by means of contact thermal welding. Special combined details allow to join polypropylene pipes with metal pipes.

The relative drawback of PPRC pipe-lines is sufficiently high thermal-expansion coefficient. The given problem is solved by compensator usage.

AS 4796-2001 water supply - metal bodied and plastic bodied ball valves for

property service connection Standard Number: AS 4796-2001 Title: water supply - metal bodied and plastic bodied ball valves for property service connection Language: English Publication Date: 2001-5-5

Pressure Tapping Ferrules and Standard Ferrules AS3496 / AS3718 Under Pressure PP Tapping Ferrules

Under Pressure PP Tapping Ferrule - Threaded Outlet ( with knife)

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: 17

D x G C A D1 Approx. wt. Product Code BSP x BSP mm mm mm kg / pc TFT116MF 1 1/4" x 3/4" 125 54 22.5 0.23 TFT113MF 1 1/4" x 1" 125 54 22.5 0.23

RFQ Quantity

Under Pressure PP Tapping Ferrule - Compression Joint Outlet (with knife)

D x G C A D1 Approx. wt. Product Code BSP x BSP mm mm mm kg / pc TFT116MF 1 1/4" x 25 125 54 22.5 0.25 TFT113MF 1 1/4" x 32 125 54 22.5 0.27

BS EN 10226-2:2005

Pipe threads where pressure tight joints are made on the threads. Taper external threads and taper internal threads. Dimensions, tolerances and designation

------Save Name: ProblemAnalysisPVCuClampSaddle By: NJ Date: