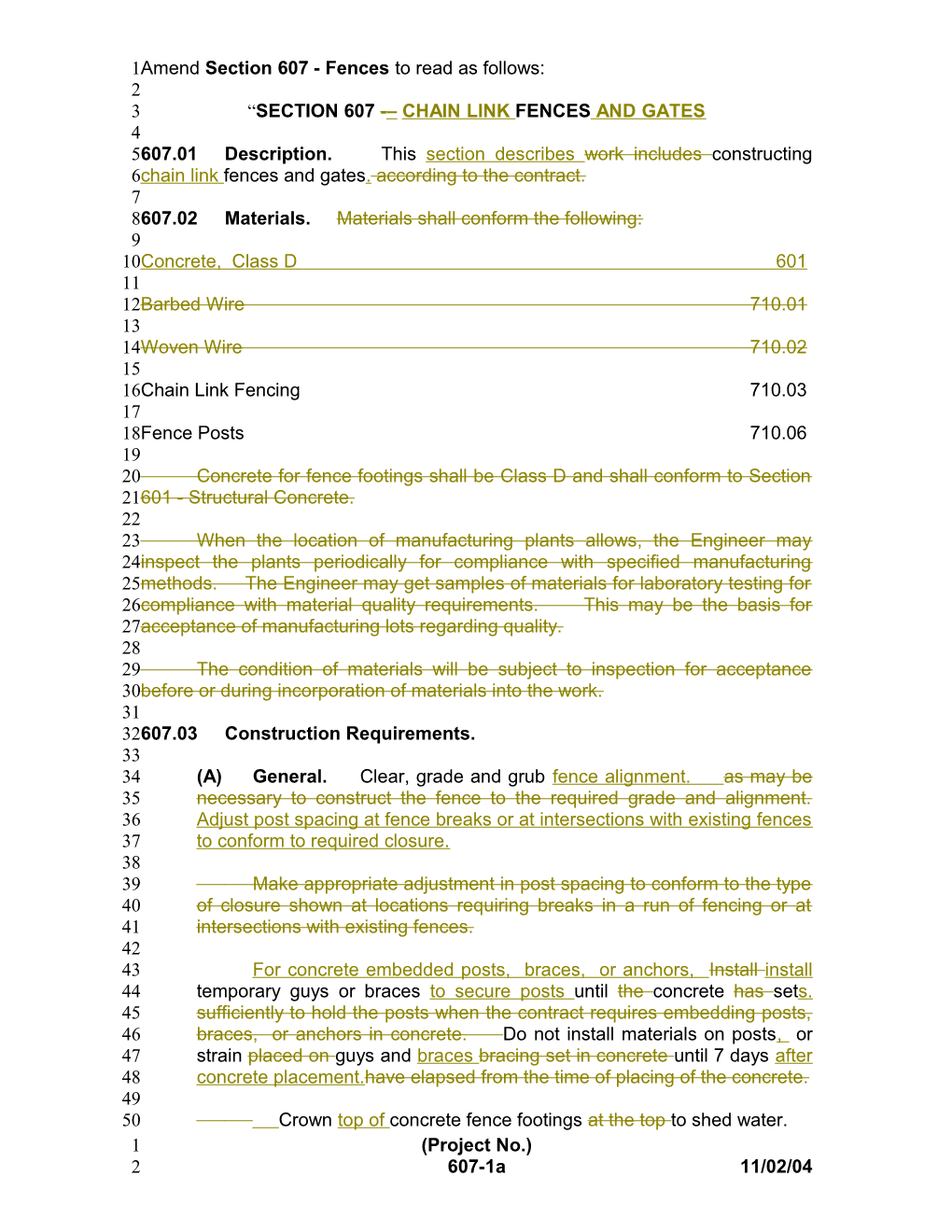

1Amend Section 607 - Fences to read as follows: 2 3 “SECTION 607 -– CHAIN LINK FENCES AND GATES 4 5607.01 Description. This section describes work includes constructing 6chain link fences and gates. according to the contract. 7 8607.02 Materials. Materials shall conform the following: 9 10Concrete, Class D 601 11 12Barbed Wire 710.01 13 14Woven Wire 710.02 15 16Chain Link Fencing 710.03 17 18Fence Posts 710.06 19 20 Concrete for fence footings shall be Class D and shall conform to Section 21601 - Structural Concrete. 22 23 When the location of manufacturing plants allows, the Engineer may 24inspect the plants periodically for compliance with specified manufacturing 25methods. The Engineer may get samples of materials for laboratory testing for 26compliance with material quality requirements. This may be the basis for 27acceptance of manufacturing lots regarding quality. 28 29 The condition of materials will be subject to inspection for acceptance 30before or during incorporation of materials into the work. 31 32607.03 Construction Requirements. 33 34 (A) General. Clear, grade and grub fence alignment. as may be 35 necessary to construct the fence to the required grade and alignment. 36 Adjust post spacing at fence breaks or at intersections with existing fences 37 to conform to required closure. 38 39 Make appropriate adjustment in post spacing to conform to the type 40 of closure shown at locations requiring breaks in a run of fencing or at 41 intersections with existing fences. 42 43 For concrete embedded posts, braces, or anchors, Install install 44 temporary guys or braces to secure posts until the concrete has sets. 45 sufficiently to hold the posts when the contract requires embedding posts, 46 braces, or anchors in concrete. Do not install materials on posts, or 47 strain placed on guys and braces bracing set in concrete until 7 days after 48 concrete placement.have elapsed from the time of placing of the concrete. 49 50 Crown top of concrete fence footings at the top to shed water. 1 (Project No.) 2 607-1a 11/02/04 51 52 Set the tops of posts to the required grade and alignment. Do not 53 cut top of posts unless accepted.The Engineer will allow cutting of the tops 54 of the posts only under the written request and the conditions specified. 55 56 Firmly attach Attach wire or fencing firmly of the size and type 57 required to the posts and braces, according to the contract. Stretch 58 stretch the wires taut, and install to the wires to the required elevations. 59 60 Provide Furnish and install a ground conforming to Section 9 of the 61 National Electric Safety Code at each crossing location where an electric 62 transmission, distribution, or secondary line. crosses the fences covered 63 by the contract. 64 65 (B) Chain Link FencePosts. Furnish Fabricate posts from pipes 66 conforming to Table 607.03 -– I1 – Schedule of Chain Link Fence Posts. 67 Space line posts at not more than 10 feet -foot maximum intervals, 68 measured from center to center of posts. Measure post spacing In 69 general, make measurement parallel to the slope of the natural ground. 70 in determining the post spacing. Install Place posts in a vertical position. 71 72 TABLE 607.03-1 - SCHEDULE OF CHAIN LINK FENCE POST ZINC-COATED PIPE – NOMINAL End, Corner Fence Line Post Brace Top Rail & Pull Post Height OD Wt OD Wt OD Wt OD Wt (Feet) Inch lbs/ft Inch lbs/ft Inch lbs/ft Inch Lbs/ft 3 1-7/8 2.72 1-7/8 2.72 1-5/8 2.57 1-3/8 1.68 4 1-7/8 2.72 1-7/8 3.65 1-5/8 2.57 1-3/8 1.68 5 1-7/8 2.72 2-3/8 3.65 1-5/8 2.57 1-5/8 2.27 6 2-3/8 3.65 3 5.79 1-5/8 2.57 1-5/8 2.27 ALUMINUM PIPE – NOMINAL End, Corner Fence Line Post Brace Top Rail & Pull Post Height OD Wt OD Wt OD Wt OD Wt (Feet Inch lbs/ft Inch lbs/ft Inch lbs/ft Inch Lbs/ft 3 2 1.264 3 2.621 1-1/4 0.786 1-1/4 0.786 73 74 Conform footing The depths of footing are as follows to Table 75 607.03-2 – Footing Depths.: 76 TABLE 607.03-2 – FOOTING DEPTHS Fabric Height Footing Depth Type of Post Inches (Minimum) Foot Line Post 36 2 End, Corner, and Gate Post 36 2-1/2 Line Post 48 2-1/2

3 (Project No.) 4 607-2a 11/02/04 Other Post -- 3 77 78 Use In cross section, the minimum footing diameter of 8-inches, or 79 dimension of footings shall not be less than three times diameter the 80 maximum cross-sectional dimension of the post, whichever is greater. 81 Also the minimum dimension of footings shall not be less than 8 inches. 82 83 For fence heights greater than 6 feet, Brace brace end, corner, and 84 gate posts for fencing of a height of 6 feet or more to the nearest line post 85 with horizontal braces used as compression members, and truss rods 86 with turnbuckles used as tension members. Provide Brace brace and 87 truss pull post shall be at intervals of 300 feet in both directions. as 88 specified above. 89 90 Install corner posts when the fence line changes 30 degrees or 91 more. 92 93 TABLE 607-I - SCHEDULE OF CHAIN LINK FENCE POST ZINC-COATED PIPE – NOMINAL Height End, Corner Line Posts Braces Top Rails of & Pull Posts Fence OD Wt OD Wt OD Wt OD Wt (Feet) Inch #/ft Inch #/ft Inch #/ft Inch #/ft 3 1-7/8 2.72 1-7/8 2.72 1-5/8 2.57 1-3/8 1.68 4 1-7/8 2.72 1-7/8 3.65 1-5/8 2.57 1-3/8 1.68 5 1-7/8 2.72 2-3/8 3.65 1-5/8 2.57 1-5/8 2.27 6 2-3/8 3.65 3 5.79 1-5/8 2.57 1-5/8 2.27 ALUMINUM PIPE – NOMINAL Height End, Corner Line Posts Braces Top Rails of & Pull Posts Fence OD Wt OD Wt OD Wt OD Wt (Feet Inch #/ft Inch #/ft Inch #/ft Inch #/ft 3 2 1.264 3 2.621 1-1/4 0.786 1-1/4 0.786 94 95 Pass The top rail or top tension wire shall pass through the base of 96 line post tops or extension arms and form a continuous brace from end to 97 end of each stretch of fence section. 98 99 Furnish top rails in approximately 20-foot lengths. Provide top 100 rails with accepted outside couplings or expansion sleeves. Fasten the 101 top rail or top tension wire securely to terminal posts with by rail ends and 102 brace bands. 103 104 Furnish brace rails in the required lengths. 105 106 (C) Fence Fabric. Fasten chain link fabric on the designated side of 107 the posts. Position Also, mount chain link fabric to follow ground

5 (Project No.) 6 607-3a 11/02/04 108 contour with on the posts so that the bottom of the fabric is 2 two inches 109 above ground. 110 111 Provide Chain link fences shall have knuckled finish on the bottom 112 edge of chain link fabric. For Chain chain link fences with fabric widths 113 greater than over 60 inches, provide shall have a twisted and barbed 114 finish on the top edge. projecting over the top rail or top tension wire of 115 the fence. For Chain chain link fences with fabric widths of 60 inches or 116 less, provide shall have knuckled finish on the top edge. 117 118 Weave chain link fence fabric into approximately two inch mesh 119 except around tennis courts. Weave chain link fence fabric into 120 approximately 1.75 inches mesh around tennis courts. 121 122 Fasten between posts, the top edge of the chain link fabric to a top 123 rail or top tension wire between posts. and the lower edge fastened to a 124 tension wire. Fasten bottom edge of chain link fabric to tension wire 125 between posts. Excavate high points of ground to Install install the 126 bottom tension wire on a straight grade between posts. by excavating 127 the high points of ground. Do not fillThe Engineer will not permit filling of 128 depressions. 129 130 Fasten the chain link fabric to end, corner, and gate posts with 131 stretcher bars and stretcher bar bands spaced at 12 inches. one-foot 132 intervals; and to Fasten chain link fabric to line posts and tension wires 133 with tie wires or metal bands. Space tie wires or metal bands on line 134 posts at intervals of approximately 14 inches, and on top rails and tension 135 wires at approximately 24 inches. 136 137 (D) Gates. Drive gates shall be of the widths designated in the 138 contract. Walk gates shall be four-foot wide. 139 140 Furnish Fabricate gate frames and posts from pipes conforming to 141 of Table 607.03-3 – Gates (3 Feet to 6 Feet Height)-II, or from if accepted, 142 from shapes of equivalent structural strength. Cross-truss Drive drive 143 gates shall be cross-trussed with accepted adjustable truss rods. 144 Assemble by using the use of properly designed fittings, or by accepted 145 welding techniques. 146 147 Use chain link Fabric fabric for the gate. shall be the same as 148 that used for the fence. Attach the fabric to for the gate to the gate frame 149 by stretcher bars and tie wires, as specified for fence construction, and 150 suitable tension connectors spaced at approximately 12 inches.one-foot 151 intervals. 152 153 For gate heights up to 60 inches, Hang hang the gates with by at 154 least two hinges. For gate heights greater than 60 inches, hang gate 155 with three hinges. Provide hinges designed to clamp securely to the 156 gate post, and permit the gate to swing back against the fence. 157 7 (Project No.) 8 607-4a 11/02/04 158 Provide gates with a combination catch and locking attachment of 159 acceptable design. Provide stops to hold gates open and a center rest 160 with catch where required. 161 TABLE 607.03-3-II - GATES (3 FEET TO 6 FEET HEIGHT) ZINC-COATED PIPE GATE FRAMES GATE POSTS Nominal Nominal O.D. GATE OPENING O.D. Weight Weight Inch Inch lbs/ft lbs/ft Single to 6' or 1.875 2.72 3 5.79 Double to 12' Single over 6' to 1.875 2.72 13' or Double over 4 9.11 12' to 26' inclusive Single over 13' to 1.875 2.72 18' or Double over 6.625 18.97 26' to 36' inclusive Single over 18' or 1.875 2.72 8.625 24.70 Double over 36' ALUMINUM PIPE GATE FRAMES GATE POSTS Nominal Nominal GATE Nominal Nominal Wt. Wt. Size O.D. OPENING Size O.D. lbs/ft lbs/ft Inch Inch Inch Inch Single to 6' or 1.50 1.9 0.94 3 3-1/2 2.621 Double to 12' Single over 6' to 13' or Double 1.50 1.9 0.94 3.50 4 3.151 over 12' to 26' inclusive Single over 13' to 18' or Double 1.50 1.9 0.94 6 6.625 6.564 over 26' to 36' inclusive Single over 18' or 1.50 1.9 0.94 8 8.625 9.878 Double over 36' 162 163 (C) Wire Fences. Stretch the wires tightly with an accepted fence 164 wire stretcher and stapled to each wooden post with zinc-coated staples 165 or wired to each concrete post with several turns of tie wire. Staple or 166 wire wood spreaders, if required by the contract, to each strand of the 167 fence wires. The wire shall always be on the side of the fence that faces 168 this pasturage when the fence impounds animals. 169 170 Brace the fence at corners and angles and anchor against pull 171 according to details shown in the contract. 172 173 Dip wood posts before use in creosote as required on the plans. 174 Set posts vertically in the ground to the approximate depth shown on the 175 plans. Tamp posts thoroughly into place.

9 (Project No.) 10 607-5a 11/02/04 176 177607.04 Method of Measurement. Fence and gate will be paid on a lump 178sum basis.The Engineer will measure the fence per linear foot. Measurement 179will be along the top of the fence from outside to outside of end post for each 180continuous run of fence. Measurement for payment will not apply. 181 182 The Engineer will measure the gate per each. 183 184607.05 Basis of Payment. The Engineer will pay for the accepted fence 185and gate on a at the contract lump sum basis.unit price per linear foot complete 186in place. Payment will be full compensation for the work prescribed in this 187section and the contract documents.The price includes full compensation for 188clearing, grading, and grubbing; placing and crowning the concrete footing; 189installing temporary bracing; setting the tops of post; furnishing and installing the 190fence, wires, posts, top rail or top tension wires, grounds and its accessories; 191and furnishing labor, materials, tools, equipment, and incidentals necessary to 192complete the work. 193 194 The Engineer will pay for the accepted gate at the contract unit price per 195each complete in place. The price includes full compensation for clearing, 196grading, and grubbing; placing and crowning the concrete footing; installing 197temporary bracing; furnishing and installing the gate and its accessories; and 198furnishing labor, materials, tools, equipment, and incidentals necessary to 199complete the work. 200 201 The Engineer will pay for the following pay items when included in the 202proposal schedule:make payment under: 203 204Pay Item Pay Unit 205 206_____ - Feet, Chain Link ______Fence Linear Foot Lump Sum 207 208Chain Link ______Gate, _____ Feet High And _____ Feet WideEach 209Lump Sum” 210 211______Fence With ______Posts Linear Foot” 212 213 214 215 216 217 END OF SECTION 607

11 (Project No.) 12 607-6a 11/02/04