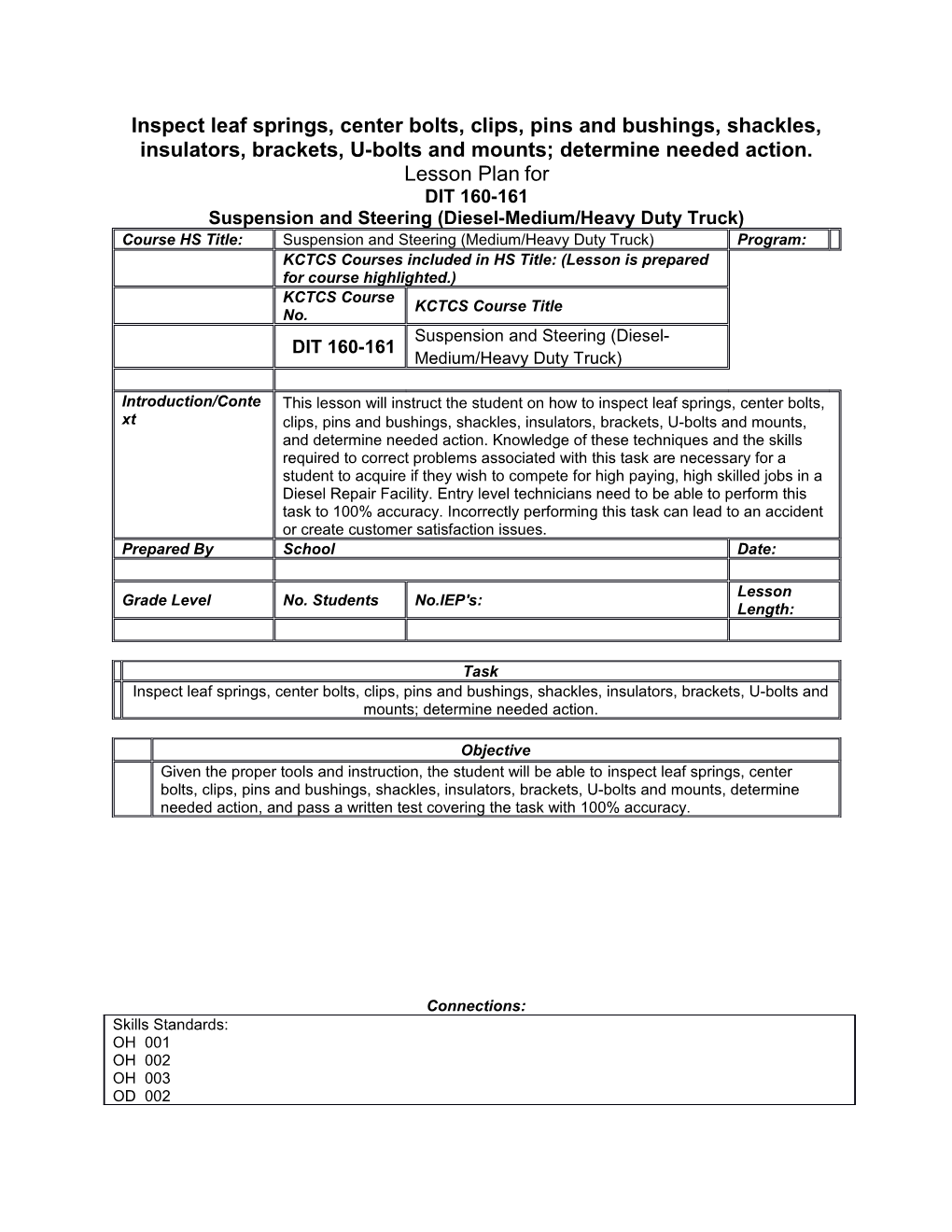

Inspect leaf springs, center bolts, clips, pins and bushings, shackles, insulators, brackets, U-bolts and mounts; determine needed action. Lesson Plan for DIT 160-161 Suspension and Steering (Diesel-Medium/Heavy Duty Truck) Course HS Title: Suspension and Steering (Medium/Heavy Duty Truck) Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course KCTCS Course Title No. Suspension and Steering (Diesel- DIT 160-161 Medium/Heavy Duty Truck)

Introduction/Conte This lesson will instruct the student on how to inspect leaf springs, center bolts, xt clips, pins and bushings, shackles, insulators, brackets, U-bolts and mounts, and determine needed action. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Diesel Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Inspect leaf springs, center bolts, clips, pins and bushings, shackles, insulators, brackets, U-bolts and mounts; determine needed action.

Objective Given the proper tools and instruction, the student will be able to inspect leaf springs, center bolts, clips, pins and bushings, shackles, insulators, brackets, U-bolts and mounts, determine needed action, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-OPS.2 TD-SYS.2 New Common Core State Standards: RST 11-12 3 N-Q-3 New Generation Science Standards: HS-PS2-1. HS-PS3-3

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various Suspension and Steering ASE Test Prep T5 Fifth Delmar 23-24

Equipment Quantity Item Source

Web Site Author URL

Content/Presentation/Demonstration Outline Explain that a leaf spring is a spring assembly where the individual leaves are the same width for the whole length of the assembly. Parabolic springs are assemblies where the leaf width is usually greater at the center of the spring, and the width decreases toward the outer end of the spring. Tell students that a taperleaf spring is also classified as a parabolic spring since the leaves are thicker in the center, and the thickness decreases toward the end of the leaf. Let students know that regardless of what type of spring assembly is installed on a vehicle, the inspection process is the same. Tell students that When inspecting the leaf/parabolic spring assemblies, they should look for broken or shifting leaves in the spring pack, inspect the front and rear shackle spring pins and bushings for wear, and inspect the U-bolts, spring seats, and top plates for looseness or wear. Instruct students that the suspension system should be inspected periodically to ensure vehicle safety. This inspection should be part of a regular maintenance schedule recommended by the truck manufacturer or truck owner. During a front or rear suspension inspection, tell students to check these components: * Inspect the tires for excessive tread wear. * Check the torque on the wheel nuts, and inspect the wheel rims for damage. * On rear suspension systems, inspect all torque rods for damage or a bent condition. Inspect all torque rod bushings for looseness, wear, and deterioration. * Inspect all spring shackles, bushings, and brackets for looseness. A pry bar may be used to pry downward on the outer end of the spring to check for looseness in the shackles and bushings. * Inspect all spring U-bolts for damage and check the torque on the U-bolt nuts. B Inspect the springs for broken leaves, damaged clamps, broken center bolts, and a sagged condition. * Inspect all equalizer components for wear. Tell students to be sure each side of the drive axle housing is positioned on the same location on each spring. Let them know that a broken center bolt may allow the drive axle to slide backward on the spring. Loose spring shackles will not break the spring center bolt. Instruct students that loose front spring U-bolts can break the spring center bolt or leaves between the U-bolts. A broken leaf spring center bolt can cause axle shifting leading to premature toe-like tire wear and steering pull. Also, if the spring assembly is replaced, tell them to always replace the U-bolts. U- bolt threads stretch during initial installation and scale and rust buildup may prevent improper pull-up torque and insufficient clamping force. Inform students that if a defective spring assembly is identified, the following recommendations should be considered: * Whenever one spring leaf is broken, all of the other leaves in the assembly have been overloaded and running under increased stress. Consideration should be made to the age and condition of the other leaves prior to repair. * If one spring leaf is broken, and the remaining leaves are deemed serviceable, it is acceptable to replace only the broken leaf However, tell them it is advisable to replace the same leaf in the other spring pack on that axle to ensure both spring assemblies remain matched regarding load carrying capacity, rate of deflection, and ride height characteristics. * If two or more leaves are broken in the spring pack, it is recommended that the entire spring assembly be replaced. * If the spring assembly on one side of the vehicle is being replaced, it is advisable to replace both spring assemblies across that axle.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.) REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)