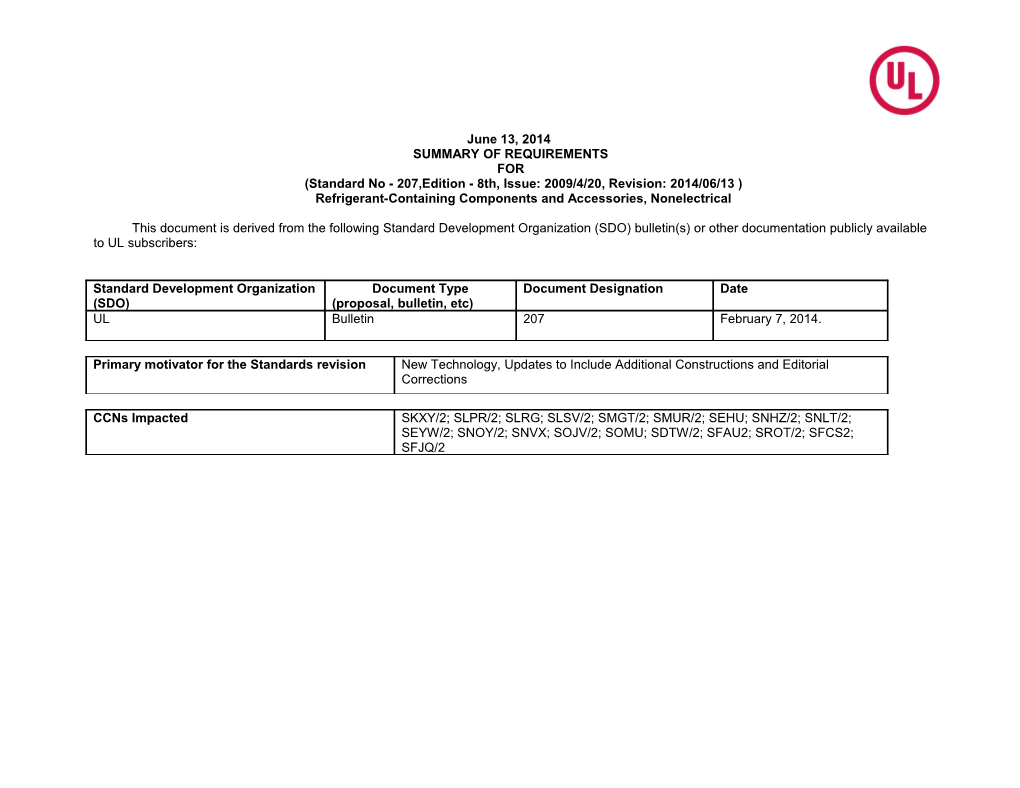

June 13, 2014 SUMMARY OF REQUIREMENTS FOR (Standard No - 207,Edition - 8th, Issue: 2009/4/20, Revision: 2014/06/13 ) Refrigerant-Containing Components and Accessories, Nonelectrical

This document is derived from the following Standard Development Organization (SDO) bulletin(s) or other documentation publicly available to UL subscribers:

Standard Development Organization Document Type Document Designation Date (SDO) (proposal, bulletin, etc) UL Bulletin 207 February 7, 2014.

Primary motivator for the Standards revision New Technology, Updates to Include Additional Constructions and Editorial Corrections

CCNs Impacted SKXY/2; SLPR/2; SLRG; SLSV/2; SMGT/2; SMUR/2; SEHU; SNHZ/2; SNLT/2; SEYW/2; SNOY/2; SNVX; SOJV/2; SOMU; SDTW/2; SFAU2; SROT/2; SFCS2; SFJQ/2 The following is a summary of the revised/new certification requirements.

Action is Not Required for current certified products and the new/revised certification requirements will be applied in evaluation of the new and revised products effective June 4, 2014. Section Summary of requirements Action Paragraph Clause

This paragraph is being modified to include the option for a high-side refrigerant 12.1.2 containing component to be subjected to the pressure of only three times the pressures specified in 12.1.2.1, if the component complies with 12.1.4. Revised Requirement Although this appears as a “new” paragraph, it is actually a re-statement of the original 12.1.2.1 paragraph previously located in 12.1.2 (prior to this revision). This paragraph is being Revised revised to allow the additional option as specified above in 12.1.2(c). Requirement This paragraph specifies the option for a high-side refrigerant containing component to New Requirement 12.1.4 be subjected to the pressure of only three times the pressures specified in 12.1.2(c). (provides Such a component is required to be provided with either a pressure relief valve as alternate specified in sub-item (a) or a marking as specified in sub-item (b). compliance path) Editorial 12.1.5 & Minor changes are being made to these paragraphs to account for the new paragraph 12.1.6 locations.

New Requirements 22.10.1 & These new requirements specify the marking that is to be used if the refrigerant (provides 22.10.2 containing component complies with alternate compliance path as specified in 12.1.4(b). alternate compliance path) 4.8, 18.1.1, Editorial 18.1.1.1, These paragraphs include minor editorial changes to permit the addition of the alternate 18.1.2, 18.2 24-hour moist ammonia air stress cracking test specified in 18.3. & 18.2.1 Editorial An editorial correction made to this paragraph clarifies the chamber pressure for the 18.2.2 (correction) moist ammonia test.

This new section only applies to components that are made of brass and contain more New Requirement 18.3 than 15% zinc. This section outlines the alternate moist ammonia test which will enable (provides refrigerant containing components to be tested within only 24 hours instead of the alternate present 10 day requirement. This new test is based on and references ASTM B858. compliance path) Editorial Table 8.1 Minor editorial clarifications are being made to this table.

The following is Summary of Action Not Required new/revised certification requirements effective June 4, 2015 based on revisions dated July 12, 2013 to the 8th Edition of the Standard.

Section Summary of requirements Paragraph Clause 6.2 This new clause requires a heat exchanger intended for connection to a potable (drinkable) water source to have a double wall (e.g., redundant or vented interface) construction. In addition, a marking is required on such heat exchangers. See comments under Clause 23.2 below. 6.3 Heat exchangers with a single wall (e.g., that do not have a double wall, redundant or vented interface) construction are not to be intended for connection to a potable (drinkable) water supply source. In addition, a marking is required on such heat exchangers. See comments under Clause 23.3 below. 6.4, 6.5 & These requirements apply to heat exchangers intended for connection to a potable water source and having a 12.4.1 vented interface. Such products are required to be subjected to the vented interface test. Also, the vented interface is required to withstand a pressure of not less than 1-1/2 times the maximum rated design pressure of the refrigerant side. 12.1.3 This requirement applies to all heat exchangers where the high-side parts are intended for connection to the refrigerant high-pressure side and the other side is intended for connection to a water supply source. This clause requires the test referenced in Clause 12.1.2 to be conducted with the water side maintained at atmospheric pressure. Heat exchangers in which the test was previously conducted with the pressure in the water side of the heat exchanger held at other than atmospheric pressure may need to be re-tested. 12.2.3.1 & These requirements apply to all heat exchangers where the high-side parts are intended for connection to the 12.3.2 refrigerant high-pressure side and the other side is intended for connection to the refrigerant low-side pressure or a water supply source. This clause requires the tests referenced in Clauses 12.2.2 or 12.2.3 to be conducted with the side intended for connection to the refrigerant high-side pressure to be maintained at atmospheric pressure. Heat exchangers in which the test was previously conducted with the pressure in the high-side of the heat exchanger held at other than atmospheric pressure may need to be re-tested. 23.1(a) This clause applies to heat exchangers or other components intended for connection to a water source and requires the water side design pressure to be marked on the component.

23.2 The marking referenced in this new clause is applicable to all double wall heat exchangers intended for connection to a potable water supply source. Section Summary of requirements Paragraph Clause 23.3 The marking referenced in this new clause is applicable to all heat exchangers (of a single rather than double wall construction) that are not intended for connection to a potable water supply source.