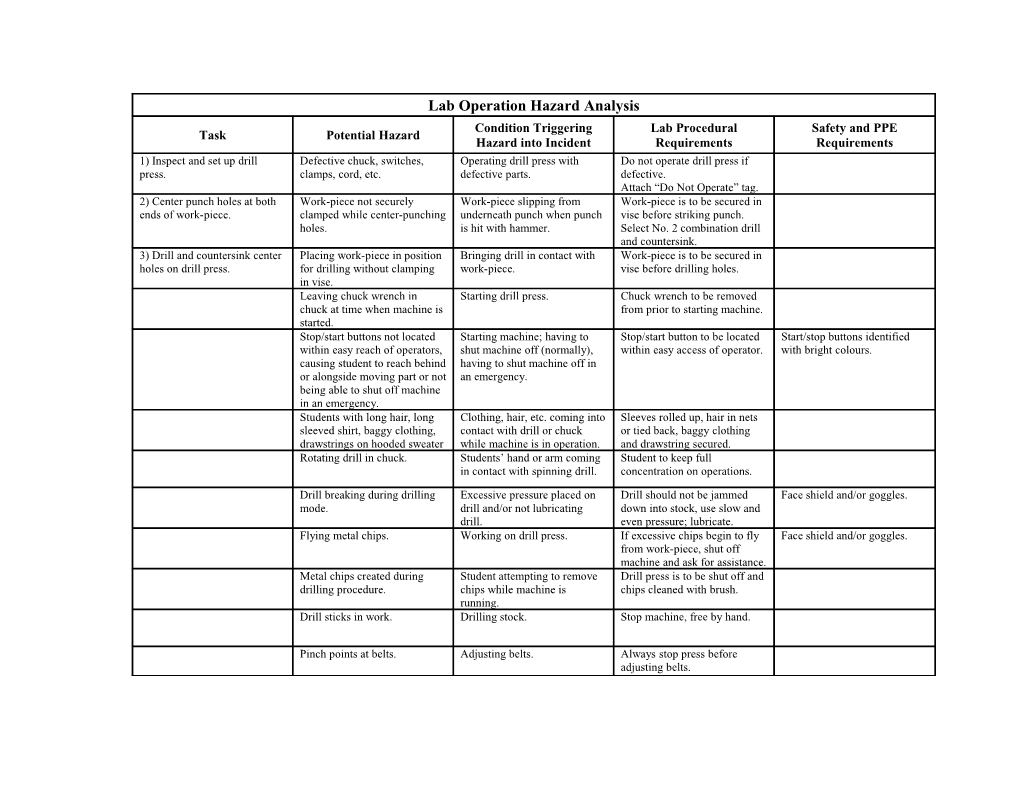

Lab Operation Hazard Analysis Condition Triggering Lab Procedural Safety and PPE Task Potential Hazard Hazard into Incident Requirements Requirements 1) Inspect and set up drill Defective chuck, switches, Operating drill press with Do not operate drill press if press. clamps, cord, etc. defective parts. defective. Attach “Do Not Operate” tag. 2) Center punch holes at both Work-piece not securely Work-piece slipping from Work-piece is to be secured in ends of work-piece. clamped while center-punching underneath punch when punch vise before striking punch. holes. is hit with hammer. Select No. 2 combination drill and countersink. 3) Drill and countersink center Placing work-piece in position Bringing drill in contact with Work-piece is to be secured in holes on drill press. for drilling without clamping work-piece. vise before drilling holes. in vise. Leaving chuck wrench in Starting drill press. Chuck wrench to be removed chuck at time when machine is from prior to starting machine. started. Stop/start buttons not located Starting machine; having to Stop/start button to be located Start/stop buttons identified within easy reach of operators, shut machine off (normally), within easy access of operator. with bright colours. causing student to reach behind having to shut machine off in or alongside moving part or not an emergency. being able to shut off machine in an emergency. Students with long hair, long Clothing, hair, etc. coming into Sleeves rolled up, hair in nets sleeved shirt, baggy clothing, contact with drill or chuck or tied back, baggy clothing drawstrings on hooded sweater while machine is in operation. and drawstring secured. Rotating drill in chuck. Students’ hand or arm coming Student to keep full in contact with spinning drill. concentration on operations.

Drill breaking during drilling Excessive pressure placed on Drill should not be jammed Face shield and/or goggles. mode. drill and/or not lubricating down into stock, use slow and drill. even pressure; lubricate. Flying metal chips. Working on drill press. If excessive chips begin to fly Face shield and/or goggles. from work-piece, shut off machine and ask for assistance. Metal chips created during Student attempting to remove Drill press is to be shut off and drilling procedure. chips while machine is chips cleaned with brush. running. Drill sticks in work. Drilling stock. Stop machine, free by hand.

Pinch points at belts. Adjusting belts. Always stop press before adjusting belts.