How do we determine the speed and load-carrying capability of our vehicle?

The goal is to move the greatest mass the fastest. We know that there is a trade-off between the load we can carry and the speed at which we can carry that load. This trade- off is expressed as the mechanical power P = force x velocity = torque x angular velocity. For the same power, if we increase the load (force or torque) then the linear or angular velocity is decreased. With our motor-gear system we determined that, for each gear ratio, there is a maximum mechanical power. That is, there is a combination of force and velocity at which the product of force and velocity is optimized. That product tells the force and velocity at which we will move the greatest mass the fastest. It is the combination that provides the maximum power output.

You determined, for two gear ratios, the combinations of torque and angular velocity that provide maximum power output. Pick one of those combinations. The objective is then to choose the wheel size and the load such that the motor-gear combination ends up operating at its optimum torque and velocity.

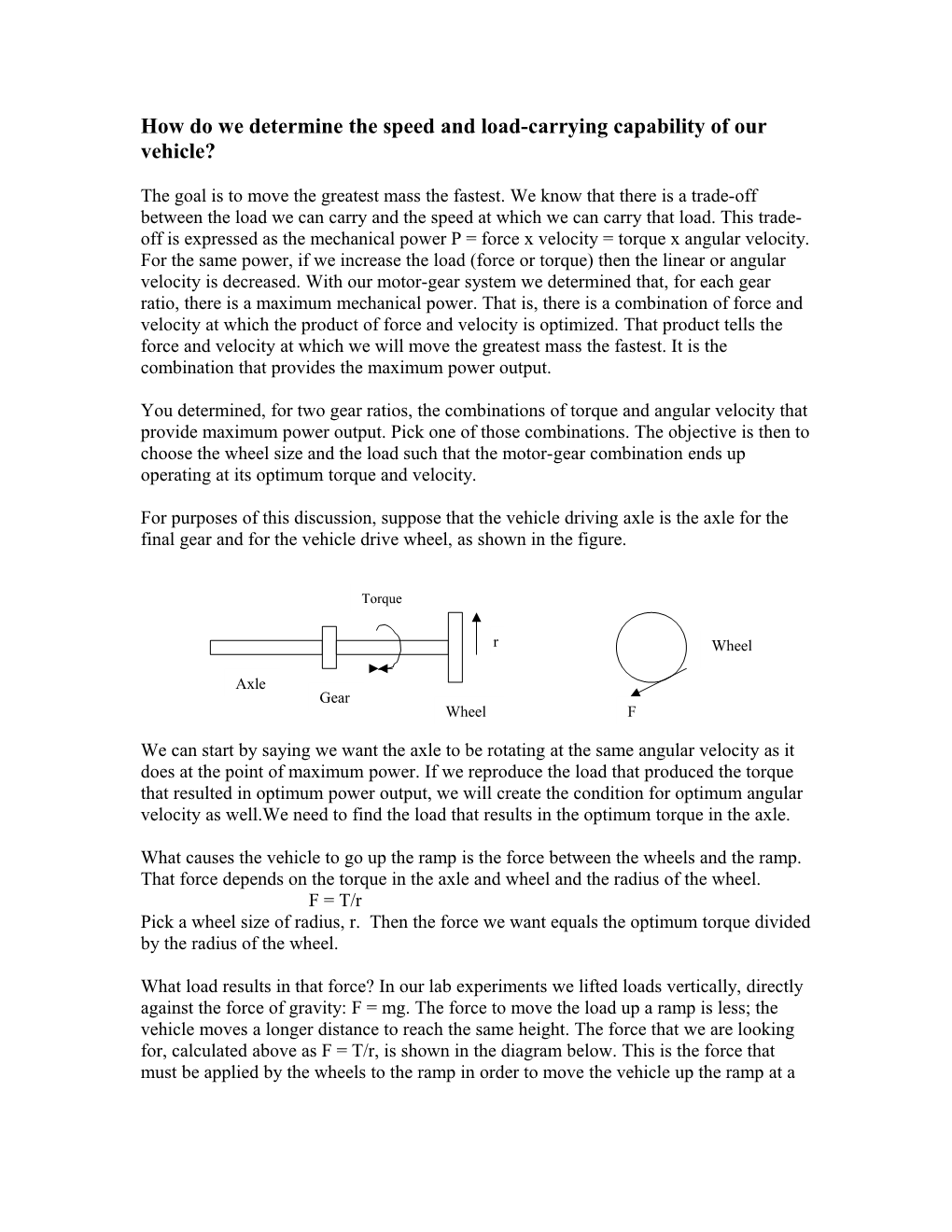

For purposes of this discussion, suppose that the vehicle driving axle is the axle for the final gear and for the vehicle drive wheel, as shown in the figure.

Torque

r Wheel

Axle Gear Wheel F

We can start by saying we want the axle to be rotating at the same angular velocity as it does at the point of maximum power. If we reproduce the load that produced the torque that resulted in optimum power output, we will create the condition for optimum angular velocity as well.We need to find the load that results in the optimum torque in the axle.

What causes the vehicle to go up the ramp is the force between the wheels and the ramp. That force depends on the torque in the axle and wheel and the radius of the wheel. F = T/r Pick a wheel size of radius, r. Then the force we want equals the optimum torque divided by the radius of the wheel.

What load results in that force? In our lab experiments we lifted loads vertically, directly against the force of gravity: F = mg. The force to move the load up a ramp is less; the vehicle moves a longer distance to reach the same height. The force that we are looking for, calculated above as F = T/r, is shown in the diagram below. This is the force that must be applied by the wheels to the ramp in order to move the vehicle up the ramp at a constant velocity. Notice that we need the elevation angle of the ramp to make the calculation: F = mg sin where m is the total of the vehicle mass and the payload mass.

mgSin F

mg

Since we know F, g, and sin , we can calculate the total mass (vehicle plus payload) that will theoretically make the motor gear system operate at maximum power output. Actually, the mass will be somewhat smaller, since the above analysis assumes that there are no additional efficiency losses in the vehicle itself.

Now we can predict the velocity of the vehicle. First, the vehicle velocity is the same as the circumferential velocity of the wheel, as shown in the diagram below.

Axle travel

C

Suppose the circumference of the wheel “unrolls” on the surface of the ground. When a complete circumference has “unrolled” the axle of the wheel has traveled the same distance. Since both have occurred in the same time, the forward velocity of the axle (i.e. vehicle) is the same as the circumferential velocity of the wheel. That velocity can be calculated as v = r, where and r are the angular velocity and radius of the wheel. Picking a larger wheel radius increases the vehicle velocity but reduces the load that can be carried.

These calculations can be used to predict load and velocity to provide maximum performance. Testing of the vehicle on the ramp is necessary to determine what the actual load is to provide maximum performance.