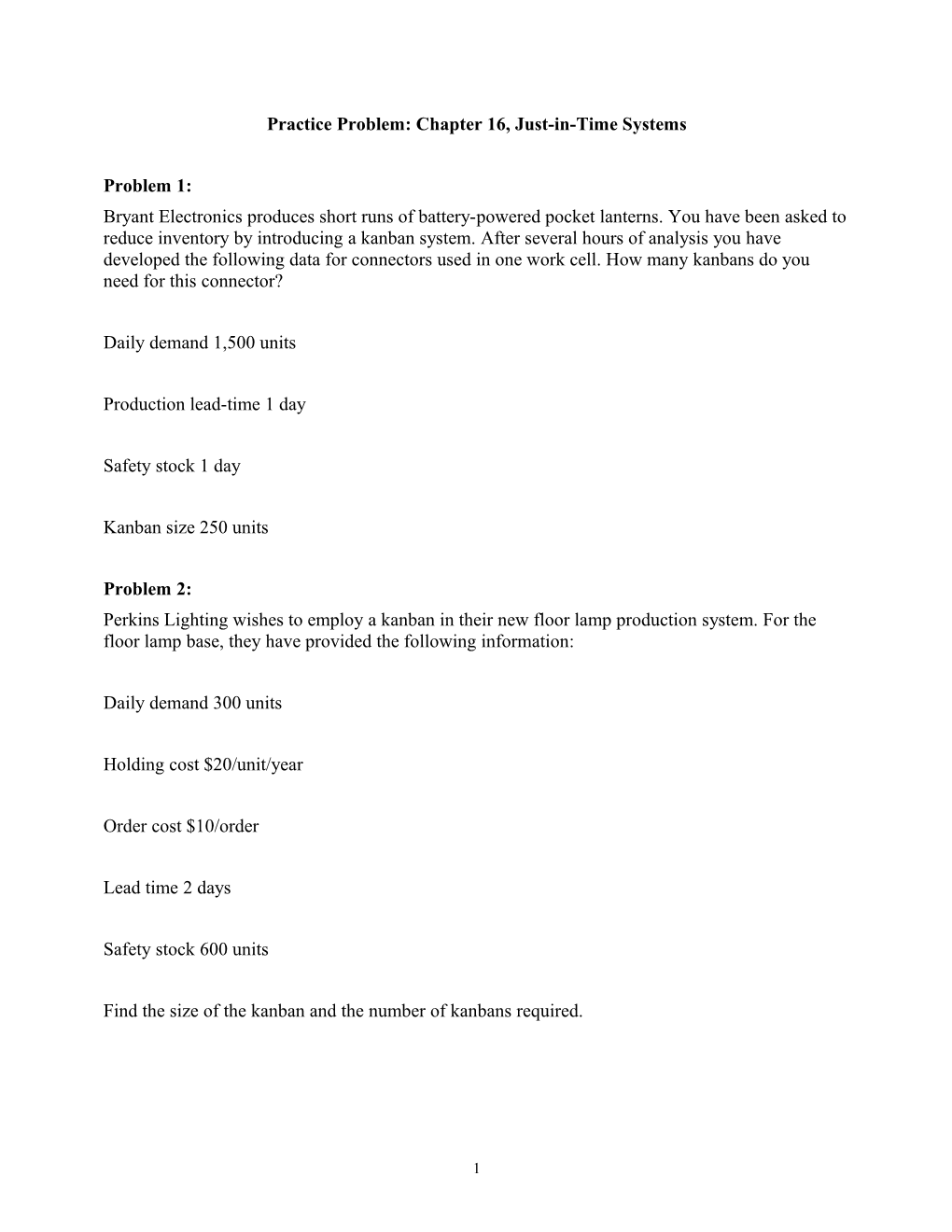

Practice Problem: Chapter 16, Just-in-Time Systems

Problem 1: Bryant Electronics produces short runs of battery-powered pocket lanterns. You have been asked to reduce inventory by introducing a kanban system. After several hours of analysis you have developed the following data for connectors used in one work cell. How many kanbans do you need for this connector?

Daily demand 1,500 units

Production lead-time 1 day

Safety stock 1 day

Kanban size 250 units

Problem 2: Perkins Lighting wishes to employ a kanban in their new floor lamp production system. For the floor lamp base, they have provided the following information:

Daily demand 300 units

Holding cost $20/unit/year

Order cost $10/order

Lead time 2 days

Safety stock 600 units

Find the size of the kanban and the number of kanbans required.

1 ANSWERS

Problem 1:

Demand during lead time= 1,500

Safety stock= 1,500

Therefore: Maximum inventory level= 1,500 + 1,500 = 3,000

Number of kanbans needed= maximum inventory level/kanban size = 3000 / 250 = 12

Problem 2:

Daily demand 300 units

Holding cost $20/unit/year

Order cost $10/order

Lead time 2 days

Safety stock 2 days demand

Find the size of the kanban and the number of kanbans required.

Assume that the size of the kanban is the EOQ:

2*Demand *Order cost 2*300*300*10 Q= = = 90,000 = 300 units Holding cost 20 \kanban size = 300

2 Number of kanbans= (demand during lead time + safety stock) / size of kanban

=[(2*300) + 600]/ 300 = 1200 / 300 = 4 kanbans

3