Supplementary information

Influence of Al2O3 buffer layer on catalyst morphologyand spinnability of carbon nanotube arrays

5 Yani Zhanga*, Gengzhi Sunb,Zhaoyao Zhanc, Lianxi Zhengd*

a Science and Technology on Thermostructural Composite Materials Laboratory, Northwestern Polytechnical University, 710072, Xi An, China. b Institute of advanced materials, Nanjing Tech University, Nanjing 210009, China. c School of Mechanical and Aerospace Engineering, Nanyang Technological University, Singapore 10 639798. d Department of Mechanical Engineering, Khalifa University, P.O.Box: 127788, Abu Dhabi, UAE. * [email protected], [email protected]

15

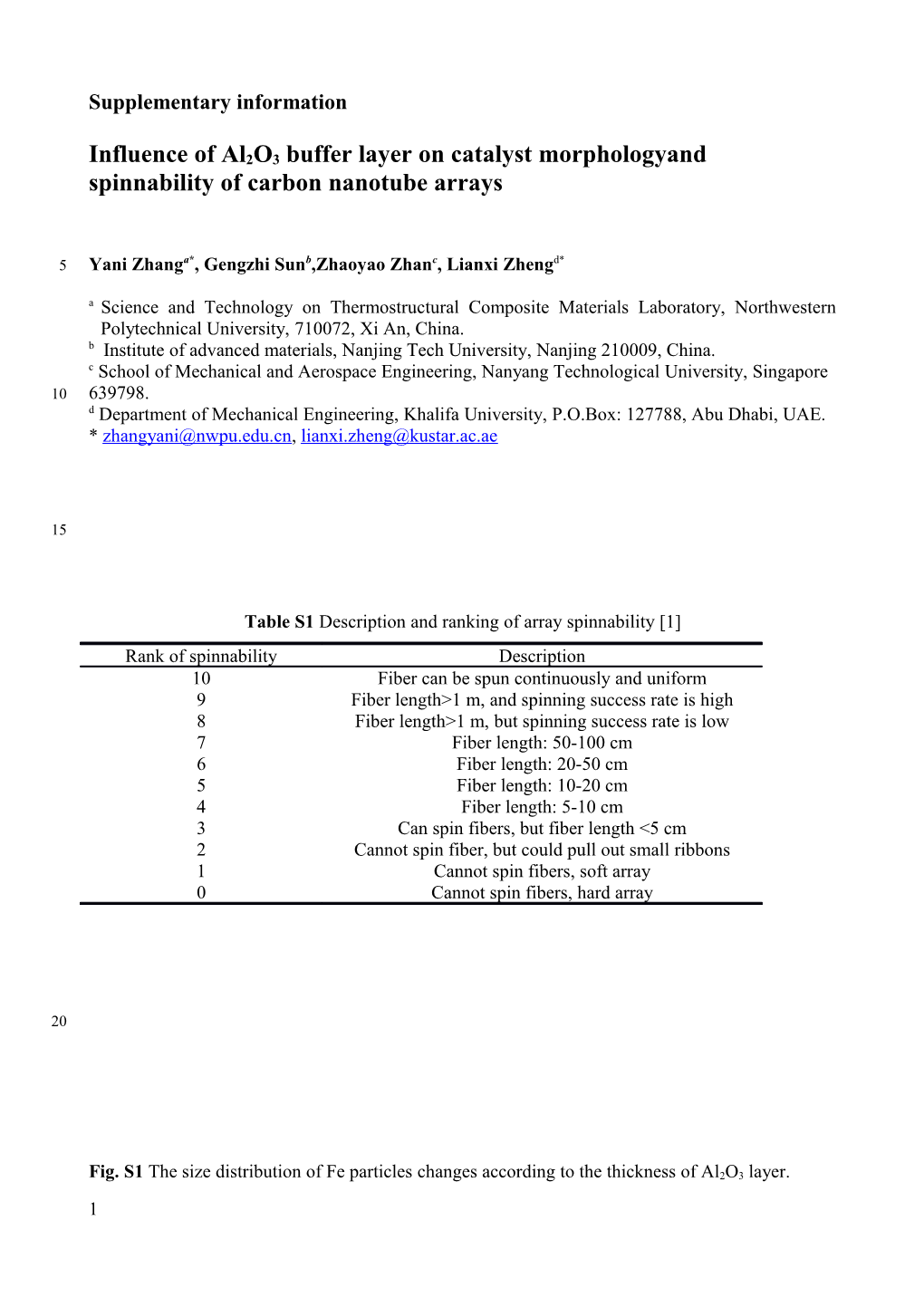

Table S1 Description and ranking of array spinnability [1] Rank of spinnability Description 10 Fiber can be spun continuously and uniform 9 Fiber length>1 m, and spinning success rate is high 8 Fiber length>1 m, but spinning success rate is low 7 Fiber length: 50-100 cm 6 Fiber length: 20-50 cm 5 Fiber length: 10-20 cm 4 Fiber length: 5-10 cm 3 Can spin fibers, but fiber length <5 cm 2 Cannot spin fiber, but could pull out small ribbons 1 Cannot spin fibers, soft array 0 Cannot spin fibers, hard array

20

Fig. S1 The size distribution of Fe particles changes according to the thickness of Al2O3 layer.

1 Fig. S2 (a) The XPS spectra of the as-deposited catalyst film and the catalyst film after annealing.

(b) Magnification of XPS spectra of the Fe 2p. The sample has 1 nm Fe layer and 30 nm Al2O3

5 layer.

[1] Zheng LX, Sun GZ, and Zhan ZY (2010) Tuning array morphology for high-strength carbon- 10 nanotube fibers, Small 6:132-7.

2