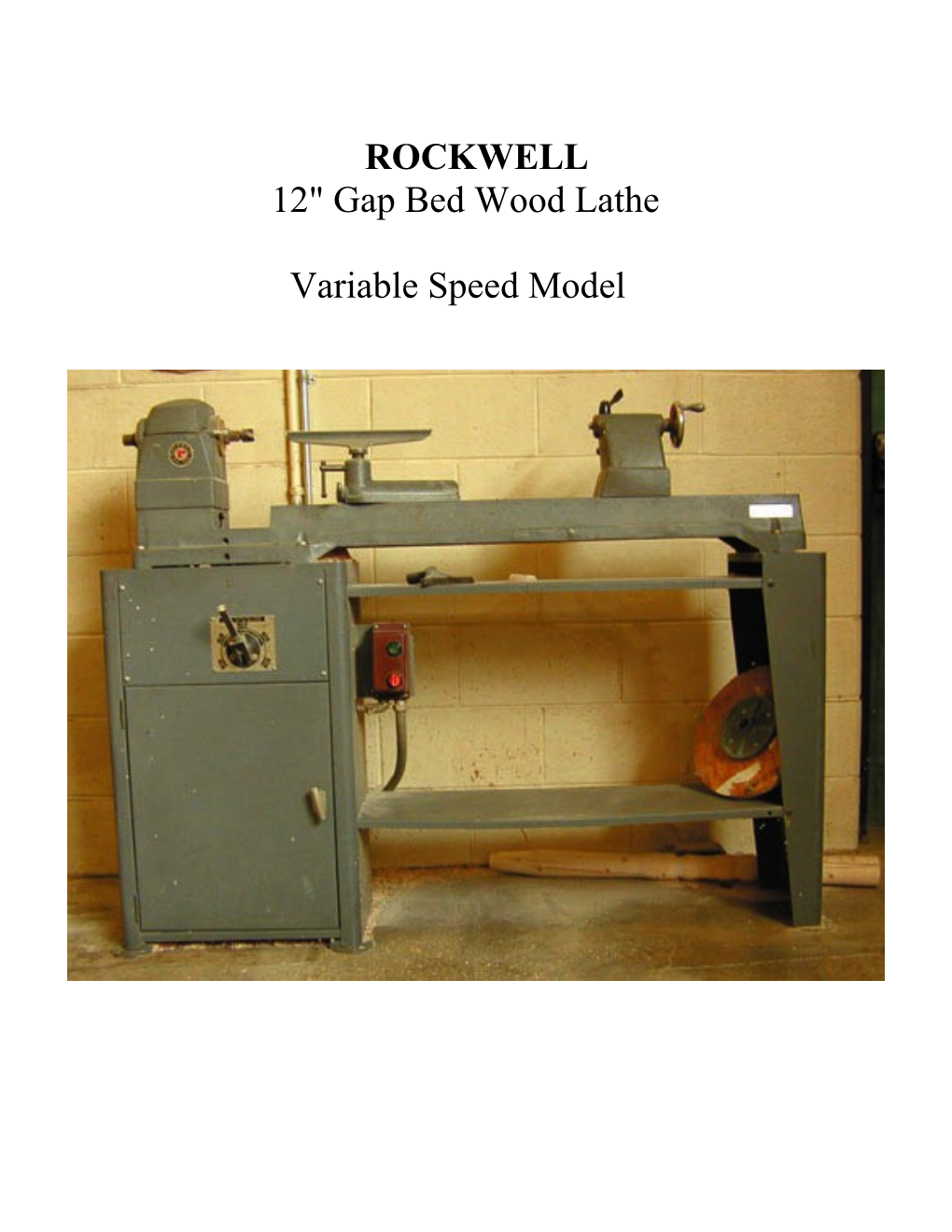

ROCKWELL 12" Gap Bed Wood Lathe

Variable Speed Model Lathe Safety Guidelines

1. Safe, effective use of a wood lathe requires study and knowledge of procedures for using this tool. Read and thoroughly understand the label warnings on the lathe and in the owner's/operator's manual.

2. Always wear safety goggles or safety glasses that include side protectors and a full face shield when needed. Wood dust can be harmful to your respiratory system. Use a dust mask or helmet and proper ventilation (dust collection system) in dusty work conditions. Wear hearing protection during extended periods of operation.

3. Tie back long hair, do not wear gloves, loose clothing, jewellery or any dangling objects that may catch in rotating parts or accessories.

4. Check the owner/operator's manual for proper speed recommendations. Use slower speeds for larger diameter or rough pieces and increased speed for smaller diameters and pieces that are balanced. If the lathe is shaking or vibrating, lower the speed. If the workpiece vibrates, always stop the machine to check the reason.

5. Make certain that the belt guard or cover is in place. Check that all clamping devices (locks), such as on the tailstock and toolrest are tight.

6. Rotate your workpiece by hand to make sure it clears the toolrest and bed before turning the lathe "on". Be sure that the workpiece turns freely and is firmly mounted. It is always safest to turn the lathe "off" before adjusting the tool rest.

7. Exercise caution when using stock with cracks, splits, checks, bark, knots, irregular shapes or protuberances.

8. Hold turning tools securely on the toolrest and hold the tool in a controlled but comfortable manner. Always use a slower speed when starting until the workpiece is balanced. This helps avoid the possibility of an unbalanced piece jumping out of the lathe and striking the operator.

9. When running a lathe in reverse, it is possible for a chuck or faceplate to unscrew unless it is securely tightened on the lathe spindle.

10. Know your capabilities and limits. An experienced woodturner may be capable of techniques and procedures not recommended for beginning turners.

11. When using a faceplate, be certain the workpiece is solidly mounted. When turning between centers, be certain the workpiece is secure.

12. Always remove the fence or toolrest before sanding or polishing operations.

13. Don't overreach, keep proper footing and balance at all times.

14. Keep lathe in good repair. Check for damaged parts, alignment, binding of moving parts and other conditions that may affect its operation.

15. Keep tools sharp and clean for better and safer performance. Don't force a dull tool. Don't use a tool for a purpose not intended. Keep tools out of reach of children.

16. Consider your work environment. Don't use lathe in damp or wet locations. Do not use in presence of flammable liquids or gases. Keep work area well lit.

17. Stay alert. Watch what you are doing, use common sense. Don't operate tool when you are tired or under the influence of drugs or alcohol.

18. Guard against electric shock. Inspect electric cords for damage. Avoid the use of extension cords.

19. Remove chuck keys and adjusting wrenches. Form a habit of checking for these before switching on the lathe.

20. Never leave the lathe running unattended. Turn power off. Don't leave the lathe until it comes to a complete stop.

21. Inform the technician if the tool seems to be malfunctioning or is damaged

General Procedures

1. Eye protection meeting current ANSI safety standards must be worn at all times while anyone is working in the lab. 2. Never make any adjustments to a machine while it is running. 3. Never walk away while a machine is still in motion. For example, when you turn the bandsaw off, the blade continues to move unless the break is applied. The only exception to this is the stationary grinder. 4. Disconnect electrical power when changing blades, bits, etc. or anytime an injury could occur if the machine is accidentally turned on. Generally this requires that the machine be unplugged or the circuit breaker turned to the off position.

Wood Lathe Fundamentals:

1. Tie back your hair if it falls forward when you tilt your head downward. 2. Keep the tool rest no farther than 1/8" away from your work. Rotate the hand wheel by hand before turning the lathe on to check the clearance. Never adjust the tool rest when the lathe is running. 3. Keep the turning chisels sharp and always grip the tools with both hands. 4. Check stock for defects and allow laminated stock enough time to cure before turning. 5. Always remove the tool rest when sanding or finishing.

Wood Lathe: Introduction

Mankind has been using woodturning for thousands of years. From simply bending a sapling over in a wood and then tying the end down to a footpedal. Since then the machine has evolved into the type you see today. The wood lathe is a complicated machine and although they all have the same basic components variations do exist between models.

The shapes you can turn* do vary, but they all have one thing in common and that is that they are variations of cylindrical shapes, i.e. rods, domes, cones etc. A considerable amount of time is required to set up the machine safely for your particular workpiece. However the actual act of "turning" itself is quite relaxing.

*this is the actual word for working on a Lathe. Hence " Turning" and not "Latheing".

Wood Lathe: Components

*(see parts diagram)

1: Bed

This runs across the full width of the machine. Normally two beams support the Saddle and Tailstock allowing them to be adjusted to any position along its length.

2: Head

The "heart" of the machine. The Head houses the drive belt(s), the pulleys and the rotating Spindle. All the moving parts safely concealed behind the casing of the machine.

3: Saddle

The Saddle sits over the Bed similar to that of a horse - hence its name. It supports the Fence and can be adjusted along the complete length of the bed. It is locked in position by a lever/nut assembly.

4: Fence

The Fence, sometimes called the Rest, is the actual place where you place (or rest) the end of the Turning tool whilst working. It too is adjusted up or down in accordance to the work being performed. When turning between centers the top of the tool rest is positioned just above center. 5: Tailstock

The Tailstock is always mounted on the right hand side of the bed as the operator looks at it. Using a lever/nut assembly it can also be moved and locked along the full length of the bed. It has two Levers and one wheel on it. One is to lock the Tailstock's spindle in position and the other locks the tailstock to the bed. The wheel is to move the cup center backwards and forwards.

6: Chuck

Two types of Chuck are normally used. The 3 jaw and the 4 jaw. This machine is not equipped with chucks.

7: Spindle

The Spindle is the actual moving part of the machine and is powered from the motor. A screw thread with a hollow centre allows a wide variety of attachments to be fitted.

8: On/Off Switch

The usual On/Off switch for starting and stopping the machine.

9: Motor

This drives the belts.

10: Variable Speed Control Lever

This is rotated thus changing the speed.

11: Two Faceplates

There are two different sizes of faceplate. They are stored in the store and can be signed out and are used for end turning such as in bowls.

Wood Lathe: Changing the Speed

The first thing most people want to do when they wish to use the lathe is to check what speed it is running at. To do this you simply turn the On/Off button (fig 1) to "On and turn the variable speed handle (fig 1) to the desired speed. Roughing out we start our turning at the slowest speed and increase the speed as the turning becomes more refined. However before you do so you must ensure that the attachments are secure and that anything resting on the machine will not fly off. You do this by feeling the attachments - the Chuck, Centre "Dogs" etc. VARIABLE SPEED HANDLE

ON

OFF

Fig 1

Once the speed at which the Woodlathe is operating at has been determined you can then alter it if you wish. They do vary between models but essentially they are same.

Preparing a Piece of Wood

Band & sand or cut to take edges off, so that you don't encounter a spinning right angle which will really clout the turning tool and possibly knock it out of your hands resulting in nasty consequences.

Wood Lathe: Turning "Between Centres"

This is the most common operation to start with. The workpiece is held securely at both ends - hence the terms "between centres". Two attachments are placed at either end of the machine, one coming out of the spindle and the other out of the tailstock . The workpiece is then mounted between these two attachments and gripped tight. Step 1

Look at the Lathe itself. Does the spindle at the Head (fig 2) end of the machine have its' drive center with the spurs inserted? This is the mounting point for attachments.

Head

Spindle Center with Spur

Fig 2

Both the Spindle and the Centre have a Morse Taper (the Centre, Male & the Spindle Female). If you were to push the Centre into the Spindle until it would go no further then the taper would grip it and prevent it from dropping out.

Step 2

Now examine the other end of the machine and see if the tailstock end has a similar hole to that of the Spindle, which would contain a center that serves the same purpose. There are two types: the first is the Dead Centre - so-called because it doesn't revolve; the second is the "Live Centre". Our machine is only equipped with a dead center.

After you have done this look at the two bolts/levers on the tailstock (fig 3).

Spindle Locking Lever

Spindle adjusting wheel

Tailstock Locking Lever

Tailstock Center

Fig 3 The one on the top of the tailstock will either lock or unlock the Spindle. This is achieved by moving a wheel at the rear. The spindle can be moved either forwards or backwards inside the tailstock. This means that the Centre, or any other attachment inside the spindle, can be moved either closer or further away from the workpiece, which is very useful for gripping the workpiece and for other operations.

There is a Lever to the rear wallside that locks the bolt underneath which also insures that you can, by either loosening or tightening it, move the tailstock to any position you desire on the bed and once there you can lock it in position. You have to loosen this Lever to allow it freedom of movement. This will prove useful later on when you begin to mount the workpiece.

Step 3

You should have obtained a piece of timber to use as the workpiece. How you prepare and select the piece is a little outside this package. The piece of wood has to be roughly cylindrical. To achieve this you need to determine the centre of the piece. Center is determined by drawing crosslines across the end of it and then marking.

Step 4

Place the wood horizontally between centers and lightly tap with a mallet cinching the workpiece onto the "Dogs" located on the headstock spindle. Position the opposite end in position to align with the tailstock center and slide the tailstock into place. Lock the tailstock in place with the lower, wallside lever. Turn the tailstock wheel burying the center into the workpiece. Lock the center into place with the top lever. This in effect will be the centre of rotation for the workpiece.

The centre has to be buried into the wood deep enough to ensure that the two " Dogs" are adequately buried as well. The two Dogs will grip the wood and prevent the workpiece from spinning around within the central point.

Step 5

At the end of Step 5 I usually place my hand on the workpiece and give it a spin. This tells me if the workpiece is secure at both ends and gives me some idea of whether the weight is roughly symmetrical on the work piece. This is usually judged by eye. When you draw your crosshairs on the end of the workpiece , the idea is to position the centre for support on the centre of rotation of the workpiece. Not only in terms of rotation but also that of mass. It is no good having a large part of the workpiece on one side of it as the action of rotation will result in the weight being violently flung about - not unlike that of a washing machine which has been loaded incorrectly. This will cause the woodlathe to rattle and vibrate and increases the chance of the workpiece being flung out. Getting the Workplace roughly symmetrical is also important for the next step

Step 6

The next job is to adjust the saddle and fence (fig 4) such that it is in the best position to rest one of the turning tools on. The idea is that the fence is positioned along the length of the workpiece, and the top of the rest approximately 3mm or 1/8 " above center (fig 5) so that the clearance between it and the rapidly spinning piece of wood is as small as practical. This is a basic safety requirement. The fence ensures an adequate rest and allows more control of the chisel during the operation. If set correctly the gap will be small enough to prevent the chisel, if snatched by the workpiece, from falling in between the fence and the workpiece. Basically this is what we are trying to avoid. If this should happen the chisel will flick up and fly out catching the operator under the chin if they are unlucky. Fence set up and positioning is vital to ensure a safe operation.

If you look over the bed of the woodlathe you will see the saddle in its position on top of the bed. It is attached to the bed by a large nut. The nut comes with a lever/knob assembly attached to the saddle. Turn the Lever to release or lock the saddle.

Fence or Toolrest

Fence Locking Lever

Saddle

Saddle Locking Lever

Fig 4 Fig 5

Step 7

Next pull and swivel the fence/saddle combination until they are parallel to the workpiece. You judge this by eye. Once in position tighten the lever on the side which locks the fence. This will lock the fence into position on the saddle. Then looking directly down from above, adjust the saddle/fence until a gap of about 10 mm can be seen along the length of the workpiece. This measurement is inserted here to serve as a guide only. The general rule is that the gap should be as small as practical.

Next secure the saddle in position by tightening the lever/knob. Then spin the workpiece by hand. If you have done the job correctly the workpiece will rotate freely. However you may find that the workpiece crashes into the fence as it rotates. This means that it is wider at some points than at others. In which case you will have to undo and readjust the Fence/Saddle to allow a minimum clearance over these points. Then re-tighten to its new position. Now spin the workpiece again until you are satisfied that it will clear the fence on full rotation. You are now ready to proceed.

Wood Lathe: Turning Using the Faceplate

Step 1

The faceplate (fig 6) is the other main attachment for the lathe. It is a large diameter circular plate usually made from aluminium for lightness, but sometimes steel. The face of the plate has a series of holes drilled all the way through it. These are the same size as the screws which are used to secure the workpiece on to the faceplate. In the middle of the faceplate is another larger hole. This is used for centering your symmetrically. It also lines up with the spindle screw thread. Faceplate mounted To plywood

Fig 6 The faceplate is very useful for turning workpieces which have a diameter much larger than their height, e.g. a dome. They are not very good at or should be used for long thin workpieces where the length is much longer than the width.

The first thing you will want to do in setting up the faceplate is to screw your workpiece to a piece of MDF (fig 7) (Normally about 18-25mm thick). You do this because it will increase the distance between the turning tool and the aluminium chuck if you want to turn the whole length of the workpiece. If you slip at the left hand end of the workpiece the chisel will hit the MDF and not the aluminium of the faceplate itself. Normally 3 screws are screwed in symmetrically around the workpiece. You may find that drawing a crosshair on the face of the MDF will assist you in placing the workpiece centrally upon the faceplate before screwing it in.

Fig 7 Step 2

Turn the piece of MDF ,with the workpiece attached, over and draw another cross hair on the rear. Put the MDF down on a table with the workpiece lower most. Line the crosshairs on the MDF up on the centre of the hole in the middle of the faceplate, (this is what it is for), and screw in the 4 screws.

Step 3

Pick up the faceplate and bring it over to the lathe. Secure the faceplate to the spindle screw thread.

Step 4

Once the face plate has been secured , move the saddle and fence, as before and adjust the Fence for the minimum clearance.

Wood Lathe: Roughing Out

This is the operation you do to begin with. You will be turning a workpiece of roughly cylindrical proportions into a true cylinder.

This process is called roughing out and for this you select a turning tool with a "U" cross- section. This is called a gouge, check to see if it is sharp enough. If it is not, ask a member of staff to show you how to sharpen it.

Next place it on the fence. Hold it down at an angle of 45 Degrees.

This is the correct position for this type of turning tool, (or Gouge). You will then see that you may have to "Fine adjust the Fence" so that the turning tool is in the correct position for using. Refer to the diagram below.

Loosen the lever/knob on the side of the fence mounting and move the fence up and down to the optimum position. Remember to double check the minimum clearance as you tighten it up!

Wood Lathe: Holding the Turning Tool (Gouge)

The aim of holding the turning tool is to allow for maximum control of the cutting surface as well as gripping it tightly enough. So if the worse came to the worse and the end of the turning tool did dig into the workpiece, or shudder and kick suddenly, you would have a secure hold preventing the it from flying out of your grasp.

I always make sure that I am comfortable in terms of my posture and I normally stand with one foot in front of the other. This helps with balance if nothing else. The correct grip is such that it allows the handle to be in line with your forearm and that your forearm is on top of the handle. This is a matter of safety. If the turning tool kicks violently it would hit and be stopped by your forearm. A bruise, although unpleasant, is preferable to getting the full force of the handle in the teeth!

The main point is to grip it tight enough for safety, but also loose enough so that you can comfortably move the cutting edge of the turning tool across the workpiece. If you do it correctly you will see a stream of wood chips fly off the workpiece as the gouge travels across it. If however you get a fine mist of dust it means that you are scraping the workpiece as opposed to cutting into it. This is normally caused by holding the gouge at the incorrect cutting angle, ( normally should be held at 45 degrees). The usual cause is that the angle is low. In which case you should increase the angle of holding the gouge for better results.

Always make sure that you leave enough room between the end of the workpiece that you want to shape and the centers. Otherwise you may find that you inadvertently hit the centers with the turning tool. This will at best kick the tool out of your hand, or at worst take a chunk out of the ground end of the tool. Try a few "Dry Runs" first to get the feel of the turning tool.

Wood Lathe: Finishing

Once the workpiece has been taken down to a cylinder, you can then proceed to the next operation, "Finishing". This as it name suggests is where you actually shape the workpiece to its final form. For this you need to change to a "Knife Tool", which is flat. Its plan view is a square and the side elevation is a "V" with long sides. This tool cuts much finer than the Gouge and because it is a square as seen from above, it is much easier to cut parallel to the length of the workpiece. In operation the method is similar to the one employed when using the Gouge. The actual angle of holding is less however, more like 20 degrees.

Note that because the knife tool in cross section is shallower than the gouge. You must lower the fence so that the apex of the "V" section is on the centre line, then retighten it.

Wood Lathe: Sanding

As its name implies this is operation involves sanding with sandpaper or Wet & Dry the surface of the workpiece to obtain a smooth finish. You can do this either: with the workpiece stopped in which case it is exactly like sanding a piece of wood normally, i.e. off the woodlathe. or with the workpiece spinning.

However although the latter option is quicker you have to be aware of the attendant dangers and take appropriate precautions.

To safely sand a moving workpiece follow the steps below: Step 1

Always wear your full face shield.

Step 2

Always tie back loose hair, and loose clothing.

Step 3

Remove bangles, rings, watches etc, which could get caught in the spinning machine.

Step 4

Always hold the sandpaper underneath the spinning workpiece. In this way the sandpaper if it gets caught or snatched will be throw out towards you, (and your fingers), away from the workpiece. If you hold the paper on top of the workpiece, you will be pulled towards and round the workpiece if it gets caught. Never do This!!!

Step 5

It is best to fold a sheet of sandpaper in quarters, this results in a greater thickness of paper between you and the wood. You will also find that the paper becomes quite hot due to the friction generated by sanding. By increasing the layers of sandpaper, this helps to prevent you from burning yourself.

Wood Lathe: Parting Off

Parting off is the operation where you cut or "part off" the section of the workpiece that you want to keep and is fairly simple to do. However instead of using a gouge or a knife tool you use the "Parting Off Tool". This tool is similar in appearance to the Knife tool, but the other way up. From above in plan view the tool looks like an elongated square with a width of about 5mm, (this value is an average as it may vary between models).

In elevation the tool looks like a "V". In effect the tool is much longer than it is wide and is designed such that it can be pushed into the workpiece and cut out a thin slice.

To part off the workpiece, always remember that the idea is not to cut the workpiece off totally. If you did this it would leave it would unsupported and it may fly off the lathe. Usually if it avoids hitting you, it will hit either the bed or the floor of the workshop. This will normally damage or dent your work. To avoid this you only cut about 3/4 of the way through the workpiece. This means that it is still safely attached.

You will also need to lower the fence so that the apex of the "V" is on the centre line of rotation. Now line up the tool with the place you want to part off. Turn the machine on and using the grip mentioned previously to push the tool into the workpiece.

However if you just push you will find that the tool and the workpiece will become very hot. You may even find that smoke will start to rise up!

To prevent this you need to back off the parting tool every now and again. I usually employ a method of going in and then backing off for about 1/2 the distance I have just gone in.

Continue to part off the Workpiece until you have gone into 3 quarters of the diameter. Then turn off the machine and wait until it has finished revolving.

You then take a handsaw and cut through the remainder of the workpiece until it drops into your hand.

A large part of this manual has been extracted from http://www.herts.ac.uk/lis/ltdu/projects/mm2/woodlathe/introduction7.htm