Background Statement for SEMI Draft Document #5548A Revision to SEMI C36-1107, SPECIFICATIONS FOR PHOSPHORIC ACID

Notice: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this Document.

Notice: Recipients of this Document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided.

Background:

SEMI C36 is due for its 5-year review. As a result of the review process, this ballot proposes minor changes for consistency with other SEMI Standards on liquid chemicals. In addition, the ICP-MS trace metals procedure in the previous version was found to contain inappropriate methodology. This ballot proposes a revised ICP-MS method for trace metals in Grade 2 and 3 phosphoric acid. Validation data for the new ICP-MS method applied to Grade 3 specifications is included as an Appendix. As recommended by the NA Liquid Chemicals committee, previous validation data for the existing ion chromatography method for trace anions, originally submitted in 2007, is also included in the Appendix. Finally, the nomenclature or specifications for particular acid strengths have been modified to agree with current industry standards.

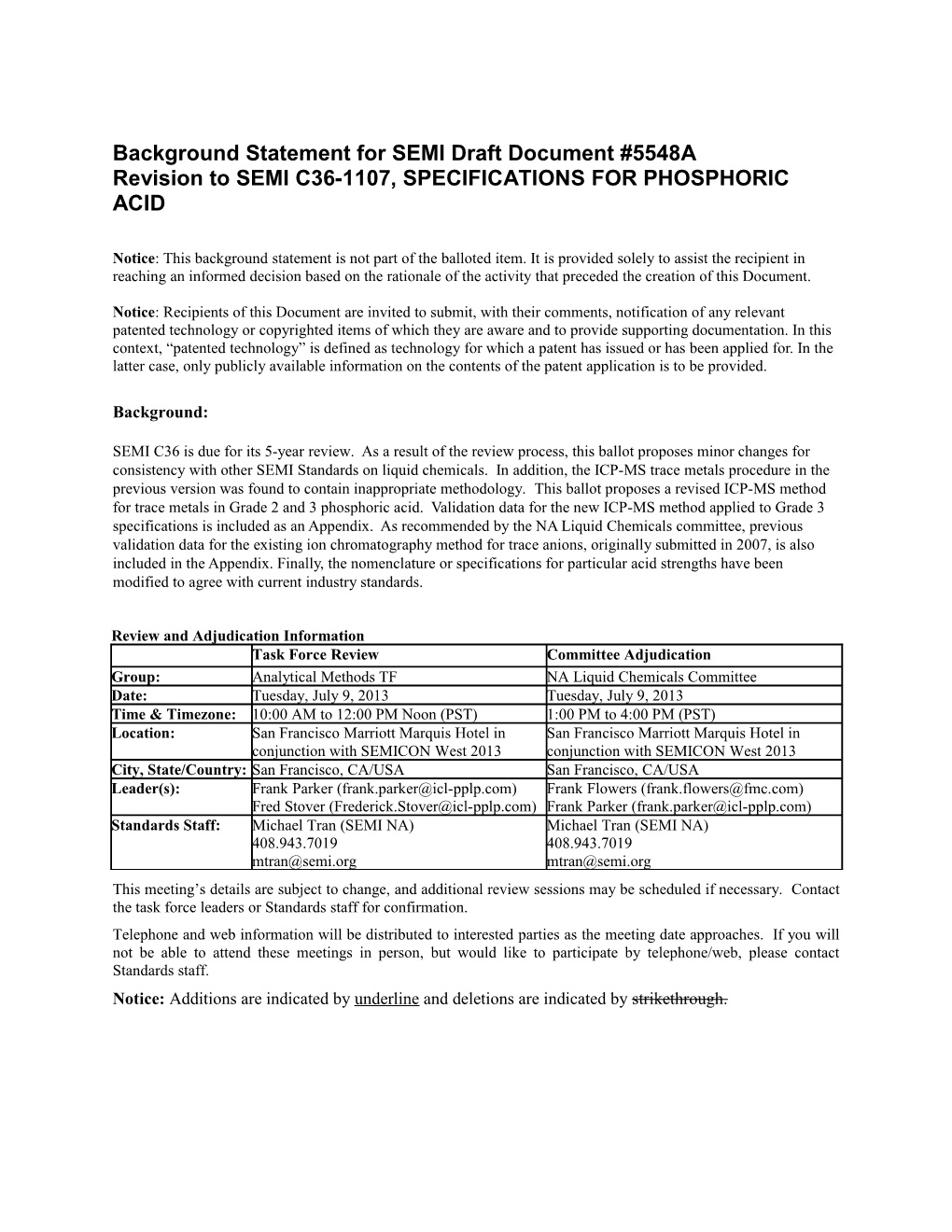

Review and Adjudication Information Task Force Review Committee Adjudication Group: Analytical Methods TF NA Liquid Chemicals Committee Date: Tuesday, July 9, 2013 Tuesday, July 9, 2013 Time & Timezone: 10:00 AM to 12:00 PM Noon (PST) 1:00 PM to 4:00 PM (PST) Location: San Francisco Marriott Marquis Hotel in San Francisco Marriott Marquis Hotel in conjunction with SEMICON West 2013 conjunction with SEMICON West 2013 City, State/Country: San Francisco, CA/USA San Francisco, CA/USA Leader(s): Frank Parker ([email protected]) Frank Flowers ([email protected]) Fred Stover ([email protected]) Frank Parker ([email protected]) Standards Staff: Michael Tran (SEMI NA) Michael Tran (SEMI NA) 408.943.7019 408.943.7019 [email protected] [email protected] This meeting’s details are subject to change, and additional review sessions may be scheduled if necessary. Contact the task force leaders or Standards staff for confirmation. Telephone and web information will be distributed to interested parties as the meeting date approaches. If you will not be able to attend these meetings in person, but would like to participate by telephone/web, please contact Standards staff. Notice: Additions are indicated by underline and deletions are indicated by strikethrough. Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and ASTM D5127 — Standard Guide for Ultra Pure Water Used in the ElectronicsSemiconductor in WaterIndustry Guide UltraUsed and D5127for the ASTM Pure —Standard 4.2 SEMI C35 —Guidethe Analysis ofChemicals SEMI C1 for Liquid 4.1 4 3.1 3 and practices, health and safety other ofprior thelimitations use. applicability regulatoryor to determine appropriate establish to Documents the of users the of responsibility the is It use. NOTICE: 2.1 2 validation. results. valid statistically give to shown been have methods Test standards. those support to procedures testing and industry 1.1 1 ACID toSEMIC36-1107, Revision FOR PHOSPHORIC SPECIFICATIONS Draft Document SEMI #5548A emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This Fax: 610.832.9555; 610.832.9585; 1 7.1 7 Table 1 6 5.1 5 NOTICE:

Molecular Formula Molecular

American Society for Testing and Conshohocken, Testing 19428-2959,American Materials,Drive, 100Barr for Harbor West Pennsylvania Society USA. Telephone: Molecular WeightMolecular Density 25 at Referenced Standards Referenced Documents and Limitations Scope Purpose Requirements PropertyPhysical Terminology CAS Number CAS ASTM SEMI None. of is scope thisThe document semiconductor the in used acid phosphoric for requirements standardize to is document this of purpose The The requirements for phosphoric acid for Grades 1,2,andin phosphoricfor3arelisted for requirements Table acid Grades The None. Properties ofPhosphoricAcid Alternative methods Alternative

Unless otherwise indicated, all documents cited shall be theversions. latestpublished otherwise documents all cited be shall Unless indicated, Standard their with associated issues safety all address to purport not do Guidelines Safety and Standards SEMI Standard — Specifications and GuidesNitric Acid— Specificationsfor and C s andSafety Guidelines 1 Properties 1. 70 1.63g/mL http://www.astm.org 6 7664-38-2 9 m

H g/mL 98.00 3 ay be used as long as they comply with SEMI C1 SEMI with comply they as long as used be ay PO for for (80%)

4 (for information information (for only) (8 all 6 5 grades of phosphoric acid used in acid of grades industry. used phosphoric the semiconductor %)

Page jn l jn 2 1 2 . requirements Document Document Number: Doc. Date:

for method for SEMI 1/9/2018 DRAFT

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and B. The absorbance of SampleSolution Theof B. absorbance A Solution Control of absorbance the determine and path light the in A Solution Sample with absorbance zero read to the instrument A. Adjust Sample Solution of absorbance the determine Then path. the light in Solution C Blank with absorbance zero read to instrument the adjust cells, cm 1 using and, nm 410 at spectrophotometer a Set temperature. 8.3.1 8.3 as treated (Cl) is the ion sample. of0.015 mg chloride solution reagent nitrate 8.2 a bluewhite colorbackground. hydroxide of against sodium thea first to appearance indicator add of solution 0.5mL thymolphthalein of120 mL water, 8.1 8 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This 8.4.4 concentrationof 40ppm.) scandium solution 8.4.3.1 8.4.3 scandium concentrationof 40ppm. a have 8.4.2.2 E1.1in Type D5127criteria for ASTM 8.4.2.1 8.4.2 “calculated”the sulfatebe value than higher may the sulfate actual concentration a in given sample. and method, this by determined be also will etc.) (organic, species sulfur other Therefore, sulfur. evaluates actually methodology 1: NOTE sulfate. (SO sulfate 8.4.1 8.4 Grade 1 Grade1 Procedures Nitrate Chloride Assay Sulfate Heat the three solutions in a preheated (boiling water) bath for 10 minutes. Cool rapidly in an ice bath to roomto bath ice an in rapidly Cool 10 minutes. bath for water)(boiling a preheated solutions in the three Heat Analysis Sample Special of the determination for results given satisfactory methodhas (ICP) plasma coupled inductively following The Dilute 20 g of phosphoric acid to 100 mL with water. (An aliquot of the concentrated scandium standard scandium concentrated the of aliquot (An water. with mL 100 to acid phosphoric of g 20 Dilute — Standard Internal Scandium — Water

hudshould % — Weigh to the nearest 1 mg about 1 mL of sample in a 250 mL glass-stoppered flask, dilute with with dilute flask, glass-stoppered mL 250 a in sample of mL 1 about mg 1 nearest the to Weigh —

—Prepare thesolutions: following 4 While this method has been shown to accurately determine sulfate concentration in phosphoric acid, the ICP the acid, phosphoric in concentration sulfate determine accurately to shown been has method this While ) by the analysis of sulfur (S) and subsequent calculation to determine the stoichiometric equivalent of equivalent stoichiometric the determine to calculation subsequent and (S) sulfur of analysis the by ) Assay — Dilute 9 mL (15 g) of sample with 25 mL of water, and add 0.5 mL of nitric acid and 1 mL of of (151mL sample0.5mL silver —Dilute9mL 25nitricacid g) with water,and and of add of

Reagents Preparation

hl shall h ae sdfraldlto,clbainadsadrsstandards and calibration dilution, all for used water The Volume also be added during the dilution process such that the final diluted sample will have a have will sample diluted final the that such process dilution the during added be also (see SEMI C1) SEMI (see

Control B: Solution A: Sample Solution Blank C: Solution NaOH Mass ( mL y a s s A % with regards Sulfate with to content . Any turbidity produced produced turbidity Any . A scandium standard solution is utilized such that final diluted samples will samples diluted final that such utilized is solution standard scandium A ) of should Normality Sample = Add 3 (5 to of of Add mL g) 0.025 sample mg nitrate ( 50 with sulfateto mL brucine reagent solution 3 (5 to of mL water,Add mL g) 2of sample dilute Use 50 of brucineUse mL the sulfate solution. reagent solution,andreagent mix. (NO ion shall shall s ee SEMI ee C1) L m ( g not exceed that of that Control exceed SolutionB.not Page ) NaOH ) g ( e l p m a s f o t h g i e W 3 ).Dilute 50 with sulfate to mL brucine N jn l jn

f o 3 and mix. H O a N 4 should should . 900 (seeSEMIC1)

. 0 0 9 . 4 shall shall be no greater than that produced when produced that than greater no be should should , and titrate with standardized titrate with 1N , and hl shall meet at a minimum, the minimum, a at meet Document Document Number: Doc. Date:

SEMI 1/9/2018 DRAFT (1)

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and cups. To one of the cups make standard addition. Add 5 g of water meeting the criteria for Type for criteria the meeting water of g D5127 5 Add addition. standard make cups the of one To cups. 8.5.3.1 validation method methods Alternate they as long (Zn). as used be may zinc and (Ti), titanium (Na), sodium (K), potassium (Mn), manganese (Mg), magnesium (Li), lithium (Fe), iron (Cu), copper (Ca), calcium (Al), aluminum metals: trace following the of each for specified 8.5.3 using atomicabsorption manufacturer spectroscopy furnace 8.5.2.3 D5127 ASTM in blank. PrepareMix. reagent E1.1 Type for criteria the meeting water using g 10 to cups both 0.2 mL Add cups. polypropylene mL 30 8.5.2.2 8.5.2.1 and (Pb), 8.5.2 lead (Ni), nickel (Cr), chromium they as (As), long as co arsenic used be metals: may trace methods Alternate following (Sb). antimony the of each for specified 8.5.1 8.5 8.4.5.1 8.4.5 giveto satisfactoryresults. shown been has nm 180.731 of wavelength A solutions. standard sulfur appropriate using standardized been has that 8.4.4.1 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This 4 A 3 2 8.6.3 as system chromatography in referencesdescribed ion the Configure mm). (2 Column Trap Anion ATC-1 IonPac mm), (2 Analytical HC AS11- IonPac mm), (2 Guard AG11-HC IonPac mm), (4 Concentrator AG11-HC IonPac mm), (9 Pre-separator ICE 8.6.2 ‘Method C1, SEMI to according anion each for validated are Validation’. they as long as (NO used nitrate be (Cl), may chloride methods following: the Alternative of each for specified values the at impurities anion 8.6.1 8.6 manufacturer spectroscopy using emission 8.5.3.2 “ 3 Dionex, CA; from 2 Available Sunnyvale, “Automated trace anion determinations in concentrated electronic grade phosphoric acid byion electronic phosphoric chromatography”,F. Stover, anion in grade concentrated S. trace “Automated determinations , 956 (2002) 121-128., 956(2002) m The determination of trace anions in concentrated phosphoric acid”, Dionex Technical Note in ofDionex Sunnyvale, anions concentrated acid”, The 44,Dionex, Technical determination trace phosphoric CA, 1998. ply withply Trace Metal Analysis Trace Trace AnionTrace The following method has given satisfactory results in determining trace metal impurities at the value the at impurities metal trace determining in results satisfactory given has method following The Special value the at impurities metal trace determining in results satisfactory given has method following The Calculation The following i following The i The has chromatography Ion (with regardsmetalcontent) to Analysis Preparation Sample Analysis Preparation Sample Acid, UltraNitric Pure sulfate associated (SO The spectroscopy (ICP) plasma coupled inductively using content sulfur the analyze sample, prepared the Using I on chromatography columns chromatography on SEMI C1

Reagents

Analysis — —

, ‘ Using the solutions from ¶ 8.5.2.2 and reagent blank, analyze elements specified by graphite by specified elements analyze blank, reagent and 8.5.2.2 ¶ from solutions the Using Using the solutions from ¶ 8.5.3.1 and reagent blank, analyze elements specified by plasma by specified elements analyze blank, reagent and 8.5.3.1 ¶ from solutions the Using Method Validation I on chromatography conditions requirements for method for requirements validation 3

, 4 . Eluent may be NaOH or generated KOH or EG40 generated Generator using Eluent may. Eluent be NaOH

— to according metal trace each for validated are —

In a clean environment, weigh 5 g of sample into each of two 30 mL polypropylene mL 30 two of each into sample of g 5 weigh environment, clean a In been used successfully used been — In a clean environment, weigh 1 g (5 g for arsenic) of sample into each of two two of each into sample of arsenic) for g (5 g 1 weigh environment, clean a In Use ultracontent lowmetalion for nitricspecified 4 http://www.dionex.com ) concentration is determined using the stoichiometric conversion (SO the stoichiometricconversion using ) determined concentrationis

to eachcup.to Mix. ’ . ultra pure pure ultra 2 used were as follows as were used ’ s recommended procedure.s recommended nitric acid to each cup. Make standard addition to one cup. Dilute cup. oneto addition standard Make cup. each to acid nitric were used given satisfactory results satisfactory given Page , jn l jn ’ ‘ s recommended procedure. Method Validation 4 : : ASRS-ULTRA Suppressor (2 mm), IonPac AS6- IonPac mm), (2 Suppressor ASRS-ULTRA : are validated for each trace metal according to according metal trace each for validated are comply with with comply ’ for for . the determination determination the with regards to metal content metal to regards with SEMI C35, Grade 2 SEMI C35, SEMI C1 SEMI Document Document Number: 3 ) and sulfate (SO sulfate and ) 2 . Doc. requirements for requirements

E1.1 in ASTM in E1.1 Date: determining

J. Chromatogr. . 4 SEMI = 3× 1/9/2018 DRAFT S). 4 of ). .

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This Standard dilution Sample Setting Current Suppressor Detection Volume Sample collectionConcentrator time timePre-separation Flow Pre-separation Rate Flow Eluent Rate Eluent min mM or isocratic20 KOH NaOH for min 30 High purity acid High phosphoric spiked 1 Cl,12 SO with ppm ppm D5127ASTM 1:1 mA50 Recycle ASRS, Auto-suppression Mode Conductivity Suppressed 200 min4 min8 0.5 mL/min 0.38 mL/min (w/w) utes utes utes L , to mM 5 , return 20 for min with Page water meeting the criteria for Typewater meetingthe criteriafor (with regards anion (with to content) jn l jn 5 utes utes ,stepped 100 for to mM 10 de-ionized waterde-ionized (high purity) Document Number: Document

E1.1 in E1.1 in 4 Doc. and ppm 5 NO Date: 5548A 1/9/2018

DRAFT 5548A 3 SEMI LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and specified for each of the following trace metals: aluminum (Al), antimony (Sb), arsenic (As), cadmium (Cd), cadmium (As), arsenic (Sb), antimony (Al), aluminum metals: trace following the of each for specified 9.5.1 9.5 9.4 9.3 9.2 9.1 9 8.6.4 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This water. of concentration a have will sample E1.1 Type with diluted mL 100 to dilute and pure, ultra acid, nitric final of mL 2 Add element. standard internal each the of ppb 100 that such solution stock standard internal the of aliquot an 9.5.2 calibration external diluted final standard that internal of such ppb 100 elements. utilized contain will is and elements 9.5.1.1.4 sample for ¶ concentrations appropriate in have will elements standards standard internal the and 9.5.1 ¶ 9.5.1.1.5 will solutions measured internalelement. standard concentrationof 100ppbof a each final have that such utilized is (Sc) scandium and (Lu), lutetium (In), indium (Ge), germanium 9.5.1.1.4 in Type D5127. ASTM for E1.1 9.5.1.1.3 9.5.1.1.2 9.5.1.1.1 9.5.1.1 ‘Method trace SEMIC1, metalaccordingValidation’. to forvalidated each (Mn), manganese (Mg), they areas long as used be may methods Alternate (Zn). zinc magnesium (Ti), (Na), titanium sodium (K), potassium (Ni), nickel (Li), lithium (Pb), lead (Fe), iron (Cu), copper (Cr), chromium (Ca), calcium where A where Grade 2 Grade2 Procedures Trace Metal Analysis Trace Sulfate for procedures nitrate. ¶ —see 8.3,which contains Nitrate — Chloride — Assay Conc. Of StdConc. Of B Area Std Area B Area S Area (Area Concentration S = Ion mass blank, C injection) The following method has given satisfactory results in determining trace metal impurities at the value the at impurities metal trace determining in results satisfactory given has method following The Results Calculation of Sample Preparation — — Preparation Sample Special 1 water + sample water+ xenlSadr tc ouin—— Solution Stock Standard External — Solution Stock Standard Internal — Water Acid, Ultra — Nitric Pure Ultra — Phosphoric Pure Acid, is the is the 1 2 1 — see ¶ 8.4, which contains procedures ¶sulfate.— see 8.4,whichfor contains = Peak Area of SampleIon Peak Area = = Peak Area of Standard Ion Peak Blank Area from = of Instrument Ion Peak(H Area from = 1 1 see ¶ 8.1, which contains procedures ¶assay.see 8.1,whichfor contains = Peak Area of Spiked Ion Peak Area from Standard = , A is the concentration of the the anionspiked in standard the concentrationof is

Reagents see ¶ 8.2, which contains procedures ¶chloride.see 8.2,whichfor contains area of the area of 3 1

= Concentration of Ion Spiked Concentration in of = Standard is the area of the anion peak in the in the anion peak areais of the the The water used for all dilution, calibration, and standards should meet, at a minimum, the criteria minimum, the at a meet,should standards and dilution, calibration, all for water used The

]

(g) mass sample / — See ¶ 10. — See ¶ an

In a clean environment, weigh 4 g of sample into a 100 mL polypropylene flask. Add flask. polypropylene mL 100 a into sample of g 4 weigh environment, clean a In ion peak in the sample, in A peak ion 1 –Area B Use nitric acid specified for ultra content. for lowmetalion Use specified nitricacid 2 , which contains procedures for trace metals. , which for contains procedures Use acidultracontent. low metalion for specified phosphoric 1 ppm ) (Conc. Of) Std (Conc. (g). anion

netra tnadsokslto otiigteeeet nin elements the containing solution stock standard external An n itra tnad sok slto otiig brlim (Be), beryllium containing solution stock standard internal An 2 O) BlankO) spiked A standard, Page 2 is the is ( A 1 jn l jn 1 ) (Dilution Factor)/ (Area Std (Dilution (Area ) Factor)/ 6 ( A A area of the anarea 2 3 ) A C 4 1 in ppm in ) DF 4 is the area of the anion peak in the standard in the anion peak area is of the the

, and DF is DF , and the dilution factor ion peakion the instrument in

Document Number: Document 1 – Area B – Area

Doc. 2 ) Date: 5548A blank

= [total 1/9/2018 (H

DRAFT 5548A 2 SEMI O O

(2) LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and emnu G) nim (n, ad lttu L) i tlzd sc ht fnl maue ouin il have will solutions measured elements ¶ in 10. containing the final that such utilized 10.5.1.1.4 is (Lu) lutetium and –20ppb,In internalelements. standard Be–10ppb,Ge 5and Lu –5ppbas concentrations of (In), indium (Ge), germanium 10.5.1.1.3 E1.1in Type D5127criteria for ASTM 10.5.1.1.2 calibration of matrixmatched standards.preparation 10.5.1.1.1 10.5.1.1 req they as as long used be maymethods Alternate (Na), sodium (K), potassium (Ni), nickel (Mn), manganese (Mg), magnesium (Li), lithium boron (Pb), lead (Fe), (Ba), iron (Cu), copper barium (Cr), chromium (Ca), (As), calcium (Cd), cadmium arsenic (B), (Sb), antimony (Al), aluminum metals: trace following the of each for specified 10.5.1 10.5 10.4 10.3 10.2 10.1 10 9.6 blank and elementsstandards. matrixmatched external with the sample 9.5.2.1 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This E1.1in Type D5127.criteria for ASTM 10.5.3.1.3 10.5.3.1.2 calibration of matrixmatched standards.preparation 10.5.3.1.1 10.5.3.1 SEMI C1 they as long as used be may (Sn) methods tin Alternate metals: (V). trace vanadium following and the of each for specified value the at impurities metal trace determining in results 10.5.3 standards. external blank and matched (ICP-MS). spectrometry mass plasma coupled inductively using elements 10.5.2.1 specification t 10.5.1.1.3. ¶ in elements standard internal of concentration the have will tube sample polypropylene 10.5.2 of the forsample elements. willthe measurement appropriate standards concentrations have calibration o u h eod ad tid sml ue t ie sadr diin qiaet t to equivalent additions standard give to tube sample third and second the Grade Procedures 3 Trace AnionTrace Analysis irements for irements Trace Metal Analysis Trace Sulfate Nitrate Chloride Assay The following inductively coupled plasma emission spectroscopy (ICP-OES) method has given satisfactory given has method (ICP-OES) spectroscopy emission plasma coupled inductively following The Preparation Sample value the at impurities metal trace determining in results satisfactory given has method following The Analysis — — Analysis Special Analysis Special , ‘Method Validation’ hshrcAi,UtaPr Pure Ultra Acid, Phosphoric External Solution Stock Standard Internal Water Pure Ultra Acid, Phosphoric ae Water Acid, UltraNitric Pure —

— see ¶ 8.4, which contains procedures ¶sulfate.— see 8.4,whichfor contains — see ¶ 8.3, which contains procedures ¶nitrate.— see 8.3,whichfor contains for each element. eachelement. for

— see ¶ 8.1, which contains procedures ¶assay.see 8.1,whichfor contains method validation method

Reagents Reagents

see ¶ 8.2, which contains procedures ¶chloride.see 8.2,whichfor contains — — — Analyze elements utilizing inductively coupled plasma mass spectrometry (ICP-MS). Calibrate (ICP-MS). spectrometry mass plasma coupled inductively utilizing elements Analyze Standard

The water used for all dilution, calibration, and standards should meet, at a minimum, the minimum, a at meet, should standards and calibration, dilution, all for used water The The water used for all dilution, calibration, and standards should meet, at a minimum, the minimum, a at meet, should standards and calibration, dilution, all for used water The Using the solutions from ¶ 10. ¶ from solutions the Using — See ¶ 8.6, which contains procedures for trace anions. for procedures trace ¶ 8.6,which —See contains

s . . Add an aliquot of the internal standard stock solution such that the final diluted sample diluted final the that such solution stock standard internal the of aliquot an Add — Addition Addition . 5 Dilute contents to

2 n la niomn, eg weigh environment, clean a In .1 — , ‘Method Validation’ , ‘Method at Use ultracontent lowmetal ion for nitricspecified Use standard addition calibration method to quantify additionto elements method the standard sample. in Use calibration appropriate regards metalcontent with to Stock Solution Stock Solution — —

Use phosphoric acid specified for ultra low metal ion content for content ion metal low ultra for specified acid phosphoric Use for content ion metal low ultra for specified acid phosphoric Use — are validated for each trace metal according to metal according trace each for validated are

10 concentrations. An internal standard stock solution containing beryllium (Be), beryllium containing solution stock standard internal An 50 — Page 5 mL withmL E1.1water. Type

. An external 2 2.2 jn l jn 7 A tin (Sn), (Sn), tin ayenalyze

is utilized such that final diluted external final that dilutedis such external utilized 0. . are validated for each trace metal according to according metal trace each for validated are g f sml no into sample of g 5 Prepare a Prepare iaim(i,(Ti), titanium analyze sample and standard additions for additions standard and sample analyze Add Calibrate the sample elements with matrix with elements sample the Calibrate aliquots standard standard

bu about

aaim() (V), vanadium of solution from ¶ ¶ from solution of Document Number: Document . addition addition a 0 n 0% o the of 100% and 20% ah fof each comply with comply Doc. stock solution Date: and zinc (Zn). zinc and 5548A three 10. SEMI C1 SEMI

5 1/9/2018 10 mL 10

2 DRAFT .1.1. 5548A SEMI 2 LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 16 15.1 15 14.1 14 13.1 13 12.1 12 11.1 11 10.6 procedure. recommended 10.5.3.3 E1.1water.Type 10.5.3.1.4. ¶ in elements standard internal of ppb 100 of concentration a have will sample diluted final the that such solution stock standard internal the of aliquot an Add 10.5.3.2 the sample elements. of measurement final that such utilized is 10.5.3 ¶ 10.5.3.1.5 element. standard –100ppbas final that measuredan solutionshaveconcentrationof internal Y will such a 10.5.3.1.4 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This 16.1 TierDProcedures TierCProcedures TierBProcedures TierAProcedures Grade Procedures 5 Grade Procedures 4 This section does not apply to not chemical. section this This does apply to not chemical. section this This does apply to not chemical. section this This does apply to not chemical. section this This does apply to not chemical. section this This does apply AnionTrace Analysis This section does not apply to not chemical. section this This does apply Analysis Preparation Sample xenlExternal Solution Stock Standard Internal Table 2 Table 2 Assay (H Assay Assay (H Assay Previous SEMI Previous Reference # — tnadSokSlto Solution Stock Standard Aluminum Aluminum (Al) Cadmium Cadmium (Cd) Antimony (Sb) AcidImpurity LimitsandOtherRequirementsforPhosphoric Nitrate (NO 3 Chloride (Cl) Sulfate Sulfate (SO Arsenic (As) Barium (Ba) PO A 3 Boron (B) Boron PO aye eeet elements nalyze Calibrate the sample 4 ) ( — See ¶ 8.6, which contains procedures for trace anions. for procedures trace ¶ 8.6,which —See contains 4 ) (80%) 86 — In a clean environment, sample clean weighinto —In 25.00gof a 85 4 %) 3 ) ) diluted external calibration calibration external diluted (See (See

#1

# )

1 ) — pcfe specified C1.13-96, C1.27-96 — elements with matrix matched blank and elementsstandards. matrixmatched external with

An internal standard stock solution containing yttrium (Y) is utilized is (Y) yttrium containing solution stock standard internal An (Specification) 0.05 max0.05 ppm

79 0.5ppm max 10 maxppm 12 maxppm A 1 ppm 1 max ppm 5 max Grade 1 85 80 n external n Page A ------87% 81 y pam msin setocp sn manufacturer’s using spectroscopy emission plasma by dd 1 mL of nitric acid, ultra pure, and dilute to 50 mL with mL 50 to dilute and pure, ultra acid, nitric of mL 1 dd 82 jn l jn % 8 tnadsokslto otiigteeeet nin elements the containing solution stock standard standards will have appropriate concentrations for the for concentrations appropriate have will standards (Specification) 3500 maxppb 79 450 ppb 450 max ppb 300 max 12 ppm 12 max C7.24-0697 50 maxppb 1 maxppm 5 maxppm Grade 2 Grade 85 80 -- -- 87% 81 82 % (Specification) 1,000ppb max a a Document Number: Document 79 12 maxppm 50 ppb 50 max ppb 50 max ppb 50 max ppb 50 max ppb 50 max 1 ppm 1 max ppm 5 max 50 mL polypropylene50 mL flask. 85 80 Grade 3 87% 81 82 Doc. % Date: 5548A 1/9/2018

DRAFT 5548A SEMI LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This section on calibration and measurement method for particlesin measurement liquids onand method for calibration section and supplier SEMI user.C1between See # 0.5%. variances in useragreethe on may acceptable #1 Supplierand Table 2 1

Previous SEMI Previous Reference # 2

Due to the limitations of current particle counters, particle size and agreed numberupon to size current be counters,are of particle limitations toparticle the Due Particles bottles: in Magnesium (Mg) Manganese Manganese (Mn) Chromium Chromium (Cr) Impurity Limits and Other Requirements for Phosphoric AcidImpurity LimitsandOtherRequirementsforPhosphoric Vanadium (V) Potassium (K) Potassium Titanium (Ti) Calcium (Ca) Calcium Sodium (Na) Sodium Lithium Lithium (Li) Copper (Cu) Nickel (Ni) size,#/mL Lead (Pb) Lead Zinc (Zn) Zinc Iron (Fe) Tin (Sn) , ‘Calibration and Measurement Method for Particles in Liquids’ for andMethod Particles Measurement , ‘Calibration C1.13-96, C1.27-96 (Specification) 0.05 max0.05 ppm 0.3ppm max 2.5ppm max 1.5ppm max 0.2ppm max 0.1ppm max 0.2ppm max 0.1ppm max 0.3ppm max 0.2ppm max 1.5ppm max 2 ppm 2 max 2 ppm 2 max Grade 1 (See Page -- -- # 1

2 ) jn l jn 9 minimum (Specification) 1100 maxppb 300 ppb 300 max ppb 500 max ppb 450 max ppb 200 max ppb 100 max ppb 200 max ppb 100 max ppb 300 max ppb 700 max ppb 200 max 400 ppb 400 max . C7.24-0697 50 maxppb Grade 2 Grade (See assay specificationassay -- -- # 1

2 ) (Specification) Document Number: Document , for example ± ± example , for 100 maxppb 250 maxppb 150 maxppb 100 maxppb 150 maxppb 100 maxppb 50 ppb 50 max ppb 50 max ppb 50 max ppb 50 max ppb 10 max ppb 50 max ppb 50 max ppb 50 max 50 ppb 50 max Grade 3 (See # 1

2 ) Doc.

Date: 5548A 1/9/2018

DRAFT 5548A SEMI LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and this document can be found in the tables in below. be document can found the this results. the to access have can specification R1.1.1 R1.1 date]. ballot on[A&Rapproval by letter procedures full publication for approved was Information Related This Committee. Technical name] [committee global the of work NOTICE: TRACEMETALVALIDATION TRACEDATAANIONAND 1 RELATED INFORMATION emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This Table R1.2 Specification (ppb) Specification (WLS)MDL rangerecovery average recovery % spike recovery #2 % spike recovery #1 50% RSD spike #2 (%) 50% RSD spike #1 (%) 50% avg spike #2 ( 50% avg spike #1 ( unspike avg (ppb) #2 unspike (ppb) #1 unspike (ppb) Archival Data Method Validation Table R1.1 Table R1.1 Specification (ppm)Specification (WLS)MDL rangerec recoveryavg % spike recovery #2 % spike recovery #1 50% RSD spike #2 (%) 50% RSD spike #1 (%) 50% avg spike #2 ( 50% avg spike #1 ( unspike avg (ppm) #2 unspike (ppm) #1 unspike (ppm) aiain dt s poie n ti pedx t fetvl rhv t s ht ftr eiwr f a of reviewers future that so it archive effectively to appendix this in provided is data Validation Parameter This Related Information is not an official part of SEMI [designation number] and was derived from the from derived was and number] [designation SEMI of part official an not is Information Related This Summary Table for Trace Metals forSEMIGrade3 Summary TableforTraceMetals Parameter Summary Table for Trace Anions for SEMI Grade 3 Summary TableforTraceAnions forSEMIGrade n n = = 5) = 5) n n = = 5) = 5) 50 6.0 7.4 98.9 102.6 95.2 12.5 4.3 40.5 39.7 15.4 14.8 15.9 Al 1 0.003 1.1 94.5 95.0 93.9 1.6 2.2 0.475 0.474 0.000 0.000 0.000 72.9 69.5 1000 60 2.6 101.8 103.1 100.5 1.6 2.0 588.3 571.9 71.2 Sb Cl

Validation data for trace anions and trace metals in SEMI Grade 3 of 3 Grade SEMI in metals trace and anions trace for data Validation 50 0.5 2.0 92.8 91.8 93.8 4.9 2.9 27.3 27.0 3.9 4.3 3.5 As 0.064 0.058 0.069 12 0.09 0.8 98.0 98.4 97.6 3.4 5.1 5.96 5.97

The data judged criteria. is against The SEMIC1 SO 4 Page 50 0.3 1.4 98.3 97.6 99.0 1.0 1.1 25.0 24.9 0.4 0.6 0.2 Ba 0.004 0.004 0.003 5 0.004 1.8 95.8 96.7 94.9 7.1 10.5 2.42 2.40 jn l jn 10 NO 50 0.8 9.3 105.7 110.4 101.0 2.5 2.9 95.7 83.5 63.2 68.1 58.3 B 3 50 1.4 5.4 98.3 95.6 101.0 9.6 7.6 24.8 26.3 1.0 0.9 1.0 not greater not than % 35 75 andbetween % 125 % 75 andbetween % 125 % 75 andbetween % 125 % greater not than % 20 greater not than % 20 Cd 150 5.9 13.8 87.8 94.7 80.9 1.7 14.5 164.8 134.4 83.7 93.8 73.7 Ca SEMI Criteria not greater not than specification not greater not than % 35 75 andbetween % 125 % 75 andbetween % 125 % 75 andbetween % 125 % greater not than % 20 greater not than % 20 Document Number: Document not greater not than specification SEMI Criteria Doc. Date: 5548A 1/9/2018

DRAFT 5548A SEMI LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and Table R1.4 Table R1.4 Table R1.3 emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This was data validation past but document, this with changed anions trace for purposes. archival for available values the nor method the Neither same the of Standard SEMI published previously the chemical. from changed have methods their nor values specification R1.1.2 spike 50% RSD spike #1 (%) 50% avg spike #2 ( 50% avg spike #1 ( (ppb) average unspike #2 unspike (ppb) #1 unspike (ppb) (ppb) Specification (WLS)MDL rangerecovery average recovery % spike recovery #2 % spike recovery #1 50% RSD spike #2 (%) 50% RSD spike #1 (%) 50% avg spike #2 ( 50% avg spike #1 ( (ppb) average unspike #2 unspike (ppb) #1 unspike (ppb) Specification (ppb) Specification (WLS)MDL rangerecovery average recovery % spike recovery #2 % spike recovery #1 50% RSD spike #2 (%) aiain dt o h eann muiis ad ohr rqieet s nt icue ic neither since included not is requirements other and impurities remaining the for data Validation

Parameter Parameter The method for trace metals changed with this document; hence the need to provide validation data. validation provide to need the hence document; this with changed metals trace for method The Summary Table for Trace Metals forSEMIGrade3 Summary TableforTraceMetals Summary Table for Trace Metals forSEMIGrade3 Summary TableforTraceMetals n n n n = = 5) = 5) = 5) = 5) 50 3.8 5.4 96.8 99.5 94.1 3.1 3.8 38.5 34.7 12.4 13.6 11.1 50 2.7 15.2 100.2 107.8 92.6 3.4 2.3 34.7 29.7 7.2 7.8 6.6 Cr N i 150 2.7 19.6 94.3 104.1 84.5 2.1 1.8 106.9 75.1 20.3 28.8 11.8 50 2.1 4.7 99.0 101.3 96.6 2.1 1.4 29.3 27.0 3.4 4.0 2.9 Cu K 100 6.4 2.0 95.2 96.2 94.1 2.8 3.2 77.0 74.3 28.1 28.9 27.2 250 2.7 0.1 93.1 93.0 93.1 3.8 2.5 158.2 150.0 37.8 41.9 33.6 Na Fe 50 0.1 1.6 97.8 97.0 98.6 2.3 1.1 24.5 24.8 0.2 0.2 0.1 Page 100 0.5 4.4 96.7 98.9 94.6 2.9 2.5 51.6 48.6 1.8 2.2 1.3 Pb Sn jn l jn 11 10 0.2 1.2 99.4 98.8 100.0 3.2 4.9 5.1 5.1 0.1 0.1 0.1 50 0.4 5.1 96.5 93.9 99.0 5.9 3.0 24.5 25.3 0.8 1.0 0.5 Li Ti (continued) ( c ontinued) 50 4.7 14.8 95.3 102.7 87.9 1.3 1.1 31.9 34.6 9.4 6.2 12.6 100 0.3 10.9 94.3 99.8 88.9 0.7 3.6 49.4 44.5 -0.2 -0.5 0.1 Mg V 50 0.2 16.6 99.7 108.0 91.4 2.4 2.3 27.3 23.2 0.3 0.3 0.4 50 5.9 18.1 112.6 121.7 103.6 3.6 3.7 58.0 44.5 21.9 25.3 18.6 Mn Zn

not greater not than specification greater not than % 35 75 andbetween % 125 % 75 andbetween % 125 % 75 andbetween % 125 % greater not than % 20 greater not than % 20 not greater not than % 35 75 andbetween % 125 % 75 andbetween % 125 % 75 andbetween % 125 % greater not than % 20 greater not than % 20 Document Number: Document not greater not than specification SEMI Criteria SEMI Criteria Doc. Date: 5548A 1/9/2018

DRAFT 5548A SEMI

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone: 408.943.6900, Fax:408.943.6900, Phone:408.943.7943 CASan 95134-2127 Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and this Standard or Safety Guideline are expressly advised that determination of any such patent rights or copyrights, their ofown the riskresponsibility. ofsuch areentirely infringement rights and or rights patent such any of determination that advised expressly are Guideline Safety or Standard this of Users Guideline. Safety patent or Standard any this in mentioned of items any validity with connection in the asserted copyrights or respecting rights position no takes SEMI Guideline, Safety or Standard this of publication By change to subject are Guidelines Safety and notice.without Standards herein. mentioned The equipment or application. materials literature,particular any relevant respecting other any and sheets, data for product labels, product herein instructions, manufacturer’s to forth refer to set cautioned Guidelines Safety are Users user. the of and responsibility the solely is Guideline Safety or Standard the Standards of suitability the of determination the of suitability the to NOTICE: emsin i rne t erdc ado itiue hs dcmn, i woe r i pr, ny wti h soe f EI nentoa Sadrs cmite (document committee Standards International SEMI of scope the within only part, in or whole in document, Guideline. this Safety or distribute Standard adopted or and/or official reproductiondevelopment) All and/oractivity. other theprior withoutconsent distribution SEMI written prohibited.ofis an reproduce as construed be to to is granted page this is on material No Permission program. Standards International SEMI the of Document Draft a is This Semiconductor Equipment and Materials International (SEMI) makes no warranties or representations as representations or warranties no makes (SEMI) International Materials and Equipment Semiconductor Page jn l jn 12 Document Number: Document Doc. Date: 5548A 1/9/2018

DRAFT 5548A SEMI LETTER (YELLOW) BALLOT