Model Predictive Control

• Model Predictive Control (MPC) – regulatory controls that use an explicit dynamic model of the response of process variables to changes in manipulated variables to calculate control “moves”. • Control moves are intended to force the process variables to follow a pre- specified trajectory from the current operating point to the target. • Base control action on current measurements and future predictions.

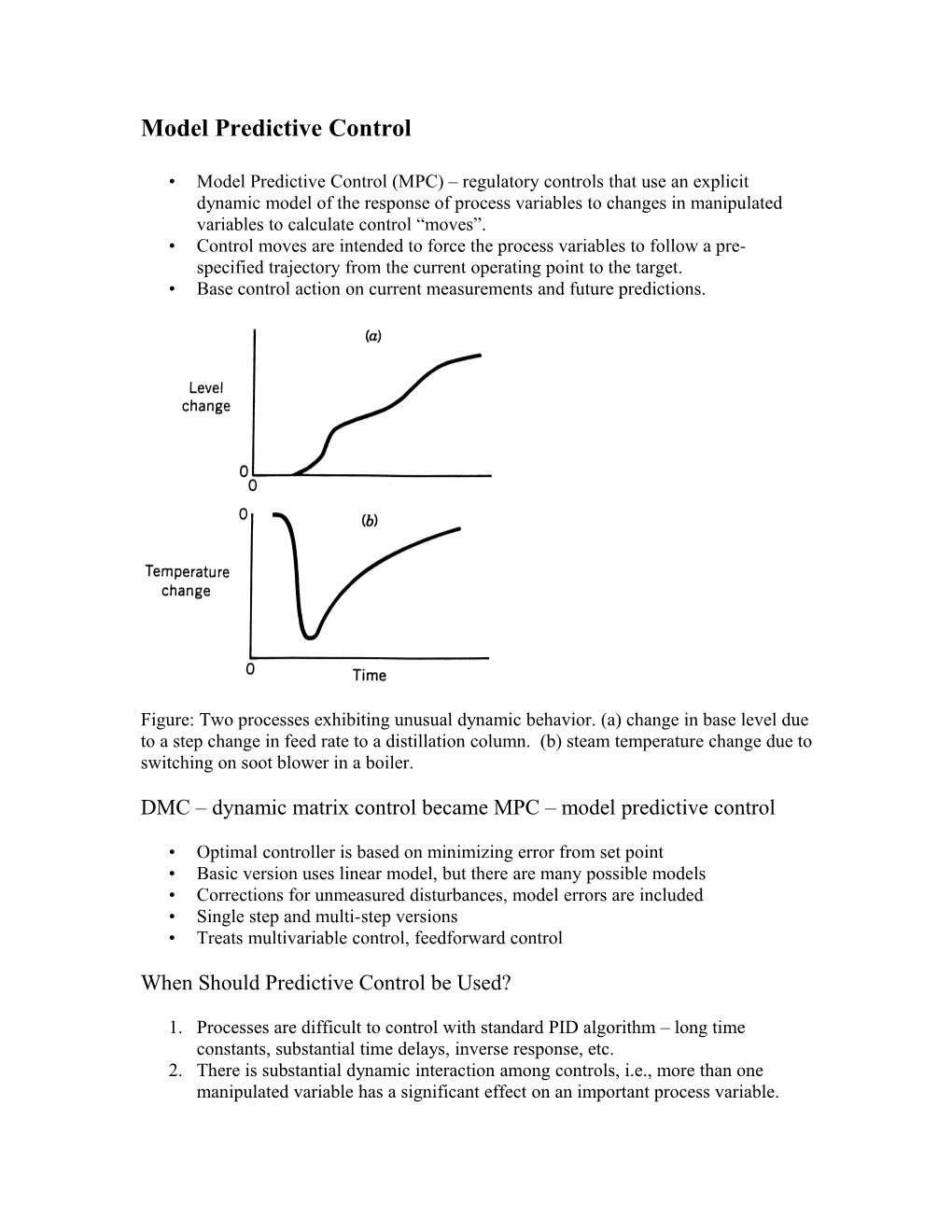

Figure: Two processes exhibiting unusual dynamic behavior. (a) change in base level due to a step change in feed rate to a distillation column. (b) steam temperature change due to switching on soot blower in a boiler.

DMC – dynamic matrix control became MPC – model predictive control

• Optimal controller is based on minimizing error from set point • Basic version uses linear model, but there are many possible models • Corrections for unmeasured disturbances, model errors are included • Single step and multi-step versions • Treats multivariable control, feedforward control

When Should Predictive Control be Used?

1. Processes are difficult to control with standard PID algorithm – long time constants, substantial time delays, inverse response, etc. 2. There is substantial dynamic interaction among controls, i.e., more than one manipulated variable has a significant effect on an important process variable. 3. Constraints (limits) on process variables and manipulated variables are important for normal control.

Model Predictive Control Originated in 1980s

• Techniques developed by industry: 1. Dynamic Matrix Control (DMC) - Shell Development Co., Cutler and Ramaker (1980), - Cutler later formed DMC, Inc. - DMC acquired by Aspentech in 1997. 2. Model Algorithmic Control (MAC) • ADERSA/GERBIOS, Richalet et al (1978) • Over 4000 applications of MPC since 1980 (Qin and Badgwell, 1998 and 2003).

Model Predictive Control Based on Discrete-time Models

• Time-delay compensation techniques predict process output one time delay ahead. • Here we are concerned with predictive control techniques that predict the process output over a longer time horizon. (e.g., open-loop response time).

Figure 20.2 Basic concept for Model Predictive Control General Characteristics • Targets (set points) selected by real-time optimization software based on current operating and economic conditions • Minimize square of deviations between predicted future outputs and specific reference trajectory to new targets • Discrete step response model • Framework handles multiple input, multiple output (MIMO) control problems. • Can include equality and inequality constraints on controlled and manipulated variables • Solves a quadratic programming problem at each sampling instant • Disturbance is estimated by comparing the actual controlled variable with the model prediction • Usually implements the first move out of M calculated moves

Discrete Step Response Models

Consider a single input, single output process:

Where u and y are deviation variables (i.e. deviations from nominal steady-state values).

Denote the sampled values as y1, y2, y3, etc. and u1, u2, u3, etc. The incremental change in u will be denoted as

Duk = u k - u k -1

The response, y(t), to a unit step change in u at t = 0 (i.e., Δu0 = 1 is shown in Figure 7.14.

Figure 7.14 Unit Step Response

In Fig. 7.14, {Si} Astep response coefficients

{hi} Aimpulse response coefficients

Note: hi = Si – Si-1 y1 = y0 + S1Δu0 y2 = y0 + S2Δu0 (Δu0 = 1 for unit step change at t = 0). . . . . yn = y0 + SnΔu0

Alternatively, suppose that a step change of u occurred at t = t. Then, 1 y = y + S u 2 0 1 1 y = y + S u 3 0 2 1 . .

. . . . y = y + S u N 0 N-1 1

If step changes in u occur at both t = 0 (u ) and t = t (u ). 0 1 From the Principle of Superposition for linear systems:

y = y + S u 1 0 1 0 y = y + S u + S u 2 0 2 0 1 1 y = y + S u + S u 3 0 3 0 2 1 ...... y = y + S u + S u N 0 N 0 N-1 1

Can extend also to MIMO Systems

Figure 20.8. Individual step-response models for a distillation column with three inputs and four outputs. Each model represents the step response for 120 minutes. Reference: Hokanson and Gerstle (1992).

Selection of Design Parameters Model predictive control techniques include a number of design parameters: N: model horizon t: sampling period P: prediction horizon M: control horizon (number of control moves) Q: weighting matrix for predicted errors (Q > 0) R: weighting matrix for control moves (R > 0) Selection of Design Parameters (continued)

1. N and t These parameters should be selected so that N t > open-loop settling time. Typical values of N: 30 < N < 120

2. Prediction Horizon, P • Increasing P results in less aggressive control action Set P = N + M

3. Control Horizon, M • Increasing M makes the controller more aggressive and increases computational effort, typically 5 < M < 20

4. Weighting matrices Q and R • Diagonal matrices with largest elements corresponding to most important variables.