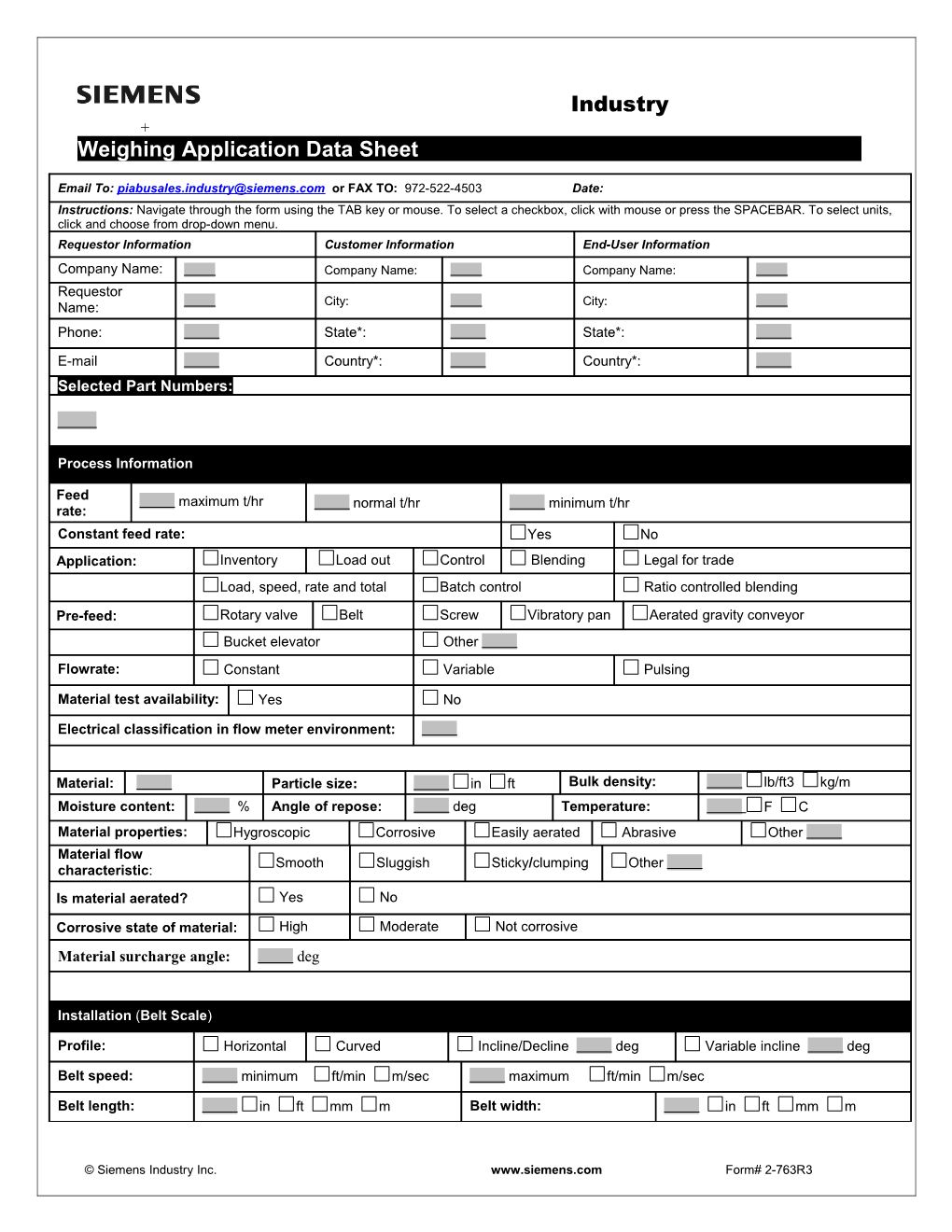

Industry + Weighing Application Data Sheet

Email To: [email protected] or FAX TO: 972-522-4503 Date: Instructions: Navigate through the form using the TAB key or mouse. To select a checkbox, click with mouse or press the SPACEBAR. To select units, click and choose from drop-down menu. Requestor Information Customer Information End-User Information

Company Name: Company Name: Company Name: Requestor Name: City: City: Phone: State*: State*:

E-mail Country*: Country*: Selected Part Numbers:

Process Information

Feed maximum t/hr normal t/hr minimum t/hr rate: Constant feed rate: Yes No Application: Inventory Load out Control Blending Legal for trade Load, speed, rate and total Batch control Ratio controlled blending

Pre-feed: Rotary valve Belt Screw Vibratory pan Aerated gravity conveyor Bucket elevator Other Flowrate: Constant Variable Pulsing

Material test availability: Yes No

Electrical classification in flow meter environment:

Material: Particle size: in ft Bulk density: lb/ft3 kg/m Moisture content: % Angle of repose: deg Temperature: F C Material properties: Hygroscopic Corrosive Easily aerated Abrasive Other Material flow Smooth Sluggish Sticky/clumping Other characteristic: Is material aerated? Yes No

Corrosive state of material: High Moderate Not corrosive

Material surcharge angle: deg

Installation (Belt Scale)

Profile: Horizontal Curved Incline/Decline deg Variable incline deg

Belt speed: minimum ft/min m/sec maximum ft/min m/sec

Belt length: in ft mm m Belt width: in ft mm m

© Siemens Industry Inc. www.siemens.com Form# 2-763R3

Industry Tail pulley in mm Idler spacing: in mm diameter: Idler diameter: in mm A Idler centres in mm

Trough angle: deg Y Drop clearance in mm

W Conveyor width in mm

Preferred MBS MUS MCS MSI MMI MLC model: Preferred construction: Painted mild steel 304 SS 316 SS Other Installation (Solids Flow Meter) Flow meter will discharge into: Headroom available: in ft mm m Temp. at flow meter: max F C min F C Sense plate exposed to air flow: No Some Estimated distance from pre-feed discharge to flow meter: in ft mm m Preferred construction: Painted mild steel 304 SS 316 SS Other Installation (Weighfeeder) Condition of operating environment: Wash down Sanitary Corrosive Duty cycle: Hours per day Space limitations: Length: ft Width: in ft m Height: in ft m Inlet dimensions: (LxW): in ft m Center length: ft (inlet to discharge) Construction: Open Closed Access side looking in direction of belt travel: Left Right Both

Transmitter

Input Power: AC - Specify DC - Specify Battery DC - Specify

Inputs required: Outputs required: Communications:

4-20 mA Digital Input 4-20 mA Pulse None AB Remote I/O

PID LVDT 0-10V Frequency Modbus 232 AB DeviceNet Load Cells Relay (#) PID Modbus 485 Profibus-DP

Pump Interlocks #: Remote Totalizer RS-232 Profibus-PA

HART ® Foundation FB

Calibration

Accuracy Required: %

Disclaimer The information contained in this data sheet is believed to be accurate however we do not assume any responsibility for errors or any liability arising from the application or use of any product herein. This data sheet neither states nor implies warranty of any kind, including fitness for any particular application.

© Siemens Industry Inc. www.siemens.com Form# 2-763R3

Industry

Insert a photo or a sketch of the application, if available: Simply copy and paste into this table. Bitmaps should be no larger than 640 X 48

© Siemens Industry Inc. www.siemens.com Form# 2-763R3

Industry 0 Pixels.

© Siemens Industry Inc. www.siemens.com Form# 2-763R3