CLASS 2a A

MARMETTOLA : PROBLEM OR RESOURCE ?

We are class 2^ A of Liceo Scientifico Marconi . We are interested in studying a big problem our territory has:” marmettola”. We are following it with our teachers : Vannucci (Scince) and Fregosi (English).

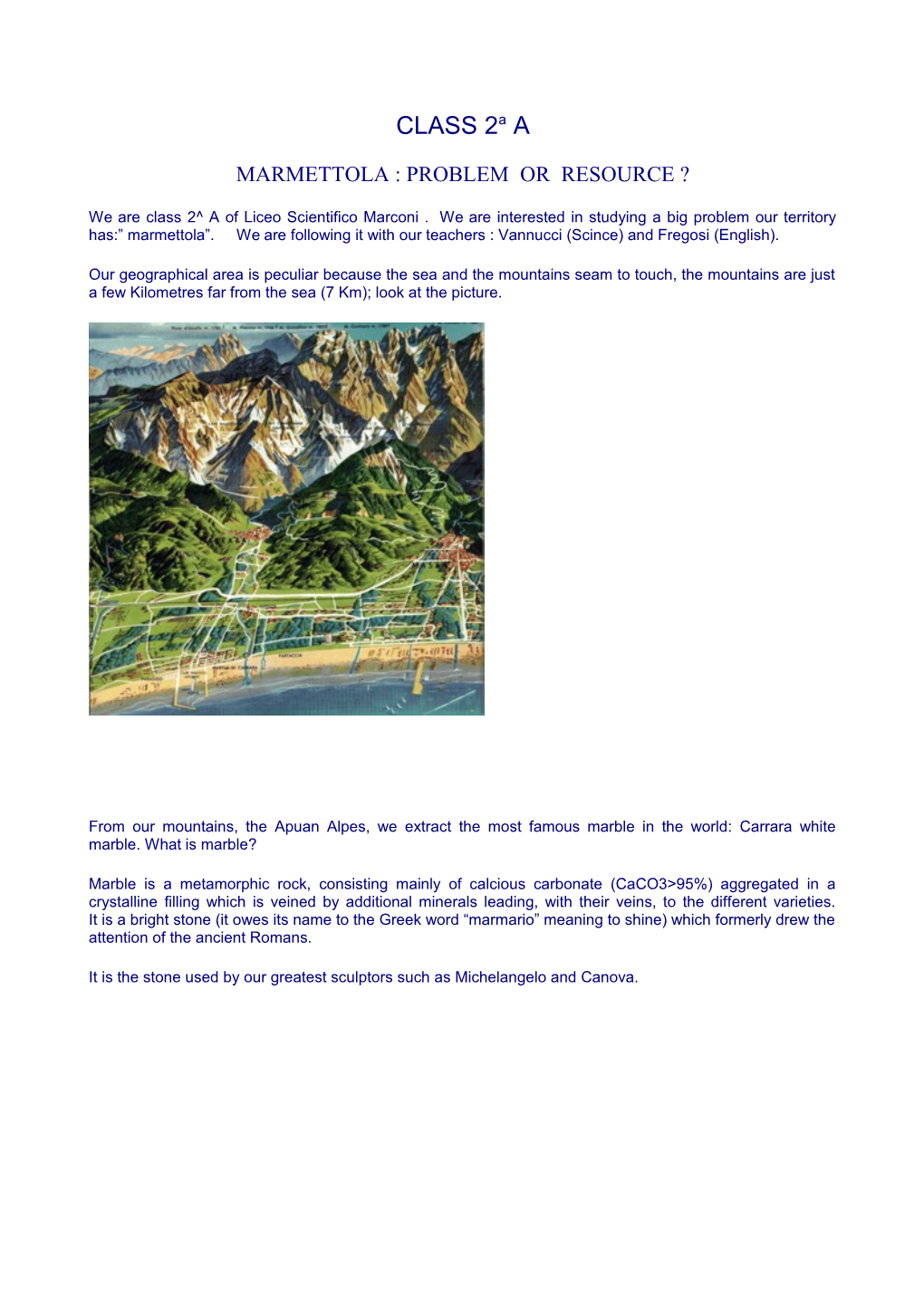

Our geographical area is peculiar because the sea and the mountains seam to touch, the mountains are just a few Kilometres far from the sea (7 Km); look at the picture.

From our mountains, the Apuan Alpes, we extract the most famous marble in the world: Carrara white marble. What is marble?

Marble is a metamorphic rock, consisting mainly of calcious carbonate (CaCO3>95%) aggregated in a crystalline filling which is veined by additional minerals leading, with their veins, to the different varieties. It is a bright stone (it owes its name to the Greek word “marmario” meaning to shine) which formerly drew the attention of the ancient Romans.

It is the stone used by our greatest sculptors such as Michelangelo and Canova.

Let’s have a look at the following scheme to understand how marble from the mountains reaches its final destination:

QUARRY

BROKEN MATERIAL BLOCK

Grinding machine slabbing machines

(marmettola) marble chips slabbed material

Stone industry marble shop

Various industries agglomerate end product

As you can see marmettola is produced in the moment in which marble is slabbed. We can say that marmettola is marble dust mingled with the water that is necessary just to slab the block.

Is marmettola a problem?

It is not a polluting material, yet there is a problem: what to do with marmettola? It has been sent into the waters of the river Carrione for centuries, but the great quantity of it was becaming a problem.

In the following picture you can see how the waters of the Carrione are milk like in presence of marmettola.

A few years ago it was found out that marmettola can be useful, for example, in a power station. In La Spezia, a town not far from Carrara, marmettola, together with water, is used in the local power station just to neutralize the dangerous smoke coming out of its chimneys.

That’ why we wander: is marmettola a problem or a resourse?

This is the first part of our work just to let you know what we are studying about. In the second part we are going to write about some interviews we have planned with local industrialists and workers.

INTERVIEWS

1 st Interview; Wednesday 5 th April, 2006

Today we paid a visit to the firm S.M.C., which is situated near our school. It is a firm which cuts marble, before polishing it and selling it as slabs. We interviewed the owner, Mr. Babbini, who showed how to work and produce marble slurry.

Mr. Babbini, how is marble slurry produced by your firm?

The blocks of marble that arrive here come directly from the quarries, and so have not been worked and are large in size. In order to sell marble, before anything else, we have to cut these huge blocks so as to create smaller, rectangular slabs. As a result of the cutting phase, which makes use of water and a diamond- studded wire, there is a residue of whitish water containing powdered marble.

Where does this whitish water laden with powdered marble end up?

It falls into a well situated beneath the cutting machine, and from there flows into a collection basin, before being pumped into the ‘decantation silos’.

What is a silo? How does it work?

It is a chamber that serves to separate the water from the marble powder. Thus water comes out of one part, and from the other exits marble powder with just a small remaining amount of water. Let’s go and see ….

What comes out is not yet marble slurry. This is produced by passing the mixture through a filter press, which compacts the powder to produce the true marble slurry.

How much marble slurry do you produce every day?

Every day we produce about 20 tonnes of marble slurry, and we have to see to the disposal of an enormous quantity of this material, which was considered one of many forms of waste in the past.

Nowadays it is no longer considered to be waste?

For us it is a by-product of the working of marble, and thus a material in need of disposal, but nowadays there are people who are able to make use of it in an ecological manner.

Where is your marble slurry disposed of?

It is collected by the firm CAGES in Massa.

Our first interview reached its conclusion at this point. Having become curious regarding the possible uses of marble slurry, the following week we interviewed Mr. Gabarra of the firm CAGES in Massa.

2 nd Interview; Wednesday 12 th April, 2006

Mr. Gabarra, we have been told that CAGES collects marble slurry from various firms in the Massa Carrara area; can you explain what you do with this slurry on a daily basis?

It’s not easy to answer this question briefly. Marble slurry can be utilised in a variety of ways, and an in-depth description of all the processes of transformation that the slurry undergoes won’t be simple … but I’ll try to give you a broad idea, making things as simple as possible.

CAGES collects only marble slurry?

Above all, but not exclusively … some forms supply us with whitish water containing marble powder.

For what reason?

These firms cannot afford to buy silos and filter presses, so in these cases it’s up to us to produce the marble slurry.

Let’s go back to the potential uses of marble slurry. Where does your slurry end up?

There are four different destinations: the firm Tioxide in Scarlino (Grosseto), the ENEL plant in La Spezia, cement works and paper mills.

How does it arrive at its destination?

It is transported by lorries. Every lorry departs from CAGES with a precise quantity of marble slurry. In fact, prior to departure the lorry has to pass over a weighing machine, and if the load is not as it should be, we see to the adding (or removal) of the appropriate amount of slurry.

What does Tioxide in Scarlino (GR) do with your marble slurry?

Tioxide produces Titanium Dioxide (TiO2), a non-toxic, white pigment which, to put it simply, gives the whiteness to our white objects. Titanium Dioxide is extracted from a mineral called ilmenite which contains titanium and oxygen, but also iron. Ilmenite comes from mines in Norway, and the first treatment which it undergoes in the Tioxide plant is the removal of the iron, in order to obtain the Titanium Dioxide. This process necessitates the use of Sulphuric Acid (a very strong acid) and as waste, produces a toxic mixture of sulphuric acid and iron. Marble slurry has proved to be an excellent means to eliminate the toxicity of this waste, given that it reacts with the mixture to transform it into ‘red chalk’ (an inert, non-toxic material), also producing water and carbon dioxide, which is subsequently gathered and sold.

Paper mills also need marble slurry?

Yes, they use it to whiten paper. The white paper used for drawing is always treated with particular substances, and among these is the marble powder from slurry. We send the purest marble slurry to the paper mills, precisely because it is used for whitening, and thus in our plant we divide the slurry into various categories … here, for example, is a deposit of the purest slurry, ready to be sent to the paper mills.

Where does the less pure marble slurry end up?

That is sent to the cement works. The cement industry has need not only of slurry, but also of larger pieces of marble waste which we gather from the quarries, put to one side and then transport to the cement works. This is a storage area for material destined for cement works, and as you can see, the piece are much larger than marble powder.

Finally, please tell us about the ENEL Plant in La Spezia.

The ENEL Plant of La Spezia is an electric power station, which produces electrical energy via combustion. Among the materials used as in this process there is also sulphur. Sulphur combines with oxygen to produce Sulphur Dioxide (S02), which is then released into the atmosphere. The emmision of this substance into the atmosphere is hazardous, given that it causes acid rain. Also in this case marble slurry has proved to be an excellent reagent, in that it is able to eliminate Sulphur Dioxide (S02), transforming it into Calcium Sulphate (CaSO4). The ENEL Plant of La Spezia is very proud of this result, which has led to the cutting of emissions into the atmosphere of threatening sulphur dioxide, exploiting a material which is a residue of the working of marble.

CLASS 2a B

CLIMATIC CHANGES

Our study plan in this school is characterised by a chemical, biological and scientific experimentation which aims at studying the environment, especially the environment of our geographic area. That is why the students of class 2B of the “Liceo Scientifico G. Marconi “ found it natural to choose this topic, even though its intrinsic difficulties are obvious. Our school is provided with a meteorological observation station which is quite important in the area. The data on rainfall and temperature, which are collected by it, are sent to the Pisa Ideographic Institute every month. Moreover the same data, together with those concerning wind, are often used by private and public organisations. Therefore we decided to analyse the climate trends of our area in the last 35 years (starting from 1970). Our science and chemistry teacher, Mr Bacciola Domenico, who is also responsible for the meteorological observation station, was our advisor and guide in the project. He provided us with the weekly rainfall figures which were registered in the archives of the observation station. We decided to analyse 2 separate periods: from 1970 to 1990 and from 1991 to 2005. Our choice was motivated by the fact that, if there have been significant climate changes, they started to take place in the early 1990s. Our project will be focused on the analysis of pluviometrical graphs: when anomalies, periods of heavy rainfall and long-lasting intervals without rain are found, the thermic trends before and during these periods will be taken into account.

Year Rainfall (mm)

1970 1139 mm 1971 1220 mm 1972 1027 mm 1973 766,6 mm 1974 1181,2 mm 1975 1194,3 mm 1976 1025,6 mm 1977 1423,3 mm 1978 1218,2 mm 1979 1598,3 mm 1980 1136,7 mm 1981 860,1 mm 1982 1041 mm 1983 971,7 mm 1984 1134,3 mm 1985 1066,2 mm 1986 1089,8 mm 1987 1514,5 mm 1988 1400 mm 1989 1286,9 mm 1990 1357,2 mm

The 1970-1990 pluviometrical figures are represented in the following chart. Total rainfall (measured in mm) for each year.

Year Rainfall mm 1991 1191,4 mm 1992 1507,9 mm 1993 800 mm 1994 1271 mm 1995 1312,9 mm 1996 mm 1997 597 mm 1998 807 mm 1999 968,5 mm 2000 1141,3 mm 2001 987,8 * mm 2002 987,8 mm 2003 1634,2 mm 2004 1052,5 mm 2005 1027,74 mm

*Does not include June

The 1991-2005 pluviometrical figures are represented in the following chart. From our rainfall statistics, apart from total annual precipitation, it is possibile to report the following features.

1997: from 30/06 to 31/10 there was 54 mm of rain, with 12 weeks having no precipitation whatsoever

1998: from 19/01 to 31/08 there was only 230 mm of rainfallì

2000: from 18/09 to 31/12 796,8 mm were recorded, in particular, from 09/10 to 29/11 precipitation amounted to 537 mm

2002: was the rainiest year amongst those examined, including the exceptional week 16/09 – 23/09, when some 239,6 mm of rain were recorded

2003: from 01/01 to 22/09 there was just 351 mm of rain. On 23/09 290 mm of rain fell on our city, of which 140 mm between 19:15 and 20:30, thereby provoking a flood which led to serious damage and, unfortunately, a victim.

Closer analysis of the data leads to several observations:

1. From the middle of the 1990s until 2003, the number of days on which rain fell tended to decrease, whilst the intensity of precipitation increased. 2. Rainfall has tended to shift towards the last 3-4 months of the year, leading to phenomena of major relevance. These pluviometric shifts are a consequence of particular thermal conditions. For example 2002 was characterised by an extremely warm October, which followed a rather dry summer. This was the prelude to an extraordinarily wet November and December. The events of 2003 were without precedence, even in the memory of the most senior citizens. From the first days of May the weather was dominated by the humid heat of the scirocco. It rained on a single day ( for little more than an hour); 31st July. The hot, humid weather then continued, causing numerous victims in Europe, and only occasionally being interrupted by timid showers from the first days of September. 23rd September was “a day of reckoning” in our city. Such an event, however, is not without explanation. In July and August the sea was recorded as being 4°- 5° warmer than the norm; a condition which was ideal for enriching the atmosphere with vapour and energy to an incredible extent. From the summary of data above, the figures for 1996 are missing. It was a year in which nobody took care of the weather station in our school. From local newspapers of the time, and other sources of information, we have discerned that on 19/06, in the higher lands of Versilia, a neighbouring zone, between 7.00 and 13.00 487 mm of rain fell; this being enough to wipe out two villages, Fornovo Casco and Cardoso, as well as causing the deaths of more than ten people. This event can also be explained. For the whole of May, and the first half of June, the temperature was much higher than the norm, without there being a single disturbance that might have mitigated the situation of an atmosphere highly charged with vapour and energy.

CONCLUSION

From all the data gathered it is possibile to see that there has undoubtedly been a severe modification of rainfall patterns since the mid-90s, with many features of a tropical nature being taken on; fewer days of rain but more intense precipitation.

The question that has to be asked is whether this is a pattern which is destined to consolidate itself in time, or whether it is a transitory state of affars, destined to last for a limited period.

The information we have on the greenhouse effect leads one to fear the first hypothesis, although, given the complex nature of the physics governing the atmosphere, only in a few years time will it be possible to receive an accurate answer to that question.

CLASS 2a E

CARRARA'S WATER-FRONT

1 Luni Antica

The origins of Marina di Carrara are linked to to the sea, and its roots should be sought in the ancient Roman colony of Luni. Luni (which is today reduced to ruins) was the historical capital of Lunigiana. It became a Roman colony in 177 B.C., but in all probability already existed prior to the arrival of the Latian population. This colony was situated in a lagoon, which was used principally for the storage and loading of marble, although it also had a miltary function (at the time of the Punic Wars) as well as a commercial role, trading wine, olive oil, and cheese from Lunigiana. The golden era of the city lasted some 300 years, during which time marble from Luni was used on a massive scale, but whose utilisation began to decline with the crisis of the Roman Empire. When, subsequently, the lagoon dried out, malaria became widespread, and the port was moved elsewhere. The city disappeared from the map in 1204, when the Bishop of Luni officially transferred his seat to Sarzana .

2

The ‘Port of Avenza’ from the Middle Ages to the Modern Era

The valley of Carrara, certainly already populated in Roman times, acquired its raison d’etre with the rebirth of the marble industry. The sea also regained importance, and the inheritance of Luni was taken up by Avenza. Situated at the mouth of the river which is today known as the Carrione, it was located on the via Frangigena, from which departed a link road to Carrara; thereby placing it at a strategic point for the trading of marble. The port consisted of little more than a semi-enclosed area of water, which was perhaps the remains of the lagoon or a coastal lake, where marble and a host of other goods, especially wool, were loaded and unloaded. In 1204 this area was ceded by the Bishop to the canons of St. Frediano in Lucca. At that time the sea came up as far as the port and, to the east, entered even further ‘inland’. Later the sea withdrew, and the coastline was modified in the 1400s and the second half of the 1500s. In 1625 Avenza was at a distance of about 1200 metres from the sea. 3

THE 1500s

The sovereign Alberico I Malaspina set up the “Officium Marmoris” on the basis of which, the lizzatori (those responsible for transporting marble) received a policy which, if countersigned to attest to the delivery of the goods, would be exchanged for money. Thus the traders in marble did not directly handle cash. This office, set up in the second half of the century, was abolished as it drew to a close. Furthermore, Alberico fortified Massa and Carrara, and also turned his attention to the coast. He oversaw the reclamation of the swamps and, having repopulated Avenza and the surrounding countryside, declared it exempt from taxation. The town subsequently became a bulwark against sea raids and its fort, in 1565, exploited cannon power to prevent a barbarian invasion. The marble industry, which was in crisis towards the middle of the 1500s, subsequently took off again in a consistent manner.

4

THE 1600s

In the 1600s a series of socio-economic phenomena led to the transformation of society, work, the economy and the landscape, and were responsible for the rise of several important families. A period of crisis followed in the marble sector. Trade turned its attention to the production of quadrelle (square, two-coloured marble tiles), which had already appeared in the 1600s, and were of great benefit to local shipping. The oldest stone buildings date back to this age. Many constructions on the beach served as wharehouses for tiles and balusters; materials which could easily be pilfered. The first religious building, the Chapel of St. Erasmus, was also erected. This continued to function until 1776. (St. Erasmus was the patron saint of navigators.)

5 THE 1700s

In 1741, thanks to the marriage of Maria Teresa Cibo Malaspina and Ercole Rinaldo D’Este, Duke of Modena, the states of Massa Carrara and Modena were united. Amongst the public works that were carried out by the Estense family in our zone was an unsuccessful attempt to construct a mega-port. This did have the result, however, of a number of workers settling in the area. In a short time, the Duchess Maria Teresa organised a powerful shipping fleet, also thanks to Genoans (or others from the area) who sought work here. It was the Genoans who subsequently settled in the area around the port, which was then still somewhat desolate, and who, in 1776, substituted the Oratory of St. Erasmus with the Chapel of St. Joseph. The owners of the Cibo-Estense fleet, during the war of Austrian Cession (1748) took advantage of the neutraliy of Massa Carrara and Modena to indulge in smuggling. However, the sea was not yet safe from barbarian invasions, and thus a type of fort was constructed on the beach, although it was not really fit to perform its defensive role adequately. In 1795 an English vessel, which had been hit by the French, was grounded on our beach. The garrison of the fort helped the English to rescue their equipment. Later the port was damaged by fire. In 1796, the arrival of the French marked a moment of great change. Carrara was annexed by the Republic of Cispadana (and later by the Republic of Cisalpina), until 1806 when it became part, along with Massa, of the Duchy of Lucca, which in 1807 was reunited with the Kingdom of Etruria. The year after, the English spread terror in Marina di Avenza, thereby contributing to the end of the Avenza fleet. However, the populace continued to move to the area, until a permanent settlement was established. In this era bathing began to gain popularity, and, furthermore, a new fortress was constructed. In 1818 the French put down the base for the optical telegraph.

6

THE 1800s

The return of the Estense family, following the Restoration, was not viewed positively. The marine barriers were reinforced and moved further out to sea. Two small forts equipped with cannons were added to the two redoubts. In 1838 an urban plan was approved, which established the layout of the town once and for all, leading to the development of the quarter. 1845 witnessed a second attempt to construct a port in the Marina di Avenza. In the first half of the 1800s the Fabbricotti family, who were destined to play an important role in the history of Carrara, began to gain prominence. In 1841 Domenico Andrea, who is considered the true founder of the dynasty, launched the schooner St. Andrea, setting off the resurgence of the marble fleet. 1848 had a profound effect on our zone, which, after various changes in government, was returned to the control of the Duke of Modena. In this period an industrialist called Walton set up a fleet and subsequently constructed a landing stage. Thus the port was born. This had a positive effect on the whole local population. Furthermore the population of Marina di Avenza settled; mostly portuaioli (employees of the great marble firms) and boscaioli (workers without a fixed position). Construction of a new church began, and schooners, brigs and two-masted sailing-boats with 20/25 sails began to inhabit the waters. Sadly, in 1854, the sea also brought cholera, which led to the deaths of about 150 inhabitants.

7

From Italian Unification to the Construction of the Port

The Risorgimento marked a great period of reprise for the marble sector. Marina was recognised as an urban area in its own right in 1861, and two more landing wharfs were constructed; the Binelli in 1874, and a second at the beginning of the 1900s. Work on the church finished in 1880, and the Society for Public Assistance was established in 1898. In 1920 construction of the port began to take place, and the size of the population grew rapidly. The seascape and landscape were transformed and the sailing-boats disappeared. Marina di Avenza became Marina di Carrara.

8

THE DEVELOPMENT OF THE APUAN COASTLINE

In order to gain more knowledge of themes connected to the development of the Apuan coast, we invited the Deputy Mayor of Carrara, Dr. Vannucci, to our school. He kindly accepted our invitation, and we would like to take this occasion to thank him for his helpfulness. This meeting provided us with the opportunity to know better the resources of our zone and to understand the future prospects for the territory. We would like to sum up what we learnt, so as to inform our European friends regarding the prospectives for development in the Apuan zone. Our territory is characterised by the presence of the coastline; by an urban centre, which has important appendages containing ruins of great historical and cultural value; and by mountains which, apart from hosting a considerable number of mountain villages, represent a source of wealth unrivalled anywhere in the world. In our territory, in fact, you can find marble quarries which are unique in the world, given their height, quality and capacity. Our area is not just formed by the coastline, but rather is a zone which brings together the coast; the mountains with their quarries, which represent such an important part of our history; and the urban centre. Tourism should not be considered an element which brings together our territory, but rather as an element that integrates several territories, given that it is difficult to think of our Apuan coastline without considering its links with the coastlines of Massa, Versilia, and the Cinque Terre. Whoever visits our territory should know that there is the seaside, should know that there is a historically important city centre, and should be made aware that the quarries of Carrara offer not only a marvellous cross-section of a landscape, but also one that is, above all, human and social in nature. Tourism should not be just for holidaymakers, but also aimed at increasing knowledge of our territory. Our Marina di Carrara is characterised by two major activities; the port and its bathing establishments. The port is destined to become even more important than it currently is. This will enable us to attract hoards of tourists, who must be catered for, without ignoring the sea and the coastline as a starting point. The development element of greatest importance is the port. Currently, it is limited in its size and specialises in the transportation of marble; the reason for which it was constructed. It becomes necessary, therefore, to integrate the mercantile activity of the port with activity based around pleasure craft, offering a space for the building of such pleasure craft, but, above all, catering for those who see sailing as a means to get to know places that can also be reached by sea. Our maritime tradition, in fact, took as its point of departure the mercantile tradition, before subsequently developing, over recent years, the sporting tradition that is characterising Marina di Carrara. The development of the port is a theme of great current importance. Our political representatives have managed to reach agreement with the administrations of neighbouring coastal areas regarding possibile development. Marina not only needs a new tourist port, but it should also be possibile to aument the mercantile port, so as to realise, through the construction of this infrastructure, an opportunity for the growth of our territory. The nature of the population living in this zone is also one of the fundamental points that needs to be taken into consideration. With regard to the private bathing establishments present in our zone, you can note that they are frequented almost exclusively by local residents. Thus, a further proposal that might serve to help tourism is the opening up of these establishments to the prospective of improving the accommodation and renewing the welcome reserved for tourists, by seeking a more direct contact with the customer. This might be achieved through the creation of small-scale structures such as ‘bed and breakfast’ hotels, which are increasing in number thanks to the political decision to offer incentives to those wishing to start up such a business. These are the things that stuck in our minds after the chat with the Deputy Mayor, who encouraged us to ask further questions should we have needed clarification and also invited us to visit him in the City Hall, so as to be ever up-to-date and thereby be more knowledgable about everything regarding our territory. We are more than happy to accept the invitation!

CLASS 2a F

Premise

In nature there is no such thing as waste. Everything is born, grows and dies; continuously being transformed into something else (plants – herbivorous animals – carnivorous animal – organic excrement - plants) in an innumerable series of cyclical processes. Likewise mankind, for thousands of years, both as hunter-gatherers as well as farmers, was a part of these cycles. Animals were tended; their excrement serving as manure for the fields. People dressed in naturally reproducible materials such as wool, cotton or silk, and built their houses and other constructions from wood taken from the local area. In the last two centuries, the industrial system has broken this cycle by extracting at ever greater speed raw materials that cannot be renewed (minerals, fuel, more trees than can be replanted etc.), transforming them into goods which in a very short time - in 50% of cases within two days of purchase – become waste. We are living in a complex society, in which we produce and consume in a complex manner, causing us to generate waste which is complex and diverse in its nature. Every day hundreds of new materials and new products are introduced to the market, only to become, within a very short time, waste. This is the principle of a ‘use and throw away’ culture. The down side of consumer society is waste. Mixing together all this huge amount of waste is extremely dangerous for the environment in which we live, because it produces a compound whose behaviour is very difficult to predict if incinerated or if left to decay in a landfill. Nobody can hypothesise with any confidence the possibile chemical-physical reactions that might take place during these processes.

Legislation

Until 1982, waste was managed only in so far as it represented a health risk, without any consideration being made to enviromental, energy or economic factors. Not until 1982 did Italian law recognise the fact that the problem of waste is a complex one, touching various fields of study and interests, and only capable of being resolved if considered in all its aspects.

In 1987 Italian law "invented" and defined so-called "Secondary Raw Materials"; raw materials used a second time in the production process. Thus new areas of activity and employment sprang up, dealing in "Differentiated Waste Collection" and the consequent recycling of “Solid Urban Waste” (Rifiuti Solidi Urbani; R.S.U.)

However, it was the Law of 1997 and the consequent Tuscan Regional Plan for the Management of Waste which made it possible to tackle the problem in a more rational manner, by individuating primary objectives such as the prevention, reduction, reuse and recycling of waste. Thanks to this law we have seen continuous improvement, at both a national and a local level, of results pertaining to the various types of differentiated waste collection.

Resources not waste

Analysis of data from recent years regarding the production of waste in Italy and Tuscany, has highlighted an increase from 0.8 kg per day per inhabitant in 1985, equal to 16 million tonnes per year, to 1.5/1.8 per day per inhabitant nowadays, (28/30 million tonnes per year); almost double in weight, but representing an even greater increase in terms of volume (2.6 times greater in 10 years). More intense analysis of the make-up of waste has demonstrated that a major part can be attributed to so-called ‘use and throw away’ products, such as containers for packaging. (60/80 million tonnes per year of industrial waste have to be added to this, into which exhaustive investigation has not yet been made).

An analysis of the composition of waste, using data gathered through sampling and analyses carried out in various parts of the Italian terrirory, is presented in the following table: URBAN WASTE Organic Material 33% Paper/Cardboard 27% Glass 5% Plastics 13% Metals 5% Inert materials (in 9% powder form) Other (wood, fabrics, 8% ceramics…)

PREVENT, REDUCE, RECYCLE To manage Urban Waste effectively you need to: PREVENT, REDUCE, RECYCLE. a) PREVENTION can be achieved via: - the development of clean technologies; - the promotion of economic incentives; - the development of techniques for the elimination of hazardous substances container in waste destined for recovery or disposal; b) REDUCTION must render the formation of waste minimal through: - a reduction in the consumption of perishable goods, with these being substituted by goods that can be used repeatedly; - a reduction in vegetable and organic waste through the valorisation of composting. c) RECYCLING can be achieved through Diversified Waste Collection (Raccolta Differenziata; R.D.).

The Law of February 1997 imposed the necessity to achieve minimium objectives regarding the quantity of differentiated material, in accordance with the following time scale:

- 15% within 3 March 1999; - 25% within 3 March 2001; - 35% within 3 March 2003.

Differentiated waste collection signifies that Urban Waste should no longer be considered as something to be removed and buried, but rather as a SECONDARY RAW MATERIAL to REUSE with: - great savings in economic terms and a high energy content; - a minor number of landfills, which can be more readily controlled and last longer, leading to a better use of land and minor environmental impact; - lower costs for the disposal of waste; - better management of the environment and the countryside; - fewer protests regarding the location of landfiulls and incinerators.

ENERGY FROM WASTE

ORGANIC WASTE

A very important portion of refuse, which can be recovered through composting, is ORGANIC WASTE, deriving from the waste of particular activities (kitchen leftovers, grass cuttings and garden trimmings).

The quantity of organic composted waste (compost) – taking into consideration an average process yield of 40% in relation to the total prior to losses caused by the composting process and refining – is roughly 1,700 tonnes in our Municipality. This level is still far too low, if you consider that organic material in Urban Waste is a third of the total. The necessity to increase substantially the Differentiated Waste Collection of this material has the clear aim, apart from that of reducing in a drastic manner the quantity of Urban Waste which is dumped in landfills at a considerable economic and environmental cost to local communities, of fulfilling a vital biological need. Traditionally, organic materials had the role, in an agronomic context, of improving the soil – ‘amendment’. Its application is, in fact, aimed at the long-term conservation of the ‘integral fertility’ of the soil. In mixed arable farming, the function of amendment was traditionally achieved via the re-utilisation of zootechinical dejections, and above all manure. The subsequent specialisation in cultivation methods, with the tendency to separate zootechnical activities from those concerned with the cultivation of vegetable products for alimentary purposes, has led to a progressive impoverishment of the organic substances in the soil, also given the widespread use of chemical

The latter state, which in some farming areas has reached worrying levels, is often defined – not without reason – as a condition of pre-desertification, given the reduced ability to sustain the growing of crops efficaciously. Thus there is increasing interest, on the part of research centres and farming organisations themselves (at an operational level), in the availability of innovative means of amendment, among which are composted products deriving from decomposed urban waste, as well as agro-industrial.

PAPER and CARDBOARD

In Carrara, we differentiate 2,800 tonnnes of PAPER and CARDBOARD; a little under 25% of that envisaged in our Urban Waste. It is not enough. In the sector of paper and cardboard used for packaging, the use of recycled material represents more than 90% of the raw material utilised. Thanks to ever more sophisticated technologies and to the development of plants for the removal of ink, paper for printing and sanitary purposes is also increasingly derived from selected cellulosic material obtained from Differentiated Waste Collection. It is important to note, in the context of the printing industry, that the paper used in the production of newspapers is prevalently recycled. Priority must be given to increasing the quantity of cellulosic material derived from differentiated collection, carefully selected so as to allow for notable savings with regard to wood cellulose, especially if you realise that: One tonne of cellulose from recycled paper leads to a saving of 15 forest trees (1 tree for every 70 kg of paper), as well as representing a major saving of water and energy, and the avoidance of the costs of disposal in a landfill.

In fact, to produce 1kg of top-quality paper, you need 2.38 kg of wood, 440 litres of water and 12 kw of energy; whilst to produce 1kg of recycled paper you need no wood at all, and only 2 litres of water and 2 kw of energy. This means that for every tonne of paper produced from recycled materials, rather than from virgin cellulose, 1,300 Kg less Carbon Dioxide ( CO2 ) is emitted into the atmosphere.

GLASS and TINS

The proportion of GLASS and TINS (Al & Fe) collected is 1,600 tonnes; more than 50% of the envisaged total. The economic and environmental advantages deriving from the recovery and recycling of GLASS cannot be denied, especially given that the recovered glass conserves perfectly intact its original physical-chemical properties, and can thus be transformed into new containers. This represents an important environmental advantage, in as much as it leads to a decrease in the consumption of the raw materials required for glass production, with a parallel drop in mining activity, thereby safeguarding the territory. The quantity of glass produced can be measured in terms of an almost equivalent amount of raw materials, such as siliceous sand, dolomite, marble, feldspar and soda. In addition to this advantage are the environmental and economic benefits deriving from the lesser quantity of energy utilised in its fusion. Energy savings can be measured as a reduction of 25% of fuel for every kilo of waste glass utilised. In effect, if in order to produce 1kg of glass from raw materials you need to burn 500g of petrol, which is reduced to 375g if you exploit waste glass. Furthermore, by using waste glass, problems connected to pollution are likewise reduced, above all by cutting exhaust fumes caused by combustion. In fact, the lower temperature required for fusion lead to a reduction in the emission of Nitrogen Oxide - the formation of which during combustion is dependant upon the temperature - as well as the emission of dust. The minor consumption of fuel is also reflected in a reduction in the emission of Carbon Dioxide in relation to the glass produced. Ultimately, particular attention should be paid to the advantages gained through the decrease in the quantity of urban waste to be disposed of. Smaller quantities in the landfill not only lead to ecological benefits for all, but also represent an economic gain, in as much as the costs of disposal of urban waste are a collective burden, which is ever increasing.

ALUMINIUM

ALUMINIUM obtained via recycling is known as secondary aluminium, this name being the only difference from that obtained from bauxite, and labelled primary. The recycling of tin cans is not of importance – given the limited proportion it represents of urban waste – because it lightens the work of the public services, but rather because it enables the production of a new secondary raw material, which has the same chemico-physical characteristics as the primary raw material, but with an energy saving of 95%. In fact, to obtain 1kg of aluminium from bauxite, 14 Kw are required; whilst to extract 1kg of aluminium from differentiated waste collection, only 0.6¸0.7 Kw are necesary. Thus the recycling of aluminium is also of economic importance. Much greater in quantity is packaging made from STEEL. Nowadays steel containers are subject to differentiated collection, generally in multi-material ‘bells’, along with glass and aluminium cans, and are subsequently separated using electromagnetism. Also in this case savings of material and energy are evident. The production of a tonne of steel from metal containers calls for only 25% of the energy required to produce steel from cast iron (1,800 Kw instead of 7,200 Kw).

PLASTIC

The uses to which recycled PLASTIC can be put are many, and ever evolving. Via the physical recycling of heterogenous plastic – i.e. not divided according to its polymeric origin – are made, above all, elements for urban decoration (benches, fences, equipment for playgrounds, street signs). However it is with plastic selected according to its polymeric origin (PE, PET, PVC) that the best results, in terms of product quality, are obtained. Recycled PE is used prevalently as an intermediate layer between two layers of virgin plastic in containers for detergents, and for bottle tops and rubbish bags. Recycled PET is used, mixed with virgin polymer, in the production of new containers for detergent, where it represents about 35% of the total weight of the bottle, as well as for car components, as a fibre-filling and in the manufacture of manmade textiles. Recycled PVC is re-used prevalently in the building industry. Current production includes rigid tubes for the carrying of water and sewage, coupling sleeves for tubes, rigid tubes to protect electrical and telephone cables.

Amongst Hazardous Urban Waste can be found:

- OUT-OF-DATE MEDICINES - DEAD BATTERIES - LEAD ACCUMULATORS - CONTAINERS LABELLED "T"(toxic) and/or "F"(inflammable) Even if the total amount of the materials in question seems modest, (it is estimated that these goods count for roughly 0.7% of the total), the damage they can provoke if mixed with other types of waste is extremely high.

OUT-OF-DATE MEDICINES can be the source of heavy environmental contamination, given the active ingredients which they contain. In the face of such a problem the only answer would seem to be the recycling of out-of-date medicines by returning them for treatment to the pharmaceutical company responsible for their production.

CONCLUSION

Throughout this paper the need for differentiated waste collection has been stressed, not only with a view to reducing the amount of urban waste in landfills, but also so as to recover materials and therefore resources, leading to high levels of energy saving and thus to less environmental pollution, etc.. A study conducted by ENEA (the National Orgainisation for Alternative Energies) and CNR (the National Research Centre) aimed at evaluating the contribution that careful management of urban waste, based on objectives regarding the reduction of manmade emissions of GASES CONTRIBUTING TO THE GREENHOUSE EFFECT based on the directives of the Kyoto Protocol, has quantified the potential reduction in global emissions of greenhouse gases with respect to the current situation. It is envisaged that by encouraging the recycling and recovery of materials through differentiated waste collection it may prove possible to obtain a decrease in the emission of greenhouse gases of between 35% and 50%, along with an optimal recovery of energy of between 24% and 30%.

SOURCES

- Ufficial Gazzette of the Italian Republic; Legislative Decree 5 February 1997; no.22. - Regional Plan for the Management of Waste; Tuscan Regional Administration. - Databank regarding the Collection of Differentiated Waste (investigation 1994). AMIA Carrara - Monthly magazine of the Legambiente (Environmental Organisation); Rifiuti Ogg i(Waste Today) - Ecosportello (Window on the Ecology).

CLASS 3a G

THE QUARRYMAN THROUGH CENTURIES

In old times men risked their lives to take a block of marble out of the mountain . The job of the quarryman has always been a very risky one, especially many years ago, when marble was extracted with rudimentary means. In more recent times marble has been extracted using explosives: a technique that requires a long, accurate preparation, because of its complexity. In the moment of the explosion the mountain wall can break and divide into many blocks of different dimensions.

This method of extraction was called “varata”, a very dangerous method. Before taking the stone out of the mountain, it was necessary to free it from every useless part. This was the work of the “tecchiaiolo”, of a man who, in order to do this, had to hang from a rope down to the quarry front. Happily toward the end of XIX century, the explosive was replaced by helicoidal wires: three steel wires wrapped up to form a helic of variable length. In an hour’s time about 60 cubic metres of marble could be taken out of the mountain.

Some old quarrymen testify they were still using helicoidal wires just before World war II, that is to say in the middle of the 20th century. This shows that the techinque got into the quarries very slowly, especially into the smallest ones. For many years the only necessary means of work were strength, pride, a good deal of experience, and dynamite. Let’s say something about “riquadratori” who appeared in this moment. They used a “subbia”(= a stone-cutter chisel) and hammers to square the block. This was a hard job and these men had to be strong and patient. Yet time goes by, the technique improves and the work in the quarry is less dangerous and more accessible, though complete safety is still a dream. During the years many things have been made to limit accidents but this obviously is not enough.

The use of explosives has been restricted, the helicoidal wire is now only a museum piece and it has been substituded by diamond wires which allow to cut the mountain at incredible speed: three or four days are enough to cut a block, while in the past a month and a half was necessary to do the same thing. A diamond wire is like a pearl nacklace, as a matter of fact quarrymen say it is made up of “perline”(small pearls), in reality they are little artificial diamonds. Recent technologies and cautions have restricted the possibility of accidents and professional figures have changed too. “Tecchiaioli” and “lizzatori” don’t exist any longer. The head of the quarry was once the most experienced man in the quarry and he could decide everything. Nowadays he is supported by a mining engineer who supervises work and controls that mining is executed in a correct way. Workers are more and more machinary operators. Another important difference concerns the salary. Nowadays a qualified quarry operator has a respectable salary, while before, up to the middle of XX century, he earned so little that, at the end of a work day, he had to find an extrawork. Their way of living has changed too: they can reach their quarry daily, by car for example, which means that they live with their families, while old quarry workers either lived in the quarry from Monday to Saturday or had to get up very early( 3 or 4 in the night ) and were back at home at 6/7 in the evening.