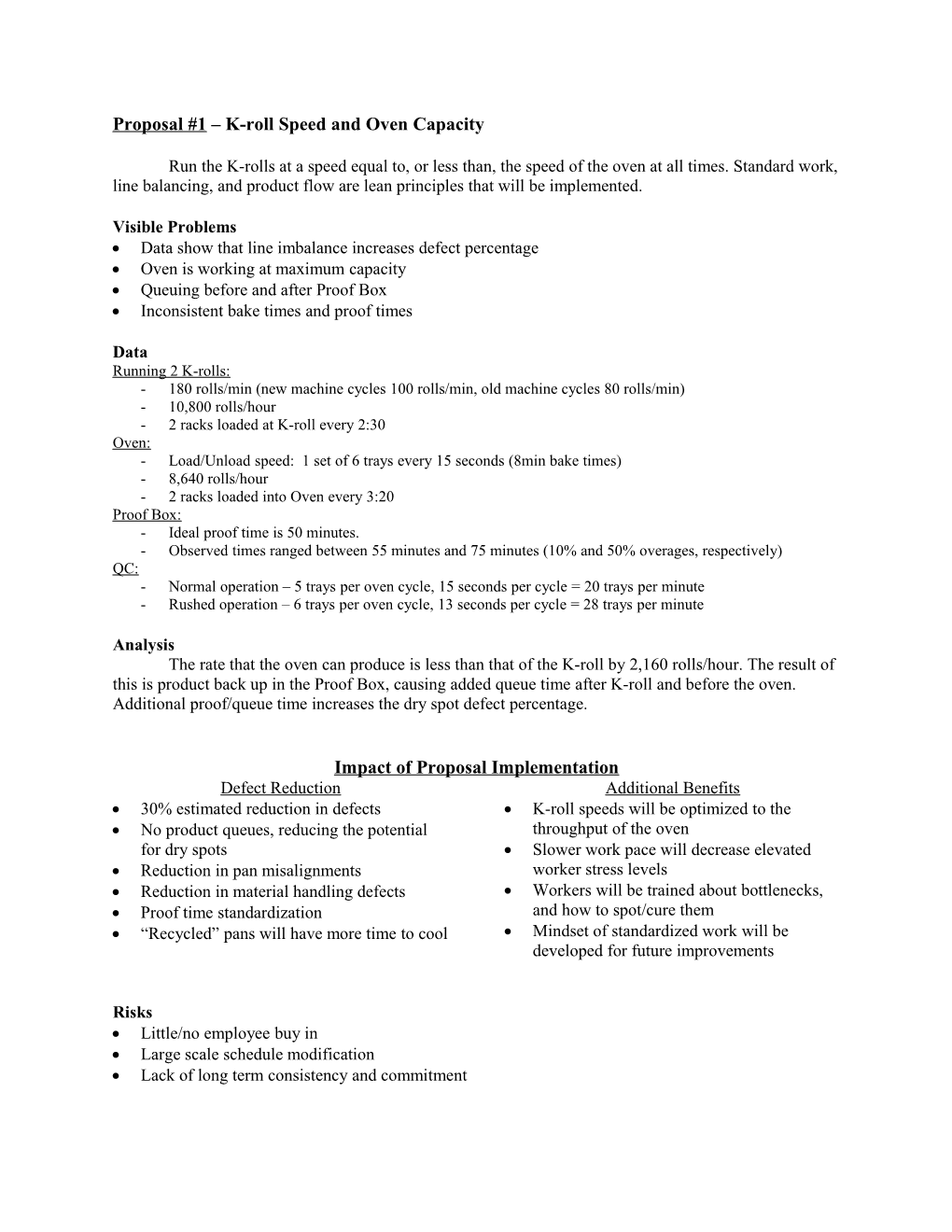

Proposal #1 – K-roll Speed and Oven Capacity

Run the K-rolls at a speed equal to, or less than, the speed of the oven at all times. Standard work, line balancing, and product flow are lean principles that will be implemented.

Visible Problems Data show that line imbalance increases defect percentage Oven is working at maximum capacity Queuing before and after Proof Box Inconsistent bake times and proof times

Data Running 2 K-rolls: - 180 rolls/min (new machine cycles 100 rolls/min, old machine cycles 80 rolls/min) - 10,800 rolls/hour - 2 racks loaded at K-roll every 2:30 Oven: - Load/Unload speed: 1 set of 6 trays every 15 seconds (8min bake times) - 8,640 rolls/hour - 2 racks loaded into Oven every 3:20 Proof Box: - Ideal proof time is 50 minutes. - Observed times ranged between 55 minutes and 75 minutes (10% and 50% overages, respectively) QC: - Normal operation – 5 trays per oven cycle, 15 seconds per cycle = 20 trays per minute - Rushed operation – 6 trays per oven cycle, 13 seconds per cycle = 28 trays per minute

Analysis The rate that the oven can produce is less than that of the K-roll by 2,160 rolls/hour. The result of this is product back up in the Proof Box, causing added queue time after K-roll and before the oven. Additional proof/queue time increases the dry spot defect percentage.

Impact of Proposal Implementation Defect Reduction Additional Benefits 30% estimated reduction in defects K-roll speeds will be optimized to the No product queues, reducing the potential throughput of the oven for dry spots Slower work pace will decrease elevated Reduction in pan misalignments worker stress levels Reduction in material handling defects Workers will be trained about bottlenecks, Proof time standardization and how to spot/cure them “Recycled” pans will have more time to cool Mindset of standardized work will be developed for future improvements

Risks Little/no employee buy in Large scale schedule modification Lack of long term consistency and commitment Financial Justification

Expenses: Minimal to none o Low cost associated with longer k-roll operations o Down stream workers will have no change in work quantity or time

Savings: Substantial o Improved resource allocation o Schedule standardization o Increased product through put o Absolute decrease in defect percentage from (10%-12%) to (7%-8%) K-roll and Oven Flow Capacity

K-roll: K-roll 1: 100 rolls/min = 6000 rolls/hr K-roll 2: 80 rolls/min = 4800 rolls/hr Both: 6000 + 4800 = 10800 rolls/hr

Oven: 6 trays of rolls at 8 min bake times (15 second cycles) Oven: 36 rolls/15s = 2.4 rolls/s = 8640 rolls/hr

Proposal #2 – Defect Sorting Efficiency Improvement

Improve defect sorting accuracy in the Quality Control (QC) area. Create a visual aid of the different types of defects. Generate a training manual to show new employees, and to reference to for all QC workers.

Visible Problems Inconsistency in defect sorting No standardization or formalized training in detecting defects

Impact of Proposal Implementation Defect Reduction Type I errors reduced (throwing away Additional Benefits acceptable rolls) Greatly tighten quality control (QC) Type II errors reduced (letting defects Reduction in sorting ambiguity through to the customer) Sorting becomes a less stressful task for QC personnel Higher quality product

Analysis o The visual aids consist of a flipbook with pictures of barely passing defects as well as barely failing defects. o The training manual will consist of detailed instructions on how to categorize/detect defects, and it will also contain pictures similar to those from the visual aids flipbook. This book will be shown to new employees as well as those who are temporarily placed in QC.

Financial Justification Expenses: o Visual Aids ≈ $300 . Paper, high-quality photo printing, laminating, stands, binding, etc. o Training Manual ≈ $200 . Paper, high-quality photo printing, binding, etc.

Savings: o Improve defect sorting efficiency . Overall defect reduction . Increase in throughput o Breakeven in about 8 months Risks: Workers may not utilize visual aids Visual aids may distract/slow-down workers

Figure 1: Page from defect flipbook

Figure 2: One defect type from page of defect flipbook Proposal #3 – Proof Box Standardization

Standardize the way in which trays are loaded and unloaded from the racks. Decrease the amount of time the door to the Proof Box is left open. Add a cover to the top of each rack to protect the highest rolls. Introduce visual aids to help standardize the Proof Box area. Standardization, variability elimination, and product flow are lean principles that will be implemented.

Visible Problems Rack loading/unloading variability No standard procedure or formal flow process to follow Inconsistent proof times, extra racks outside of Proof Box Each Oven operator has their own rack

Data K-roll: - Speed of 100 rolls/min, tray loading is 3.56 sec/tray = 2:25 minutes - Speed of 80 rolls/min, tray loading is 5.25 sec/tray = 3:30 minutes Proof Box: - Capacity: 49 racks - Ideal proof time is 50 minutes Oven: - Capacity: 6 trays loaded from 2 racks every 15 seconds, 3 per worker - Each oven operator has their own rack QC: - Not all trays from rack suffer from dry spots

Analysis Queues will be reduced once the K-roll speed matches the oven speed. This will alleviate some issues regarding queuing and uneven proof times.

Loading of racks from the bottom-up will always allow worker to see the dough. Unloading racks from the top-down will allow the worker to see the highest tray (and possible defects). Using only one rack at the Oven will reduce waiting time outside of the Proof Box. Covering the top tray will reduce drying effects of dry air blowing on rolls. Mark each rack with a time when entering the Proof Box. Re-number each door to the Proof Box. Proof box will only be opened when necessary, don’t leave open for longer than needed.

Impact of Proposal Implementation Defect Reduction 15% estimated reduction in defects Additional Benefits No waiting queues outside of Oven Standardized work throughout Proof Box Workers will know how long the rack has Energy savings due to improved Proof Box been in the Proof Box door procedures Workers will be able to see defects before Proof Box doors will be numbered and placing into Oven marked for which door is next in line to be used Project Possibilities Top Rack Cover: Time Stamp: Visual Aids: - Empty tray - Dry erase board/marker on rack - Sticker/Magnets on doors - Rack cover attachment - Colored Magnets/stickers - Signs reminding to close doors - Plastic/paper cover - A fixed timer on each rack

Financial Justification

Expenses: Minimal o Low cost associated with visual aids and timer system o No cost to implement standardization of racks

Savings: Substantial o Improved resource allocation o Decrease in overall defects due to dryness and disfigured rolls from contact with rack o End-of-line defects will be decreased from small-scale defect detection at the Oven

Risks: Workers may not agree with process changes and standardization Visual aids distract workers Timers ignored/not used Suggestion #1 – Proof Temperature and Humidity Standardization

Monitor and adjust the Proof Box in order to maintain a constant temperature and humidity level. Implement better ways to insulate the Proof Box. Perform minor capital improvements on the Proof Box. Standardization and variation elimination are lean principles that apply.

Visible Problems Proof Box door open for longer periods of time than required Inconsistency in proofing of dough due to the surrounding environment Dough will come out of Proof Box brittle and dry, not soft and moist Poor air circulation inside of Proof Box

Data/Observations K-roll/Oven: - Proof Box doors stay open longer than needed to move the racks into position Proof Box: - 7 doors on each side of the Proof Box allow for potentially different external environments at each door - The top trays are proofed differently than the bottom trays on a given rack - Ideal temperature of 100°F to 105°F at 80% to 85% relative humidity QC: - Dry rolls come through in waves, which show a trend towards individual trays and not racks

Analysis Phase I – Expense for Data Collection Phase II – Capital Investment on Proof Box - Purchase a thermo-hygrometer sensor and - Based on Phase I, perform capital investments collect data at intervals throughout the to improve the performance of the Proof Box. production day. - Improve the air circulation and increase the - Compare data collected to the ideal value of amount of insulation inside the Proof Box. 100°F to 105°F at 80% to 85% relative humidity.

Impact of Proposal Implementation Defect Reduction Additional Benefits 40% estimated reduction in “dry” defects Will be able to constantly monitor the Proof Workers will know if there is a problem Box temperature and humidity with the Proof Box in real time Energy savings due to improved Proof Box Proof Box conditions can be easily matched conditions to the ideal dough proofing conditions

Risks Disconnect between phase I an phase II resources Adjustments to the Proof Box doors not feasible Adding a fan will disrupt the proofing process more than the current configuration Financial Justification:

Expenses: Phase I o $50 investment in wireless thermo-hygrometer sensor

Phase II o Variable, dependant on data collected o Improve weather stripping across the door openings o Increase the circulation of air throughout the Proof Box with improved fans o Invest in pneumatic door closers o Addition of PVC strips across door openings

Savings: o Improved Proof Box performance o Significant dry spot defect reduction o Proof Box performance will be standard, and readily adjustable if necessary because of real-time data collection of thermo-hygrometer