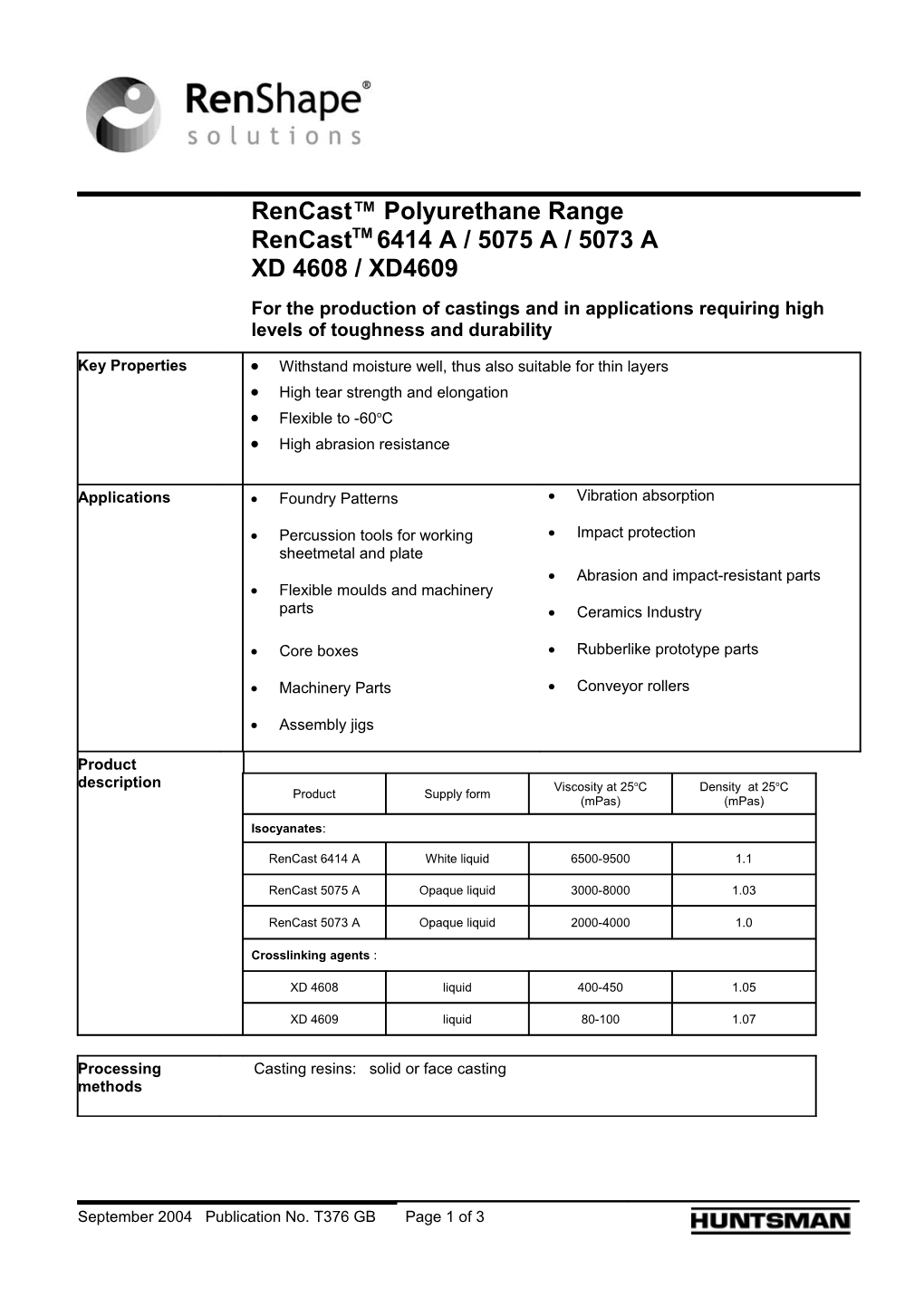

RenCast™ Polyurethane Range RenCastTM 6414 A / 5075 A / 5073 A XD 4608 / XD4609 For the production of castings and in applications requiring high levels of toughness and durability

Key Properties Withstand moisture well, thus also suitable for thin layers High tear strength and elongation Flexible to -60oC High abrasion resistance

Applications Foundry Patterns Vibration absorption

Percussion tools for working Impact protection sheetmetal and plate Abrasion and impact-resistant parts Flexible moulds and machinery parts Ceramics Industry

Core boxes Rubberlike prototype parts

Machinery Parts Conveyor rollers

Assembly jigs

Product description Viscosity at 25oC Density at 25oC Product Supply form (mPas) (mPas)

Isocyanates:

RenCast 6414 A White liquid 6500-9500 1.1

RenCast 5075 A Opaque liquid 3000-8000 1.03

RenCast 5073 A Opaque liquid 2000-4000 1.0

Crosslinking agents :

XD 4608 liquid 400-450 1.05

XD 4609 liquid 80-100 1.07

Processing Casting resins: solid or face casting methods

September 2004 Publication No. T376 GB Page 1 of 3 Processing Mixing proportions (pbw) RenCast 6414 A 100 100 75 50 25 RenCast 5075 A 25 50 75 100 50 25 RenCast 5073 A 50 75 100 XD 4608 41 XD 4609 70 60 50 40 35 30 25 20 Resin / Hardener mix (at 25oC)

Appearance Cream Orange Orange Orange Orange Cognac Cognac Cognac Cognac Mix viscosity mPas 5200 2700 3200 3000 2800 3000 2600 3200 4000 Pot life (1 Kg) min 15 - 20 15 - 22 35 - 40 20 - 25 20 - 25 20 - 25 20 - 25 20 -25 20 – 25 Demouldable after h 16 - 24* 16 - 24* 4 – 10 4 - 6 4 - 6 4 - 6 10 – 12 10 – 14 14 - 16 Max. casting layer mm 10 20 30 50 60 75 90 100 100 thickness Recommended cure schedule 14 / 24 hours @ Room Temperature + 14 hours @ 40 oC or 7 days @ RT The isocyanate components listed above can be mixed with each other in any desired proportions. Users can therefore formulate their own casting resin systems to obtain the Shore hardness required in each case. The table lists some casting resin mixtures and their respective properties. Processing The systems should be used in the temperature range between 20 - 25 oC. parameters Post curing Cure 14-24hours / RoomTemperature + 14hours / 40oC or 7 days / RT.

Properties Density g/cm3 ca. 1.1 ca. 1.1 ca. 1.1 ca. 1.1 ca. 1.1 ca. 1.1 ca. 1.1 ca. 1.1 ca. 1.1

Shore D ISO 868 67 55 35 32 30 25 15

Shore A ISO 868 90 85 80 75 60 55 45

Tensile ISO 527 MPas 21 11 11 8 8 7.5 4.5 4 3 strength Elongation at ISO 527 % 127 135 203 263 380 376 344 390 270 break Tear DIN 2 84 45 39 31 26.5 12.5 10 8 6 propagation 53 356 N/mm resistance Linear mm/m shrinkage 0.1 1.4

Abrasion resistance (NEMA) 100 rpm S 33 sandpaper strips mg ca. 7 - 14

* For parts with uniform face-cast layers of 5-15mm, allow 16 - 24 hours of final cure time prior to demoulding. To avoid creep, always store parts on a flat surface without stressing. Follow recommendation for curing before subjecting the parts to loading. Shrinkage measurement using test specimen size 500 x 50 x 10mm.

September 2004 Publication No.T376 GB Page 2 of 3 Packaging Information 6414 A 5075 A 5073 A XD 4608 XD 4609 - - 180 kg 200 kg 200 kg - - - - 25 kg ------4 x 5 kg 4 x 5 kg 4 x 4.5 kg 5 kg 5 kg - - 6 x 300 gr 6 x 600 gr 6 x 195 gr - - - -

Caution Handling Huntsman Advanced Materials products are generally quite harmless to handle provided that certain precautions precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended. These precautions are described in greater detail in publication No. 24264/3/e Hygienic precautions for handling plastics products and in the Material Safety Data sheets for the individual products. These publications are available on request and should be referred to for fuller information.

Vantico Limited All recommendations for the use of our products, whether given by us in writing, verbally, or to be implied from the Adhesives and Tooling results of tests carried out by us, are based on the current state of our knowledge. Notwithstanding any such recommendations the Buyer shall remain responsible for satisfying himself that the products as supplied by us are suitable for his intended process or purpose. Since we cannot control the application, use or processing of the products, we cannot accept responsibility therefore. The Buyer shall ensure that the intended use of the products will not infringe any third party’s intellectual property rights. We warrant that our products are free from defects in accordance with and subject to our general conditions of supply.

Duxford, Cambridge England CB2 4QA Ó Vantico Ltd, 2003 Tel: +44 (0) 1223 493 000 Ò Ren and RenShape are registered trademarks of Vantico GmbH, Basel, Switzerland, trading as Huntsman Fax: +44 (0) 1223 493 002 Advanced Materials ™ RenPaste, RenGel, RenLam, RenCast, RenLease are trademarks of Vantico GmbH, Basel, Switzerland, www.renshape.com trading as Huntsman Advanced Materials

September 2004 Publication No.T376 GB Page 3 of 3