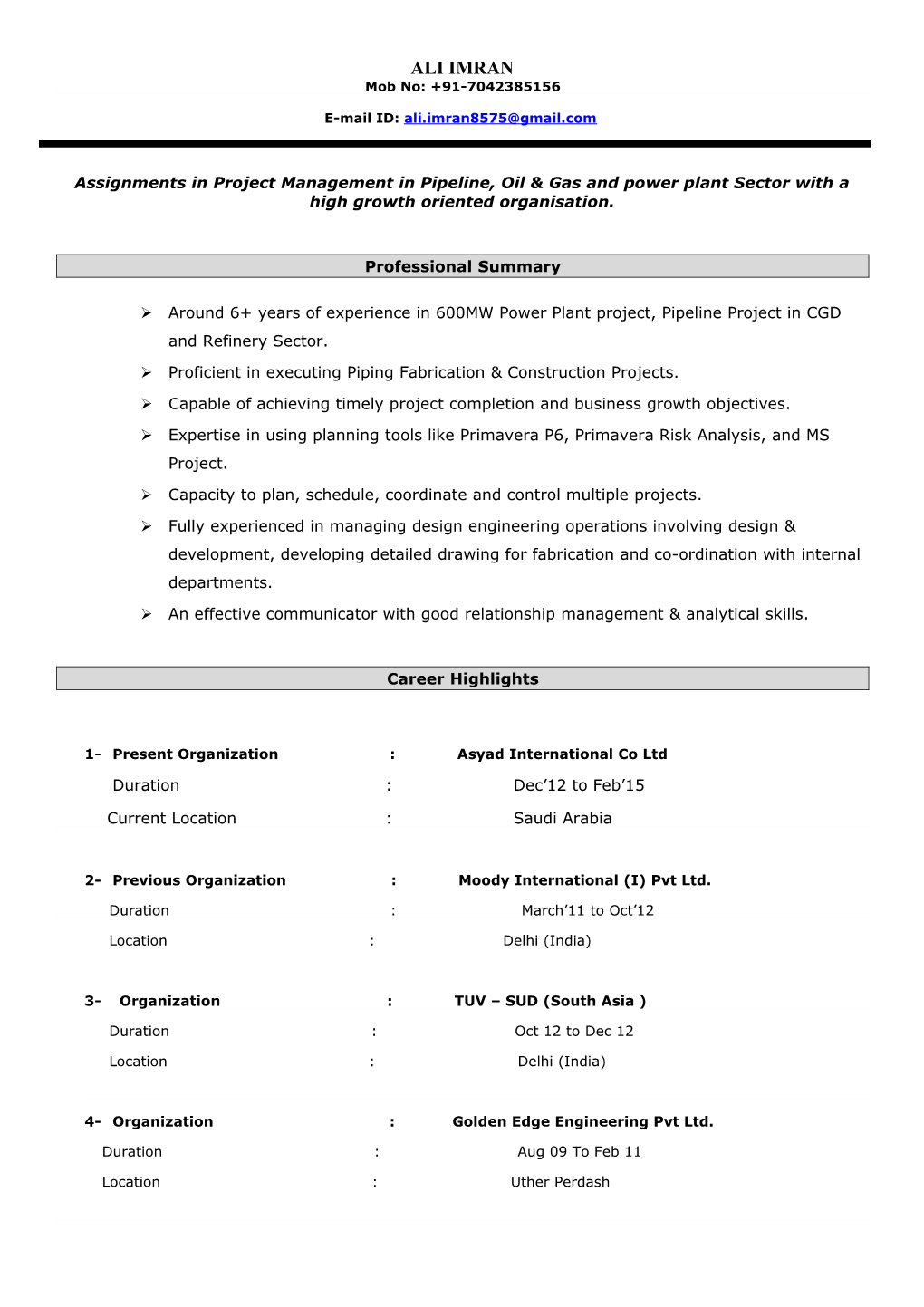

ALI IMRAN Mob No: +91-7042385156

E-mail ID: [email protected]

Assignments in Project Management in Pipeline, Oil & Gas and power plant Sector with a high growth oriented organisation.

Professional Summary

Around 6+ years of experience in 600MW Power Plant project, Pipeline Project in CGD and Refinery Sector.

Proficient in executing Piping Fabrication & Construction Projects.

Capable of achieving timely project completion and business growth objectives.

Expertise in using planning tools like Primavera P6, Primavera Risk Analysis, and MS Project.

Capacity to plan, schedule, coordinate and control multiple projects.

Fully experienced in managing design engineering operations involving design & development, developing detailed drawing for fabrication and co-ordination with internal departments.

An effective communicator with good relationship management & analytical skills.

Career Highlights

1- Present Organization : Asyad International Co Ltd

Duration : Dec’12 to Feb’15

Current Location : Saudi Arabia

2- Previous Organization : Moody International (I) Pvt Ltd.

Duration : March’11 to Oct’12

Location : Delhi (India)

3- Organization : TUV – SUD (South Asia )

Duration : Oct 12 to Dec 12

Location : Delhi (India)

4- Organization : Golden Edge Engineering Pvt Ltd.

Duration : Aug 09 To Feb 11

Location : Uther Perdash Projects

1- Client : Saudi Aramco

Project : AL HASA Pipeline Project Duration : Jan ’14 to Feb’15.

Location : Saudi Arabia (AL- Hasa)

Role : Project In Charge

2- Client : Saudi Aramco (Jeddah Refinery)

Project : Replacement Utilities Control System, (4 Boilers and 4 Compressor Areas). Duration : Dec’12 to Jan’14

Location : Saudi Arabia (Jeddah Refinery)

Role : Mechanical Lead Engineer

3- Client : Indraprastha Gas Limited

Project : Natural Gas (NG) NCT Project Phase–II Duration : March’11 to Oct’12

Location : New Delhi

Role : TPI

4- Client : Indraprastha Gas Limited ( TUV- SUD )

Project : Natural Gas (NG) NCT Project Phase–II Duration : Oct’12 to Dec 12

Location : New Delhi

Role : TPI

5- Client : Lanco Power Plant (Boiler part)

Project : 2 X 600 MW Thermal Power Project Location : Anpara (UP)

Role : Mechanical Site Engineer Over all Job Responsibility

OVERSIES RESPONSIBILITY

Handling piping fabrication, trenching/erection, stringing, welding, hydro-testing & box- up of piping systems.

Performing erection & alignment of Boiler Drum, Duct, Eco Flu Duct, Main Header Line, Fuel Gas Supply Line, Fuel Ignition line, and Fuel Oil Line.

I am familiar with Saudi Aramco Standard & Codes and International Code (API, ASME, and ASTM).

Preparing Tie-In Packages, Test Packages, Hydro Test Diagram and P&ID Test Limits Mark- Up.

Managing quality control functions as well as inspection and testing.

Reviewing work method statements and procedures.

Inspecting material before erecting the line and initial stage of welding.

Conducing on job inspection of site activities.

Drafting weekly and monthly progress reports.

Implementing PT, UT and RT test Inspection

Efficiently handling the pre-commissioning and flushing activities

Assessing Hydro Test Package to verify the completion of NDT (RT, UT, PT, PWHT, PMI and Hardness test) requirements.

Accurately defining quality systems, procedures & work schedules

Executing Quality Control Measures through – Acceptance Sampling, Vendor Quality Rating (VQR) and Quality Audit

Effetutating the calibration and validation activities

Carrying out checks on the test observations and raw data of of all the QC Operations

IGL Project (CGD) RESPONSIBILITY

Preliminary Route Survey. (With the help of approved drawing)

Trenching. Trial pit before excavation and route marking.

Proper Barricading, signboards and availability of first aid kit should be observed.

Mulling. Distance between two pits is not more than 8mtrs.

Depth should be maintain.

HDD crossing (Road, River, Nallah).

Machine should be calibrated.

Proposed drawing should be done.

Rimmer should be done before pipe pulling.

Marking should be done. Electro fusion joint Qualified and approved welder wearing the original ID-Card only can perform the Electro fusion jointing.

Calibrated bar coded EF Control Unit must be used and manual entry may be possible.

EF fittings must be used only from the approved manufacturer of GSPC along with proper packing.

The contractor must have and use alignment clamp, re rounded tool.

Before scrapping, welder must mark the size of the EF fitting on both ends of the pipe with indelible marker pen.

Stone free soil should be filling for padding.

Warning Mate Laying of warning mate should be done at 0.5mtr depth of the trench.

Backfilling. Backfilling of the entire trench should be done with the balance soil.

Testing. As laid PE network drawing must be clearly marked with pressurized, venting and flushing points.

Insure calibrated guage are used.

Prior to holding the pressure in the network, ensure water particles or debris are flushed out completely.

Valve chamber and final clean up. Valve chamber should be constructed according the guideline of GSPC tender book.

Material should be used in proper manner according tender book of GSPC.

Charging of network.

As built should be checked by the TPI/PMC.

Checked and ensure Penumatic test report.

Ensure availability of additional squeeze tools for emergency

The gas should be vented continuously by crack opening of valve until reading confirm a concentration of gas by methane detector.

Line/ equipment/ installation/ work area/ inspected.

Surrounding area checked.

Portable fire extinguisher provided.

Area / cordoned off and caution boards / tags provided.

Paper work: -- Measurement of lowering pipe with Offset, Built up, Mulling, Normal surface.

Preparation and verification of laying graph.

Verification and certification of as built.

Test certificate reviewing of all consumed material.

Verification of Bill. Highlights

At Asyad International Co. Ltd

Attained Appreciation from Saudi Aramco.

Successfully Complete Hydro Test of 4 Boilers in Jeddah Refinery.

Successfully complete the 210 Tie-In’s joints of 4 Boilers Area in Jeddah Refinery.

Academics

Degree University Institute Session Class B.E. (Mechanical) Magdh MACET, Patna, Bihar 2004/2008 First Class

Certifications

Pursuing Project Management Professional (PMP)

Certified “Professional in Project Planning & Management (PPM)” from CADD Center (Primavera P6V7)

Ms Project

Cost Control management.

Piping Design and Detail Engineering.

Certified NDT Level II

IT Skills

Tools : Primavera, MS Project, Auto CAD, SAP – MM, MS OFFICE.

Personal Details

Date of Birth : 14th -January -1987

Marital Status : Unmarried

Pass Port No : K5443760.

References

Place : New Delhi

(ALI IMRAN)