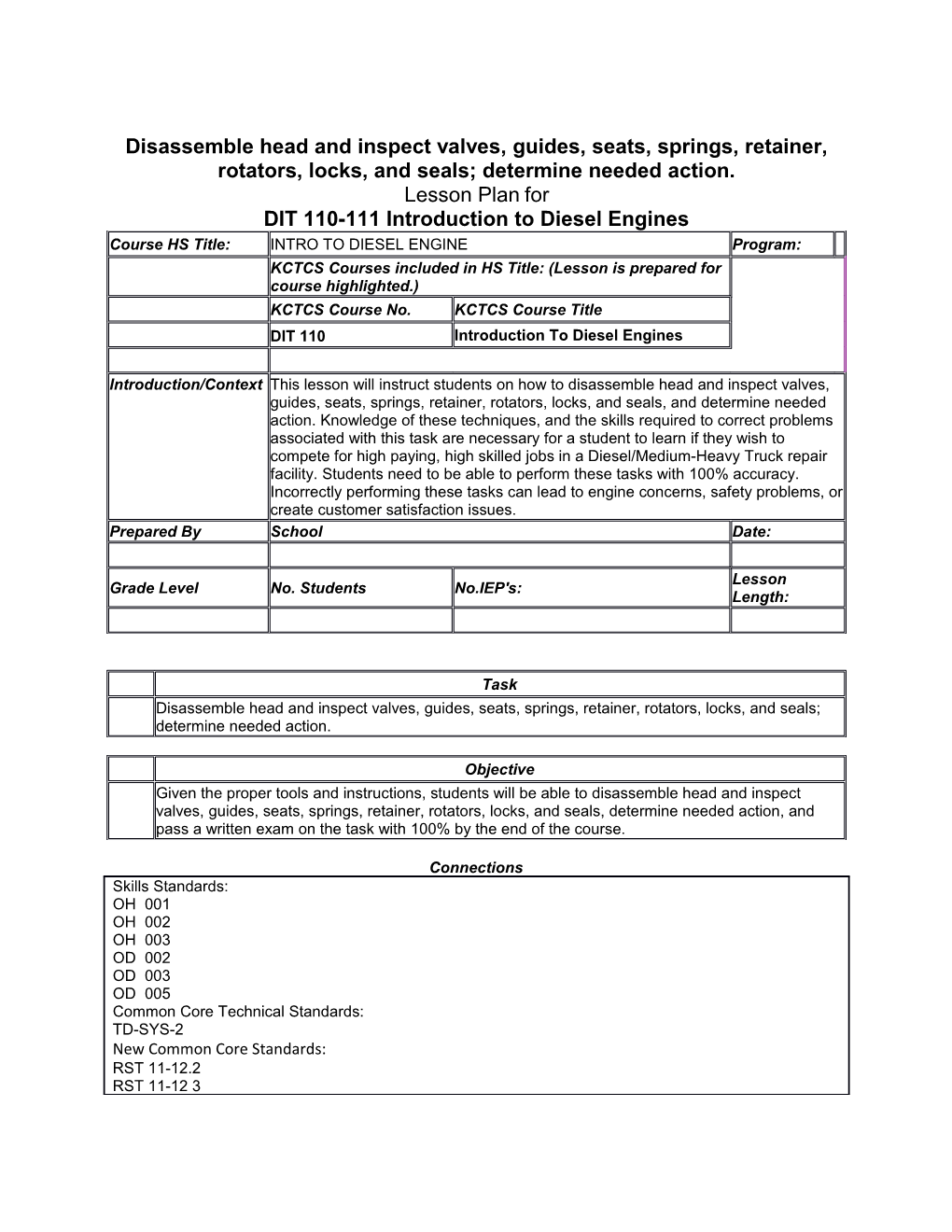

Disassemble head and inspect valves, guides, seats, springs, retainer, rotators, locks, and seals; determine needed action. Lesson Plan for DIT 110-111 Introduction to Diesel Engines Course HS Title: INTRO TO DIESEL ENGINE Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 110 Introduction To Diesel Engines

Introduction/Context This lesson will instruct students on how to disassemble head and inspect valves, guides, seats, springs, retainer, rotators, locks, and seals, and determine needed action. Knowledge of these techniques, and the skills required to correct problems associated with this task are necessary for a student to learn if they wish to compete for high paying, high skilled jobs in a Diesel/Medium-Heavy Truck repair facility. Students need to be able to perform these tasks with 100% accuracy. Incorrectly performing these tasks can lead to engine concerns, safety problems, or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Disassemble head and inspect valves, guides, seats, springs, retainer, rotators, locks, and seals; determine needed action.

Objective Given the proper tools and instructions, students will be able to disassemble head and inspect valves, guides, seats, springs, retainer, rotators, locks, and seals, determine needed action, and pass a written exam on the task with 100% by the end of the course.

Connections Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts Instructor may use the content section of this plan to create a handout for the students.

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various Diesel Engines Test T2 Fourth Delmar 22-24 Norman/Corinchock Diesel Technology Seventh Goodheart Wilcox 167-168

Equipment Quantity Item Source As Needed Snap, Ball or Dial Gauge Various As Needed Valve Grinder and Associated Tools Various As Needed Valve Guide Special Tools Various

Content/Presentation/Demonstration Outline Instruct students on how to inspect valves, guides, seats, springs, retainer, rotators, locks, and seals. First, on Valve Springs, tell students to check valve spring straightness with a T-square. This will help prevent stems from binding and twisting in guides as valves are operated. Explain that uneven side pressure causes the valve stems and guides to wear faster. Also, tell them to check the unloaded (or free length) and loaded length (or tension) of the spring using a spring-tension gauge. Inform students to replace valve springs that do not meet specifications to prevent damage to the piston or crankshaft. Let students know that valve springs using the same valve bridge must be replaced together to prevent unbalanced valve operation. Tell them this can damage the bridge from uneven stress, can cause valve guides and stems to wear faster, and can result in insufficient scavenging of the cylinder. Instruct students that Valve Spring Retainers keep the valve spring on the valve, and valve rotators are used to rotate the valve each time it is actuated. Some engines also have seals. Tell students that careful inspection of these components can prevent damage and extend the life of the engine. Teach students that retainers, also called keepers, that become worn or damaged, may allow the spring to release the valve. If this happens, tell students that the valve drops into the cylinder and jams the piston, which is a condition called dropping a valve. Let students know that Free Release Rotators use engine vibration and exhaust gases to rotate, because the spring tension is removed when it is depressed, and Mechanical Rotators apply a torque to rotate the valve each time the valve is opened. Explain that both will help eliminate carbon deposits from forming on the valve face and seats. Instruct students that seals between the valve guide and valve stem prevents oil from entering the cylinder on the intake stroke. Explain that defective seals can cause oil consumption, leading to excess smoking, carbon build-up, fouling of injectors, formation of hot spots, and pre-combustion or dieseling. Tell students that after a cylinder head has been checked or resurfaced and is considered usable, the valve guides should be checked for wear. Teach students to check the guide inside diameter with a snap, ball, or dial gauge in three different locations throughout the length of the guide. Let them know that if guides are the replaceable types and are worn excessively, they should be replaced. Inform them that in most cylinder heads, the valve guides can be removed by using a driver. Tell them to select a driver that fits the valve guide, and then do the following. Tell them to support the cylinder head on a block or stand. If the guide is to be pressed put, instruct them to place the cylinder head in the press and align the driver with the press ram. Inform students to note the position of the guide in relation to the cylinder head for reference when installing a new guide. Tell them to drive or press the guide out of cylinder head, making sure that the driver is driven or pressed straight. If it is not pressed straight, let them know that damage to the valve guide or cylinder head may result. After the guide has been removed, tell them to check the guide bore for scoring. Let them know that a badly scored guide bore may have to be reamed out to accommodate the next larger size guide. After the guide bore is checked, tell students to select the correct guide (intake or exhaust) and insert it in the guide bore, then insert the guide driver and drive or press the guide into the cylinder head until the correct guide position is reached. Explain to students that many engine manufacturers recommend that a new guide be reamed after installation to ensure that the guide inside diameter did not change during the installation process. Tell them to never ream a surface-hardened guide. Instruct students that a common practice during major maintenance is to replace all valves if they have been in the head for several thousand operating hours. Let them know that valves must be changed if the head shows signs of carbon build-up from oil leaking around the valves. In this case, tell them to also consider changing valve guides. Teach students that valves with scratched, scored, pitted, or worn stems or stems with worn keeper grooves should be replaced. If the valve head is cupped, nicked, or marred, it should be replaced. Let students know that if a valve passes the visual inspection, it must be cleaned using a wire buffing wheel or glass bead blaster, if available. Tell them to use a valve refacing tool or valve grinder to obtain the correct face angle. Instruct students to inspect the valve to ensure that the valve margin is within specifications. Tell them that insufficient valve margin may result in premature burning and subsequent failure.

Applications/Practice 1 Refer to Content

Evaluation and feedback Prior to Testing or Lab Work Objective 1/ Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist should be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1/ Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required.

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work, particularly that which is unsatisfactory, for the purpose of planning further instruction.) REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)