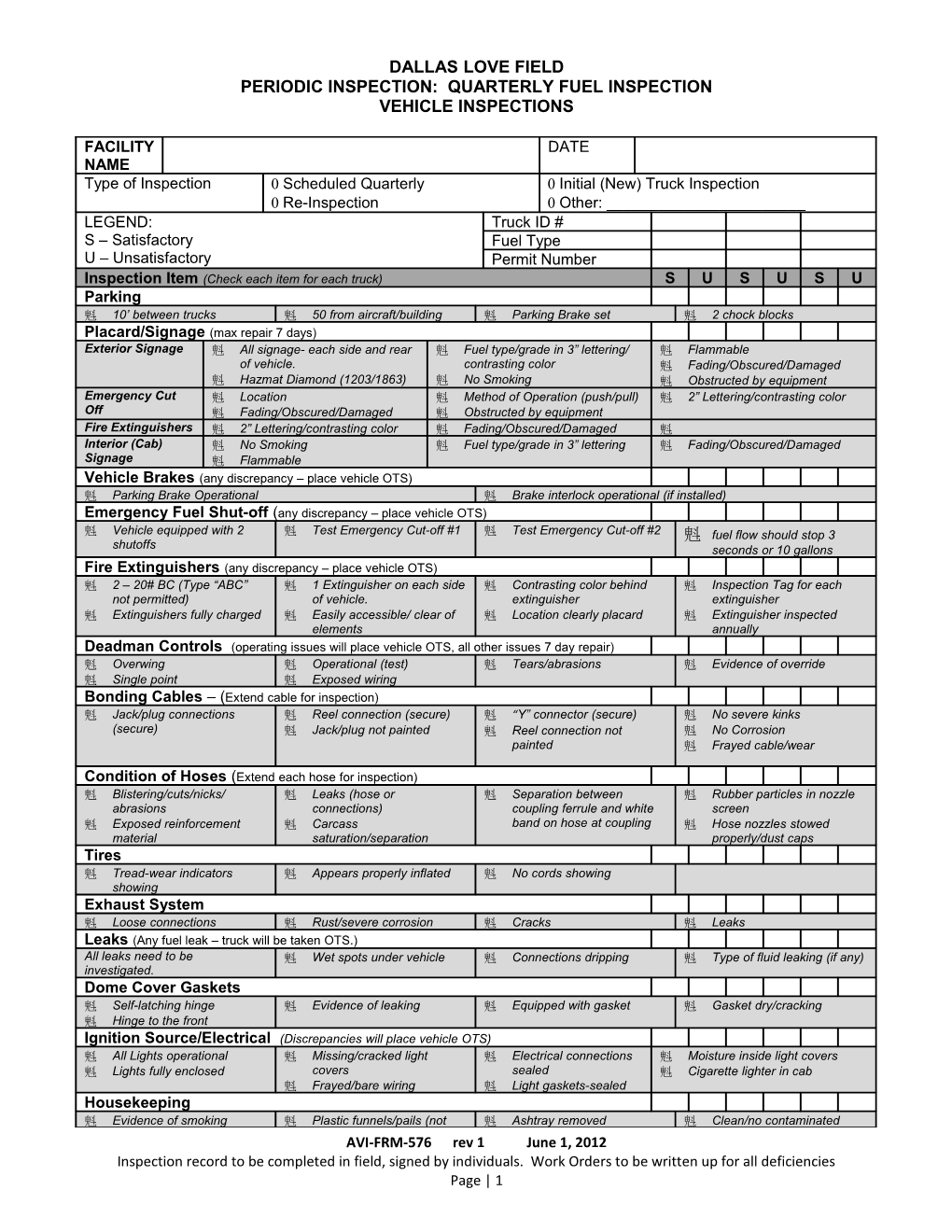

DALLAS LOVE FIELD PERIODIC INSPECTION: QUARTERLY FUEL INSPECTION VEHICLE INSPECTIONS

FACILITY DATE NAME Type of Inspection Scheduled Quarterly Initial (New) Truck Inspection Re-Inspection Other: ______LEGEND: Truck ID # S – Satisfactory Fuel Type U – Unsatisfactory Permit Number Inspection Item (Check each item for each truck) S U S U S U Parking 10’ between trucks 50 from aircraft/building Parking Brake set 2 chock blocks Placard/Signage (max repair 7 days) Exterior Signage All signage- each side and rear Fuel type/grade in 3” lettering/ Flammable of vehicle. contrasting color Fading/Obscured/Damaged Hazmat Diamond (1203/1863) No Smoking Obstructed by equipment Emergency Cut Location Method of Operation (push/pull) 2” Lettering/contrasting color Off Fading/Obscured/Damaged Obstructed by equipment Fire Extinguishers 2” Lettering/contrasting color Fading/Obscured/Damaged Interior (Cab) No Smoking Fuel type/grade in 3” lettering Fading/Obscured/Damaged Signage Flammable Vehicle Brakes (any discrepancy – place vehicle OTS) Parking Brake Operational Brake interlock operational (if installed) Emergency Fuel Shut-off (any discrepancy – place vehicle OTS) Vehicle equipped with 2 Test Emergency Cut-off #1 Test Emergency Cut-off #2 fuel flow should stop 3 shutoffs seconds or 10 gallons Fire Extinguishers (any discrepancy – place vehicle OTS) 2 – 20# BC (Type “ABC” 1 Extinguisher on each side Contrasting color behind Inspection Tag for each not permitted) of vehicle. extinguisher extinguisher Extinguishers fully charged Easily accessible/ clear of Location clearly placard Extinguisher inspected elements annually Deadman Controls (operating issues will place vehicle OTS, all other issues 7 day repair) Overwing Operational (test) Tears/abrasions Evidence of override Single point Exposed wiring Bonding Cables – (Extend cable for inspection) Jack/plug connections Reel connection (secure) “Y” connector (secure) No severe kinks (secure) Jack/plug not painted Reel connection not No Corrosion painted Frayed cable/wear

Condition of Hoses (Extend each hose for inspection) Blistering/cuts/nicks/ Leaks (hose or Separation between Rubber particles in nozzle abrasions connections) coupling ferrule and white screen Exposed reinforcement Carcass band on hose at coupling Hose nozzles stowed material saturation/separation properly/dust caps Tires Tread-wear indicators Appears properly inflated No cords showing showing Exhaust System Loose connections Rust/severe corrosion Cracks Leaks Leaks (Any fuel leak – truck will be taken OTS.) All leaks need to be Wet spots under vehicle Connections dripping Type of fluid leaking (if any) investigated. Dome Cover Gaskets Self-latching hinge Evidence of leaking Equipped with gasket Gasket dry/cracking Hinge to the front Ignition Source/Electrical (Discrepancies will place vehicle OTS) All Lights operational Missing/cracked light Electrical connections Moisture inside light covers Lights fully enclosed covers sealed Cigarette lighter in cab Frayed/bare wiring Light gaskets-sealed Housekeeping Evidence of smoking Plastic funnels/pails (not Ashtray removed Clean/no contaminated AVI-FRM-576 rev 1 June 1, 2012 Inspection record to be completed in field, signed by individuals. Work Orders to be written up for all deficiencies Page | 1 allowed) rags/towels

AVI-FRM-576 rev 1 June 1, 2012 Inspection record to be completed in field, signed by individuals. Work Orders to be written up for all deficiencies Page | 2 Truck # ADMINISTRATATIVE RECORDS S U S U S U Daily inspection records Hose damage records reviewed Hose Inspections Hose repair records Monthly inspection Hose replacement records reviewed records Monthly inspection Grounding tested (25 Bonding Cables records reviewed ohms or less) Inspection Tags or Fire Extinguishers Inspection records on file . Fueling Operations Bonding truck to Spills/Leaks Observed aircraft/farm Proper use of deadman Item Vehicle Action Action # # Deficiencies Description Due Competed 1

2

3

4

5

6

7

8

9

10 Comments

Signatures/Reviews I certify that the inspection was conducted on the date indicated and the inspection was conducted in accordance with NFPA 407, Federal Aviation Administration Part 139 Standards, and/or Department of Aviation requirements. Additionally, I certify that at the time of inspection all deficiencies have been properly recorded and the appropriate actions taken to correct any item(s) identified. Representative Printed Name Signature Date Airport Operations Tenant Facility

Airport Operations – Manager’s Review Inspection Satisfactory, No further action needed Deficiencies noted, action needed

AVI-FRM-576 rev 1 June 1, 2012 Inspection record to be completed in field, signed by individuals. Work Orders to be written up for all deficiencies Page | 3