Online Resource 1

Elemental mapping

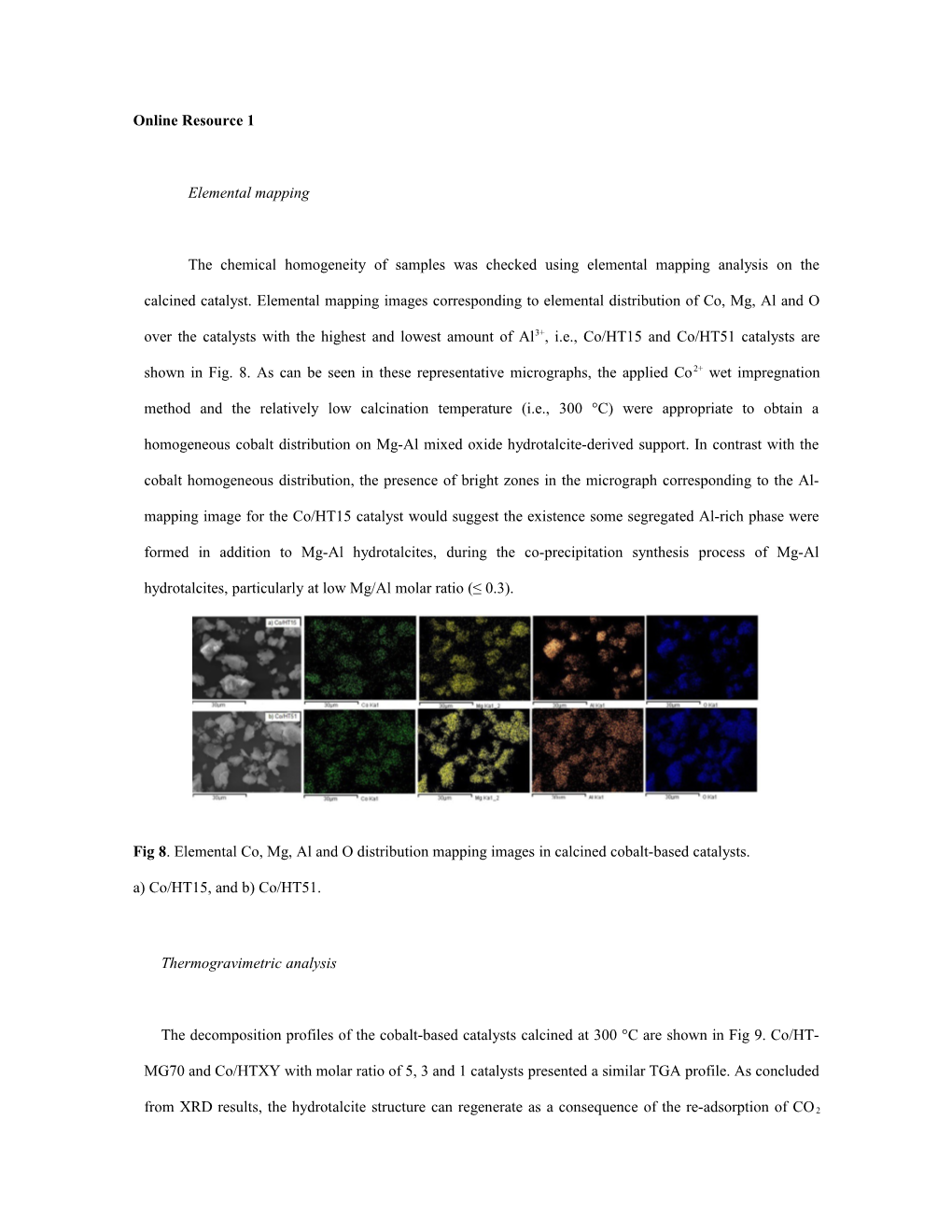

The chemical homogeneity of samples was checked using elemental mapping analysis on the

calcined catalyst. Elemental mapping images corresponding to elemental distribution of Co, Mg, Al and O

over the catalysts with the highest and lowest amount of Al3+, i.e., Co/HT15 and Co/HT51 catalysts are

shown in Fig. 8. As can be seen in these representative micrographs, the applied Co 2+ wet impregnation

method and the relatively low calcination temperature (i.e., 300 °C) were appropriate to obtain a

homogeneous cobalt distribution on Mg-Al mixed oxide hydrotalcite-derived support. In contrast with the

cobalt homogeneous distribution, the presence of bright zones in the micrograph corresponding to the Al-

mapping image for the Co/HT15 catalyst would suggest the existence some segregated Al-rich phase were

formed in addition to Mg-Al hydrotalcites, during the co-precipitation synthesis process of Mg-Al

hydrotalcites, particularly at low Mg/Al molar ratio (≤ 0.3).

Fig 8. Elemental Co, Mg, Al and O distribution mapping images in calcined cobalt-based catalysts. a) Co/HT15, and b) Co/HT51.

Thermogravimetric analysis

The decomposition profiles of the cobalt-based catalysts calcined at 300 °C are shown in Fig 9. Co/HT-

MG70 and Co/HTXY with molar ratio of 5, 3 and 1 catalysts presented a similar TGA profile. As concluded

from XRD results, the hydrotalcite structure can regenerate as a consequence of the re-adsorption of CO 2 and H2O. The TGA profiles of the calcined catalysts also suggest a reconstruction of the hydrotalcite phase.

Therefore, the first step below 250 °C corresponds to the loss of the water gained by rehydration, while the

second (250 – 500 °C) arises from the decomposition of the hydroxide layers and carbonate anions

remaining after calcination and formed by CO2 re-adsorption.

Fig 9. TGA profiles of the calcined cobalt-based catalysts: Co/HT15 (black), Co/HT13 (red), Co/HT11

(blue), Co/HT31 (magenta), Co/HT51 (violet), Co/MgO (green), Co/HT-MG70 (brown).

On the other hand, Al-rich hydrotalcites, i.e., Co/HT13 and Co/HT15 catalysts showed different

decomposition profiles. In this case, two weight losses below 160 °C and between 150 – 500 °C were

observed, with the second step characterized by a smoother curve. Taking into account the results from

XRD analysis, the first step around 150 °C in these two samples can be associated to the loss of water and

the second one to the loss of the OH- groups bonded to Al3+ in the hydrotalcite and boehmite phases, along

with the decarbonation. Finally, the TGA profile Co/MgO shows a slight first weight loss (< 150 °C)

attributed to dehydration and a marked second loss (150 - 650 °C), which could be associated to

deshydroxylation and decarbonation of nesquehonite phase (MgCO3·3H2O).