PROJECT PROPOSAL: OPTIMIZATION OF A TUNGSTEN CVD PROCESS

Heather Brown and Brian Hesse IEE 572 December 5, 2000

The tungsten chemical vapor deposition (WCVD) process has been used in the semiconductor industry for many years. WCVD is primarily used to fill interconnects such as contacts and vias. Tungsten deposition occurs according to the following reaction:

WF6 + 3H2 W + 6HF (1)

Interconnects are needed for electrical connection of different device layers that are separated by insulating layers. An example would be connecting two metal layers that are separated by an oxide layer. The tungsten fills the via or hole that links the second layer metal to the first layer metal. The objective of the process is to entirely fill the via with tungsten; otherwise the device could short when voltage is applied. In the CVD process, tungsten is applied to the wafer as a planar film and then selectively removed using chemical – mechanical polishing (CMP) so that only the plugs remain.

RECOGNITION OF AND STATEMENT OF THE PROBLEM

Recently Microchip Technology has acquired a Novellus CVD tool for applying blanket tungsten layers to be used for interconnects. The vendor calibrated the system based on a standard Novellus process flow. This standard flow is based on the WCVD performance needs of the average customer and may require changes for Microchip’s process specifications. Thus, before this CVD tool can be used in manufacturing, it is important to identify the key factors for optimized performance.

CHOICE OF FACTORS, LEVELS, AND RANGE

There are numerous different parameters that can be varied on a CVD tool, such as backside gas flow, deposition time, process pressure, flow rates, temperature, etc. It was decided that the H2 and WF6 flow rates, temperature, and via size have the greatest impact on plug fill. These factors were varied at a high and a low level as shown in Table 1. The depth of the vias will be 1200 nm. Table 1. Factor Values Factor Low High

H2 flow rate 5000 sccm 10000sccm

WF6 flow rate 100 sccm 400 sccm Temperature 400ºC 445ºC Via Size 0.2 m 0.4 m

Relative humidity, time of day the tool is operated, and operator are factors that will impact performance, but are uncontrollable and will be treated as nuisance variables. All other tool settings will be held constant at values suggested by Novellus.

SELECTION OF THE RESPONSE VARIABLE

The most important response variable that will be monitored is fill height. Conformal tungsten fill in a contact or via, in which a uniform film thickness is deposited on both the horizontal and vertical surfaces, is desirable since the purpose of the interconnect is to link metal layers. If each chip on a given wafer is to operate identically, it is necessary to have uniform plugs. Thus, a uniform layer of tungsten is needed. Incomplete or non- conformal plug filling could cause a void between metal lines. A void can then lead to high resistance and can trap chemicals in a plug during CMP, which can result in reliability problems.

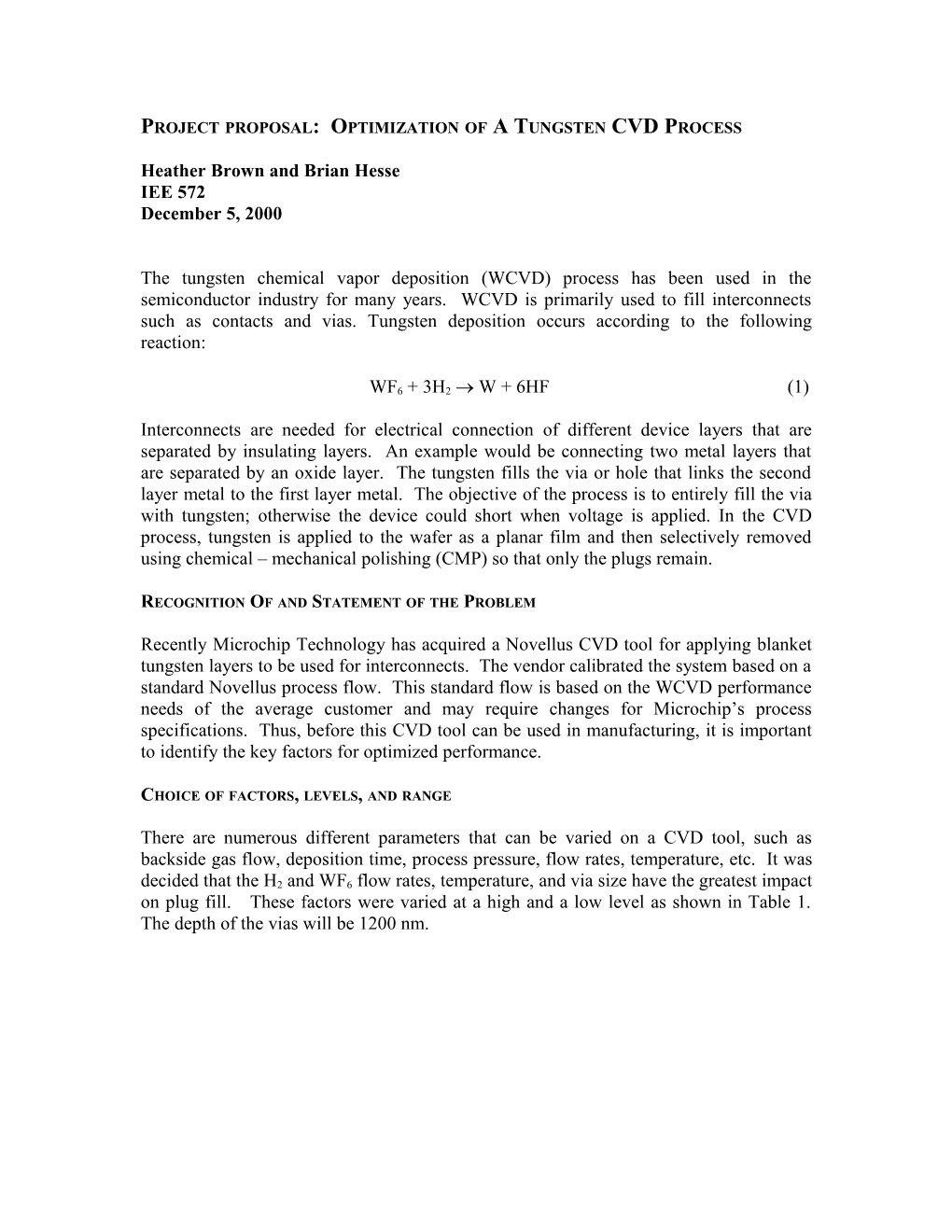

The fill height measurements are determined by cleaving the wafer and looking at plug cross-sections using a scanning electron microscope (SEM). The fill height measurements take into account the uniformity of the deposited tungsten layer in the plug. A visual representation of a plug cross-section and the concept of fill height are shown in Fig. 1.

FIGURE 1: TUNGSTEN CVD PLUG CROSS SECTIONAL VIEW CHOICE OF EXPERIMENTAL DESIGN

An optimization experiment was chosen in order to identify the key factors involved with the fill height in CVD tungsten deposition. The four factors considered in the design were H2 flow, WF6 flow, temperature, and via size. It was decided that one replicate of a full factorial would be ran due to the limited number of wafers for the experiment. If a full factorial were ran, this would only require 8 runs because each wafer will have both 0.2 and 0.4 m via sizes. If sixteen runs (and wafers) were performed with only one via size per wafer, this could create misleading results due to the wafer-to-wafer uniformity in the film. Table 2 provides the test matrix for this experiment.

Table 2: Test Matrix Run Factor 1 Factor 2 Factor 3 Factor 4 Response 1 WF6 H2 Via Size Temperature Fill Height Flowrate Flowrate ( m) (C) (nm) (sccm) (sccm) 1 500 100 0.2 400 500 1 500 100 0.4 400 757 2 1000 100 0.2 400 972 2 1000 100 0.4 400 780 3 500 400 0.2 400 1200 3 500 400 0.4 400 1053 4 1000 400 0.2 400 1200 4 1000 400 0.4 400 1200 5 500 100 0.2 445 0 5 500 100 0.4 445 0 6 1000 100 0.2 445 0 6 1000 100 0.4 445 0 7 500 400 0.2 445 1200 7 500 400 0.4 445 1200 8 1000 400 0.2 445 1200 8 1000 400 0.4 445 724

After running the proposed experiment, the effects of tungsten and hydrogen flowrates, temperature, and via size on fill height will be known. Using this information, a more precise experiment can be designed to properly optimize the factors found to be influential on the response variables.

ANALYSIS

Table 2: Fill Height ANOVA Summary Factor Effect Estimate P-value A-WF6 flowrate 373 < 0.0001 D-temperature -208.625 0.0002 AD 167.5 0.0011 One of the most important aspects of WCVD is fill height of the plug. Table 2 represents the summary of the ANOVA table that was produced from running the design in Design- Expert. The complete ANOVA table can be found in Appendix A, which after being examined, it was obvious that the WF6 flow rate and temperature were the important factors. In addition, it appears that the AD interaction is important, however, it is possible that this is due to the influence of the main effects. From the effects estimate, it is clear that increasing the WF6 flow rate has a positive effect on the fill height, where as increasing the temperature has a negative effect. The WF6 flow rate has a larger effect than temperature, and when adding the two main effects together, this gives the AD effect estimate, which confirms that the large AD effect is most likely due to the main effects.

The normal probability plot of the studentized residuals is shown in Fig. 2. Analysis of the figure by means of the fat pencil test shows that the data is indeed normal. There are slight deviations from normality, but that is expected, so the data is normal.

Figure 3 shows the half-normal plot where our previous conclusion that was drawn from the ANOVA table that WF6 flow and temperature are the most important factors is confirmed.

Figure 3: Fill height Half Normal plot Figure 2: Fill Height Normal Plot DESIGN-EXPERT PlotFill hieght

A: WF6 flowrate 99 B: H2 flowrate 99 C: Via Size D: temperature 97 95 Ha A 95 No 90 lf rm No 80 90 D al 70 rm 85 % al AD pro 50 % 80 ba 30 pro 70 bili 20 ba 60 ty bili 10 ty 40 5 20 1 0

-2.52 -1.56 -0.60 0.36 1.32 0.00 186.50 373.00 559.50 746.00

Studentized Residuals |Effect| From analysis of Fig. 4 and 5, the WF6 flow rate effect is positive and the temperature effect is negative, therefore to maximize fill height, WF6 should be run at the high level and temperature at the low level. The temperature and WF6 flow rate interaction is plotted in Fig. 6, which confirms that the fill height is maximized when the temperature is low and the WF6 flow rate is at the high level.

The residual vs. predicted plot is shown in Fig. 7. For the predicted value of zero the residual is also zero, because zero represents no plug fill. The predicted value for no plug fill is zero and the actual value of the residual is also zero. For the higher predicted values where there is variance, it appears that the residuals are randomly distributed.

The residuals were also analyzed against the different factor levels. Figures 8 and 9 show the residuals plotted versus high and low levels of temperature and WF6 flow rate. From these figures it was concluded that the value of the residual does not change based on the value of temperature or WF6 flow rate. Similar plots were analyzed for the other factors and the same conclusion was reached, but since the other factors were not significant the plots have not been included.

Conclusions

Unfortunately, this design did not yield just one optimal solution for the problem of plug fill. Two of the eight different conditions investigated gave complete fill of the 0.2 and 0.4 micron plugs. From table 2, runs 4 and 7 gave optimal solutions leaving no way to differentiate between the two different runs. Both of these runs had WF6 and H2 flow rate at the high levels, but the temperature was different. The model indicated that temperature was significant in determining fill height, however it does not appear to be true in this case. The problem here is that there is no way to determine if deeper plugs could have been filled. If the experiment had been set up with plugs deeper than 1200 nm it would have helped to determine if the high or low temperature was better. From other runs it does appear that the higher temperature is better, but that may not hold for these runs. But after analyzing the data, it would make sense to run the WCVD process conditions at the low H2 flow of 5000 sccm, the high WF6 flow of 400 sccm, and the high temperature of 445ºC (Run 7) instead of the conditions in Run 4 since running at a lower H2 flow would be more cost effective than running at a higher H2 flow at a reduced temperature.

Figure 4: WF6 effect plot Figure 5: Temperature effect plot

1242.63 1200

931.976 900

Fill height Fill height

621.317 600

310.659 300

0 0

100.00 175.00 250.00 325.00 400.00 400.00 411.25 422.50 433.75 445.00

A: WF6 flowrate D: temperature

Figure 6: Interaction Graph Fill hieght D: temperature 1333.68 X = A: WF6 flowrate Y = D: temperature

D- 400.000 957.651 D+ 445.000

Fill hie ght581.625

205.599

-170.427

100.00 175.00 250.00 325.00 400.00

A: WF6 flowrate Figure 7: Residuals vs. Predicted Figure 8: Residuals vs. temperature

3.00 3.00

St 1.50 St 1.50 ud ud ent 3 ent 3 ize ize 3 3 d 0.00 4 d 0.00 4 Re Re sid sid ual ual s s -1.50 -1.50

-3.00 -3.00

0.00 290.81 581.62 872.44 1163.25 400 408 415 423 430 438 445

Predicted temperature

Figure 9: Residuals vs. WF6 flowrate

3.00

St 1.50 ud ent 3 ize 3 d 0.00 4 Re sid ual s -1.50

-3.00

100 150 200 250 300 350 400

WF6 flowrate APPENDIX A: Fill Height

Response: Fill hieght ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean F Source Squares DF Square Value Prob > F Model 3.371E+006 31.124E+006 45.12 < 0.0001 significant A2.226E+006 12.226E+006 89.38 < 0.0001 D6.964E+005 16.964E+005 27.96 0.0002 AD4.489E+005 14.489E+005 18.03 0.0011 Residual2.989E+005 12 24904.29 Cor Total3.670E+006 15

The Model F-value of 45.12 implies the model is significant. There is only a 0.01% chance that a "Model F-Value" this large could occur due to noise.

Values of "Prob > F" less than 0.0100 indicate model terms are significant. In this case A, D, AD are significant model terms. Values greater than 0.1000 indicate the model terms are not significant. If there are many insignificant model terms (not counting those required to support hierarchy), model reduction may improve your model.

Std. Dev. 157.81 R-Squared 0.9186 Mean 749.13 Adj R-Squared 0.8982 C.V. 21.07 Pred R-Squared 0.8552 PRESS 5.313E+005 Adeq Precision 14.742

The "Pred R-Squared" of 0.8552 is in reasonable agreement with the "Adj R-Squared" of 0.8982.

"Adeq Precision" measures the signal to noise ratio. A ratio greater than 4 is desirable. Your ratio of 14.742 indicates an adequate signal. This model can be used to navigate the design space.

Coefficient Standard 99% CI 99% CI Factor Estimate DF Error Low High VIF Intercept 749.13 1 39.45 628.62 869.63 A-WF6 flowrate 373.00 1 39.45 252.49 493.51 1.00 D-temperature -208.63 1 39.45 -329.13 -88.12 1.00 AD 167.50 1 39.45 46.99 288.01 1.00

Final Equation in Terms of Coded Factors:

Fill hieght = 749.13 + 373.00* A - 208.63* D + 167.50* A * D