Metool Reeling Technical Publication

Metorq Cable Reel System in Horizontal Recovery Applications Author: Malcolm Dade

Introduction The Metool Reels Metorq reeling system is based on a dry friction drive that is technically sophisticated yet simple in use and easy to maintain. Once factory set the friction device will be ideal for many reeling applications without further need for significant maintenance or replacement of parts.

For general reeling applications the Metorq reeling system is a reliable, low cost solution to many applications where low duty cycles and less arduous reeling speeds and lifts are required.

The main consideration of any reeling system is the effect it has on cable tensions and hence cable life. This Technical Publication explains the relationship of reel torque to cable tensions and why the relationship is so important.

This Technical Publication explains the benefits of the Metorq system and why it can be used very successfully in general reeling applications.

Understanding Relationship of Cable Reel Drives and Tension in Cables To understand the benefits of the Metorq system it is important to first understand the relationship of the tensions induced in cables during the reeling cycle.

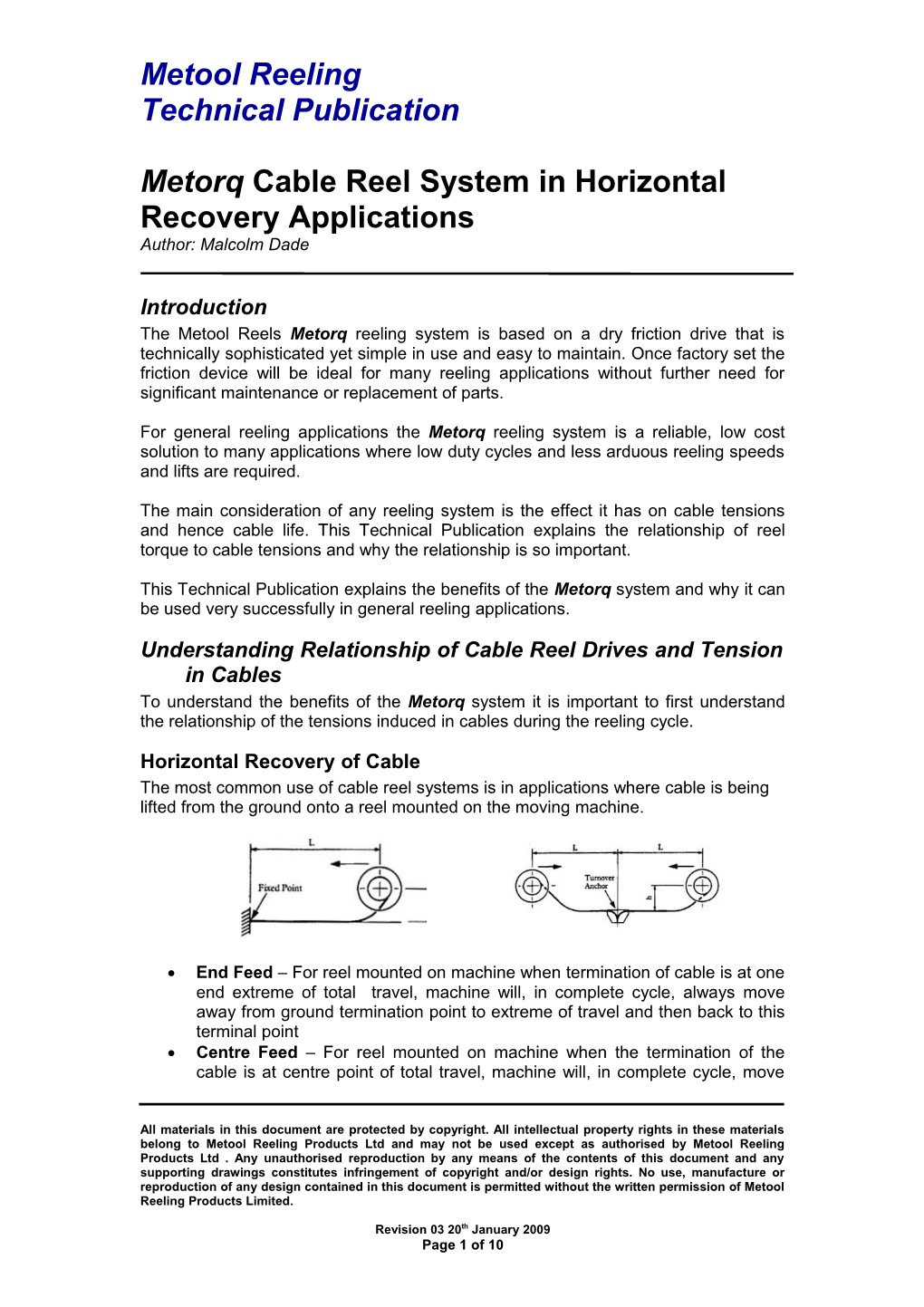

Horizontal Recovery of Cable The most common use of cable reel systems is in applications where cable is being lifted from the ground onto a reel mounted on the moving machine.

End Feed – For reel mounted on machine when termination of cable is at one end extreme of total travel, machine will, in complete cycle, always move away from ground termination point to extreme of travel and then back to this terminal point Centre Feed – For reel mounted on machine when the termination of the cable is at centre point of total travel, machine will, in complete cycle, move

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 1 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

away in one direction from centre point to extreme of travel in that direction, back to centre point, over centre point to extreme of travel in opposite direction and back to centre point

The most common application is Centre Feed and the use of the Metorq drive in this application is the basis for this Technical Publication.

Direction of Spool and Drive A very important aspect to understand is the relative directions of the spool and the motor that is used in the drive system.

Fig 1 – machine moves away from centre point o motor must allow machine to literally pull cable off the reel (unwind) o on most systems motor on the drive is usually backwound i.e. In reverse direction of normal application and acts as drag brake only thus maintaining tension (this is not how Metorq operates as is explained later) Fig 2 – machine moves towards centre point o reel must rewind the cable back onto the spool o drive function of the motor used in the drive – turning in same direction as spool

This relationship has a fundamental effect on the tension induced in cables during operation.

Reel Drives and Cable Tensions The job of a cable reel is to reel in the cable without exceeding the permissible tensions in the cable.

The cable reel must have: sufficient torque to lift the cable from the ground up to the reel overcome inertia during acceleration

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 2 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

cope with imbalance and frictional effects.

The speed of the reel is generally set at 10-15% faster than maximum speed of machine so that the cable is always under tension.

The drive system of the reel dictates the tensions in the cable. The least tension induced in the cable during the operating cycle means the operator should have longer cable life

The lifetime operating costs of the reeling system is dependent on how many times the cable has to be changed during its working life

Other cable reel manufacturers claim constant torque devices but in reality they:

Involve unreliable slipping interfaces such as magnetic coupling, wet friction device, or electrical slip in the use of a special torque motor Have some variation of torque with speed at the slipping interface which will be amplified by the gear train Have friction losses of gears, sliprings, seals

The outcome is that there is a substantial difference in the actual torque felt at the cable spool between reeling in and paying out.

The claim for constant torque therefore is only true at the drive output.

Indeed most drives are actually fixed torque - once they are set they are not variable in operation. Due to variations with speed and friction losses most exhibit higher torque at the spool on payout or backwinding. Some types of drive this can be as much as 2:1 and above.

On payout in most systems, cable has to overcome:

torque of the drive at the higher level slipring and seal friction inertia of spool and wound cable when the crane accelerates

The result is that payout tension is higher than reeling-in tension. The maximum tension is at the extreme of payout. This is a critical design factor.

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 3 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

In practice, the larger the tension is at the extreme of payout the higher the combined tensile strength of the cores of the cable needs to be.

The less tension in the cable at the extreme of travel in pay out condition, the better. It allows smaller core cables to be chosen with less tensile strength.

The minimum requirement for cable reel system is to not exceed the maximum permissible manufacturer’s design cable tension.

Metorq Drive and Cable Tensions The Metorq drive really minimises the tensions in cables through the operating cycle. It:

maintains the same stable torque on payout and pay in to minimise cable tension at all points of the cycle is a simple to understand and maintain dry friction device

Basic Reel Components The Metool Reels Metorq cable reel is a rugged and reliable drive system for many applications at an inexpensive price. It is a purely mechanical device that can be easily maintained at site.

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 4 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

Like all competitors reels there are three main components:

1. Cable Spool 2. Slipring Assembly and Slipring Assembly Mounting Frame 3. Reel Drive System

Cable Spool

Slipring Assembly Drive

Items 1 and 2 of the Metool Reels design are similar in their design and function with competitor’s designs. It is Item 3 of the Metool Reel design that is the difference..

Item 1 is the cable spool that is mounted on a flange that is attached to the output shaft of the drive. In our design above a certain size the spool is split into two semi circular sections for ease of transport and installation.

Item 2 is the slipring assembly and slipring assembly mounting frame which is selected for the application from our extensive range and are air gap designs which comply with relevant B.S, V.D.E., C.S.A. and NEMA specifications regarding minimum air gaps and creep distances and with suitable insulating spacers and brushgear are fitted in a suitably designed enclosure. It is necessary for the HV size of slipring enclosure to be supported but this is not the case for smaller enclosures for other slipring configurations.

Item 3 is where we differ from the designs of our competitors. The Metool Reel Metorq design could not be simpler.

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 5 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

Metorq Drive Components The main components of the drive are:

Single or double faced torque regulator unit with through shaft on which is mounted: o periphery directly onto torque regulator unit on one side o slipring assembly on the other side Motor - standard AC induction motor D90, D100, D112 or D132

There are three basic forms of torque regulator units – single face, double face and fixed torque all of which mount on a common gearbox. The gearbox is capable of accepting motors of D90 to D132 frame sizes. From these standard stock components twenty basic torque regulator models are available.

The power unit drives the reel through an irreversible worm and wheel transmission which is totally enclosed and lubricated for life. The reduction ratio of the gearbox is fixed and rotational speed of the output spindle is selected by choosing appropriate speed motor units. Since the motor mounts are designed to accept universally available stock motors, variations in reeling speeds are easily obtained. In all cases rotational speed of the output spindle is arranged to be in excess of that required for cable retrieval under all operating conditions. The energy dissipation capability of the torque regulator unit is greater than the energy permissible through the gearbox thus ensuring adequate safety margins are applied to the torque regulator unit.

The torque regulator employs an advanced design friction principle and the unit incorporates a unique arrangement to give stable performance during all operating conditions. A very large area of friction lining in relation to the energy dissipation ensures that an extremely long period between lining replacement. Special consideration has been given to lining renewal, if, due to a particularly high duty cycle, this ultimately becomes necessary and the complete replacement of the linings

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 6 of 10 Metorq Cable Reel System in Horizontal Recovery Applications can be accomplished by an unskilled person in less than 30 minutes. The heat dissipating arrangements employ a thermo siphon principle when the reel is in stalled condition and self induced air flow when the reel is moving

The irreversibility of the worm and wheel transmission and the stable torque characteristics of the torque regulator permit successful cable reeling on the basis of energising the motor for recovery only. The benefits of energising the rel motor for cable recovery only are not only increased friction lining life and greatly extended periods between torque correction, if that should be necessary, but, of course, massive savings on energy consumption.

The motor shaft connection to the gearbox is fitted with a backstop which prevents backwinding of the motor.

How Metorq Works in Stable Torque Mode

Principles The cable compartment is directly mounted on the torque regulator unit which is easily adjustable in output to suit the various combinations of cable size and length to be reeled. The speed differentials encountered during reeling in and out are accommodated by the torque regulator using the friction drive as a slipping interface. When engineering torque motor or fluid coupling reels it is very easily established that the inertia of the torque motor rotor or fluid coupling casings coupled with the effects of back driving relatively high reduction ratios produce massive increases in cable tensions.

The Metorq reeling system using the torque regulator unit overcomes this problem. The slipping interface of the torque regulator is positioned on the outboard shaft of the transmission thus isolating the reel from referred inertia effects.

By setting the friction in the torque regulator for reeling in and payout, the actual torque at the spool is controlled to be reasonably constant irrespective of direction.

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 7 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

Settings for Stable Torque Mode “ Stable Torque” for the Metorq drive actually defines stable torque at the spool irrespective of reeling direction. At the motor there is a variable drive torque dependent on where reel is in cycle.

The torque regulator is factory set for the calculated torque required for the reel to function correctly in operation. In practice rotational speed at the output spindle is arranged to be in excess of that required for cable retrieval which ensures correct cable retrieval under all operating conditions. A combination of this and the applied torque through the friction device ensures stable torque in the system.

In Operation in Stable Torque Mode When the machine becomes live power is made available to the motor

When the operator wishes to move the machine away from centre or end point of travel (payout):

Simple electrical controls turn OFF the motor Machine moves away pulling the cable off the reel, against the torque generated by the dry friction device so that cable tension is always maintained. Machine stops and the torque is still maintained controlling the cable by the dry friction device.

When the operator wishes to travel the machine back towards the centre or end point of travel position:

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 8 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

Simple electrical controls turn ON the motor The motor drives the output shaft through the gearbox to rotate the reel at a speed slightly in excess of the machine speed so that the cable is maintained in tension at all times. Machine stops and the torque is still maintained controlling the cable by the dry friction device.

If the reel is full of cable, the backstop prevents the motor backwinding and thus prevents cable spill.

Where can the Metorq System be Used? The Metorq reel can be used in this mode for:

Centre feed or end feed applications for horizontal recovery reeling of robust cables with spools of 3/2 design at low or medium speed Centre feed or end feed applications for horizontal recovery reeling of robust cables with spools of monospiral design at low speed and relatively low mounting height (generally less than 7 metres) Vertical lift applications

Advantages and Benefits In summary the advantages are:

Use of standard AC or DC motor as prime mover Design reduces substantially the tensions in reeled cable as against other forms of drive Range of drive units to suit various sizes and lengths of cables to be reeled Reduced overall size as compared with other reels Can be fitted with flameproof or marine specification motors Brake is a function of the design

The benefits are:

Low cost, short lead time, no replacement problems Can reel smaller cables with longer life thus showing lifetime cost savings No chain drives and thus less maintenance Can be used in hazardous areas and shipboard

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 9 of 10 Metorq Cable Reel System in Horizontal Recovery Applications

Supplied System

Cable Reel The Metorq drive system is supplied factory set for operation. The friction force of the liners to the disc is preset and the unit is bedded in on our test unit. A final check is made by our engineers at site following installation during commissioning phase. Once set the unit can be expect to require only minimal maintenance for most applications.

Roller Guides There will be a requirement for a roller guide dependent on the application and height of mounting:

Twin Directional Roller Guide for centre feed applications Single Directional Roller Guide for end feed applications

Cable Anchors A turnover anchor will be required for centre feed applications:

Cable Clamp generally for low and medium voltage cables Cable Grip for HV cables

Other Equipment Required with Metorq Because the Metorq system is a mechanical system it is important that these controls are fitted:

Travel Limit Switch Payout Sensor for Centre Feed Applications Over Tension Under Tension

Conclusion Using the Metorq drive system the client can expect a simple mechanical system that can be corrected and maintained by non specialist maintenance personnel. In most applications there is a minimal need for maintenance. Metorq is a reliable system for very many straightforward reeling applications that is kind to cables especially in hazardous and difficult conditions such as bulk handling of coal, iron ore and other mineral works and storage areas.

All materials in this document are protected by copyright. All intellectual property rights in these materials belong to Metool Reeling Products Ltd and may not be used except as authorised by Metool Reeling Products Ltd . Any unauthorised reproduction by any means of the contents of this document and any supporting drawings constitutes infringement of copyright and/or design rights. No use, manufacture or reproduction of any design contained in this document is permitted without the written permission of Metool Reeling Products Limited.

Revision 03 20th January 2009 Page 10 of 10