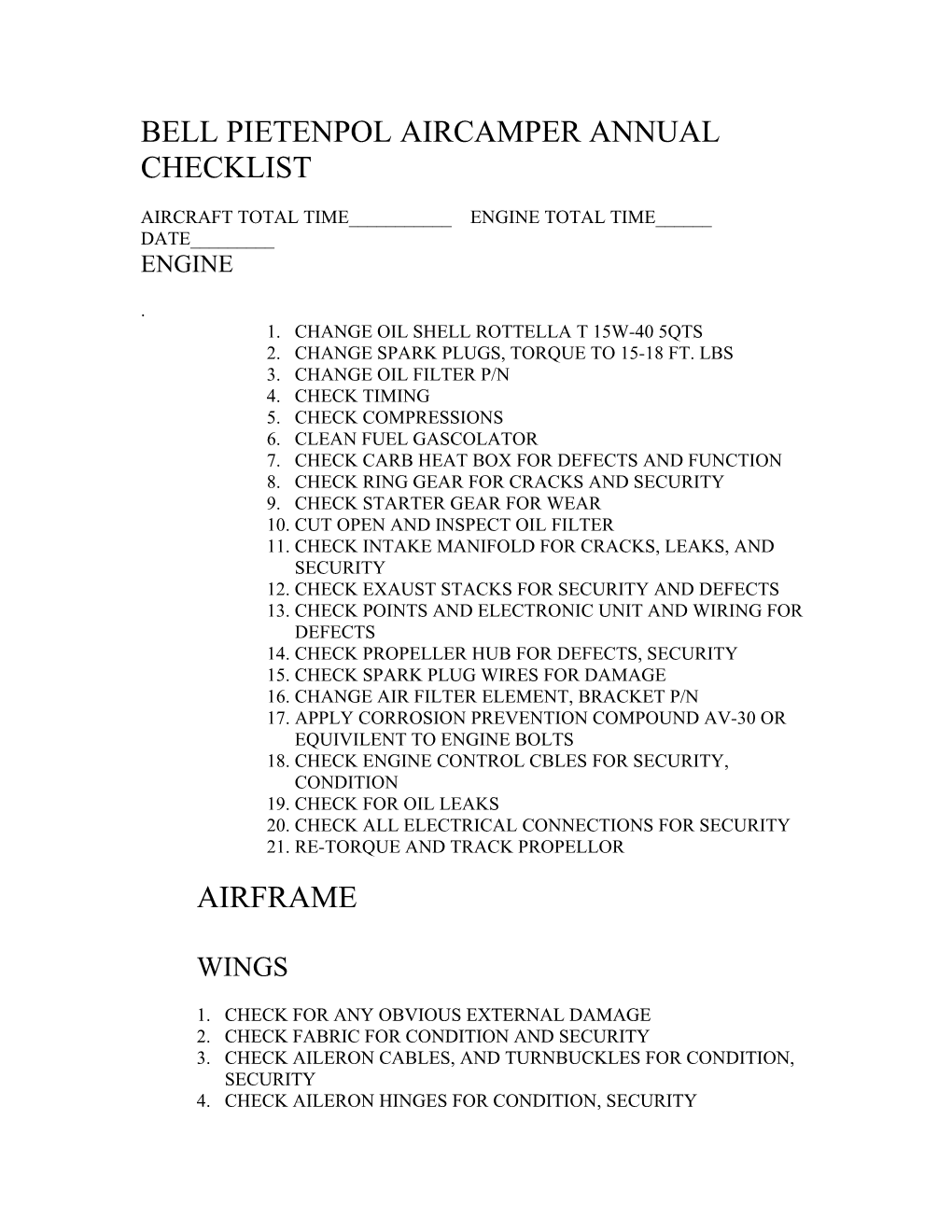

BELL PIETENPOL AIRCAMPER ANNUAL CHECKLIST

AIRCRAFT TOTAL TIME______ENGINE TOTAL TIME______DATE______ENGINE

. 1. CHANGE OIL SHELL ROTTELLA T 15W-40 5QTS 2. CHANGE SPARK PLUGS, TORQUE TO 15-18 FT. LBS 3. CHANGE OIL FILTER P/N 4. CHECK TIMING 5. CHECK COMPRESSIONS 6. CLEAN FUEL GASCOLATOR 7. CHECK CARB HEAT BOX FOR DEFECTS AND FUNCTION 8. CHECK RING GEAR FOR CRACKS AND SECURITY 9. CHECK STARTER GEAR FOR WEAR 10. CUT OPEN AND INSPECT OIL FILTER 11. CHECK INTAKE MANIFOLD FOR CRACKS, LEAKS, AND SECURITY 12. CHECK EXAUST STACKS FOR SECURITY AND DEFECTS 13. CHECK POINTS AND ELECTRONIC UNIT AND WIRING FOR DEFECTS 14. CHECK PROPELLER HUB FOR DEFECTS, SECURITY 15. CHECK SPARK PLUG WIRES FOR DAMAGE 16. CHANGE AIR FILTER ELEMENT, BRACKET P/N 17. APPLY CORROSION PREVENTION COMPOUND AV-30 OR EQUIVILENT TO ENGINE BOLTS 18. CHECK ENGINE CONTROL CBLES FOR SECURITY, CONDITION 19. CHECK FOR OIL LEAKS 20. CHECK ALL ELECTRICAL CONNECTIONS FOR SECURITY 21. RE-TORQUE AND TRACK PROPELLOR AIRFRAME

WINGS

1. CHECK FOR ANY OBVIOUS EXTERNAL DAMAGE 2. CHECK FABRIC FOR CONDITION AND SECURITY 3. CHECK AILERON CABLES, AND TURNBUCKLES FOR CONDITION, SECURITY 4. CHECK AILERON HINGES FOR CONDITION, SECURITY 5. CHECK SECURITY OF RADIO ANTENNAS 6. CHECK LIFT STRUTS FOR CONDITION, SECURITY, CORROSION 7. CHECK CROSS BRACE WIRES FOR SECURITY, CONDITION, ADJUSTMENT 8. CHECK ALL WING FITTINGS FOR CONDITION, SECURITY 9. CHECK SPARS FOR CRACKS, DAMAGE, CONDITION OF VARNISH 10. CHECK PULLYS FOR CONDITION, SECURITY, OBSTRUCTIONS 11. LUBRICATE PULLYS 12. CHECK INSIDE OF WING FOR MOUSE NESTS ETC.

FUSELAGE

1. CHECK FOR OBVIOUS EXTERNAL DAMAGE 2. CHECK FABRIC FOR SECURITY, DAMAGE 3. CHECK LANDING GEAR BOLTS FOR CONDITION, SECURITY 4. CHECK TAILWHEEL BUSHINGS FOR WEAR 5. CHECK TAILWHEEL ARM FOR CONDITION, SECURITY 6. CHECK TAILWHEEL CABLES FOR CONDITION, SECURITY 7. CHECK WHEELS FOR CONDITION 8. CLEAN AND REPACK WHEEL BEARINGS WITH MOBILE 28 GREESE 9. CHECK BRAKE DRUMS, AND PADS FOR CONDITION, WEAR, ANDCONTAMINATION 10. CHECK BRAKE CABLES FOR CONDITION, ADJUSTMENT, AND SECURITY 11. CHECK ALL LANDING GEAR TUBES FOR CONDITION 12. CHECK LANDING GEAR BUNGEES FOR CONDITION 13. CHECK SAFTEY CABLES ON LANDING GEAR 14. CHECK, AND CLEAN BUNGEE COVERS, REINSTALL 15. CHECK INSIDE STRUCTURE FOR CONDITION, PAY ATTENTION TO AREAS WITH OIL CONTAMINATION 16. CHECK ENGINE MOUNT FITTINGS FOR CONDITION 17. CHECK CABANE FITTINGS FOR CONDITION, HARDWARE SECURITY 18. CHECK CONTROL STICKS FOR CONDITION, SECURITY 19. CHECK RUDDER PEDALS FOR SECURITY, CONDITION 20. CHECK ALL CONTROLL CABLES FOR CONDITION 21. CHECK ELEVATOR BELL CRANK BEHIND SEAT FOR CONDITION, SECURITY 22. CHECK ELT FOR OPERATION AND BATTERY EXPIRATON DATE 23. CHECK INSURMENTS FOR CONDITION, SECURITY, MARKINGS 24. CHECK PRIMER, AND PLUMBING FOR CONDITION, AND SECURITY, LEAKS 25. CHECK ALL WIRING FORE CONDITION, SECURITY 26. CHECK PITOT STATIC LINES FOR CONDITION, CONTAMINATION, AND SECURITY 27. CHECK FOR REGISTRATION, AIRWORTHINESS, AND WEIGHT AND BALANCE PAPERWORK 28. VACUME OUT ALL DEBRIS IN COCKPIT AREA 29. WIPE ALL OIL OFF BELLY AND FIREWALL 30. WASH ENTIRE AIRCRAFT 31. CHECK ALL INSPECTION PANELS ARE INSTALLED

EMPENAGE

1. CHECK FABRIC FOR CONDITION, SECURITY 2. CHECK ALL TAIL BRACE CABLES FOR CONDITION, SECURITY 3. CHECK ALL HINGES FOR CONDITION, SECURITY POST INSPECTION

1. PERFORM ENGINE RUNS FOR TIMING CHECKS, OIL LEAK CHECKS, STATIC RPM, AND VIBRATIONS. 2. REINSTALL COWLING 3. PERFORM LOCAL TEST FLIGHT AFTER ANNUAL CONDITION INSPECTION IS SIGNED OFF IN LOG BOOK

ANNUAL CONDITION INSPECTION COMPLETE THIS DATE ______, HOBBS METER______

COMPLETED BY ______