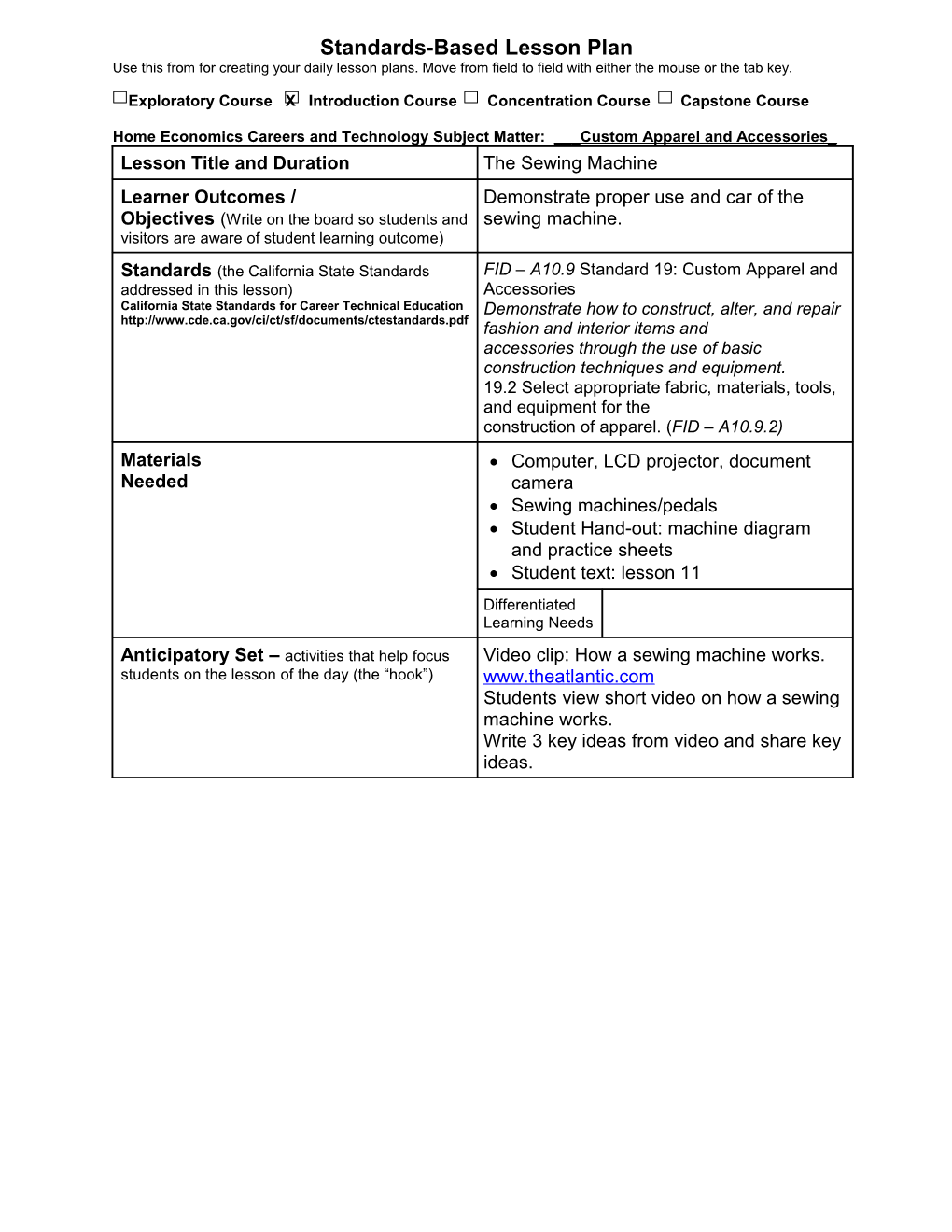

Standards-Based Lesson Plan Use this from for creating your daily lesson plans. Move from field to field with either the mouse or the tab key.

Exploratory Course X Introduction Course Concentration Course Capstone Course

Home Economics Careers and Technology Subject Matter: ___Custom Apparel and Accessories_ Lesson Title and Duration The Sewing Machine Learner Outcomes / Demonstrate proper use and car of the Objectives (Write on the board so students and sewing machine. visitors are aware of student learning outcome)

Standards (the California State Standards FID – A10.9 Standard 19: Custom Apparel and addressed in this lesson) Accessories California State Standards for Career Technical Education Demonstrate how to construct, alter, and repair http://www.cde.ca.gov/ci/ct/sf/documents/ctestandards.pdf fashion and interior items and accessories through the use of basic construction techniques and equipment. 19.2 Select appropriate fabric, materials, tools, and equipment for the construction of apparel. (FID – A10.9.2) Materials Computer, LCD projector, document Needed camera Sewing machines/pedals Student Hand-out: machine diagram and practice sheets Student text: lesson 11 Differentiated Learning Needs

Anticipatory Set – activities that help focus Video clip: How a sewing machine works. students on the lesson of the day (the “hook”) www.theatlantic.com Students view short video on how a sewing machine works. Write 3 key ideas from video and share key ideas. Teaching the Lesson 1. Use document camera to identify sewing machine parts and functions. Modeling – how will you demonstrate Students write and label key part on the skill or competency? machine diagram. 2. Explain a general overview of how the Instructional Strategies – how will you sewing machine works, pointing out the deliver the lesson? key parts involved. 3. Demonstrate how to set the stitch Check for Understanding – how will you ensure the skill or competency is settings. Students will set the stitch understood by the students? selector, stitch length control and stitch width control and tension dial. 4. Demonstrate the key part of the machine. Student will place their hands on key parts, referring to their diagram as needed. Have students move the parts and describe what they do. For Example: the hand wheel – instruct student to move it toward them and describe the other parts of the machine they move. Key parts: 1 Hand wheel 5 Feed dog 2 Take-up lever 6 Presser foot 3 Needle 7 Presser foot lever 4 Throat plate 8 Foot Control 5. Food Control – speed control. Have students practice controlling the speed of the machine and maintain an even speed. 6. Remove and replace parts: needle, presser foot, bobbin.

Differentiated Learning Needs Guided Practice / Students touch/move machine parts as you Monitoring – an activity directly supervised by call out parts. Observe correct hand the instructor that allows students to demonstrate placement on machine. grasp of new learning. Instructor moves around the room determining the level of mastery and providing individual remediation as needed. Differentiated Work with a partner and Learning Needs touch parts together

Closure – Statements or actions made by the The sewing machine requires proper instructor that help students make sense out of operation, using a sequence of settings and what has just been taught, to help form a coherent proper movement of parts. picture, to eliminate confusion and frustration, and to reinforce major points to be learned. Independent Student use lined paper and paper sheets Practice – a question or problem for students to with printed path to “sew”. Place sheet in ponder on their own or in small groups or pairs. machine, using proper parts to raise The aim is to reinforce and extend the learning needle, lower presser food and hand wheel. beyond the lesson and ideally into real world settings. This may be a homework assignment. Sew “on the lines” using presser foot to maintain even speed control.

Differentiated Learning Needs Summarize, 1. Create a “Top 10” list of 10 key machine Evaluate & Reflect – after teaching the parts and their function. lesson, ask students to reflect on their learning. 2. Describe the importance of maintaining Instructors can also reflect on the lesson, its even speed control when sewing. success, and how it can be improved.