SECTION C. PROJECT DESCRIPTION

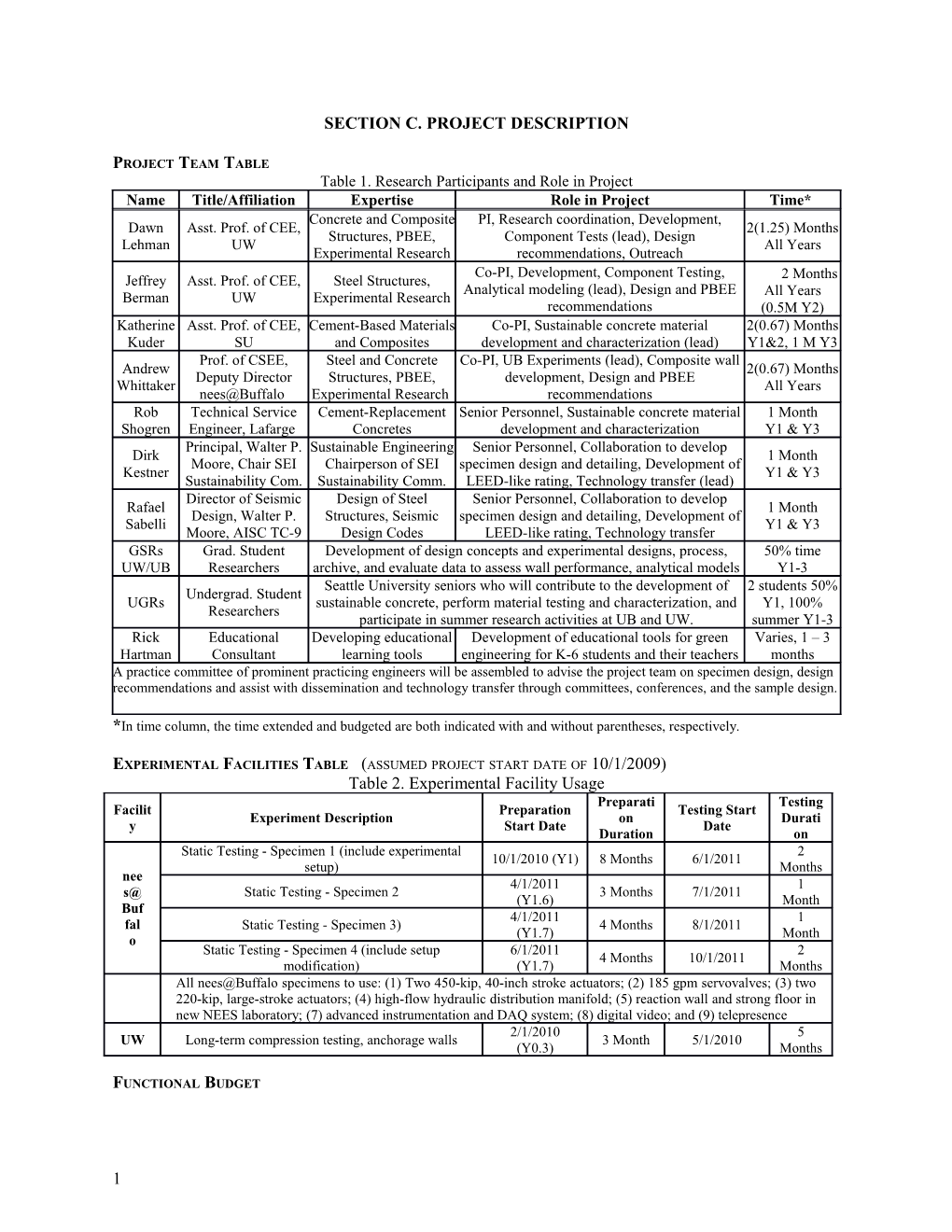

PROJECT TEAM TABLE Table 1. Research Participants and Role in Project Name Title/Affiliation Expertise Role in Project Time* Concrete and Composite PI, Research coordination, Development, Dawn Asst. Prof. of CEE, 2(1.25) Months Structures, PBEE, Component Tests (lead), Design Lehman UW All Years Experimental Research recommendations, Outreach Co-PI, Development, Component Testing, Jeffrey Asst. Prof. of CEE, Steel Structures, 2 Months Analytical modeling (lead), Design and PBEE Berman UW Experimental Research All Years recommendations (0.5M Y2) Katherine Asst. Prof. of CEE, Cement-Based Materials Co-PI, Sustainable concrete material 2(0.67) Months Kuder SU and Composites development and characterization (lead) Y1&2, 1 M Y3 Prof. of CSEE, Steel and Concrete Co-PI, UB Experiments (lead), Composite wall Andrew 2(0.67) Months Deputy Director Structures, PBEE, development, Design and PBEE Whittaker All Years nees@Buffalo Experimental Research recommendations Rob Technical Service Cement-Replacement Senior Personnel, Sustainable concrete material 1 Month Shogren Engineer, Lafarge Concretes development and characterization Y1 & Y3 Principal, Walter P. Sustainable Engineering Senior Personnel, Collaboration to develop Dirk 1 Month Moore, Chair SEI Chairperson of SEI specimen design and detailing, Development of Kestner Y1 & Y3 Sustainability Com. Sustainability Comm. LEED-like rating, Technology transfer (lead) Director of Seismic Design of Steel Senior Personnel, Collaboration to develop Rafael 1 Month Design, Walter P. Structures, Seismic specimen design and detailing, Development of Sabelli Y1 & Y3 Moore, AISC TC-9 Design Codes LEED-like rating, Technology transfer GSRs Grad. Student Development of design concepts and experimental designs, process, 50% time UW/UB Researchers archive, and evaluate data to assess wall performance, analytical models Y1-3 Seattle University seniors who will contribute to the development of 2 students 50% Undergrad. Student UGRs sustainable concrete, perform material testing and characterization, and Y1, 100% Researchers participate in summer research activities at UB and UW. summer Y1-3 Rick Educational Developing educational Development of educational tools for green Varies, 1 – 3 Hartman Consultant learning tools engineering for K-6 students and their teachers months A practice committee of prominent practicing engineers will be assembled to advise the project team on specimen design, design recommendations and assist with dissemination and technology transfer through committees, conferences, and the sample design.

*In time column, the time extended and budgeted are both indicated with and without parentheses, respectively.

EXPERIMENTAL FACILITIES TABLE (ASSUMED PROJECT START DATE OF 10/1/2009) Table 2. Experimental Facility Usage Preparati Testing Facilit Preparation Testing Start Experiment Description on Durati y Start Date Date Duration on Static Testing - Specimen 1 (include experimental 2 10/1/2010 (Y1) 8 Months 6/1/2011 setup) Months nee 4/1/2011 1 s@ Static Testing - Specimen 2 3 Months 7/1/2011 (Y1.6) Month Buf 4/1/2011 1 fal Static Testing - Specimen 3) 4 Months 8/1/2011 (Y1.7) Month o Static Testing - Specimen 4 (include setup 6/1/2011 2 4 Months 10/1/2011 modification) (Y1.7) Months All nees@Buffalo specimens to use: (1) Two 450-kip, 40-inch stroke actuators; (2) 185 gpm servovalves; (3) two 220-kip, large-stroke actuators; (4) high-flow hydraulic distribution manifold; (5) reaction wall and strong floor in new NEES laboratory; (7) advanced instrumentation and DAQ system; (8) digital video; and (9) telepresence 2/1/2010 5 UW Long-term compression testing, anchorage walls 3 Month 5/1/2010 (Y0.3) Months

FUNCTIONAL BUDGET

1 Table 3 shows the functional budget and Figure 1 illustrates the distribution of funding to the various project activities. As shown, the vast majority of the project funding is dedicated to the experimental activities at nees@Buffalo.

Table 3. Functional Budget Catego Y1 Y2 Y3 Amount % ry Resear $385,918 $378,989 $275,239 $1,040,146 86.9 ch nees@ $222,794 $225,713 $156,003 $604,510 50.5 UB UW $81,312 $100,836 $0 $182,148 15.2 SU $66,524 $31,380 $1,000 $98,904 8.3 Disposa $0 $0 $6,340 $6,340 0.5 l Other $15,288 $21,059 $111,896 $148,244 12.4 Data $0 $3,864 $36,875 $40,738 3.4 EOT $5,215 $5,364 $62,587 $73,166 6.1 Mang $8,395 $11,644 $22,964 $43,004 3.6 mnt Total $399,529 $399,861 $397,665 $1,197,055 100.0

SUMMARY OF PROPOSAL PREPARATION DISCUSSION WITH NEES@BUFFALO EQUIPMENT SITE This proposal was a collaborative effort developed by the investigators over the course of the past four months. Professor Whittaker, Deputy Director of the nees@Buffalo Equipment Site, discussed the scope and detail of the UB testing program with UB Site Operations Manager Tom Albrechcinski, Technical Services Manager Mark Pitman and IT Manager Goran Josipovic in early 2009. Mr. Albrechcinski provided costs for materials, specimen fabrication and specimen disposal that were used to prepare the budget for the UB test specimens.

VISION Meeting tomorrow’s challenge of reducing the environmental impact of engineered structures means needing to do more than taking existing structural framing systems and forcing them into LEED or other related environmental certification requirements. It means reimagining structural systems to be inclusive of the current and future engineering challenges with an eye towards the environment. Although reducing environmental impact is just part of the sustainability solution, it is important in and of itself. The project’s vision is to promote environmental stewardship in structural engineering in three ways: (1) by minimizing material use, eliminating unnecessary materials, and using recycled materials, (2) minimizing the carbon footprint, and (3) optimizing constructability.

Performance-based earthquake engineering (PBEE) also serves to promote environmental stewardship. Today it is common for a developer of a “green” building to make significant initial investments in high performance mechanical building envelope systems to reduce the environmental impacts associated with energy use of the building’s life. It is also common for mechanical engineers to perform energy analyses, which exceed the minimum code requirements. Code-based structural design, which uses prescriptive details and likely excessive materials, will not protect this expensive investment from the full-range of seismic demands; a more performance-based approach is needed. A structural system developed to minimize the environmental impact and simultaneously minimize seismic damage to itself and its contents is truly green in the eyes of the earthquake engineer.

An innovative composite wall system, shown in Figure 2, is proposed to meet these combined objectives. The wall comprises a recycled steel shell with end caps. The concrete fill is a self-consolidating concrete (SCC) containing (90-100%) supplemental cementitious materials (SCM). Staggered, embedded steel

2 studs are attached to the steel shell to engage composite action and restrain local buckling (see cutout in Figure 2). With respect to the seismic and environmental performance objectives, the proposed system: Maximizes the use of recycled materials including steel and SCM concrete. Minimizes the carbon footprint with SCM concrete. Optimizes the constructability by using stiffened steel skin plates that act as stay-in-place formwork and reinforcement for the wall, and SCC to reduce labor associated with concrete placement. Possesses exceptional seismic performance by limiting foundation damage and local buckling. Use of SCM concrete presents an engineering challenge, as the cure time to full strength is far longer than that of convention concrete. A composite system, with its permanent formwork, provides an elegant engineering solution by sustaining construction and other loads via the studded steel skin plates.

A research project with coordinated material and structural experimental, analytical and integrated practical technology development and transfer tasks is proposed. Each has theoretical significance, coordination with other research tasks, and contribution to practice. The material study will be conducted by researchers from Seattle University (SU), a primarily undergraduate institution, and is aimed at evaluating and modeling the SCM concrete. The SCM material, developed by the SU research team, will be utilized in the wall and tested to assess the immediate and time-dependent response at the University of Washington; the anchorage detail will also be explored experimentally. These results will culminate in the large-scale testing of the walls to generate experimental and performance data to develop much-needed engineering models for composite wall design and their connections. These results will be combined with and extended by numerical studies. Finally, the team will partner will leaders in sustainability in structural engineering from Walter P. Moore to lay the foundation for PBEE tools and to develop sample building designs to compare the environmental impact and seismic performance of the proposed and conventional systems. Future advances in the system design may include its use in precast construction, which will further improve construction efficiency and reduce carbon footprints, and expand the green seismic construction into heavy civil and nuclear infrastructure.

LITERATURE REVIEW The research impetus for developing engineering methods for sustainable composite walls are twofold: 1) to improve the performance of conventional reinforced concrete walls, one of the most commonly used seismic resisting system in current construction, and 2) to develop a system that meets the objectives of sustainability. However, a primary obstacle in achieving this system is the lack of research on the seismic behavior of composite walls and cement-replacement concretes. The literature review presented below addresses: the shortfalls of the seismic response of reinforced concrete walls, the possible improvements offered by composite walls and the data lacking to support these hypotheses, and the limited data on the engineering and time-dependent properties of SCM concretes.

Reinforced Concrete Walls Reinforced concrete walls are stiff and strong and are a commonly used seismic resisting system. Although earthquake damage has been observed in walled buildings, as indicated in 3(a), generally they have been deemed to perform well and they are commonly used the primary lateral load resisting system (Wallace and Moehle 1993). As such there has been a keen interest in the structural engineering community to improve understanding of the earthquake response of walls and numerous research studies have been undertaken. A more recent example of a wall test is a specimen tested by Adebar and his associates intended to simulate a seven-story wall (Adebar et al. 2007) in which a single actuator was used to simulate the full lateral load and the demands in the lower levels are not modeled. The damage

3 sustained by the wall is shown in Figure 3(b) and do not clearly correspond to the post-earthquake observations. In contrast, there are the results of the NEES research program studying the seismic performance of walls (Figure 3c). Use of the LBCB equipment at the NEES MUST-SIM facility has permitted more accurate simulation of the loading demands from the upper stories and the advanced controller has permitted multiple actuators to be used to simulate floor-shearing (inertial) loads. As a result, as shown in 3c, the laboratory damage pattern more closely agrees with that observed in the field for midrise buildings. The figure shows the damage concentrates at the base of the wall, limiting the drift capacity to between 1% and 1.5%, which falls well short of the codified drift limit.

Beyond these seismic response limitations, reinforced concrete walls have numerous issues regarding constructability and environmental impact. In seismic design, the reinforcing detailing requirements are extensive and the construction of the cage is tedious (Figure 4) and time-consuming; a result of the anchorage and confinement requirements. A tour of recent high-rise construction in Seattle and Bellevue, WA shows that the majority of these buildings have been constructed with reinforced concrete core walls as the lateral load resisting system. As Mehta (2009) notes, the carbon footprint of the concrete industry is large and the emission of CO2 is largely attributed to the production of Portland cement. Replacing a commonly used yet mediocre and complicated framing system with a seismically improved and environmentally friendlier system is a logical place to start to meet the structural engineering challenges facing today’s professional engineer.

Steel-Concrete Composite Walls Relative to reinforced concrete walls, composite walls greatly simplify the construction process. Composite walls have begun to be used in construction outside of the United States. For example, Corus, the UK steel producer, has developed a product called CoreFast to use steel panels connected by a series of welded steel bars filled with concrete. Originally developed as a blast-resistant system, the system has been used in multi-unit residential construction (Gough and Grubb 2007) and design recommendations are available from the manufacturer with behavior limited to elastic response. According to the company literature, the primary benefits of the system are the expedited construction time and reduced material use.

The enhanced constructability may have an even larger impact on the constructability of the structural walls in seismic regions, which is evident when comparing the panels with the cage construction shown in Figure 4. However, composite walls have not been used in seismic construction, in part because there has been limited research on the seismic performance of composite shear walls. AISC 341-05 (AISC 2005) contains limited seismic design requirements for composite shear walls. The steel plate(s) are designed to carry the design shear, neglecting any contribution of the concrete, and specific compressive and flexural composite design expressions are not provided.

Without experimental data development of even simple design expressions is not possible. Prior research has included steel-concrete-steel sandwich double skin panels (Zhao and Han 2006) and double-skin

4 composite elements (Wright et al. 1991). Although these investigations did result in some design recommendations, the experiments were not focused on cyclic behavior. Other research has focused on the details and response of the composite panels, which are related to but not directly applicable to the composite walls addressed here. For example, Hossain and Wright (2004) investigated profiled connection details for double skin composite shear walls to improve the buckling strength and reduce stiffener requirements, resulting in basic design equations for elastic shear strength response. Liang et al. (2004) analytically investigated double skin composite plates to study the local buckling of steel plates under combined biaxial compression and shear. The composite infill wall systems subjected to seismic loading studied by Zhao and Asteneh (2004) does indicate promise of ability to sustain large drift ratios, but the system differed from composite walls in that boundary-frame elements were present. A current research project on composite walls, conducted by Professor Kreger (work undergoing) at Purdue University and sponsored by the Pankow Foundation, represents a first-step towards understanding the behavior of the seismic response of these systems and an important collaborator if this project is funded.

The literature suggests that composite walls hold promise for seismic engineering but need additional to ensure that they are capable of sustaining multiple, inelastic drift cycles. Robust connection details between the concrete and steel are needed. Equally important is the connection between the composite wall and the adjacent components, in particular the foundation elements. This deficiency is common and noted in many areas of composite component research (Roeder et al. 2002). Although different approaches have been researched (e.g., Hajjar 2002, Fujikura et al. 2008, Morino et al. 2003 and Azizinamini and Schneider 2004), most use complicated details with large connection components and excessive welding requirements. Researchers at the University of Washington have developed a simple yet effective connection for CFT columns using an annular ring welded to the base of the tube as shown in Figure 5 and an anchorage depth of one column diameter (Kingsley et al. 2005). The experimental results show the specimen is capable of reaching drift ratios of 4 to 6% without damage and sustaining drifts exceeding 8%. Of course, the technology is not directly applicable to walls, as circular CFT have a different distribution of normal stresses around the circumference of the steel tube, symmetric and large confining pressures, and a larger footing-to-cross-sectional area ratio for columns than walls. However, the concepts and technologies of the research findings are relevant and their application and adaption is discussed in the research program.

Cement-Replacement Concrete Portland cement is a hydraulic cement that, when combined with water, undergoes a chemical reaction in which calcium silicate hydrate (cementitious gel) and calcium hydroxide (lime) are produced. Calcium silicate hydrate is the glue that holds all the constituent materials together and contributes to the strength and durability of the composite. Lime is a deleterious component that can cause expansive behavior. Supplementary cementitious materials (SCMs) are a form of mineral admixtures that are often used in an effort to develop sustainable concrete mixes (Malhotra 2006). SCMs are generally waste materials, such as fly ash, silica fume and slag that have cement-like qualities and are typically used to partially replace cement. Use of SCMs is becoming increasingly popular to produce sustainable concrete because it reduces the amount of cement needed, thereby reducing the CO 2 emissions that occur during cement production, and utilizes waste that would otherwise be land-filled and reduces cost. SCMs possess hydraulic and/or pozzolanic reactivity. SCMs with hydraulic reactivity can react with water without the presence of a hydraulic component, similar to the self-cementing behavior of Portland cement. In the presence of water, a pozzolan will react with the calcium hydroxide released from the hydration reaction to form additional calcium silicate hydrate, thus improving strength and durability. Pozzolanic reactions occur more slowly than hydraulic reactions, causing a delayed time of set and slower strength development.

5 Minimizing the amount of Portland cement in concrete is a key aspect of minimizing the carbon footprint in construction (Stevenson and Panian 2009). For example, a recently constructed reinforced concrete building in northern California attempted to achieve this objective by using concretes with both 50% and 70% cement-replacement. However, the authors report challenges with using concretes with large cement-replacement values including strength gain and finishing. Where overcoming these obstacles in reinforced concrete construction is difficult at best, composite construction naturally lends itself to the use of even higher cement-replacement concretes, as the rate of strength gain and finishing are not critical engineering or construction parameters. Therefore, the composite wall is a solution for improving sustainability in seismic engineering practice.

Research Program Justification A primary future focus of the building industry nowadays is improving environmental stewardship, which is generally quantified with LEED credits. Although structural engineering has largely been sidelined from this enterprise, forward-looking structural engineering firms, research laboratories, and the SEI committee on sustainability are looking at strategies to use optimal amounts of recycled materials and materials with minimal environmental impact for new construction, building systems that can be reused and recycled and new building construction with reduced long-term landfill mass and carbon footprint.

Materials that are deemed “green” are most easily LEED credited. The most commonly LEED-termed green material are SCM concretes, however SCM concretes are difficult to use in structural engineering applications with key challenges stemming from the rate of curing and finishing (Stevenson and Panian 2009). As a result, SCM concretes are not used extensively and building framing systems are not playing a role in environmental stewardship. The framing system proposed herein is different. The shortcomings of SCM concretes are overcome here by placing it within a permanent steel skin system with key benefits including a) SCM concrete strengthening over an extended timeframe without the need for formwork, and b) faster floor-to-floor cycle times because the steel skins can resist construction gravity loads. Importantly, the SCM will delay local buckling of the steel skins through the anchorage of the skins to the concrete with studs.

Theorizing about a practical system and developing it into a viable framing system are quite different and a significant amount of work is needed to realize the latter. Analysis and theory alone are not sufficient. A robust experimental program and associated numerical simulations are needed to substantiate these new systems and materials and to characterize a framing system suitable for inclusion in a building codes and standards such as the International Building Code (ICC 2006) and ASCE-7 (ASCE 2005), respectively.

Research Plan A compelling research program is proposed here and is illustrated in Figure 6. The research program uses appropriate laboratory facilities, existing equipment, and experimental and technical expertise for each of the three testing programs proposed. As such, the facilities, personnel, and equipment were selected with thought and purpose. The figure lays out the research tasks. The timeline is provided at the left of the figure. For each task, the tasks objective, lead personnel, principal outcome, and interaction with other task are indicated. The illustration within each task provides a visual clue as to its aim. UW and SU student involvement with the nees@Buffalo tests is illustrated with airplanes, as travel is required. At the bottom of the figure the primary technical and the EOT outcomes are listed. The following paragraph provides an overview of the research plan. Specifics about each task, its schedule, objective, staffing, research methods to be used, and anticipated outcomes are described in the individual task subsections.

6 The research project utilizes an integrated team of researchers with expertise in material, concrete, steel, and composite testing in partnership with industry leaders in sustainable structural engineering to develop, test, extend, validate, and disseminate an innovative, recycled composite wall system for seismic engineering. The developmental phase of the project will be a team effort to brainstorm, refine and finalize transformative yet practical design and detailing concepts for the wall system (Task 1). In parallel, the material testing will be conducted at Seattle University and LaFarge Cement using their combined cemetitious testing equipment to demonstrate that the high-strength 100% SCM concrete is practical and to support the development of the time-dependent design and constitutive models (Task 2). In support of the detailing concepts and material tests, component tests will be conducted at the University of Washington using the 2.4-million pound Universal Testing Machine to evaluate the construction and other long-term response of parts of the composite walls (Task 3). The wall system tests, conducted at nees@Buffalo, will utilize the large capacities of the actuators, reaction floor and walls as well as experimental equipment developed for PI Whittaker’s Squat Wall NEES research project (Task

7 4). These capabilities, together with the expertise that PI Whittaker brings to the proposal makes nees@Buffalo the NEES site to select for large-scale testing of this innovative wall system. Task 5 will use numerical simulation models to both predict the experimental response (to aid in the set up) and validate the measurements to extend the study to lay the groundwork for PBEE and other design methods. Finally, the results will be distilled into a sample design to compare the seismic, construction and environmental efficiencies of the proposed framing system and its conventional counterpart (Task 6).

Task 1 (All): Development of Practical Design and Detailing Concepts for Wall and SCM Concrete The proposed system uses new materials, designs, details, and construction methods to achieve the dual

Task 2 Task 1 (All): Task 3 (Lehman): (Kuder/Shogren): Develop Design, Anchorage and Time- SCM Concrete Mix and Detailing Dependent Loading Concepts Outcomes: Year 1 Innovative and 10/09- Practical Designs 9/10 and Details Outcomes: Outcomes: High Cement Recommended Replacement Concrete Anchorage Details, Time- Mixes, Properties, and Task 4 (Whittaker): Dependent Compressive Models Full-Scale Experiments Response at NEES@Buffalo SU UW Graduate Undergraduate Student to UB Year 2 Students to UB 10/10- 9/11 Task 5 (Berman): Task 6 Analytical (Kestner/Sabelli): Models/Design & Sample Building PBEE Tools Designs

Outcomes: Rich Unique Data Sets on Composite Year 3 Wall Behavior 10/11- 9/12 Outcomes: Outcomes: Sample Modeling & Design Designs, Performance Recommendations, Trial and CO2 Comparisons Fragility Curves with RC Walls

PRODUCTS • Rich, First of Their Kind Data Sets on Composite Walls • Innovative, “Green” Seismic Force Resisting System • Initial Performance Based Earthquake Eng. Recommendations • Sample Building Designs for Dissemination to Practice • EOT FOCUS: K-12: Engineered Recycled Materials Ed. Modules • EOT FOCUS: Transfer via SEI/ACI Committees • Dissemination at Conferences and Graduate Course Content objectives of mitigating seismic damage and environmental impact. Of course, throughout the development of the proposal, the project team has brainstormed and solidified ideas on each aspect of the project, and those results are presented throughout the proposal. Task 1 will serve to further the

8 development of the proposed concepts and solicit input from all involved on the: (i) modified mix designs for the high-strength SCM concrete, (ii) wall cross sections details with a particular focus on the end cap, (iii) stiffening, confining, and bond details for the steel skin plates, (iv) anchorage connections, and (v) practical construction and fabrication methods.

To successfully achieve this idea-generating task, the entire team must be engaged. Professor Lehman will facilitate the task, with Mr. Sabelli and Mr. Kestner of Walter P. Moore taking the lead on the design concepts and Dr. Shogren taking the lead on the SCM concrete design. These men are leaders in their respective fields and will guide the research team to ensure that the details of the proposed system are developed to meet the present and future needs of the practicing engineers who will implement this system. By informing the research team on the state-of-practice with regard to the environmental impacts of current structural systems, strategies implemented to minimize those impacts, and alternative strategies that are not presently implemented and note the barriers preventing implementation, the practicing engineers will help shape the details and design methods of the proposed system. Input from other practicing engineers that will serve on the practice committee will also be solicited. This will ensure that the system properly addresses environmental objectives while maintaining constructability.

This task, and this project, represents an ambitious goal to achieve in a short time. Here the time constraint will be managed using Web-Ex based meetings, which was successful for the team during the proposal development. The task will be initiated as the project commences, and carried out over the first four months. The task products include the design (including concrete and structure) and detailing concepts for testing, evaluation, validation, and dissemination throughout the remaining tasks.

Task 2 (Kuder (lead)/Shogren): Characterizations of High-Replacement SCM Concrete This work will focus on the use of slag and Class-C fly ash to produce an environmentally sustainable, self consolidating concrete (SCC) mix design in which most, if not all, of the Portland cement is replaced. Typically, slag demonstrates more hydraulic reactivity than Class C fly ash, resulting in earlier strength gains (Gesoligu and Ozbay 2007). However, Class C fly ash has more pozzolanic properties, which could contribute to superior strength and durability long-term (Naik et al. 2005 and Yazici 2008). In addition to single SCM replacement mixes, binary and ternary mixes will be evaluated in an attempt to optimize the performance of the SCMs. Table 4 provides some of the first-of-its-kind data on high-replacement SCM concrete, in this case with a target strength of 3,000 psi. As indicated in the table, the impact of the SCM on the early strength is quite substantial and cannot be ignored in the design or in construction, as echoed by (Stevenson and Panian 2009). Here, the objective is to further this by developing mix designs to achieve a target strength of 6000 psi, which in line with modern concrete material requirements. The partnering of PI Kuder and Dr. Shogren is the best way to achieve the task. This partnership is enhanced by the generosity of Lafarge North America, who has assured donation of all concrete to the project.

Table 4. 3000-psi Target CR Concrete Mix Designs (Lafarge and Central Pre-mix Concrete Data) % Cement % Slag 7-day (psi) 14-day (psi) 28-day (psi) 10 90 2710 4500 5950 5 95 2280 3670 4740 0 100 1650 2900 3950

Five test categories are proposed; the specific references and duration are provided in Table 5. Task 2.1 evaluates the material properties of the SCMs, including chemical composition and particle size distribution. A variety of slag and Class C fly ashes will be tested, since SCMs can vary greatly based on the plants and operating conditions from which they originate. The workability (Slump flow, L-box, V- funnel) of the SCC mixes will be evaluated to study placement and setting behavior. Compressive strength and elastic modulus of the concrete mixes will be measured at 7, 14 and 28 days and then at 28-

9 day increments up to one year to establish the time-dependent mechanical properties, which is of central importance to Tasks 3 and 4 and the project as a whole. At the same time as Tasks 2.2 and 2.3 are underway, free and restrained shrinkage tests will be performed to evaluate the durability of the mixes. Once promising mixes have been identified, Task 2.5 will be conducted in which the effect of the mix designs on formwork pressure will be evaluated. The rheology of the mixes will be modified as needed to increase the thixotropy, which reduces formwork pressure (Assad et al. 2003 and Assad 2004).

Table 5. SCM Concrete Test Matrix Test Category Experimental Methods/References Duration SCM characterization ASTM C618 & ASTM C989 2 months Fresh state properties European Glne for SCC & ASTM C403 12 months Mechanical properties ASTM C39 & ASTM C469 12 months Durability ASTM C157, ASSHTO T160 & M PP34 12 months Rheology – formwork pressure 4 months

The task results and data will be used to develop time-dependant engineering expressions for the mechanical properties, as warranted, and to modify commonly used concrete constitutive relations to account for the time-dependencies so important in SCM concretes.

Task 3 (Lehman (lead)/Berman) Anchorage, Time-Dependent Tests on Walls with Recycled Materials Development of a new system requires substantial understanding of the connections and as-built response during and just after construction. In this system, two practical issues must be addressed in conjunction with the system response testing (Task 4): Task 3.1: Anchorage details for the connection of the walls to the foundation. As noted in the literature review, without validated connection details, use of any seismic component in actual construction cannot be realized. Here, development of a simple yet robust connection able to sustain the seismic demand and maximize energy dissipation is the goal.

Task 3.2: Behavior under immediate and longer loads. Use of SCM concrete is a challenge, in part because of the extended cure time. Although not a specific issue for seismic response, the immediate and short-term mechanical properties of the concrete and composite wall must be known to ensure stability during and after construction. This task focuses on these variables.

These experiments are basic and do not require use of, and would not represent optimized use of, a NEES facility. Instead the structural engineering laboratory at UW is used to permit the experiments to be conducted in parallel. As shown in the functional budget, the Task 3 experiments represent 15% of the total budget and 17% of the experimental costs.

Task 3.1: Wall-to-Foundation Anchorage Connection The primary design objective for the anchorage connection is that it be able to develop the moment strength of the composite wall, and therefore the tensile capacity of the steel. Simple, yet innovative anchorage details will be considered for the critical interface between the concrete foundation and the double skin shear wall. The details will draw on PI Lehman’s extensive experience in developing anchorage connections for composite structural members and use available structural members, such as staggered angles, to ensure adequate embedment and pullout resistance without creating a plane of weakness. Flange connections have been found to work well in CFT (Figure 3) and can also reduce required anchorage lengths relative to stud connections in foundations that are congested with reinforcing steel. To avoid creating a plane of weakness, the depth of the flanges within the concrete foundation will be varied along the wall’s length.

Figure 7 shows an anchorage test. Each specimen consists of a partial-width of a composite wall embedded into foundation. The test matrix will evaluate the influence of: (1) studs, (2) debonding, and (3)

10 anchorage depth, on response. The results will be used to generate connection design recommendations and to complete the design of the specimens for the large-scale experiments at nees@Buffalo (Task 4).

Task 3.2: Time-Dependent Compressive Response The time-dependent compressive behavior of the composite wall system must be understood prior to field implementation. To investigate this, the 2.4-million pound universal testing machine (UTM) in the SEL at UW will be used (Figure 8). A half-scale (or larger) wall specimen will be constructed under the UTM and filled with the selected SCM concrete mix. Although long-term properties of the selected mix will be determined in Task 1, it is important to study the behavior of the composite system as a whole, and to study the changes in formwork pressure with time. Strain gages on the steel skin plates will be used to monitor formwork pressure and compressive stress in the skin plates throughout the pouring curing and loading stages. The specimen will be loaded with increasing compression loads representing the addition of construction loads. To simulate application of gravity loads to the wall in a building, the compression force will not be directly applied to the wall specimen; instead the wall will be loading in through shear-tab connections that are welded to the exterior of the plate, as shown in Figure 8. Axial deformation, skin plate strains, and changes in formwork pressure will be carefully monitored by a combination of strain gauges and a non-contact optical displacement measurement system. This testing is critical if this system is to be used in practice as one of the reasons practitioners are reluctant to use high-replacement SCM concrete is the slow gain of compressive strength.

Task 4 (Whittaker (lead)/Lehman/Berman): Large-Scale Wall Tests at nees@Buffalo The scope of the experimental program was prepared after the research team reviewed the literature and to realize the project vision. The scope of this project will build on that of co-PI Lehman and Professor Lowes who have focused on conventional reinforced concrete flexure-critical (tall) walls in their NEESR project (Brown et al. 2006, and Lehman et al. 2008) and that of co-PI Whittaker who is addressing the behavior of conventional reinforced concrete squat (shear-critical) walls. Specifically, Task 4 will provide robust thesis-oriented data for each Ph.D. student involving both physical and numerical simulation and enable meaningful participation of undergraduate students (from Seattle University). The specific objectives for this task are: 1. Generate large-scale test data to examine and describe the response of rectangular, recycled-material composite walls to cyclic lateral loading. 2. Provide a substantial body of performance data (numerical and visual) to: a. Validate the detailed design models to be used in the numerical simulation tasks of the project. b. Enable development of teaching tools to involve undergraduate students in research and development of curriculum modules in the curriculum development portion of this project. c. Enable the PIs and other researchers, via the NEES Data Repository, to develop efficient demand parameters, fragility curves and loss-related acceptance criteria for double skin composite walls. 3. Engage the students from UW and SU in all aspects of the testing. Form student teams at UW, SU and UB, led by the Ph.D. students at UW. Assign students meaningful tasks that go beyond lab-tech work on strain gauging: make them responsible for video data and Krytpon or Lieca 3D laser data

11 acquisition systems, the synchronization of these measurements with the conventional measurements, the interpretation of this data and the presentation of their findings at appropriate forums. 4. Engage Mr. Sabelli, Mr. Kestner, and other advisory engineers from practice in specimen design decisions. Introduce practicing engineers to NEES and involve them in tele-participation activities through the project web site and WebEx teleconferences. 5. Exercise key aspects and equipment of the nees@Buffalo Site with demanding testing activities. 6. Disseminate the results using the project web site, the resources of NEES Inc, and the appropriate ACI and AISC materials committees

This phase of the project will be conducted at the nees@Buffalo Equipment site under the supervision of co-PI Whittaker. Four large-scale specimens will be tested with preliminary dimensions of 8-in. thick and 10-20 feet high (depending on specimen), 0.25-in. steel skin thickness and specified concrete strength of 6000 psi. Study parameters include (1) aspect ratio, (2) stud spacing and geometry (Figure 3) and (3) axial load ratio. Specific values and details have been preliminarily developed by the project team and include comparison with both tall and squat reinforced concrete walls. Stud spacings will be varied to evaluate conservative design expressions based only on plate buckling equations, to evaluate expressions based solely on concrete damage prevention, to evaluate economically-driven spacings. The stud lengths and head dimensions will be determined in consideration of gaining full anchorage while minimizing local concrete damage. These discussions will take place during and the test matrix will result from Task 1.

Figure 9 shows the proposed test set-up at the nees@Buffalo Equipment Sites using NEES actuators (see Table 2). The loading system proposed for the squat wall NEESR tests at UB will be used to test the composite walls. A separate system will be used to impose axial load. The multi-dof controllers available at the nees@Buffalo site can control multiple horizontal actuators to simultaneously impose lateral loads. Lateral restraint will be provided at one end of each specimen so that coupled with the horizontal actuators, the specimens will displace in plane.

Measurements and photographs will be taken to mark the progression of damage during the test. After each test the specimens will be taken out of the test setup for further documentation of observed damage. Failure surfaces will be carefully documented, and materials sampled to establish as- built properties. The specimens will be disposed of following the relevant environmental protection practices and protocols established at nees@Buffalo. The cost of specimen disposal is included in the budget. To the best of our knowledge, the specimens tested in this task will be the only walls of this type tested in the world to date. Equally important, they will be the largest composite wall specimens tested to date. The resulting data, which will be archived and curated by the Ph.D. students at UB and UW will enable the development and validation of robust numerical tools as described in Task 5. These validated numerical tools will substantially expand the scope of the testing program described above to consider alternate aspect ratios, steel skin thicknesses, and concrete strengths, in a most cost-effective manner.

Task 5 (Berman (lead)/Lehman/Whittaker): Analytical Models for Wall Behavior and Engineering The number of wall parameters studied in the experimental program is limited due to the high cost and necessity of large-scale testing. The objectives of this task are to: Recommend methods of modeling composite wall systems for structural design.

12 Develop basic design recommendations by exploring parameters beyond the scope of the experimental study.

Develop damage states and preliminary fragility curves for use in performance based design and implementation in the ATC-58 framework.

The first phase will consist of modeling the nees@Buffalo experiments. Several different software packages will be used, including packages common in research settings (Abaqus, VecTor, and OpenSees) and those common in design (CSI Perform). The concrete constitutive models developed in Task 2 will be used. For VecTor and OpenSees analyses, the steel plates will be treated as external smeared reinforcement. For Abaqus analyses, a more detailed treatment of the exterior skin plates will be permitted, allowing plate local buckling to be investigated. The rich experimental data will be used to develop and validate the models.

The validated models will be used to conduct limited parametric studies to evaluate the impact of important design parameters such as wall aspect ratio, the equivalent reinforcing steel of the steel plate skins, wall thickness, material properties and axial load ratio. The results of the analyses will be the generation of fragility curves for damage states observed in the testing.

Calibration of analytical models for use in design (e.g., CSI Perform models) will be developed and validated using the procedure described above in partnership with Mr. Kestner and Mr. Sabelli from Walter P Moore (WPM), as well as others on the post-award selected advisory committee. The results of these Perform analyses combined with the test results will form the basis of design and modeling expressions and methods for composite wall systems.

Task 6 (Kestner, Sabelli from WPM): Sample Building Designs and Performance Comparison To validate the system and disseminate the results to a wide body of practicing engineers, the engineers from Walter P. Moore will develop sample building designs for the composite wall system using recycled materials and conventional reinforced concrete walls. These sample building designs will demonstrate the practicality, seismic performance, and reduced environmental impact of this innovative composite shear wall system, and these enhancements will be more clearly illustrated when compared with a conventional wall system. Once complete, the information will be disseminated through committees including the SEI Committee on Sustainability, AISC committees, and presentations and publications.

Walter P. Moore (WPM) will use Building Information Modeling to compare the resulting structural material quantities with a conventional concrete wall system. Environmental impact will be estimated based on two current sustainability rating systems and the overall reduction in environmental impacts, likely quantified as CO2 emissions. Additionally, the reduction in embodied impacts in terms of tangible units such as transportation and energy consumption will also be quantified. WPM has extensive experience in quantifying the environmental impact of projects and Mr. Kestner is an expert in this area.

Seismic performance will be assessed using nonlinear response-history analysis in CSI Perform using the modeling techniques developed in Task 5 for composite walls. Based on the damage states and fragility curves developed in Task 5, estimates of wall repair costs subject to design ground motions will be made and compared with results for traditional reinforced concrete walls. Some consideration for performance of nonstructural components, as estimated by peak drifts, will be made.

Expected Outcomes The primary outcome of this project is a system that minimizes its environmental impact while achieving exceptional seismic performance. As part of achieving this comprehensive objective, there are important research findings and products that will be developed along the research trajectory. These are the specific outcomes of each research tasks, illustrated in figure 6, and highlighted below.

13 Task 1 will result in designs and details for the composite wall system that are practical, efficient, and likely to have robust seismic response. Task 2 on developing and characterizing the 100% (or nearly) cement-replacement concrete will result in expressions for the time-dependant engineering properties of these materials and will be used to modify current concrete constitutive models.

Task 3, aimed in part at developing and validating constructible anchorage details for composite walls, will result in experimentally-verified design expressions for connecting composite walls to foundation elements. This is a critical yet missing component of the seismic design procedure for these systems and this outcome should move the composite structural wall system forward in its application to seismic design.

The primary outcome of Task 4 will be test results on and data from large-scale composite walls that use recycled materials, maximize constructability and enhance seismic performance.

Task 5 will use the results of Tasks 3 and 4 to validate an analytical model of the tested walls and extend these results using the validated model. This effort will result in validated design and analysis methods for practice, preliminary fragility curves will lay the foundation to establish PBEE tools for this system, and an initial recommendation for practical nonlinear analysis models.

Task 6 will produce a set of sample composite wall designs and compare their seismic performance and environmental impact with conventional walls for dissemination.

Education, Outreach, and Technology Transfer Activities The educational, outreach and technology-transfer (EOT) activities affiliated with this proposal include conventional activities including education of graduate and undergraduate students (Tasks 2, 3, 4 and 5), outreach and technology transfer to the practicing and academic engineering communities. For the students at Seattle University, a primary educational objective, voiced by Professor Kuder, is broadening their exposure to the research process, which is achieved through their integral participation in the research activities at UW and nees@Buffalo (Tasks 3 and 4). One of the limitations of multi-institutional research teams is difficulty in integrating and uniformly understanding research progress, challenges, and findings throughout the program; this educational transfer activity will be achieved through weekly or bi- weekly WebEx conference calls facilitated by the faculty but with the discussion organized, led, and carried out by the student(s).

Outreach and technology-transfer to the academic and practicing engineering communities will be achieved through presentations and publication of the research results at engineering firms, technical conferences, and conferences of interested engineering societies (Tasks 5 and 6). Task 6 specifically addresses the transfer of the engineering, analysis, and design technology through the development of sample building designs, including an environmental impact assessment. To ensure these activities come to fruition, funding for travel and consulting for Mr. Kestner and Sabelli is specifically in place. This sample building designs will go beyond a traditional seismic example comparison. A Building Information Model will be develop and used to assess the environmental impact of the proposed system to a conventional reinforced concrete wall, and will include quantification of CO 2 emissions, transportation, energy consumption, as well as material and construction related metrics.

As noted by the National Academy of Engineering, engaging young people in engineering is critical to increasing the number and quality of future engineers. To that end, a specific and unique EOT activity, specifically, the development of a K-12 educational learning module on engineering with recycled materials is proposed. This effort is lead by Rick Hartman, a leader in the development of educational toys for enrichment and learning (see Mr. Hartman’s bio for additional information), who will work in collaboration with PIs Lehman and Berman and their graduate students on this activity. Specifically, Mr.

14 Hartman will develop, field test and disseminate a series of engaging hands-on projects for K-8 students that emphasize the science, excitement, and challenges of designing structures for earthquakes while remaining “green”. Using a variety and mixture of recycled, “green”, and conventional building materials, Mr. Hartman will produce a prototype workshop and companion video that teach students how to construct their own fun and surprising toys that demonstrate important concepts about engineering structures for earthquakes while challenging them to consider its impact on the environment. Mr. Hartman will offer live presentations of his workshop to schools and museums. His tools will be made available so that teachers and parents may conduct their own workshops based on the projects developed.

Data Archiving and Sharing Plan This project will adhere to the requirements of the NEESinc Data Sharing and Archiving Policies and Guidelines and to newer requirements established by the NEES operations awardee. Raw data from the shared use experiments will be uploaded within 24 hours of the test where possible. All appropriate documentation will be provided within the framework of the NEES repository. Interpreted data will be uploaded in a reasonable time, after interpretations are made and discussed with the project team to ensure accuracy of results. Full data release to the public will be performed in adherence with the NEES requirements and any new requirements of the NEES operations awardee. As noted in the functional budget, there are significant funds dedicated to the archiving and curating of the data. Those funds will support time for students and researchers to organize, document, and upload the data. Findings will also be disseminated at conferences, including the NEES Annual Meetings, and through journal publications.

Payload Opportunities Sample opportunities for payload projects are listed below. Development of advanced sensor concepts for damage detection in composite wall systems. Development of novel anchorage connection details. Further development and validation of hybrid testing algorithms for stiff structural systems.

Project Implementation Plan

Project Management Plan and Organizational Chart A multi-institutional research project such as this one needs careful consideration of the management of the research activities, researcher interaction, and technology and information transfer. As shown in Figure 10, the project has participants from the west (SU and UW), the south (WPM), and the east (UB). With an ambitious project such as this, it is not possible with the time allotted to solely depend on travel to accomplish these objectives. Instead, we must turn to technology. The project will be managed by PI Lehman and she will facilitate the realization of these important activities. Most importantly, we will use conference calls and when appropriate Web-Ex, in particular for the design development and research exchange that must happen. As indicated in Figure 6, each PI is the lead on a specific task, and they will assume the managerial and other administrative responsibilities for that tasks, including (if appropriate) support and advising of graduate and undergraduate students, design of all aspects of test or analysis program, including ensuring accurate data reduction and analysis, and posting data to NEES Central. Travel is allotted to enable transfer of research technology within the project team and to the practicing engineering community. Funds for SU and UW students to participate in the nees@Buffalo testing are included and these students will be under the supervision of PI Whittaker during their stay, as indicated in the chart.

Project Web Site The project team will develop a website that will be hosted on UW web servers and will prove an important resource for project team members and interested parties alike. The website will provide information regarding current project activities, results, schedules. For the project team, the website will serve to facilitate access to NEES central; for outsiders NEES Central links will be provided data viewing and live experimental observation. The EOT products will be posted as they become available.

15 Project Risk Mitigation Plan and Schedule are included in the supplementary documents.

Results from Prior NSF Support Project Title: NEESR-SG: Seismic Behavior, Simulation and Design of Complex Wall Systems NSF Award Number: CMS-0421577 Amount/Period of Support: $1,537,000 10/2004 – 9/2008-2009 Principal Investigator: L. Lowes, with co-PIs D. Lehman (UW), D. Kuchma (UIUC), J. Zhang (UCLA) Summary of the Results: The research seeks to improve understanding of the seismic performance of reinforced concrete walls with complex configurations. Results include stiffness- and damage- prediction models for use by practicing engineers and an analytical and experimental investigation of code-compliant coupled-walls. Development of Human Resources: At Universities of Washington and Illinois, two students have completed MS degrees and five are currently working towards MS degrees. At the Universities of Illinois and California, two students are working towards PhDs. Also several undergraduate students are gaining research experience. Publications: Papers have been published and presented at conferences. Two papers are in preparation.

Project Title: NEESR-SG: Smart and Resilient Steel Plate Shear Walls for Reducing Earthquake Impacts NSF Award Number: CMMI- 0830294 Amount/Period of Support: $1,531,077.00 10/2008 – 9/2012 Principal Investigator: J. Berman w/L. Lowes (UW), M. Bruneau (SUNY Buffalo), T. Okazaki (UMinn) Summary of the Results: The research seeks to develop a new lateral-load resisting system combining self-centering moment frame technology with steel plate shear technology and is also investigating key issues that are barriers to steel plate shear wall implementation. Results to date include characterization of column demands in steel plate shear walls and development of analytical models for the resilient shear wall system. Development of Human Resources: At UW and SUNY-Buffalo, a total of 2 PhD students and 2 MS students are supported. Three undergraduate students from Seattle University have been participating. Publications: One journal paper from the project is under review.

Project Title: NEESR-II: Sidesway Collapse of Deteriorating Structural Systems NSF Award Number: CMS-0421551 Amount/Period of Support: $449,320; 10/2004 – 9/2008 Principal Investigator: PI H. Krawinkler (Stanford University), co-PI A. Whittaker (UB) Summary of the Results: The completed research project involved integrated numerical and experimental studies of steel moment frame structures from elastic behavior to collapse. Two models of four-story structures were tested on a NEES earthquake simulator at UB in 2007. A comprehensive database of experimental information has been assembled and used to propose hysteretic models for steel moment frame construction. Numerical models have been implemented in OpenSees to trace the response of the tested frames through collapse. Development of Human Resources: One student at Stanford University (Dr. D. Lignos) completed his PhD degree in 2008. Undergraduate students at UB worked on the research project in 2007 and 2008. Publications: Conference papers have been presented. One journal paper has been submitted.

16