WHITE - BRONZE PLATING PROCESS UNIBRONZE 830

PHYSICAL PROPERTIES: UNIBRONZE BZ 831: Light yellowish Liquid.

DESCRIPTION:

UNIBRONZE 830 produces brilliant, stainless steel-coloured, ductile bronze deposits with good levelling. The process has a highly corrosion resistance and can be used as a substitute for nickel plating (where nickel is prohibited). Deposits over 10 my can easily be achieved. UNIBRONZE 830 is highly suitable as an interim deposit prior rhodium-, silver-, or goldplating. Additionally, the absence of pores provided by UNIBRONZE 830 is superior to that of nickel deposits, nor do any allergies arise, which can be the case with nickel (jewellery). UNIBRONZE 830 can be plated directly onto copper or brass.

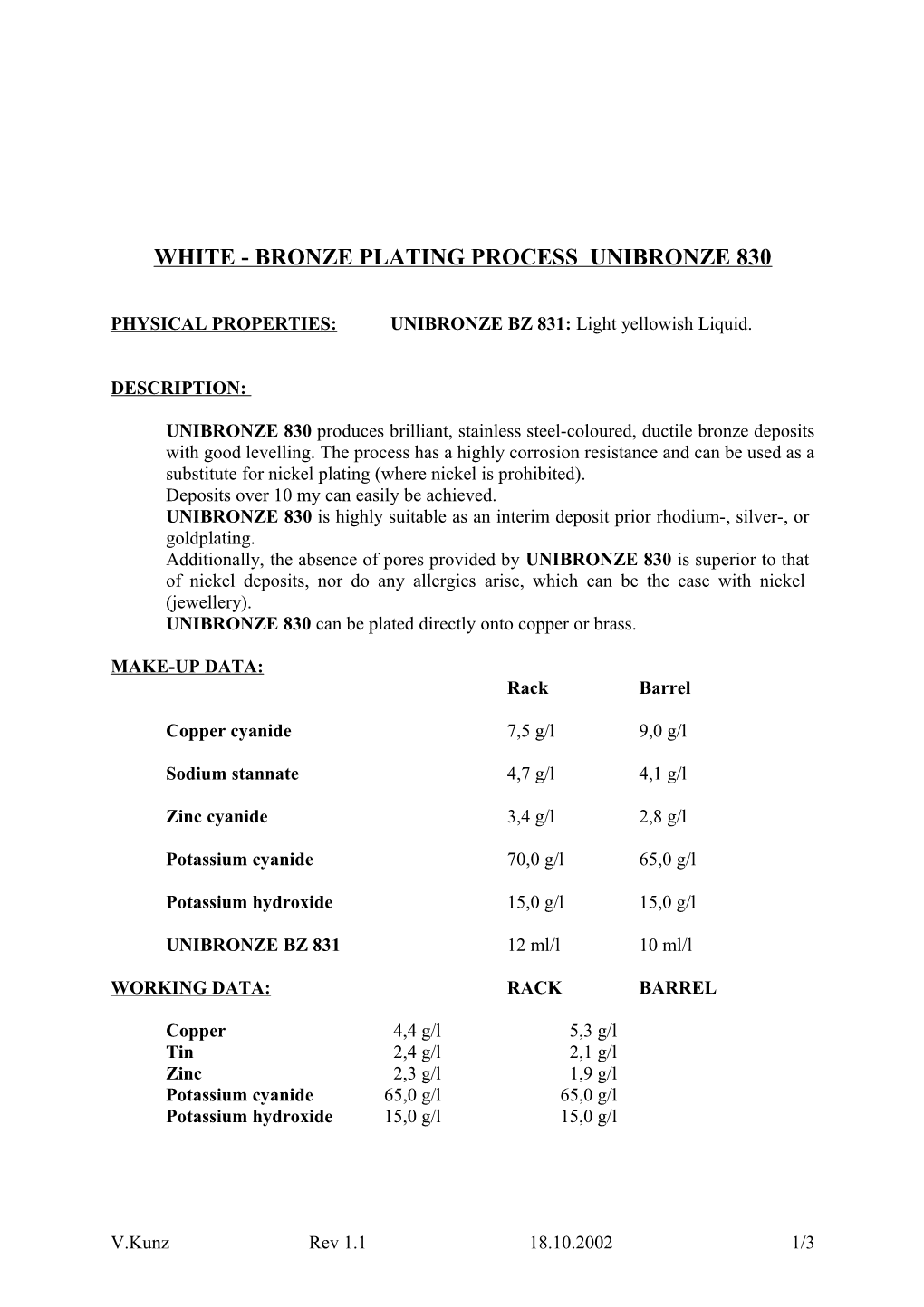

MAKE-UP DATA: Rack Barrel

Copper cyanide 7,5 g/l 9,0 g/l

Sodium stannate 4,7 g/l 4,1 g/l

Zinc cyanide 3,4 g/l 2,8 g/l

Potassium cyanide 70,0 g/l 65,0 g/l

Potassium hydroxide 15,0 g/l 15,0 g/l

UNIBRONZE BZ 831 12 ml/l 10 ml/l

WORKING DATA: RACK BARREL

Copper 4,4 g/l 5,3 g/l Tin 2,4 g/l 2,1 g/l Zinc 2,3 g/l 1,9 g/l Potassium cyanide 65,0 g/l 65,0 g/l Potassium hydroxide 15,0 g/l 15,0 g/l

V.Kunz Rev 1.1 18.10.2002 1/3 OPERATING CONDITIONS:

Current Density, cath. 1,0 A/dm² 0,7 A/dm²

Current Density, anod. 1,5 A/dm² 1,5 A/dm²

pH-Value 11-13 11-13

Temperature 62° C 65° C

Thickness Appr. 14 mg per A-min. Appr. 1 my in 6 min. at 1 A/dm²

CONSUMPTION:

The consumption of the UNIBRONZE 831 is appr. 2 - 4 l /10.000 Ah.

EQUIPMENT:

Tanks: Non-pigmented and temperature stabilized polypropylene.

Filtration: Constant. 1 - 5 micron woven polypropylene cartridges must be used.

Heating: Tanks must be equipped with alkaline resistant heating facilities to keep the temperature at 60° C.

Power supply: 6 V DC stabilized supply, with infinitely variable control and an ampere-minute meter.

Agitation: Regular agitation of the cathodes, moderate speed, filter pump.

Anodes: Graphite.

GENERAL INFORMATION:

To insure a trouble-free operation, it is mandatory to maintain the plating solution within the recommended analysis values.

Should the tin concentration drop below its optimum value Sodiumstannate should be added. An addition of 2,5 g/l will raise the tin content by 1 g/l.

V.Kunz Rev 1.1 18.10.2002 2/3 Should the copper concentration drop below its optimum value CuCN should be added. An addition of 1,4 g/l CuCN, mixed with 2,1 g/l KCN, that it is soluble, will raise the copper content by 1 g/l.

1 g of CuCN will lower the potassium cyanide content by 1,8 g/l.

The pH-value can be increased with pure, prediluted potassium hydroxide.

The pH-value can be lowered with pure, highly diluted phosphoric acid.

SPECIAL INFORMATION:

Deposit:

Composition: 55 - 60% Copper, 22 - 25% Tin, 16 - 19% Zinc.

Description: Bright deposits with low porosity and good wear and corrosion resistance.

If deposits turn milky, 0,1 - 0,5 ml/l UNIBRONZE BZ 831 should be added.

Problems are easily reproducible and corrected in the Hull-Cell at 1 A for 5 minutes and 60° C.

SAFETY PRECAUTIONS: see Material Safety Data Sheet

GUARANTEE:

Above instructions and recommendations are the result of intensive testing and shop experiences. They are for your information, only. Our guarantee extends to the continuous quality of our products as they leave our factory and not to their useage in the field, which is a factor beyond the control of a supplier.

V.Kunz Rev 1.1 18.10.2002 3/3