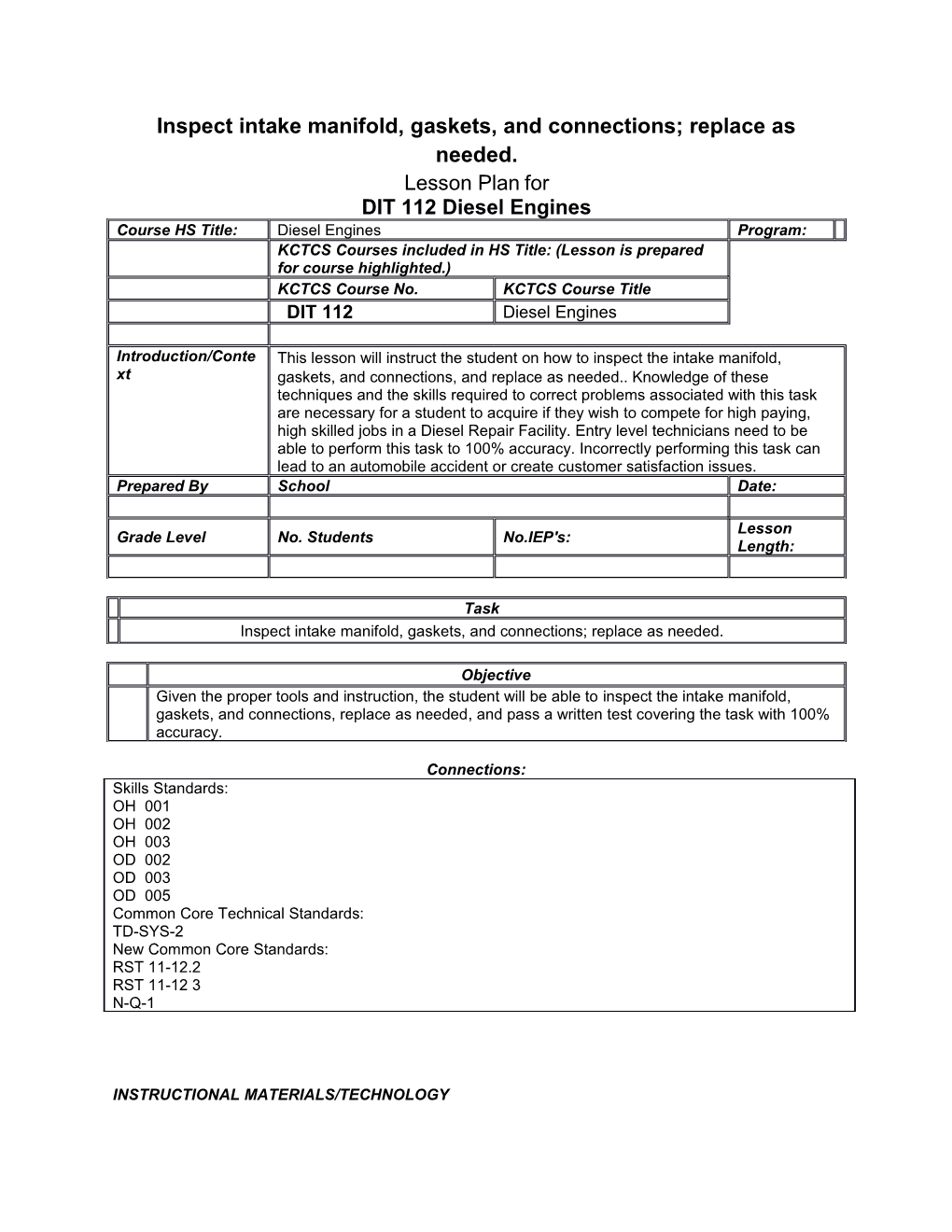

Inspect intake manifold, gaskets, and connections; replace as needed. Lesson Plan for DIT 112 Diesel Engines Course HS Title: Diesel Engines Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title DIT 112 Diesel Engines

Introduction/Conte This lesson will instruct the student on how to inspect the intake manifold, xt gaskets, and connections, and replace as needed.. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Diesel Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Inspect intake manifold, gaskets, and connections; replace as needed.

Objective Given the proper tools and instruction, the student will be able to inspect the intake manifold, gaskets, and connections, replace as needed, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 Common Core Technical Standards: TD-SYS-2 New Common Core Standards: RST 11-12.2 RST 11-12 3 N-Q-1

INSTRUCTIONAL MATERIALS/TECHNOLOGY Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Author Title/ISBN No. Edition Publisher Pages Various Diesel Engines ASE Test Prep 2007 Delmar 47

Equipment Quantity Item Source

Content/Presentation/Demonstration Outline Instruct students on how to inspect the Intake Manifold. Tell them that when inspecting, be aware that the intake piping, tubing, and hoses are durable yet flexible to allow for movement of the engine. Let them know that to reduce weight, solid piping is usually made of aluminum or ridged plastic, and those connections between the solid section of piping and major components are made using rubber sections clamped at both ends. Explain that when these connections become loose, unfiltered air is allowed to enter the intake system. Airborne abrasive or corrosive particulates can then cause damage to critical components. Teach students that on the other hand, as the rubber or plastic components age or become exposed to extreme heat, they will collapse and cause restrictions in the airflow. Let them know that to provide a visual warning to the operator of problems in the air intake system, most manufacturers include an air intake inlet restriction indicator. Explain that this could be as simple as a vacuum tube attached to the intake piping that runs to an instrument panel indicator, or an electronic sensor that is monitored by an electronic module. If the inlet restriction increases, tell them to check for a restriction such as a collapsed pipe or clogged filter. Let them know that a drop in vacuum indicates a possible leak, clogged vacuum indicator tube, or defective sensor. Tell students that two sensors are located on or near the intake manifold. One it the solid state boost pressure (BP) sensor monitors positive intake manifold pressure, and is used by the ECM to control fuel metering and injection timing and to limit smoke during acceleration. The other is the intake manifold temperature (IMT) sensor monitors intake manifold temperature. Explain that the ECM uses this signal to control injection timing, fuel metering, and engine protection.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) 1 Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)